check engine SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 794 of 2053

OM600 ENGINE CONTROLS 1F3 -- 37

D AEW OO M Y_2000

Tools Required

617 589 08 21 00 Position Sensor

Test Procedure

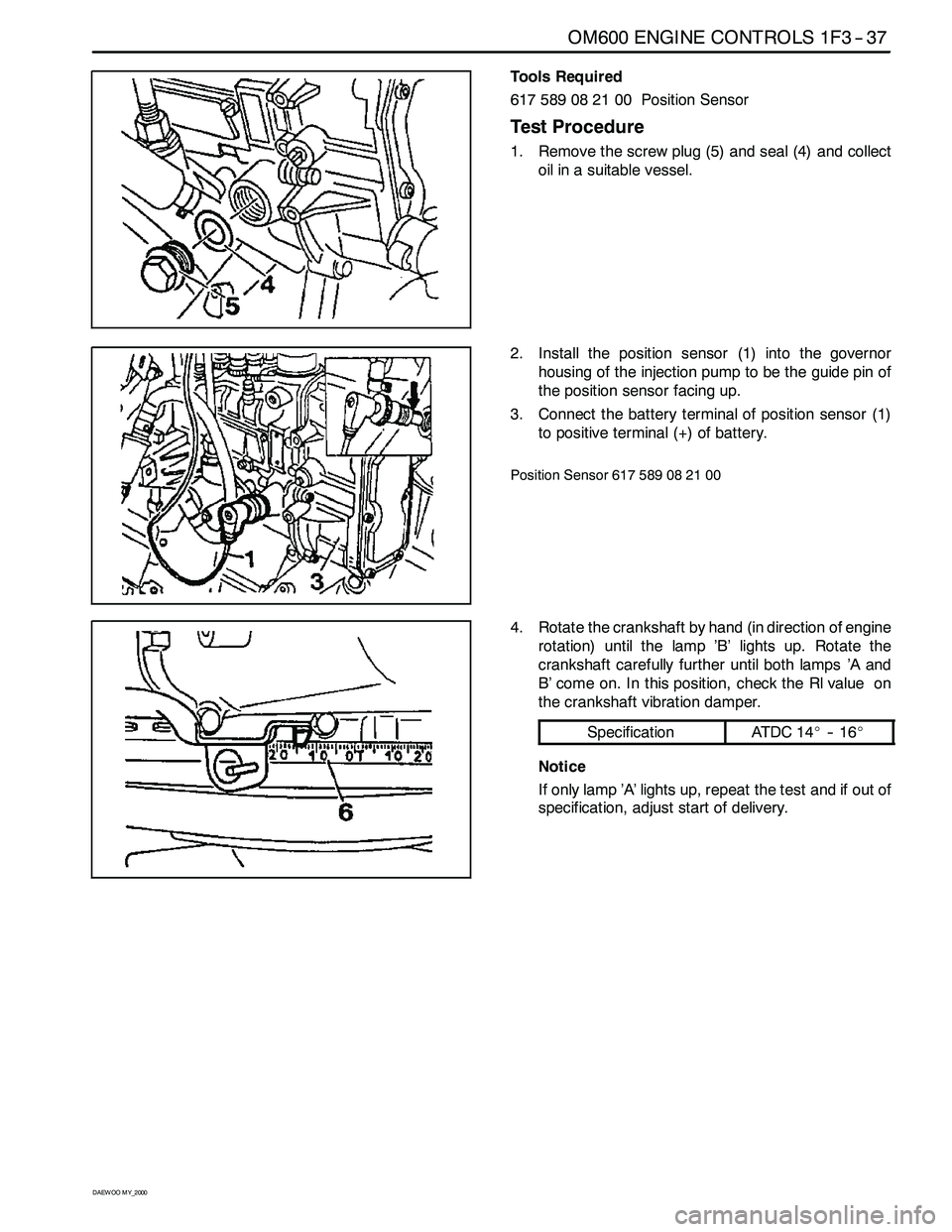

1. Remove the screw plug (5) and seal (4) and collect

oil in a suitable vessel.

