sensor SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 986 of 2053

EBCM Connection Fact View.............................4E-95

EBCM Connector...............................................4E-95

Hydraulic Modulator Connector..........................4E-96

Repair Instructions..............................................4E-99

On-Vehicle Service...............................................4E-99

Service Precautions...........................................4E-99

ABS 5.3 Assembly..........................................4E-100

ABS/TCS Unit..................................................4E-100

Front Wheel Speed Sensor..............................4E-101Rear Wheel Speed Sensor...............................4E-101

Acceleration Sensor .........................................4E-102

System Fuse...................................................4E-102

Indicators........................................................4E-102

Unit Repair........................................................4E-103

ABS Front Tooth Wheel....................................4E-103

Special Tools and Equipment..........................4E-104

Special Tools Table..........................................4E-104

Page 987 of 2053

ABS AND TCS 4F-3

SSANGYONG MY2002

GENERAL DESCRIPTION AND SYSTEM OPERATION

BASIC KNOWLEDGE REQUIRED

Before using this section, it is important that you have

a basic knowledge of the following items. Without this

knowledge, it will be difficult to use the diagnostic

procedures contained in this section.

•Basic Electrical Circuits - You should understand

the basic theory of electricity and know the meaning

of voltage, current (amps), and resistance (ohms).

You should understand what happens in a circuit

with an open or shorted wire. You should be able to

read and understand a wiring diagram.

Use of Circuit Testing Tools - You should know

how to use a test light and how to bypass

components to test circuits using fused jumper

wires. You should be familiar with a digital

multimeter. You should be able to measure voltage,

resistance, and current, and be familiar with the

controls and how to use them correctly.

ABS SYSTEM COMPONENTS

The ABS 5.3 Antilock Braking System (ABS) consists

of a conventional hydraulic brake system plus antilock

components. The conventional brake system includes

a vacuum booster, master cylinder, front disc brakes,

rear disc brakes, interconnecting hydraulic brake pipes

and hoses, brake fluid level switch and the BRAKE

indicator.

The ABS components include a hydraulic unit, an elec-

tronic brake control module (EBCM), two system fuses,

four wheel speed sensors (one at each wheel), intercon-

necting wiring, the ABS indicator, the EBD indicator

and the TCS indicator. See “ABS Component Locator”

in this section for the general layout of this system.

The hydraulic unit with the attached EBCM is located

between the surge tank and the bulkhead on the left

side of the vehicle.

The basic hydraulic unit configuration consists of hy-

draulic check valves, two solenoid valves for each

wheel, a hydraulic pump, and two accumulators. The

hydraulic unit controls hydraulic pressure to the front

calipers and rear calipers by modulating hydraulic

pressure to prevent wheel lockup.

Units equipped with TCS add two more valves for each

drive wheel for the purpose of applying the brake to a

wheel that is slipping. This is done with pressure from

the hydraulic pump in the unit. There is also a TCS

indicator lamp on the instrument panel to alert the driver

to the fact that the TCS system is active. The

components identified in the drawing are those added

to the basic ABS 5.3 system to provide traction control.

Nothing in the hydraulic unit or the EBCM is serviceable.

In the event of any failure, the entire ABS unit withattached EBCM must be replaced. For more

information, refer to “Base Braking Mode” and

“Antilock Braking Mode” in this section.

TRACTION CONTROL SYSTEM

(TCS) DESCRIPTION

General Information

The traction control system (TCS) is a traction system

by means of brake intervention only, available in a low

speed range (< 60kph).

It workes on µ - split roads with sidewise different friction

coefficients.

The spinning driven wheel is braked and the drive

torque can be transferred to the wheel on the high-µ

side. During TCS active, the TCS information lamp is

blinking.

The temperature of the brakes is calculated by a mathe-

matical model and TCS is switched passive if the calcu-

lated temperature is greater than a threshold value (500

°C).

TCS is permitted again, when the calculated tempera-

ture is less than 350 °C.

