SSANGYONG KORANDO 1997 Service Repair Manual

KORANDO 1997

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57502/w960_57502-0.png

SSANGYONG KORANDO 1997 Service Repair Manual

Page 682 of 2053

OM600 ENGINE MECHANICAL 1B3 -- 133

D AEW OO M Y_2000

Service Data

ItemIntakeExhaust

Valve Arrears ’a’0.1 -- 0.7 mm0.1 -- 0.7 mm

Valve Seat Width ’b’1.2 -- 1.7 mm1.5 -- 2.0 mm

Valve Seat Angle ’α’45_45_

Valve Seat Free Angle ’β’65_65_

Permissible Radial Runout0.03 mm0.03 mm

ValveLength’I’Standard106.20 -- 106.60 mm106.20 -- 106.60 mmValveLength’I’Repair105.30 -- 105.70 mm105.30 -- 105.70 mm

Matching Valves

Camshaft Cam Basic Dia.

W = 38.0±0.2 mmCamshaft Cam Basic Dia.

W=36.6±0.2 mmValvetobeUsed

Size (x)19.5 -- 20.3 mm19.5 -- 20.1 mm

Use machined valve,

if needed

new repair valve

I = 105.5±0.2mm

Size (x)20.4 -- 21.4 mm20.2 -- 21.2 mmReuse valve

Size (x)21.4 -- 21.97 mm21.2 -- 21.97 mm

Use standard size

valve

I = 106.4±0.2mm

Commercial Tools

Cylinder Head Clamping DeviceHunger

D-- 8000 München 70

Type Ventilknecht K2000

Order No. 221 00 100

Valve Seat Turning ToolHunger

D-- 8000 München 70

Ty p e VDS 1 A

Order No. 236 03 308

Test Set for ValvesHunger

D-- 8000 München 70

Order No. 217 93 601

Page 684 of 2053

OM600 ENGINE MECHANICAL 1B3 -- 135

D AEW OO M Y_2000

5. Insert the valve (1) into the valve guide according to

marking and measure amount by which the valve ar-

rears ’a’.

Arrears ’a’0.1 -- 0.7mm

6. Measure camshaft cam basic circle diameter (w).

Diameter ’w’38±0.2mm

or 37.6±0.2mm

7. Measure distance ’z’ (cylinder head cover parting

surface -- valve stem).

Page 685 of 2053

1B3 -- 136 OM600 ENGINE MECHANICAL

D AEW OO M Y_2000

I Length of Valve

w Camshaft Cam Basic Circle Diameter

x Distance (Camshaft basic bore -- valve stem)y Half Camshaft Basic Bore Diameter

z Distance (Cylinder head cover parting surface --

valve stem)

8. Measure ’x’ (Camshaft basic bore -- valve stem).

’x’ = ’z’ -- ’y’

9. Determine the valve to be used.

(See ’Matching valves’)

Example) Measured value ’w’ = 38.2 mm

Measured value ’z’ = 36.5 mm

Value ’y’ = 15.5 mm

’x’ = 36.5 -- 15.5 = 21.0 mm

In the case of a camshaft cam basic circle diameter

’w’ = 38.2mm and a distance ’x’ = 21.0mm, the

installed valve may be used.