2. Install the position sensor (1) into the governor

housing of the injection pump to be the guide pin of

the position sensor facing up.

3. Connect the battery terminal of position sensor (1)

to positive terminal (+) of battery.

Position Sensor 617 589 08 21 00

4. Rotate the crankshaft by hand (in direction of engine

rotation) until the lamp ’B’ lights up. Rotate the

crankshaft carefully further until both lamps ’A and

B’ come on. In this position, check the Rl value on

the crankshaft vibration damper.

SpecificationAT DC 1 4_-- 1 6_

Notice

If only lamp ’A’ lights up, repeat the test and if out of

specification, adjust start of delivery.

Page 797 of 2053

1F3 -- 40 OM600 ENGINE CONTROLS

D AEW OO M Y_2000

Tools Required

617 589 09 21 00 Rl Sensor

617589102100 TimingTester

667589002100 TDCPulseGenerator

Commercial Tools

ItemTools

Digigal TesterWith Pulse GeneratorBosch, MOT 001.03gg

Hartmann & Braun, EOMT3

Without Pulse GeneratorBosch, ETD 019.00

Sun, DIT 9000

ALV, Diesel -- Tester 875

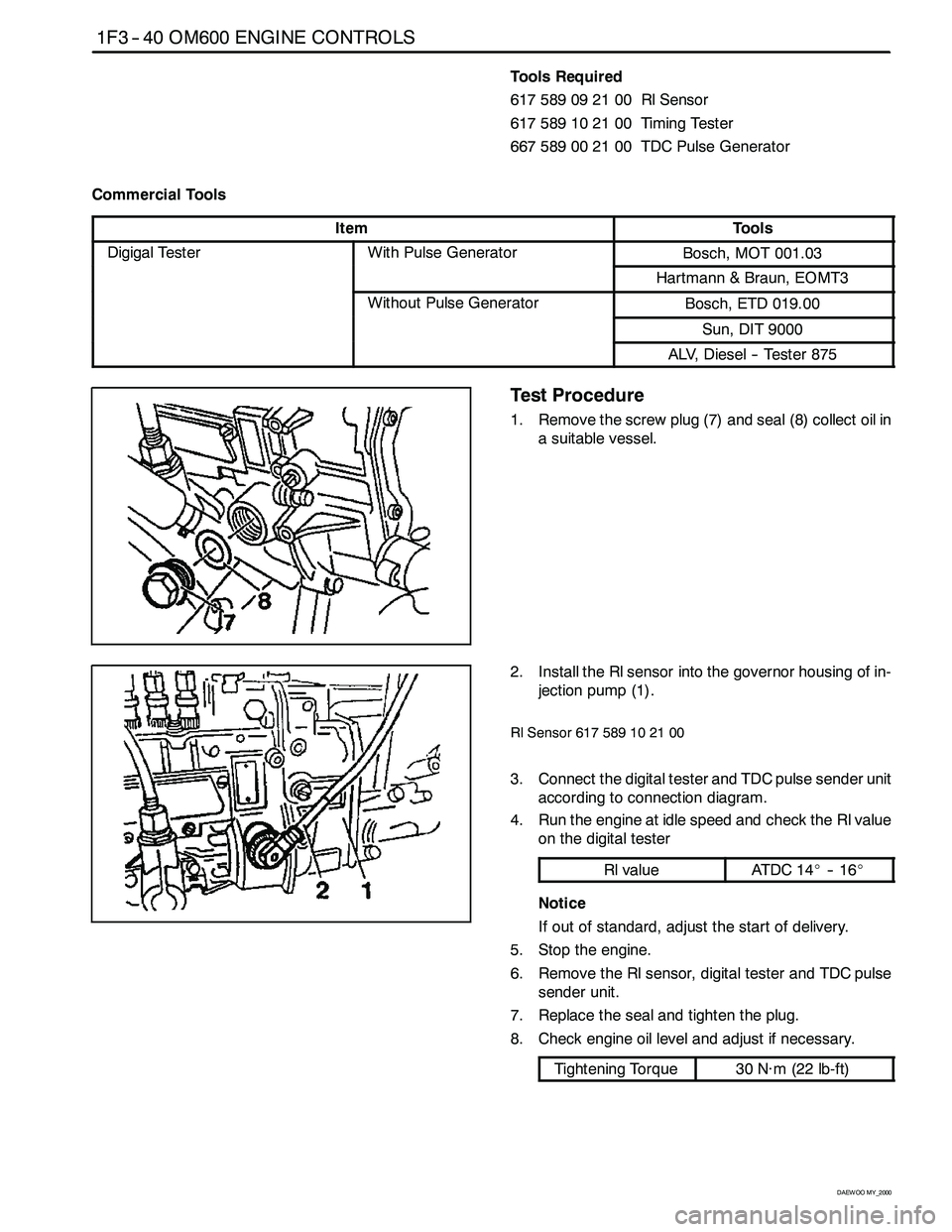

Test Procedure

1. Remove the screw plug (7) and seal (8) collect oil in

a suitable vessel.

2. Install the Rl sensor into the governor housing of in-

jection pump (1).

Rl Sensor 617 589 10 21 00

3. Connect the digital tester and TDC pulse sender unit

according to connection diagram.

4. Run the engine at idle speed and check the Rl value

on the digital tester

Rl valueAT DC 1 4_-- 1 6_

Notice

If out of standard, adjust the start of delivery.

5. Stop the engine.

6. Remove the Rl sensor, digital tester and TDC pulse

sender unit.

7. Replace the seal and tighten the plug.

8. Check engine oil level and adjust if necessary.

Tightening Torque30 N∙m (22 lb-ft)

Page 807 of 2053

1F3 -- 50 OM600 ENGINE CONTROLS

D AEW OO M Y_2000

11. Assemble the plastic clip (8).

12. Connect the vacuum line (13, 14).