Control Algorithm

The input signals for the control algorithm are the

filtered wheel speed signals from the ABS speed

processing.

With the speed difference of the driven wheels, the

control deviation is calculated.

If the control deviation exceeds a certain threshold

value, the wheel with the greater slip is braked actively.

The threshold value depends on the vehicle speed:

It is reduced with increasing vehicle speed down to a

constant value.

KAA4F010

Page 989 of 2053

ABS AND TCS 4F-5

SSANGYONG MY2002

EBD (ELECTRONIC BRAKE

FORCE DISTRIBUTION) SYSTEM

System Description

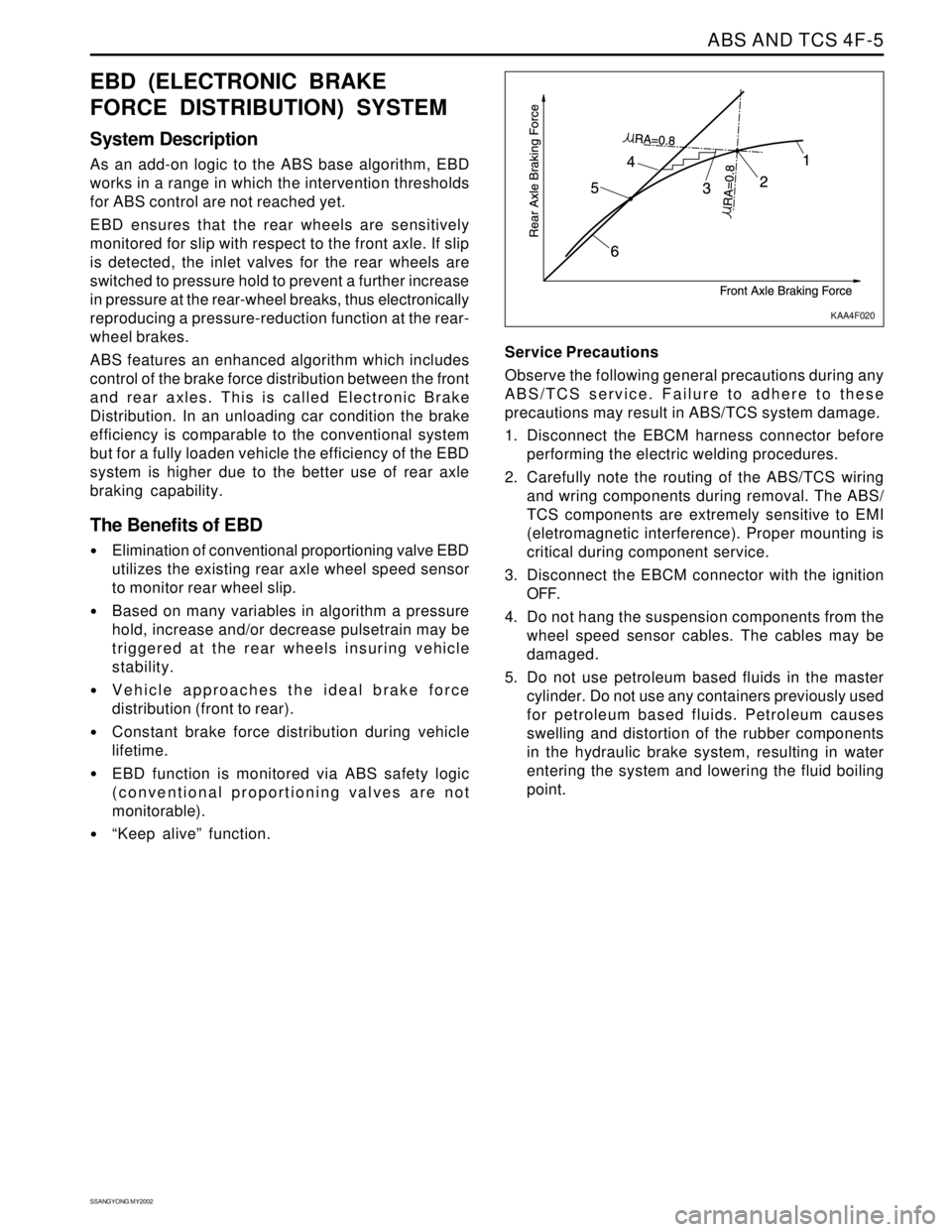

As an add-on logic to the ABS base algorithm, EBD

works in a range in which the intervention thresholds

for ABS control are not reached yet.