Page 686 of 2053

OM600 ENGINE MECHANICAL 1B3 -- 137

D AEW OO M Y_2000

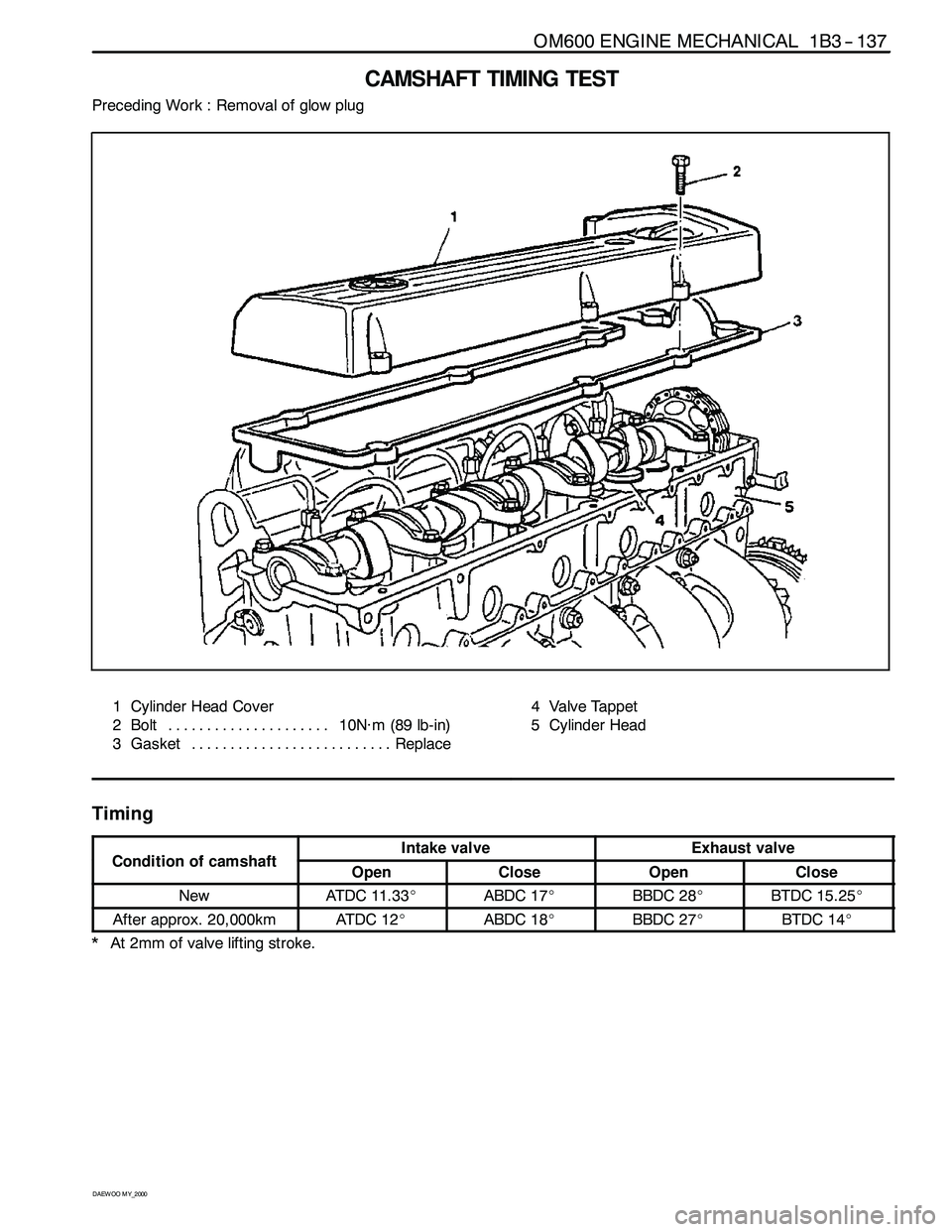

CAMSHAFT TIMING TEST

Preceding Work : Removal of glow plug

1 Cylinder Head Cover

2 Bolt 10N∙m (89 lb-in) .....................

3 Gasket Replace..........................4 Valve Tappet

5 Cylinder Head

Timing

CditifhftIntake valveExhaust valveCondition of camshaftOpenCloseOpenClose

NewAT DC 11 . 3 3_ABDC 17_BBDC 28_BTDC 15.25_

After approx. 20,000kmAT DC 1 2_ABDC 18_BBDC 27_BTDC 14_

* At 2mm of valve lifting stroke.

Page 687 of 2053

1B3 -- 138 OM600 ENGINE MECHANICAL

D AEW OO M Y_2000

Tools Required

001589532100 DialGauge

363 589 02 21 00 Dial Gauge Holder

366589002105 Extension

Measurement Procedure

1. Remove the cylinder head cover.

2. Rotate the engine in the direction of engine rotation

until the intake valve of NO.1 cylinder is completely

closed. The cam lobe faces up (arrow).

