head SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1482 of 2053

SSANGYONG MY2002

6C-14 POWER STEERING GEAR

8. Counterhold the pinion-side inner tie rod and re-

move the cylinder-side inner tie rod.

Installation Notice:

To prevent the inner tie rods from loosening,

use Loctite 242 (or equivalent) on both inner

tie rod connections to secure them to the rack

shaft.

KAA6C180

KAA6C190

KAA6C210

KAA6C200

Important: The retaining ring can be released by

inserting a small screwdriver through the hole in

the side of the housing.

9. Remove the bulkhead inner cylinder retaining ring.

Installation Notice:

Coat all the seals with power steering fluid to

ensure proper sealing.

10. Place a rag over the rack, counterhold the rack

assembly on the teeth with a wrench, and remove

the pinion-side inner tie rod.

Installation Notice:

The right and left inner tie rods are unequal in

length. Be sure to install the correct inner tie

rod on the proper side of the power steering

gear.

VALVE AND PINION ASSEMBLY

Disassembly and Assembly Procedure

1. Remove the rack and pinion steering assembly

from the vehicle. Refer to “Rack and Pinion

Assembly” in this section.

2. Remove the dust cover from the lower end of the

housing.

Notice: If the stub shaft is not held, damage to

the pinion teeth will occur.

3. While holding the stub shaft with a wrench, remove

the locknut from the pinion.

Page 1487 of 2053

SECTION 6E

POWER STEERING AND COLUMN

TABLE OF CONTENTS

Description and Operation...................................6E-2

General Description.............................................6E-2

Ignition Switch Keyhole Lamp..............................6E-2

Ignition Key Reminder .........................................6E-2

Component Locator.............................................6E-3

Diagnostic Information and Procedures..............6E-4

Steering Wheel Freeplay Inspection.....................6E-4

Steering Effort Inspection.....................................6E-4

Steering Column Diagnosis..................................6E-5

Repair Instructions................................................6E-9On-Vehicle Service.................................................6E-9

Headlamp/Turn Signal Switch and Lever...............6E-9

Wiper Switch and Lever.....................................6E-10

Steering Wheel With Sir.....................................6E-10

Ignition Lock Cylinder and Switch......................6E-11

Steering Column................................................6E-12

Specifications.....................................................6E-14

Fastener Tightening Specifications.....................6E-14

Special Tools and Equipment............................6E-15

Special Tools Table............................................6E-15

Page 1488 of 2053

SSANGYONG MY2002

6E-2 POWER STEERING AND COLUMN

GENERAL DESCRIPTION

Caution: To ensure the energy-absorbing action of

the steering column, it is important to use only the

specified screws, bolts, and nuts, tightened to the

specified torque.

In addition to the steering function, the steering column

provides safety and security.

The energy-absorbing column is designed to compress

in a front-end collision to lessen the chance of driver

injury.

The ignition switch and the lock are mounted on the

column, allowing the ignition and steering operations

to be locked to inhibit theft of the car.

The column levers trigger the turn signals, the headlight

beams, and the windshield washer and wipers.

A tilt steering column uses a spherical joint to allow

the steering wheel to tilt up and down. This enables

the driver to adjust the steering wheel to a comfortable

position.

Notice: Apply a thin coat of lithium grease to all friction

points when reassembling.

The column may be disassembled and reassembled

easily.

DESCRIPTION AND OPERATION

IGNITION SWITCH KEYHOLE LAMP

For description and lamp replacement information, Re-

fer to Section 9B, Lighting Systems.

IGNITION KEY REMINDER

The ignition key reminder alerts the driver that the key

is still in the ignition when the driver attempts to exit

the vehicle.

An internal switch in the ignition lock cylinder supplies

battery voltage to the reminder chime module when all

of the following conditions are true:

•The key is in the ignition switch.

The ignition is OFF.

The driver’s door is open.

For information on removal and installation of the re-

minder chime module, Refer to Section 9E, Instrumen-

tation/Driver Information.

