head SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1643 of 2053

SUPPLEMENTAL RESTRAINTS SYSTEM 8B-61

SSANGYONG MY2002

KAA8B050

CLOCK SPRING

Removal and installation Procedure

Caution: The SDM can maintain sufficient voltage

to deploy the airbags for 0.15 seconds after the

Ignition is OFF and the airbag fuse has been

removed. If the airbags are not disconnected, service

cannot begin until one minute has passed after

disconnecting power to the SDM. If the airbags are

disconnected, service can begin immediately

without waiting for one-minute time period to

expire. Failure to temporarily disable the SRS

during service result in unexpected deployment,

personal injury, and otherwise unneeded SRS repair.

1. Disconnect the negative battery cable.

2. Remove the driver airbag module. Refer to “Driver

Airbag Module” in this section.

3. Remove the steering wheel. Refer to Section 6E,

Steering Wheel and Column.

4. Remove the steering column cover. Refer to

Section 6E, Steering Wheel and Column.

5. Carefully full the instrument panel lower cover.

6. Remove driver side knee bolster.

7. Disconnect the clock spring, horn and remote

audio control connectors at the lower steering

column.

8. Remove the screws and the clock spring from the

steering shaft.

Installation Notice

Turning the clock spring more than three turns

clockwise or counterclockwise can damage the

spring.

Align the clock spring before installation. Turn

the lobe of the clock spring clockwise to lock

but do not force. Then turn the lobe of clock

spring count clockwise approximately three

turns to the neutral position, with the front of

the wheels straight ahead. Properly align the

pointed marks on the components of the clock

spring.

9. Installation should follow the removal procedure

in the reverse order.

Caution: If the clock spring is not properly

aligned, the steering wheel may not be able to

rotate completely during a turn. Restricted

turning ability can cause the vehicle to crash.

Improper alignment of the clock spring also may

make the supplemental restraint system (SRS)

inoperative, preventing the airbag from

deploying during crash. Both of the out comes

can result in injury.

Tightening Torque 4 Nm (35 lb-in)