EBD ensures that the rear wheels are sensitively

monitored for slip with respect to the front axle. If slip

is detected, the inlet valves for the rear wheels are

switched to pressure hold to prevent a further increase

in pressure at the rear-wheel breaks, thus electronically

reproducing a pressure-reduction function at the rear-

wheel brakes.

ABS features an enhanced algorithm which includes

control of the brake force distribution between the front

and rear axles. This is called Electronic Brake

Distribution. In an unloading car condition the brake

efficiency is comparable to the conventional system

but for a fully loaden vehicle the efficiency of the EBD

system is higher due to the better use of rear axle

braking capability.

The Benefits of EBD

Elimination of conventional proportioning valve EBD

utilizes the existing rear axle wheel speed sensor

to monitor rear wheel slip.

Based on many variables in algorithm a pressure

hold, increase and/or decrease pulsetrain may be

triggered at the rear wheels insuring vehicle

stability.

Vehicle approaches the ideal brake force

distribution (front to rear).

Constant brake force distribution during vehicle

lifetime.

EBD function is monitored via ABS safety logic

(conventional proportioning valves are not

monitorable).

“Keep alive” function.Service Precautions

Observe the following general precautions during any

ABS/TCS service. Failure to adhere to these

precautions may result in ABS/TCS system damage.

1. Disconnect the EBCM harness connector before

performing the electric welding procedures.

2. Carefully note the routing of the ABS/TCS wiring

and wring components during removal. The ABS/

TCS components are extremely sensitive to EMI

(eletromagnetic interference). Proper mounting is

critical during component service.

3. Disconnect the EBCM connector with the ignition

OFF.

4. Do not hang the suspension components from the

wheel speed sensor cables. The cables may be

damaged.

5. Do not use petroleum based fluids in the master

cylinder. Do not use any containers previously used

for petroleum based fluids. Petroleum causes

swelling and distortion of the rubber components

in the hydraulic brake system, resulting in water

entering the system and lowering the fluid boiling

point.

KAA4F020

Page 997 of 2053

SSANGYONG MY2002

4F-14 ABS AND TCS

COMPONENT LOCATOR

ABS, ABS/TCS 5.3

1 ABS/TCS Hydraulic Unit

(with EBCM in case of ABS only)

2 ABS/TCS EBCM Unit (in case of TCS)

3 Rear Wheel Speed Sensor

KAA4F100

4 ABS Warning Indicator Light

5 Diagnosis Connector

6 Front Wheel Speed Sensor

7 Acceleration Sensor

Page 1021 of 2053

SSANGYONG MY2002

4F-38 ABS AND TCS

DIAGNOSTIC TROUBLE CODE (DTC) 03

LEFT FRONT WHEEL SPEED SENSOR FAULT

KAA4F140

Circuit Description

The toothed wheel generates a voltage pulse as it

moves past the sensor. Each tooth-gap-tooth series

on the wheel generates the pulses. The electronic brake

control module (EBCM) uses the frequency of these

pulses to determine the wheel speed. The voltage gen-

erated depends on the air gap between the sensor and

the toothed wheel, and on the wheel speed.

Diagnosis

This procedure checks for a malfunctioning wheel speed

sensor, a short to ground or to voltage in the wiring, or

a contact problem in a connector.

Cause(s)

The wheel speed sensor is defective.

There is a problem in the wiring.

There is a problem with a connector.

Fail Action

ABS action is disabled, and the ABS warning lamp is

ON.