Page 1489 of 2053

POWER STEERING AND COLUMN 6E-3

SSANGYONG MY2002

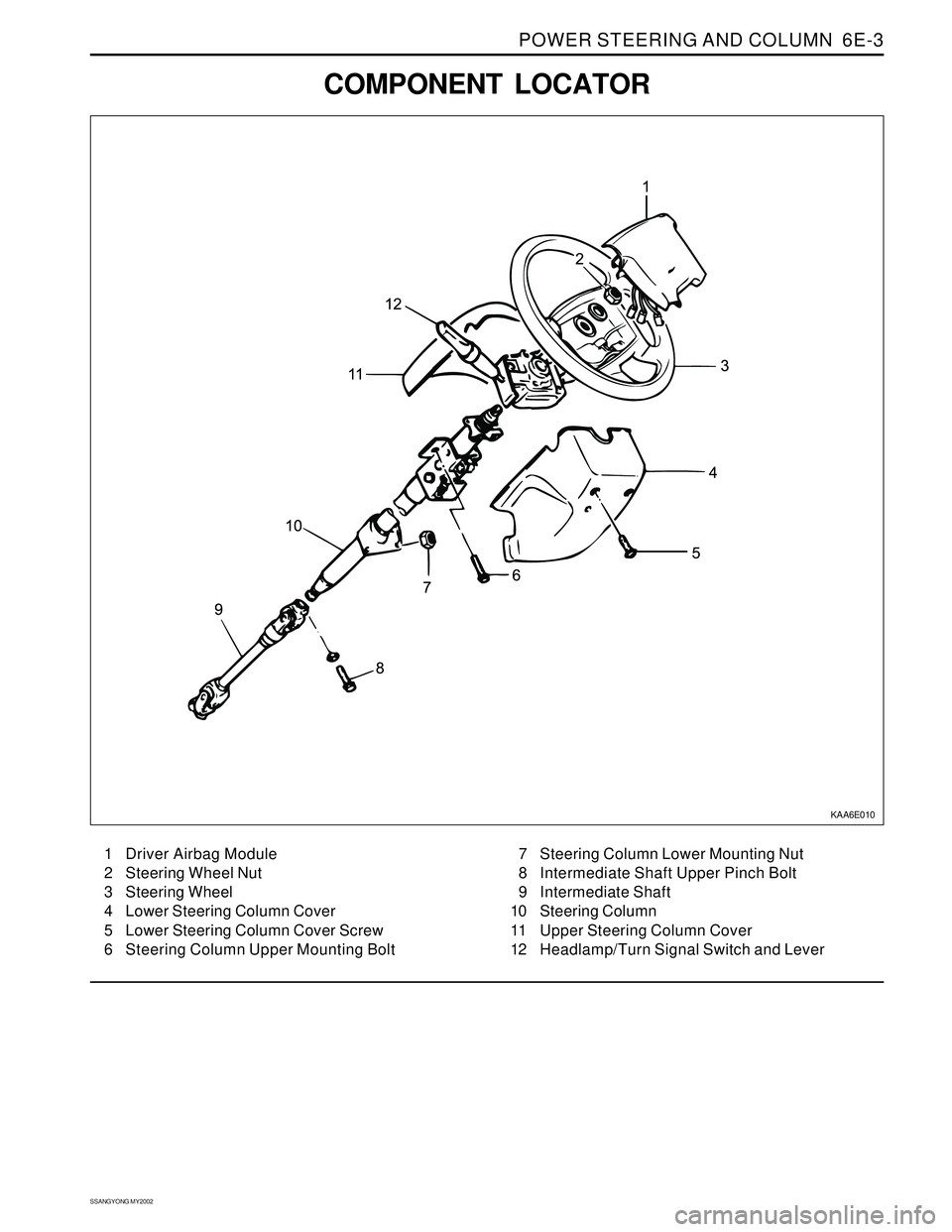

COMPONENT LOCATOR

KAA6E010

1 Driver Airbag Module

2 Steering Wheel Nut

3 Steering Wheel

4 Lower Steering Column Cover

5 Lower Steering Column Cover Screw

6 Steering Column Upper Mounting Bolt7 Steering Column Lower Mounting Nut

8 Intermediate Shaft Upper Pinch Bolt

9 Intermediate Shaft

10 Steering Column

11 Upper Steering Column Cover

12 Headlamp/Turn Signal Switch and Lever

Page 1490 of 2053

SSANGYONG MY2002

6E-4 POWER STEERING AND COLUMN

DIAGNOSTIC INFORMATION AND PROCEDURES

STEERING WHEEL FREEPLAY

INSPECTION

KAA6E020

Inspection Procedure

1. Start the engine and set the wheels in straight

ahead position.

2. Slightly move the steering wheel to the left and

right and measure steering wheel free play when

the front wheel is start to move.

Notice: If exceeds specification, the steering

column shaft connections and steering linkage

clearance. Replace or repair if necessary.

StandardMax. 30 mm

STEERING EFFORT INSPECTION

KAA6E030

Inspection Procedure

1. Place a vehicle on the paved flat ground with front

wheels in a straight ahead position.

2. Start the engine and run it at 1,000 rpm.

3. Using a scale, measure the steering effort in both

directions.