Page 1656 of 2053

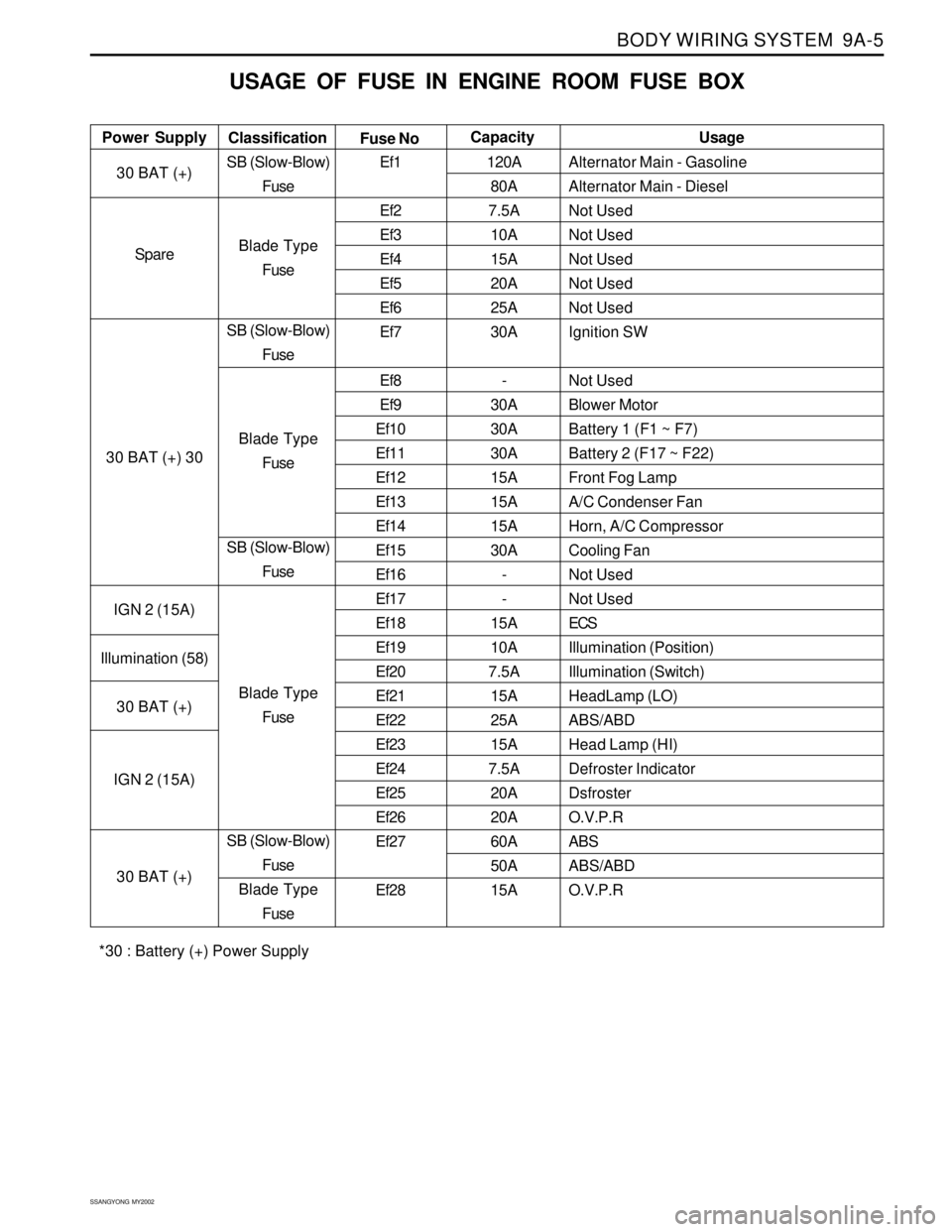

BODY WIRING SYSTEM 9A-5

SSANGYONG MY2002

USAGE OF FUSE IN ENGINE ROOM FUSE BOX

Alternator Main - Gasoline

Alternator Main - Diesel

Not Used

Not Used

Not Used

Not Used

Not Used

Ignition SW

Not Used

Blower Motor

Battery 1 (F1 ~ F7)

Battery 2 (F17 ~ F22)

Front Fog Lamp

A/C Condenser Fan

Horn, A/C Compressor

Cooling Fan

Not Used

Not Used

ECS

Illumination (Position)

Illumination (Switch)

HeadLamp (LO)

ABS/ABD

Head Lamp (HI)

Defroster Indicator

Dsfroster

O.V.P.R

ABS

ABS/ABD

O.V.P.R Power SupplyUsage

Classification

Fuse NoCapacity

30 BAT (+)

Spare

30 BAT (+) 30

IGN 2 (15A)

Illumination (58)

30 BAT (+)

IGN 2 (15A)

30 BAT (+)SB (Slow-Blow)

Fuse

Blade Type

Fuse

SB (Slow-Blow)

Fuse

Blade Type

Fuse

SB (Slow-Blow)

Fuse

Blade Type

Fuse

SB (Slow-Blow)