Test Description

The number(s) below refer to step(s) on the diagnostic

table.1. This step begins an examination for a defective

wheel speed sensor.

6. This step tests the wiring for a short to voltage.

8. This step tests the wiring for a short to ground.

10. This step tests for an open or a high resistance in

the wiring.

Diagnostic Aids

Be sure that the speed sensor wiring is properly routed

and retained. This will help to prevent false signals due

to the pickup of electrical noise.

It is very important to perform a thorough inspection of

the wiring and the connectors. Failure to inspect the

wiring and the connectors carefully and completely may

result in misdiagnosis, causing part replacement with

the reappearance of the malfunction.

Use the scan tool to monitor wheel speeds during a

road test. Watch the wheel speeds being displayed on

the scan tool to see if any of the readings are unusual,

such as one sensor varying in speed from the other

three, a signal going intermittently high or low, etc. If

this does not identify the intermittent, wet the speed

sensor harness on the underside of the vehicle and

perform a road test, monitoring wheel speeds with the

scan tool.

Step

1

DTC 03 - Left Front Wheel Speed Sensor Fault

Action Yes

Go to Step 3No

Go to Step 2 Value(s)

-

Examine the wheel speed sensor.

Are there any signs of physical damage?

Page 1022 of 2053

ABS AND TCS 4F-39

SSANGYONG MY2002

Step

2

3

4

5

6

7

8

9

10

11

12

DTC 03 - Left Front Wheel Speed Sensor Fault (Cont’d)

Action

Go to Step 4

System OK

Go to Step 6

System OK

Go to Step 7

System OK

Go to Step 9

System OK

Go to Step 11

System OK

System OKGo to Step 3

-

Go to Step 5

-

Go to Step 8

-

Go to Step 10

-

Go to Step 12

-

- 1280 - 1920 Ω

-

≈ 70 mv

-

>1v

-

∞

-

>5 Ω

-

-

1. Turn the ignition to LOCK.

2. Disconnect the left rear wheel speed sensor

connector.

3. Use a digital voltmeter (DVM) to measure resis-

tance between the sensor terminals.

Is the resistance within the specified value at approxi-

mately 25-C (77-F)?

Replace the wheel speed sensor.

Is the repair complete?

1. Switch the DVM to the ac millivolt range.

2. Measure the voltage output between the wheel

speed sensor terminals while rotating the wheel

about 1 revolution per second.

Is the output within the specified value?

Replace the speed sensor or the toothed wheel, as

required.

Is the repair complete?

1. Disconnect the harness from the EBCM.

2. Connect a DVM between ground and one terminal of

the wheel speed connector.

3. Turn the ignition to ON.

4. Repeat the above test for the other terminal of the

wheel speed connector.

Is the voltage for either of these terminals within the

specified value?

Repair the short to voltage in the affected circuit.

Is the repair complete?

1. Turn the ignition to LOCK.

2. Measure the resistance to ground from terminal at

the harness EBCM connector.

3. Measure the resistance to ground from terminal 36

at the harness EBCM connector.

Is the resistance at either circuit less than the speci-

fied value?

Repair the short to ground in the affected circuit.

Is the repair complete?

1. Measure the resistance between terminal 10 at the

harness EBCM connector and the harness wheel

speed sensor connector.

2. Measure the resistance between terminal 36 at the

harness EBCM connector and the harness wheel

speed sensor connector.

Is the resistance on either circuit within the specified

value?

Repair the open or the high resistance in the affected

circuit, as required. Be sure to check terminals 2 and 8

of connector C113 and junction J101 and J102.

Is the repair complete?

Replace the ABS unit.

Is the repair complete?

Value(s) Yes No

Page 1023 of 2053

SSANGYONG MY2002

4F-40 ABS AND TCS

DIAGNOSTIC TROUBLE CODE (DTC) 07

LEFT FRONT WHEEL SPEED SENSOR CONTINUITY FAULT

KAA4F140

Circuit Description

The toothed wheel generates a voltage pulse as it

moves past the sensor. Each tooth-gap-tooth series

on the wheel generates the pulses. The electronic brake

control module (EBCM) uses the frequency of these

pulses to determine the wheel speed. The voltage gen-

erated depends on the air gap between the sensor and

the toothed wheel, and on the wheel speed.