Notice

Do not rotate the engine at the bolt of the crankshaft

sprocket. Do not rotate the engine in the opposite di-

rection of engine rotation. If do, thiswill cause seri-

ous measuring errors.

3. Install the dial gauge holder and dial gauge (7) with

the extension (8) to the cylinder head and position

the tracer pin (9) onto the valve tappet (intake valve

of cylinder NO.1) with a preload of min. 3mm.

Notice

The tracer pin should be positioned exactly vertical.

Dial gauge Holder 363 589 02 21 00

Dial Gauge 001 589 53 21 00

Extension 366 589 00 21 05

4. Set the dial gauge to ’0’.

5. Rotate the engine further in direction of rotation until

the dial gauge has moved back by 2mm (valve lift) to

1mm.

6. Check the timing.

NewAT DC 11 . 3 3_

After approx. 20,000kmAT DC 1 2_

Notice

If timing is out standard, the camshaft should be

checked for wear and the timing chain for stretch. If

adifferenceofmorethan4_exists, the timing chain

should be replaced.

7. Replace the gasket and install the cylinder head

cover.

Tightening Torque10 N∙m(89lb-in)

Page 688 of 2053

OM600 ENGINE MECHANICAL 1B3 -- 139

D AEW OO M Y_2000

CAMSHAFT

Preceding Work : Removal of cylinder head cover

1 Bolt 25N∙m (18 lb-ft) ......................

2 Washer

3 Camshaft Bearing Cap

4 Camshaft

5 Dowel Pin

6 Locking Washer

7 Timing Chain8 Cylinder Head

9OilPan

10 Camshaft Sprocket

11 Was h er

12 12-- Sided Bolt (M11)

Check, 25N∙m (18 lb-ft)+90_ ...............

13 Gasket Replace..........................

14 Chain Tensioner 80N∙m (59 lb-ft) ............

Page 691 of 2053

1B3 -- 142 OM600 ENGINE MECHANICAL

D AEW OO M Y_2000

7. Remove the camshaft bearing cap.

8. Pull off the camshaft.

Notice

Be careful not to miss front locking washer.

9. Pull out the locking washer.

Notice

Check the condition of locking washer and replace if

necessary.

Installation Procedure

1. Insert the locking washer.

2. Check the valve tappet and ensure that tappet

moves smoothly.

3. Coat the camshaft with oil and install the camshaft

onto the cylinder head so that the TDC marking (ar-

row) is positioned upward vertically.

4. Install the camshaft bearing caps according to

markings(1, 2, 3 etc.).

Page 695 of 2053

1B3 -- 146 OM600 ENGINE MECHANICAL

D AEW OO M Y_2000

Notice

Always install the chain tensioner to be filled with oil.

Place the chain tensioner in engine oil up to over the

collar on the hexagon headwith the thrust pin facing

up. Slowly push down the thrust pin as far as the

stop 7~10 times with the aid of a press or a column

drill

Faulty chain tensioners should be replaced com-

pletely.

3 Screw Plug

4 Aluminum Gasket

5Ball

6 Ball Guide

7 Compression Spring

8 Compression Spring

9 Housing

10 Thrust Pin11 Valve Disc

12 O -- Ring

13 Snap Ring

14 Compression Spring

15 Filler

A Feed Bore from Cylinder Head

BToOilPan

Page 696 of 2053

OM600 ENGINE MECHANICAL 1B3 -- 147

D AEW OO M Y_2000

TIMING CHAIN

Preceding Work : Removal of glow plug

Removal of chain tensioner

Removal of cooling fan

Removal of cylinder head cover

1 Chain Link

2 Timing Chain

3 Camshaft Sprocket

4 Outer Plate

Page 700 of 2053

OM600 ENGINE MECHANICAL 1B3 -- 151

D AEW OO M Y_2000

TENSIONING RAIL

Preceding Work : Removal of cylinder head

Removal of timing case cover

1 Tensioning Rail2 Bearing Pin

Notice

The plastic coating of the tensioning rail can not be

replaced.