Fuse

Blade Type

FuseEf1

Ef2

Ef3

Ef4

Ef5

Ef6

Ef7

Ef8

Ef9

Ef10

Ef11

Ef12

Ef13

Ef14

Ef15

Ef16

Ef17

Ef18

Ef19

Ef20

Ef21

Ef22

Ef23

Ef24

Ef25

Ef26

Ef27

Ef28120A

80A

7.5A

10A

15A

20A

25A

30A

-

30A

30A

30A

15A

15A

15A

30A

-

-

15A

10A

7.5A

15A

25A

15A

7.5A

20A

20A

60A

50A

15A

*30 : Battery (+) Power Supply

Page 1658 of 2053

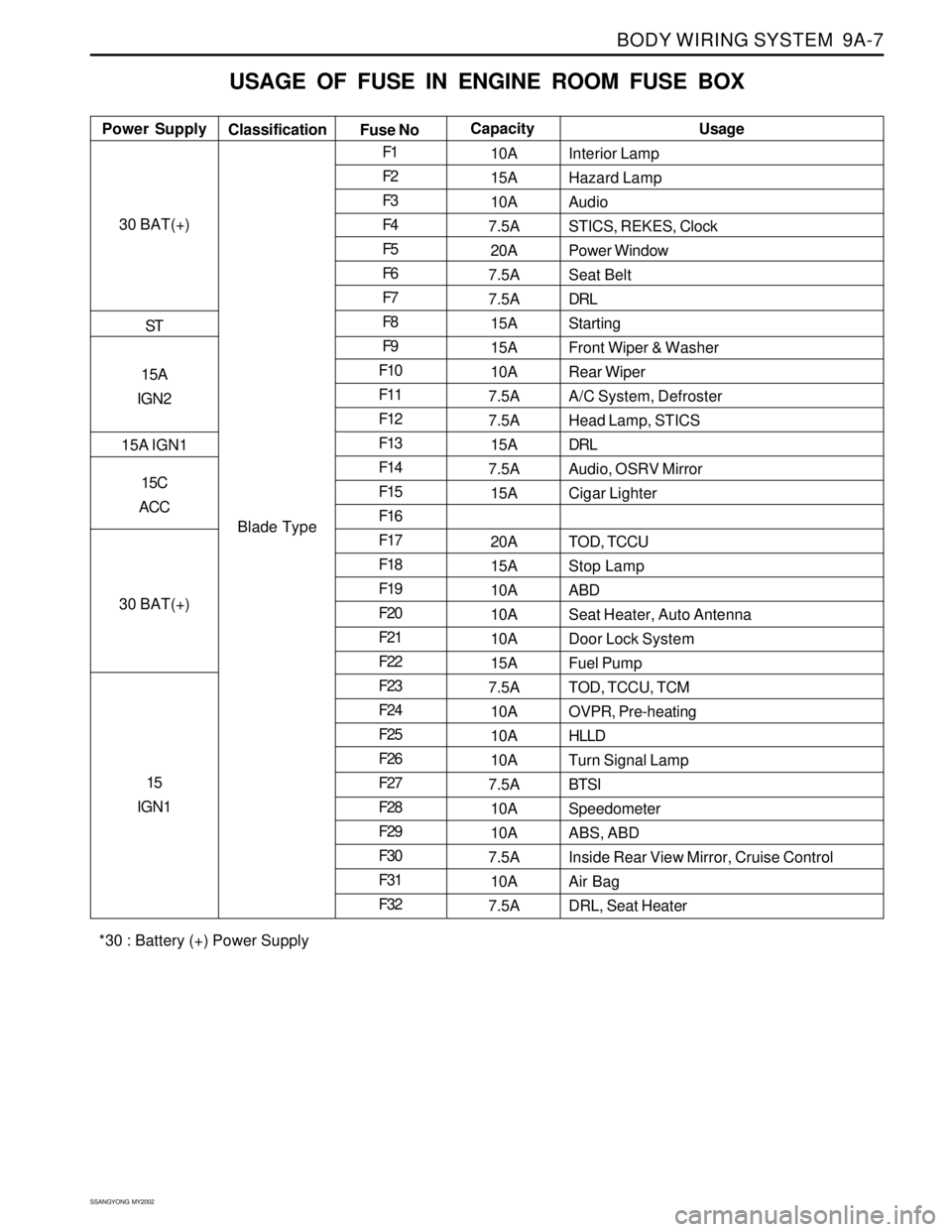

BODY WIRING SYSTEM 9A-7

SSANGYONG MY2002

USAGE OF FUSE IN ENGINE ROOM FUSE BOX

Interior Lamp

Hazard Lamp

Audio

STICS, REKES, Clock

Power Window

Seat Belt

DRL

Starting

Front Wiper & Washer

Rear Wiper

A/C System, Defroster

Head Lamp, STICS

DRL

Audio, OSRV Mirror

Cigar Lighter

TOD, TCCU

Stop Lamp

ABD

Seat Heater, Auto Antenna

Door Lock System

Fuel Pump

TOD, TCCU, TCM

OVPR, Pre-heating

HLLD

Turn Signal Lamp

BTSI

Speedometer

ABS, ABD

Inside Rear View Mirror, Cruise Control

Air Bag

DRL, Seat Heater Power SupplyUsage

Classification

Fuse NoCapacity

30 BAT(+)

ST

15A

IGN2

15A IGN1

15C

ACC

30 BAT(+)

15

IGN1

Blade TypeF1

F2

F3

F4

F5

F6

F7

F8

F9

F10

F11

F12

F13

F14

F15

F16

F17

F18

F19

F20

F21

F22

F23

F24

F25

F26

F27

F28

F29

F30

F31

F3210A

15A

10A

7.5A

20A

7.5A

7.5A

15A

15A

10A

7.5A

7.5A

15A

7.5A

15A

20A

15A

10A

10A

10A

15A

7.5A

10A

10A

10A

7.5A

10A

10A

7.5A

10A

7.5A

*30 : Battery (+) Power Supply

Page 1662 of 2053

BODY WIRING SYSTEM 9A-11

SSANGYONG MY2002

WIRING HARNESS & CONNECTOR & GROUND LOCATION

W/H ENGINE ROOM

KAA9A070

1 Starting motor

2 G102

3 Damper solenoid (FRT LH)

4 Compressor

5 Wheel speed sensor (FRT LH)

6 Starting motor “ST” terminal connector

7 Canister purge valve (Gasoline E/G)

8 Pre-heating time control unit (Diesel E/G)

9 C109 (Diesel E/G)

10 J102

11 J101

12 G101

13 Turn signal & position lamp (FRT LH)

14 Fog lamp (FRT LH)

15 Head lamp (FRT LH)

16 HLLD (FRT LH)

17 Hood switch

18 Thermo switch (Diesel E/G)

19 LH horn

20 Condenser fan motor-Non A/conditioner

21 Condenser fan motor (LH)22 Resistor

23 RH horn

24 Fog lamp (FRT RH)

25 Condenser fan motor (RH)