13. Connect the connecting rod (9).

14. Connect the accelerator control damper (10).

(Manual transmission vehicle)

15. Install the chain tensioner.

16. Install the vacuum pump.

17. Check the start of delivery.

18. Adjust the idle speed.

Page 821 of 2053

SSANGYONG MY2002

2B-2 WHEEL ALIGNMENT

FOUR WHEEL ALIGNMENT

The first responsibility of engineering is to design safe

steering and suspension systems. Each component

must be strong enough to withstand and absorb extreme

punishment. Both the steering system and the front

and the rear suspension must function geometrically

with the body mass.

The steering and the suspension systems require that

the front wheels self-return and that the tire rolling effor t

and the road friction be held to a negligible force in

order to allow the customer to direct the vehicle with

the least effort and the most comfort.

A complete wheel alignment check should include mea-

surements of the rear toe and camber.

Four-wheel alignment assures that all four wheels will

be running in precisely the same direction.

When the vehicle is geometrically aligned, fuel economy

and tire life are at their peak, and steering and perfor

mance are maximized.

TOE-IN

Toe-in is the turning in of the tires, while toe-out is the

turning out of the tires from the geometric centerline or

thrust line. The toe ensures parallel rolling of the wheels.

The toe serves to offset the small deflections of the

wheel support system which occur when the vehicle is

rolling forward. The specified toe angle is the setting

which achieves 0 degrees of toe when the vehicle is

moving.

Incorrect toe-in or toe-out will cause tire wear and re

duced fuel economy. As the individual steering and

sus-pension components wear from vehicle mileage,

additional toe will be needed to compensate for the

wear.

Always correct the toe dimension last.