Notice : The difference in steering effort of left

and right should be within 0.6 kg.

StandardMax. 3.0 kg

Page 1495 of 2053

POWER STEERING AND COLUMN 6E-9

SSANGYONG MY2002

KAA6E060

KAA6E040

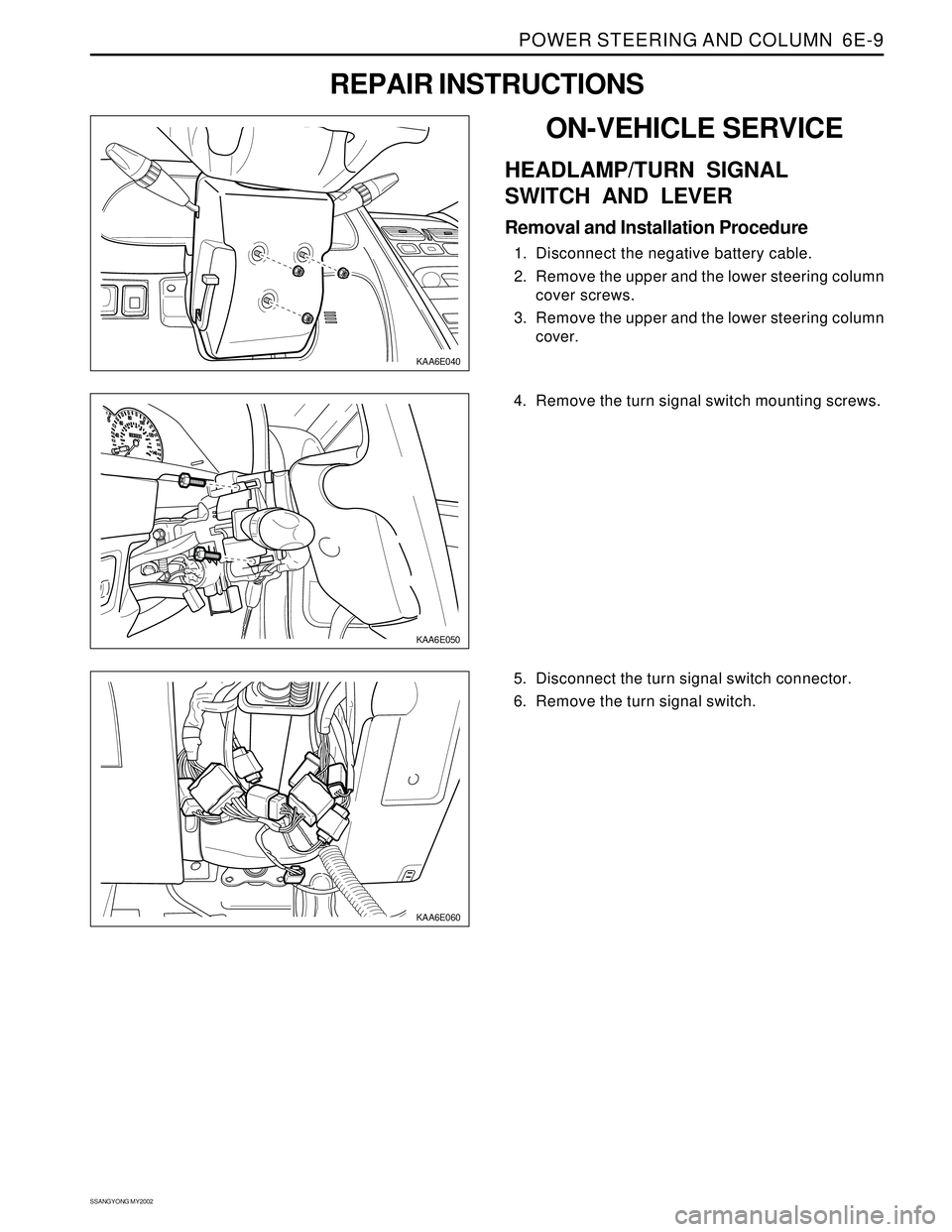

ON-VEHICLE SERVICE

HEADLAMP/TURN SIGNAL

SWITCH AND LEVER

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Remove the upper and the lower steering column

cover screws.

3. Remove the upper and the lower steering column

cover.

REPAIR INSTRUCTIONS

KAA6E050

4. Remove the turn signal switch mounting screws.

5. Disconnect the turn signal switch connector.

6. Remove the turn signal switch.

Page 1498 of 2053

SSANGYONG MY2002

6E-12 POWER STEERING AND COLUMN

KAA6E040

KAA6E120

STEERING COLUMN

Important: Remove the steering column only if the

following conditions exist:

The steering column requires replacement.