26 Head lamp (FRT RH)

27 HLLD (FRT RH)

28 Turn signal & position lamp (FRT RH)

29 G103

30 C110 (Diesel E/G)

31 Alternator B+ (Diesel E/G)

32 J104

33 J103

34 C110 (Gasoline E/G)

35 Alternator B+ (Gasoline E/G)

36 Damper Solenoid (FRT RH)

37 C111

38 Wheel speed sensor (FRT RH)

39 Dual pressure switch

40 Washer motor

41 ADD (FRT RH)

42 C112

43 C113

Page 1675 of 2053

SECTION 9B

LIGHTING SYSTEM

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless

otherwise noted.

TABLE OF CONTENTS

Description and Operation...................................9B-2

Head Lamps - ON Reminder................................9B-2

Head Lamps........................................................9B-2

Daytime Running Lamps......................................9B-2

Parking and Turn Signal Lamps...........................9B-2

Fog Lamps..........................................................9B-2

Rear Combination Lamps.....................................9B-2

Center High-Mounted Stop Lamp.........................9B-2

Backup Lamps....................................................9B-3

License Plate Lamps ...........................................9B-3

Interior Room Lamps ...........................................9B-3

Luggage Lamps..................................................9B-3

Components Locator............................................9B-4

Diagnostic Information and Procedure...............9B-5

Head Lamps........................................................9B-5

Fog Lamps..........................................................9B-7

Tail Lamps..........................................................9B-8

Interior Room and Luggage Lamps....................9B-11

Door Courtesy Lamps ........................................9B-13

Cigar Lighter......................................................9B-14

Repair Instructions..............................................9B-15

On-Vehicle Service Unit Repair..............................9B-15

Head Lamps......................................................9B-15Front Combination Lamp....................................9B-16