CASTER

Caster is the tilting of the uppermost point of the steering

axis either forward or backward from the vertical when

viewed from the side of the vehicle. A backward tilt is

positive, and a forward tilt is negative. Caster influences

directional control of the steering but does not affect

tire wear. Weak springs or overloading a vehicle will

affect caster. One wheel with more positive caster will

pull toward the center of the car. This condition will

cause the car to move or lean toward the side with the

least amount of positive caster. Caster is measured in

degrees.

CAMBER

Camber is the tilting of the top of the tire from the

vertical when viewed from the front of the vehicle. When

the tires tilt outward, the camber is positive. When the

tires tilt inward, the camber is negative. The camber

angle is measured in degrees from the vertical. Camber

in-fluences both directional control and tire wear.

If the vehicle has too much positive camber, the outside

shoulder of the tire will wear. If the vehicle has too

much negative camber, the inside shoulder of the tire

will wear.

DESCRIPTION AND OPERATION

Page 923 of 2053

HYDRAULIC BRAKES 4A-3

SSANGYONG MY2002

DIAGNOSTIC INFORMATION AND PROCEDURES

BRAKE SYSTEM TESTING

Brakes should be tested on a dry, clean, reasonably

smooth and level roadway. A true test of brake perfor-

mance cannot be made if the roadway is wet, greasy,

or covered with loose dirt which can cause tires not to

grip the road unequally. Testing also will be inaccurate

on a crowned roadway because the wheels tend to

bounce.

Test the brakes at different vehicle speeds with both

light-and heavy-pedal pressure; however, avoid locking

the brakes and sliding the tires. Locked brakes and

slid-ing tires do not indicate brake efficiency since

heavily braked but turning wheels will stop the vehicle

in less distance than locked brakes. More tire-to-road

friction is present with a heavily braked, turning tire

than with a sliding tire.

Because of the high deceleration capability, a firmer

pedal may be felt at higher deceleration levels.

There are three major external conditions that affect

brake performance:

•Tires having unequal contact and grip of the road

will cause unequal braking. Tires must be equally

inflated, and the tread pattern of the right and the

left tires must be approximately equal.

Unequal loading of the vehicle can affect the brake

performance since the most heavily loaded wheels

require more braking power, and thus more braking

effort, than the others.

Misalignment of the wheels, particularly conditions

of excessive camber and caster, will cause the

brakes to pull to one side.

To check for brake fluid leaks, hold constant foot pres-

sure on the pedal with the engine running at idle and

the shift lever in NEUTRAL. If the pedal gradually falls

away with the constant pressure, the hydraulic system

may be leaking. Perform a visual check to confirm any

suspected leaks.

Check the master cylinder fluid level. While a slight

drop in the reservoir level results from normal lining

wear, an abnormally low level indicates a leak in the

system. The hydraulic system may be leaking either

internally or externally. Refer to the procedure below

to check the master cylinder. The system may appear

to pass this test while still having a slight leak. If the

fluid level is normal, check the vacuum booster pushrod

length. If an incorrect pushrod length is found, adjust

or replace the rod.Check the master cylinder using the following proce

dure:

Check for a cracked master cylinder casting or a

brake fluid leak around the master cylinder. Leaks

are indicated only if there is at least one drop of

fluid. A damp condition is not abnormal.

Check for a binding pedal linkage and for an

incorrect pushrod length. If both of these parts are

in satisfactory condition, disassemble the master

cylinder and check for an elongated or swollen

primary cylinder or piston seals. If swollen seals

are found, substandard or contaminated brake fluid

should be suspected. If contaminated brake fluid

is found, all the components should be

disassembled and cleaned, and all the rubber

components should be replaced. All of the pipes

must also be flushed.

Improper brake fluid, or mineral oil or water in the fluid,

may cause the brake fluid to boil or cause deterioration

of the rubber components. If the primary piston cups in

the master cylinder are swollen, the rubber parts have

deteriorated.

If deterioration of the rubber is evident, disassemble

all the hydraulic parts and wash the parts with alcohol.