Diagnosis

This procedure checks for a malfunctioning wheel speed

sensor, a short to ground or to voltage in the wiring, or

a contact problem in a connector.

Cause(s)

The wheel speed sensor is defective.

There is a problem in the wiring.

There is a problem with a connector.

Fail Action

ABS action is disabled, and the ABS warning lamp is

ON.Test Description

The number(s) below refer to step(s) on the diagnostic

table.

1. This step begins an examination for a defective

wheel speed sensor.

4. This step tests the wiring for a short to voltage.

6. This step tests the wiring for a short to ground.

8. This step tests for an open or high resistance in

the wiring.

Diagnostic Aids

Be sure that the speed sensor wiring is properly routed

and retained. This will help to prevent false signals due

to the pickup of electrical noise.

It is very important to perform a thorough inspection of

the wiring and the connectors. Failure to inspect the

wiring and the connectors carefully and completely may

result in misdiagnosis, causing part replacement with

the reappearance of the malfunction.

Page 1024 of 2053

ABS AND TCS 4F-41

SSANGYONG MY2002

Step

1

2

3

4

5

6

7

8

9

10

DTC 07 - Left Front Wheel Speed Sensor Continuity Fault

Action

Go to Step 3

Go to Step 4

System OK

Go to Step 5

System OK

Go to Step 7

System OK

Go to Step 9

System OK

System OKGo to Step 2

Go to Step 3

-

Go to Step 6

-

Go to Step 8

-

Go to Step 10

-

- -

1280 - 1920 Ω

-

>1v

-

∞

-

>5 Ω

-

-

Examine the wheel speed sensor.

Are there any signs of physical damage?

1. Turn the ignition to LOCK.

2. Disconnect the left rear wheel speed sensor

connector.

3. Use a digital voltmeter (DVM) to measure resis-

tance between the sensor terminals.

Is the resistance within the specified value at ap-

proximately 25-C (77-F)?

Replace the wheel speed sensor.

Is the repair complete?

1. Disconnect the harness from the EBCM.

2. Connect a DVM between ground and one terminal

of the wheel speed connector.

3. Turn the ignition to ON.

4. Repeat the above test for the other terminal of the

wheel speed connector.

Is the voltage for either of these terminals within the

specified value?

Repair the short to voltage in the affected circuit.

Is the repair complete?

1. Turn the ignition to LOCK.

2. Measure the resistance to ground from terminal 10

at the harness EBCM connector.

3. Measure the resistance to ground from terminal 36

at the harness EBCM connector.

Is the resistance at either circuit less than the speci-

fied value?

Repair the short to ground in the affected circuit.

Is the repair complete?

1. Measure the resistance between terminal 10 at the

harness EBCM connector and the harness wheel

speed sensor connector.

2. Measure the resistance between terminal 36 at the

harness EBCM connector and the harness wheel

speed sensor connector.

Is the resistance on either circuit within the specified

value?

Repair the open or high resistance in the affected

circuit as required. Be sure to check terminals 2 and

8 of connector C113 and junction J101 and J102.

Is the repair complete?

Replace the ABS unit.

Is the repair complete?

Value(s) Yes No

Page 1025 of 2053

SSANGYONG MY2002

4F-42 ABS AND TCS

DIAGNOSTIC TROUBLE CODE (DTC) 04

RIGHT FRONT WHEEL SPEED SENSOR FAULT

KAA4F150

Circuit Description

The toothed wheel generates a voltage pulse as it

moves past the sensor. Each tooth-gap-tooth series

on the wheel generates the pulses. The electronic brake

control module (EBCM) uses the frequency of these

pulses to determine the wheel speed. The voltage gen-

erated depends on the air gap between the sensor and

the toothed wheel, and on the wheel speed.