Center High-Mounted Stop Lamp.......................9B-16

Rear Combination Lamps...................................9B-17

Fog Lamps........................................................9B-17

Interior Courtesy Lamp .......................................9B-18

Door Courtesy Lamp ..........................................9B-18

Luggage Lamp..................................................9B-19

License Plate Lamps .........................................9B-19

Specifications.....................................................9B-20

Bulb Usage Chart..............................................9B-20

Fastener Tightening Specifications.....................9B-20

Schematic and Routing Diagrams.....................9B-21

Head Lamp Leveling Device (HLLD) : Gasoline ..9B-21

Head Lamp Leveling Device (HLLD) : Diesel......9B-22

Tail Lamp Relay Circuit Position Lamp,

Tail Lamp, License Lamp................................9B-23

Illumination Switch.............................................9B-24

Turn Signal Lamp...............................................9B-25

Front Fog Lamp.................................................9B-26

Rear Fog Lamp..................................................9B-27

Stop Lamp, BTSI (Brake Transmission

Shift Interlock) - Metal Top..............................9B-28

Stop Lamp, BTSI (Brake Transmission

Shift Interlock) - Soft Top.................................9B-29

Page 1676 of 2053

SSANGYONG MY2002

9B-2 LIGHTING SYSTEM

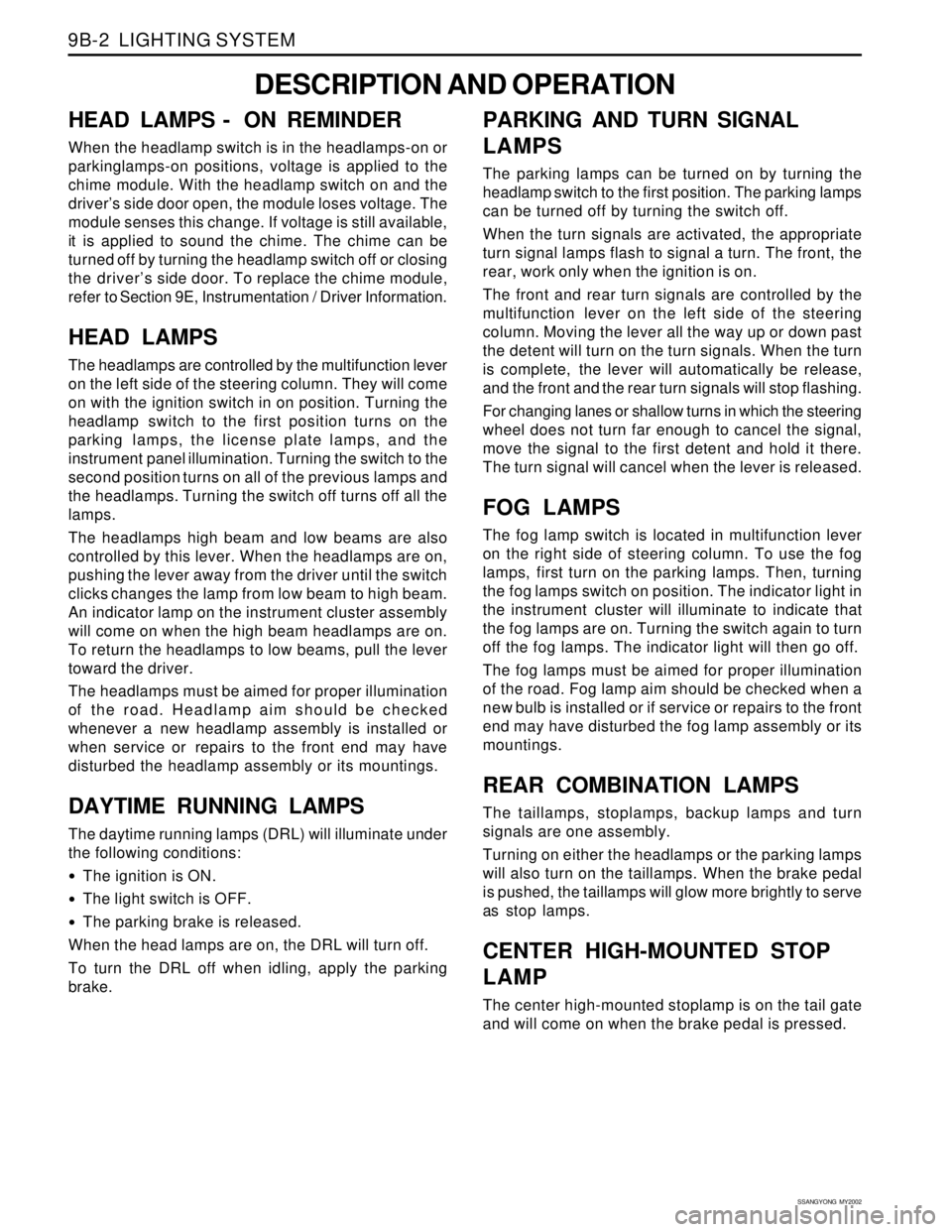

DESCRIPTION AND OPERATION

HEAD LAMPS - ON REMINDER

When the headlamp switch is in the headlamps-on or

parkinglamps-on positions, voltage is applied to the

chime module. With the headlamp switch on and the

driver’s side door open, the module loses voltage. The

module senses this change. If voltage is still available,

it is applied to sound the chime. The chime can be

turned off by turning the headlamp switch off or closing

the driver’s side door. To replace the chime module,

refer to Section 9E, Instrumentation / Driver Information.

HEAD LAMPS

The headlamps are controlled by the multifunction lever

on the left side of the steering column. They will come

on with the ignition switch in on position. Turning the

headlamp switch to the first position turns on the

parking lamps, the license plate lamps, and the

instrument panel illumination. Turning the switch to the

second position turns on all of the previous lamps and

the headlamps. Turning the switch off turns off all the

lamps.

The headlamps high beam and low beams are also

controlled by this lever. When the headlamps are on,

pushing the lever away from the driver until the switch

clicks changes the lamp from low beam to high beam.

An indicator lamp on the instrument cluster assembly

will come on when the high beam headlamps are on.

To return the headlamps to low beams, pull the lever

toward the driver.

The headlamps must be aimed for proper illumination

of the road. Headlamp aim should be checked

whenever a new headlamp assembly is installed or

when service or repairs to the front end may have

disturbed the headlamp assembly or its mountings.

DAYTIME RUNNING LAMPS

The daytime running lamps (DRL) will illuminate under

the following conditions:

The ignition is ON.

The light switch is OFF.

The parking brake is released.

When the head lamps are on, the DRL will turn off.

To turn the DRL off when idling, apply the parking

brake.

PARKING AND TURN SIGNAL

LAMPS

The parking lamps can be turned on by turning the

headlamp switch to the first position. The parking lamps

can be turned off by turning the switch off.

When the turn signals are activated, the appropriate

turn signal lamps flash to signal a turn. The front, the

rear, work only when the ignition is on.

The front and rear turn signals are controlled by the

multifunction lever on the left side of the steering

column. Moving the lever all the way up or down past

the detent will turn on the turn signals. When the turn

is complete, the lever will automatically be release,

and the front and the rear turn signals will stop flashing.

For changing lanes or shallow turns in which the steering

wheel does not turn far enough to cancel the signal,

move the signal to the first detent and hold it there.