Dry these parts with compressed air before reassembly

to keep the alcohol out of the system. Replace all the

rubber parts in the system, including the hoses. When

working on the brake mechanisms, check for fluid on

the linings. If excessive fluid is found, replace the

linings.

If the master cylinder piston seals are in satisfactory

condition, check for leaks or excessive heat conditions.

If these conditions are not found, drain the fluid, flush

the master cylinder with brake fluid, refill the master

cylinder, and bleed the system.

BRAKE HOSE INSPECTION

The hydraulic brake hoses should be inspected at least

twice a year. The brake hose assembly should be

checked for road hazard damage, cracks, chafing of

the outer cover, and for leaks or blisters. Inspect the

hoses for proper routing and mounting. A brake hose

that rubs on a suspension component will wear and

eventually fail. A light and a mirror may be needed for

an adequate inspection. If any of the above conditions

are observed on the brake hose, adjust or replace the

hose as necessary.

Page 925 of 2053

HYDRAULIC BRAKES 4A-5

SSANGYONG MY2002

Value(s)

-

-

-

-

-

-

-

-

-

-

-

-

-

-

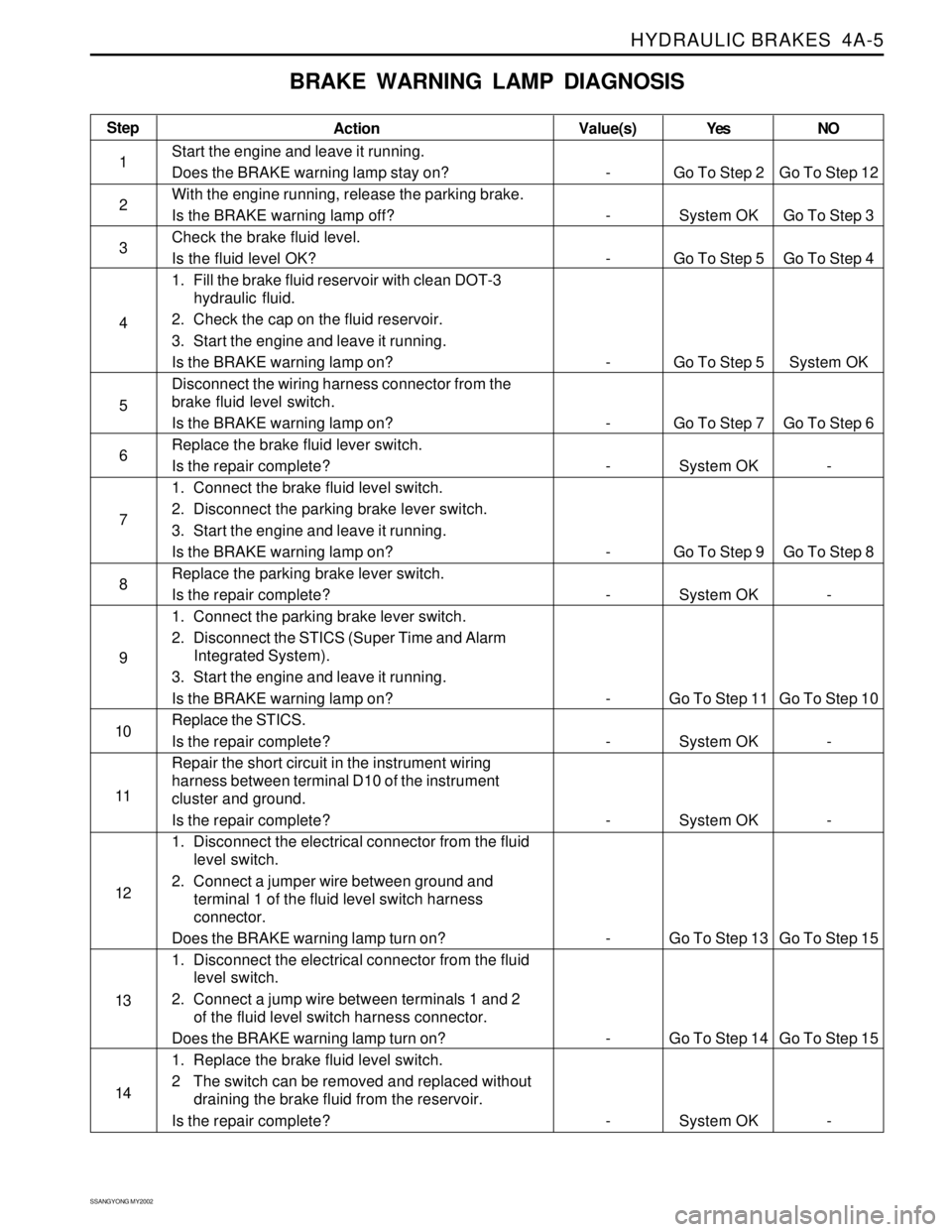

BRAKE WARNING LAMP DIAGNOSIS

Step

1

2

3

4

5

6

7

8

9

10

11

12

13

14Action

Start the engine and leave it running.

Does the BRAKE warning lamp stay on?

With the engine running, release the parking brake.

Is the BRAKE warning lamp off?

Check the brake fluid level.

Is the fluid level OK?