Diagnosis

This procedure checks for a malfunctioning wheel speed

sensor, a short to ground or to voltage in the wiring, or

a contact problem in a connector.

Cause(s)

The wheel speed sensor is defective.

There is a problem in the wiring.

There is a problem with a connector.

Fail Action

ABS action is disabled, and the ABS warning lamp is

ON.

Test Description

The number(s) below refer to step(s) on the diagnostic

table.1. This step begins an examination for a defective

wheel speed sensor.

6. This step tests the wiring for a short to voltage.

8. This step tests the wiring for a short to ground.

10. This step tests for an open or high resistance in

the wiring.

Diagnostic Aids

Be sure that the speed sensor wiring is properly routed

and retained. This will help to prevent false signals due

to the pickup of electrical noise.

It is very important to perform a thorough inspection of

the wiring and the connectors. Failure to inspect the

wiring and the connectors carefully and completely may

result in misdiagnosis, causing part replacement with

the reappearance of the malfunction.

Use the scan tool to monitor wheel speeds during a

road test. Watch the wheel speeds being displayed on

the scan tool to see if any of the readings are unusual,

such as one sensor varying in speed from the other

three, a signal going intermittently high or low, etc. If

this does not identify the intermittent, wet the speed

sensor harness on the underside of the vehicle and

perform a road test, monitoring wheel speeds with the

scan tool.

Step

1

DTC 04 - Right Front Wheel Speed Sensor Fault

Action Yes

Go to Step 3No

Go to Step 2 Value(s)

-

Examine the wheel speed sensor.

Are there any signs of physical damage?

Page 1026 of 2053

ABS AND TCS 4F-43

SSANGYONG MY2002

Step

2

3

4

5

6

7

8

9

10

11

12

DTC 04 - Right Front Wheel Speed Sensor Fault (Cont’d)

Action

Go to Step 4

System OK

Go to Step 6

System OK

Go to Step 7

System OK

Go to Step 9

System OK

Go to Step 11

System OK

System OKGo to Step 3

-

Go to Step 5

-

Go to Step 8

-

Go to Step 10

-

Go to Step 12

-

- 1280 - 1920 Ω

-

≈ 70 mv

-

>1v

-

∞

-

>5 Ω

-

-

1. Turn the ignition to LOCK.

2. Disconnect the left rear wheel speed sensor

connector.

3. Use a digital voltmeter (DVM) to measure resis-

tance between the sensor terminals.

Is the resistance within the specified value at approxi-

mately 25-C (77-F)?

Replace the wheel speed sensor.

Is the repair complete?

1. Switch the DVM to the ac millivolt range.

2. Measure the voltage output between the wheel

speed sensor terminals while rotating the wheel

about 1 revolution per second.

Is the output within the specified value?

Replace the speed sensor or the toothed wheel, as

required.

Is the repair complete?

1. Disconnect the harness from the EBCM.

2. Connect a DVM between ground and one terminal of

the wheel speed connector.

3. Turn the ignition to ON.

4. Repeat the above test for the other terminal of the

wheel speed connector.

Is the voltage for either of these terminals within the

specified value?

Repair the short to voltage in the affected circuit.

Is the repair complete?

1. Turn the ignition to LOCK.

2. Measure the resistance to ground from terminal 14

at the harness EBCM connector.

3. Measure the resistance to ground from terminal 15

at the harness EBCM connector.

Is the resistance at either circuit less than the speci-

fied value?

Repair the short to ground in the affected circuit.

Is the repair complete?

1. Measure the resistance between terminal 14 at the

harness EBCM connector and the harness wheel

speed sensor connector.

2. Measure the resistance between terminal 15 at the

harness EBCM connector and the harness wheel

speed sensor connector.

Is the resistance on either circuit within the specified

value?

Repair the open or the high resistance in the affected

circuit, as required. Be sure to check terminals 7 and 1

of connector C113 and junction J103 and J104.

Is the repair complete?

Replace the ABS unit.

Is the repair complete?

Value(s) Yes No