The turn signal will cancel when the lever is released.

FOG LAMPS

The fog lamp switch is located in multifunction lever

on the right side of steering column. To use the fog

lamps, first turn on the parking lamps. Then, turning

the fog lamps switch on position. The indicator light in

the instrument cluster will illuminate to indicate that

the fog lamps are on. Turning the switch again to turn

off the fog lamps. The indicator light will then go off.

The fog lamps must be aimed for proper illumination

of the road. Fog lamp aim should be checked when a

new bulb is installed or if service or repairs to the front

end may have disturbed the fog lamp assembly or its

mountings.

REAR COMBINATION LAMPS

The taillamps, stoplamps, backup lamps and turn

signals are one assembly.

Turning on either the headlamps or the parking lamps

will also turn on the taillamps. When the brake pedal

is pushed, the taillamps will glow more brightly to serve

as stop lamps.

CENTER HIGH-MOUNTED STOP

LAMP

The center high-mounted stoplamp is on the tail gate

and will come on when the brake pedal is pressed.

Page 1677 of 2053

LIGHTING SYSTEM 9B-3

SSANGYONG MY2002

BACKUP LAMPS

The backup lamps will come on when the transaxle is

shifted into reverse. On a vehicle with an automatic

transaxle, the backup lamps are activated by inhibitor

switch. On a vehicle with a manual transaxle, they are

activated by a reverse switch with is part of the

transaxle.

LICENSE PLATE LAMPS

The license plate lamps will come on when the head

lamps or the parking lamps are on. The license plate

lamps are mounted on the rear door handle cover,

above the license plate.

INTERIOR ROOM LAMPS

The room lamp is located on the front position of head

liner and has three the center switch pushed, both of

two bulbs of the lamp are on at the same tine. When

any door is open. The switchs on the left and right

side turn on the bulbs of each side. They are off, if the

switch is pushed again the second room lamp is located

on the middle position it the switch push off again, the

lamp will turn off.

LUGGAGE LAMPS

The luggage lamp is under the trin plate on the left

side of quarter.