1. Fill the brake fluid reservoir with clean DOT-3

hydraulic fluid.

2. Check the cap on the fluid reservoir.

3. Start the engine and leave it running.

Is the BRAKE warning lamp on?

Disconnect the wiring harness connector from the

brake fluid level switch.

Is the BRAKE warning lamp on?

Replace the brake fluid lever switch.

Is the repair complete?

1. Connect the brake fluid level switch.

2. Disconnect the parking brake lever switch.

3. Start the engine and leave it running.

Is the BRAKE warning lamp on?

Replace the parking brake lever switch.

Is the repair complete?

1. Connect the parking brake lever switch.

2. Disconnect the STICS (Super Time and Alarm

Integrated System).

3. Start the engine and leave it running.

Is the BRAKE warning lamp on?

Replace the STICS.

Is the repair complete?

Repair the short circuit in the instrument wiring

harness between terminal D10 of the instrument

cluster and ground.

Is the repair complete?

1. Disconnect the electrical connector from the fluid

level switch.

2. Connect a jumper wire between ground and

terminal 1 of the fluid level switch harness

connector.

Does the BRAKE warning lamp turn on?

1. Disconnect the electrical connector from the fluid

level switch.

2. Connect a jump wire between terminals 1 and 2

of the fluid level switch harness connector.

Does the BRAKE warning lamp turn on?

1. Replace the brake fluid level switch.

2 The switch can be removed and replaced without

draining the brake fluid from the reservoir.