The steering and the ignition lock housing require

replacement.

Another operation requires the removal of the

steering column

Notice: The steering column is extremely

susceptible to damage after it has been removed

from the vehicle. Dropping the column assembly

on its end or hammering the end of the steering

shaft can collapse the steering shaft or loosen the

plastic injections which maintain column rigidity.

Leaning on the column can cause it to bend or

deform. Any of the above damage can impair the

column’s collapsible design. If it is necessary to

remove the steering wheel, use only the specified

steering wheel puller.

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Remove the upper and the lower steering column

cover screws.

3. Remove the upper and the lower steering column

cover.

KAA6E060

4. Remove the lower instrument trim panel. Refer to

Section 9E, Instrumentation/Driver Information.

5. Remove the immoblilzer module. Refer to Section

9T, Immobilizer Anti-Theft system.

6. Disconnect the airbag electrical connections.

7. Disconnect electrical switch connections.

8. Adjust the steering to the straight-ahead position.

9. Make a mark on the steering column shaft that

lines up with a mark on the intermediate shaft

upper universal joint.

10. Remove the intermediate shaft upper pinch bolt.

Installation Notice

Tightening Torque 27 Nm (20 lb-ft)

Page 1578 of 2053

SSANGYONG MY2002

8A-2 SEAT BELTS

DESCRIPTION AND OPERATION

DRIVER SEAT BELT WARNING

The driver’s seat belt incorporates a seat belt warning

lamp in the instrument cluster to remind the driver if

the seat belt is not fastened when the ignition is turned

ON. The warning lamp blinks for eight seconds with

chime and goes out.

THREE-POINT FRONT SEAT BELT

WITH PRETENSIONER

The front seat belt contains an electronically controlled

pyrotechnic retractor, pretensioner, which reduces seat

belt slack when it activated in a head-on or angled

front collision. The front seat belt must be replaced

after an accident that causes its activation. At normal

condition the driver’s seat belt operates as emergency

locking retractor (ELR).

Emergency Locking Retractor (ELR)

The ELR seat belt is always unlocked, allowing the

passenger freedom of movement, except in

emergencies such as rapid deceleration, rapid

acceleration, or hard cornering maneuvers.

THREE-POINT REAR OUTBOARD

SEAT BELT

The rear outboard seating position uses the emergency

locking retractor (ELR). Refer to Three-point front seat

belt with pretensioner in this section for details.

TWO-POINT LAP REAR CENTER

SEAT BELT

The two-point lap rear center seat belt is a single contin-

uous length of webbing. The webbing is routed from

the anchor through plate and into a single retractor.

OPERATIONAL AND FUNCTIONAL

CHECKS

Caution:

Keep sharp objects and potentially damaged ob

jects away from seat belts.

Avoid bending or damaging any portion of

buckle or the latch plate

Do not breach or dye the belt webbing. Use only

mild soap and water in order to clean the belts.

When installing the seat belt anchor bolts and

screws, start the bolts and screws by hand in or-

der to prevent cross-threading.

Do not attempt any repairs on the retractor mech-

anisms or covers. Replace any defective assem-

blies with new assemblies.

Replace any belts that are cut or damaged in any

way.

1. Inspect all seat anchor bolts and screws in order to

verify that they are secure.

2. Inspect the seat belt buckle. The buckle must lock

and unlock easily.

3. After inserting the latch into the buckle, tug sharply

on the belt. The buckle must remain locked.

4. Fully extend the shoulder belt portion to make sure

that there is no twisting or tears in the belt.

5. Let the shoulder belt retract fully. The belt should

retract easily.

CHILD SEAT TETHER ANCHOR

There are three child seat tether anchors to hold the

child seat firmly. One is located rear center of ceiling

and two are located on the rear corner of floor.

Page 1640 of 2053

SSANGYONG MY2002

8B-58 SUPPLEMENTAL RESTRAINTS SYSTEM

REPAIR INSTRUCTION

ON-VEHICLE SERVICE

SERVICE PRECAUTION

Caution: The sensing and diagnosis module (SDM)

can maintain sufficient voltage to deploy the airbags

and pretensioner for 0.15 seconds after the ignition

is OFF and the airbag fuse has been removed. If the

airbags or pretensioners are not disconnected, do

not begin service until one minute has passed after

disconnecting power to the SDM. If the airbag are

disconnected, service can begin immediately without

waiting for one-minute time period to expire. Failure

to temporarily disable the SRS during service can

result in unexpected deployment, personal injury,

and otherwise unneeded SRS repairs.