Page 1678 of 2053

SSANGYONG MY2002

9B-4 LIGHTING SYSTEM

COMPONENTS LOCATOR

1 Head Lamp

2 Front Room Lamp

3 Center Room Lamp

4 Rear Combination Lamp

5 License Plate Lamp6 Center High Mounted Stop Lamp

7 Rear Side Marker Lamp

8 Luggage Lamp

9 Door Courtesy Lamp

10 Front Combination Lamp

KAA9B010

Page 1679 of 2053

LIGHTING SYSTEM 9B-5

SSANGYONG MY2002

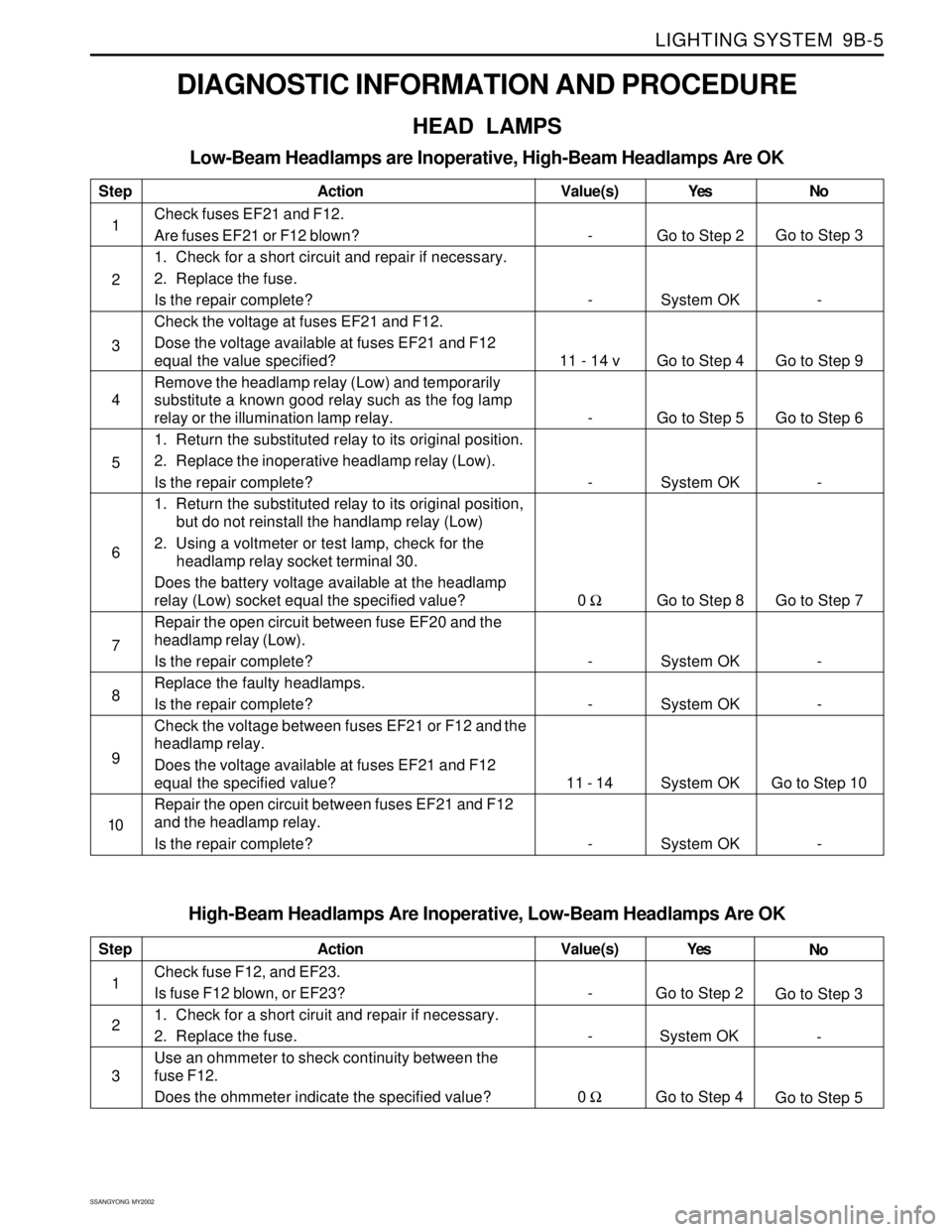

DIAGNOSTIC INFORMATION AND PROCEDURE

HEAD LAMPS

Low-Beam Headlamps are Inoperative, High-Beam Headlamps Are OK

Step

1

2

3

4

5

6

7

8

9

10Action

Check fuses EF21 and F12.

Are fuses EF21 or F12 blown?

1. Check for a short circuit and repair if necessary.

2. Replace the fuse.

Is the repair complete?

Check the voltage at fuses EF21 and F12.

Dose the voltage available at fuses EF21 and F12

equal the value specified?

Remove the headlamp relay (Low) and temporarily

substitute a known good relay such as the fog lamp

relay or the illumination lamp relay.

1. Return the substituted relay to its original position.

2. Replace the inoperative headlamp relay (Low).

Is the repair complete?

1. Return the substituted relay to its original position,

but do not reinstall the handlamp relay (Low)

2. Using a voltmeter or test lamp, check for the

headlamp relay socket terminal 30.

Does the battery voltage available at the headlamp

relay (Low) socket equal the specified value?

Repair the open circuit between fuse EF20 and the

headlamp relay (Low).

Is the repair complete?

Replace the faulty headlamps.

Is the repair complete?

Check the voltage between fuses EF21 or F12 and the

headlamp relay.

Does the voltage available at fuses EF21 and F12

equal the specified value?

Repair the open circuit between fuses EF21 and F12

and the headlamp relay.

Is the repair complete?Yes

Go to Step 2

System OK

Go to Step 4

Go to Step 5

System OK

Go to Step 8

System OK

System OK

System OK

System OKNo

Go to Step 3

-

Go to Step 9

Go to Step 6

-

Go to Step 7

-

-

Go to Step 10

- Value(s)

-

-

11 - 14 v

-

-

0 Ω

-

-

11 - 14

-

High-Beam Headlamps Are Inoperative, Low-Beam Headlamps Are OK

Step

1

2

3Action

Check fuse F12, and EF23.

Is fuse F12 blown, or EF23?

1. Check for a short ciruit and repair if necessary.

2. Replace the fuse.

Use an ohmmeter to sheck continuity between the

fuse F12.

Does the ohmmeter indicate the specified value?Yes

Go to Step 2

System OK

Go to Step 4No

Go to Step 3

-

Go to Step 5 Value(s)