DISABLING THE SUPPLEMENTAL

RESTRAINT SYSTEM (SRS)

1. Turn the steering wheel to the straight-ahead

position.

2. Turn the ignition switch to LOCK and remove the key.

3. Remove the airbag fuse F31 in the I/P fuse block

and wait more than one minute for SRS capacitor to

discharge.

ENABLING THE SUPPLEMENTAL

RESTRAINT SYSTEM (SRS)

Enabling the supplemental restraint system (SRS) is

reverse order of “Disabling the Supplemental Restraint

System (SRS)”.

Caution: Staying well away from the inflator

modules, turn the ignition key switch to ON, and

verify that the airbag indicator illuminates for 4.5

seconds and turns OFF. If it does not operate as

described, perform the “SRS Diagnostic System

Check” referring in this section.

HANDLING, INSTALLATION AND

DIAGNOSIS

Airbag modules should not be subjected to

temperature above 65°C (149°F)

An airbag module or sensing and diagnostic module

(SDM) should not be used if it has been dropped

from height of 0.9 meters (3 feet) or greater.

It is very important for the SDM to be installed flat

on the mounting surface, parallel to the vehicle’s

longitudinal axis.

To avoid setting diagnostic trouble codes (DTCs),

do not apply power to the SRS unless all components

are connected or a diagnostic chart request it.

The SRS Diagnostic System Check must be the

starting point of any SRS diagnostics. The SRS

Diagnostic System Check will verify proper airbag

indicator operation and will lead you to correct chart

to diagnose any SRS malfunctions. Bypassing

these procedures may result in extended diagnostic

time and incorrect parts replacements.

REPAIRS AND INSPECTIONS

REQUIRED AFTER AN ACCIDENT

Caution: any repairs to the vehicle’s structure must

return it to the original production configuration.

Deployment requires replacement of SDM, the

inflator modules, and a dimensional inspection of

the steering column.

If any SRS components are damaged, they must

be replaced. If SRS components mounting points

are damaged, they must be repaired or replaced.

Never use SRS parts from another vehicle. This does

not include remanufactured parts purchased from

an authorized source.

Do not attempt to service the SDM, the clock spring,

or other airbag modules, these items must be

replaced if they are defective.

Verify the part number of replacement airbag

modules. Some inflator modules look identical but

contain different internal components.

ACCIDENT WITH DEPLOYMENT -

COMPONENTS REPLACEMENT

All SRS components must be replaced after frontal crash

involving airbag deployment. After deployment, a

powdery residue may be on the surface of the airbag.

The powder consists primarily of cornstarch (used to

lubricate the bag as it inflates) and by-products of the

chemical reaction. Sodium hydroxide dust (similar to

lye soap) is produced as a by-product of the deployment

reaction. The sodium hydroxide then quickly reacts with

atmospheric moisture and is converted to sodium

carbonate and sodium bicarbonate (also known as

baking soda). Therefore, it is unlikely that sodium

hydroxide will be present after deployment. Replace

the following SRS components.

Caution: Wear gloves and safety glasses during the

disposal procedure. Refer to “Deployed Airbag

Module Disposal Procedure” in this section.

The SDM.

Airbag modules and pretensioners

SRS wiring

Clock spring

Page 1642 of 2053

SSANGYONG MY2002

8B-60 SUPPLEMENTAL RESTRAINTS SYSTEM

KAA8B140

DRIVER AIRBAG MODULE

Removal and installation Procedure

1. Disconnect the negative battery cable.

Caution: The SDM can maintain sufficient

voltage to deploy the airbags for 0.15 seconds

after the Ignition is OFF and the airbag fuse has

been removed. If the airbags are not

disconnected, service cannot begin until one

minute has passed after disconnecting power

to the SDM. If the airbags are disconnected,

service can begin immediately without waiting

for one-minute time period to expire. Failure to

temporarily disable the SRS during service

result in unexpected deployment, personal

injury, and otherwise unneeded SRS repair.

2. Disable the supplemental restraint system (SRS).

Refer to “Disabling the SRS” in this section.

3. Position the steering wheel straight ahead.

4. Remove the driver airbag module mounting bolts.

Installation Notice

Caution: When handling an airbag module,

always keeps the top of the unit facing upward.

This leaves room for the airbag to expand if the

module unexpectedly deploys. Without room

for expansion, a module suddenly propelled

toward a person or object can cause injury or

vehicle damage.

5. Remove the connector from the horn terminal and

the driver airbag module.

6. Remove the driver airbag module.

7. Installation should follow the removal procedure

in the reverse order.

Tightening Torque 8 Nm (71 lb-in)