-

-

0 Ω

Page 1680 of 2053

SSANGYONG MY2002

9B-6 LIGHTING SYSTEM

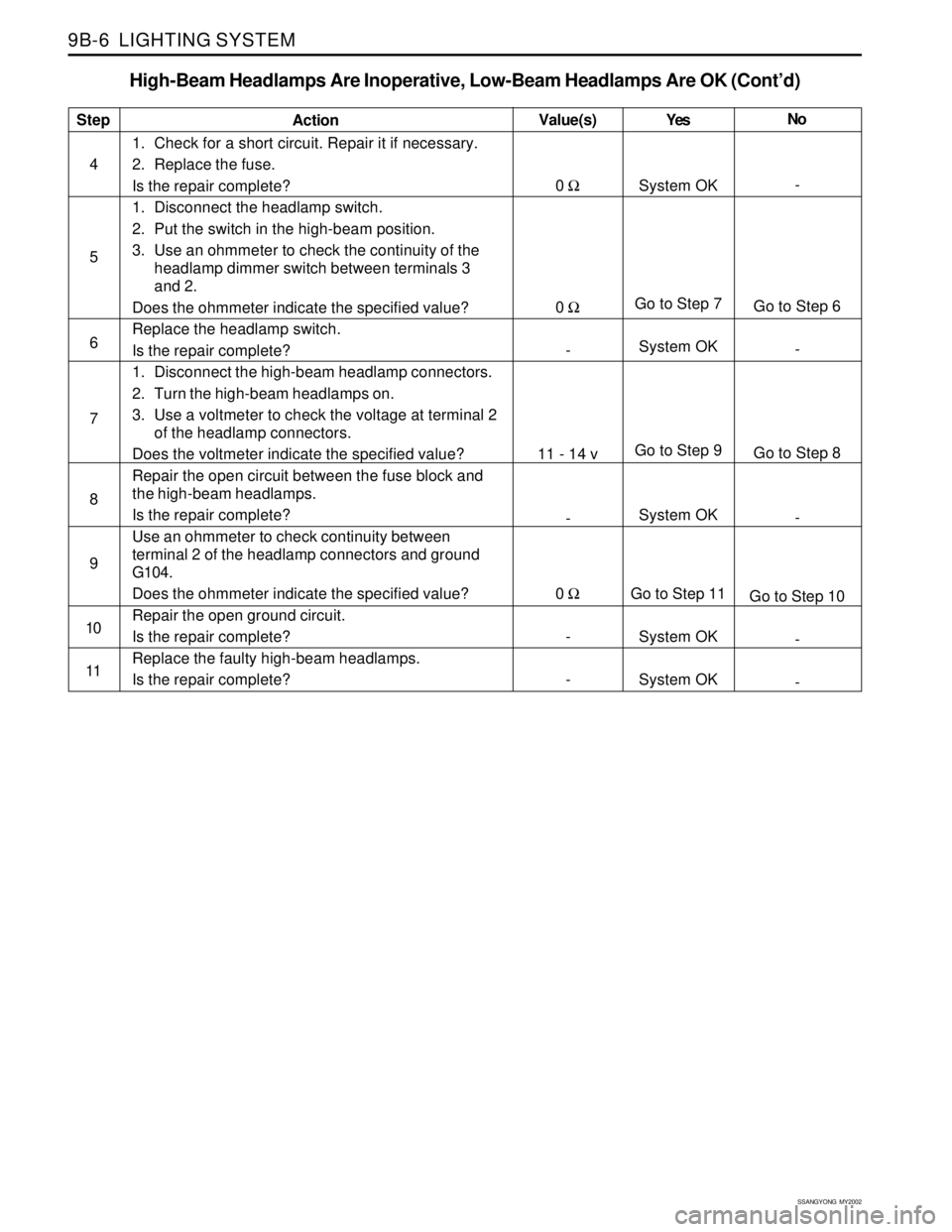

High-Beam Headlamps Are Inoperative, Low-Beam Headlamps Are OK (Cont’d)

Step

4

5

6

7

8

9

10

11Action

1. Check for a short circuit. Repair it if necessary.

2. Replace the fuse.

Is the repair complete?

1. Disconnect the headlamp switch.

2. Put the switch in the high-beam position.

3. Use an ohmmeter to check the continuity of the

headlamp dimmer switch between terminals 3

and 2.

Does the ohmmeter indicate the specified value?

Replace the headlamp switch.

Is the repair complete?

1. Disconnect the high-beam headlamp connectors.

2. Turn the high-beam headlamps on.

3. Use a voltmeter to check the voltage at terminal 2

of the headlamp connectors.

Does the voltmeter indicate the specified value?

Repair the open circuit between the fuse block and

the high-beam headlamps.

Is the repair complete?

Use an ohmmeter to check continuity between

terminal 2 of the headlamp connectors and ground

G104.

Does the ohmmeter indicate the specified value?

Repair the open ground circuit.

Is the repair complete?

Replace the faulty high-beam headlamps.

Is the repair complete?Yes

System OK

Go to Step 7

System OK

Go to Step 9

System OK

Go to Step 11

System OK

System OKNo

-

Go to Step 6

-

Go to Step 8

-

Go to Step 10

-

- Value(s)

0 Ω

0 Ω

-

11 - 14 v

-

0 Ω

-

-