Is the repair complete?Yes

Go To Step 2

System OK

Go To Step 5

Go To Step 5

Go To Step 7

System OK

Go To Step 9

System OK

Go To Step 11

System OK

System OK

Go To Step 13

Go To Step 14

System OKNO

Go To Step 12

Go To Step 3

Go To Step 4

System OK

Go To Step 6

-

Go To Step 8

-

Go To Step 10

-

-

Go To Step 15

Go To Step 15

-

Page 947 of 2053

SSANGYONG MY2002

4C-4 POWER BOOSTER

DIAGNOSTIC INFORMATION AND PROCEDURES

KAA4C020

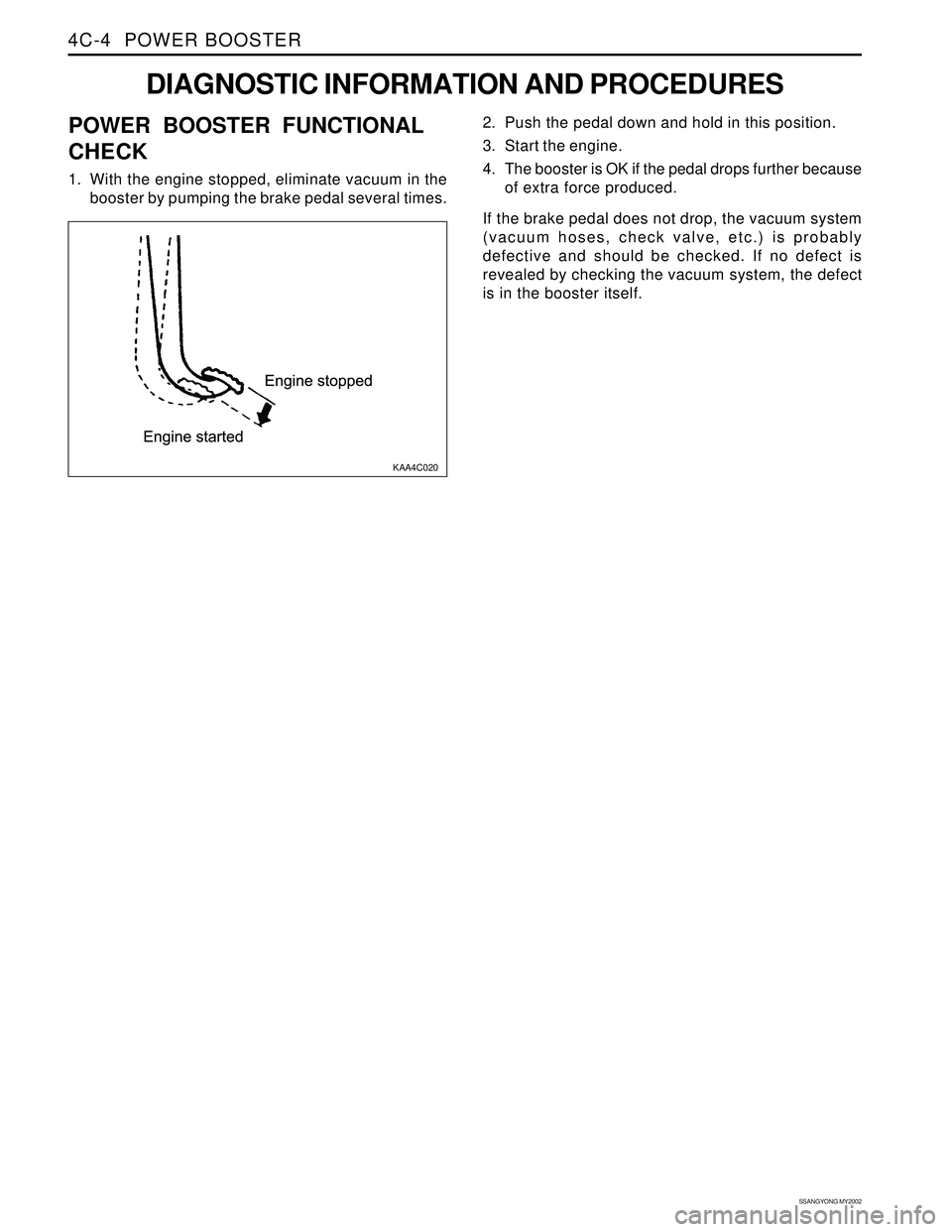

2. Push the pedal down and hold in this position.

3. Start the engine.

4. The booster is OK if the pedal drops further because

of extra force produced.

If the brake pedal does not drop, the vacuum system

(vacuum hoses, check valve, etc.) is probably

defective and should be checked. If no defect is

revealed by checking the vacuum system, the defect

is in the booster itself.POWER BOOSTER FUNCTIONAL

CHECK

1. With the engine stopped, eliminate vacuum in the

booster by pumping the brake pedal several times.

Page 1067 of 2053

SSANGYONG MY2002

4F-84 ABS AND TCS

DIAGNOSTIC TROUBLE CODE (DTC) 28

LOW VOLTAGE FAULT

KAA4F240

Circuit Description

Proper operation of the electronic brake control module

(EBCM) requires a certain minimum voltage. The EBCM

monitors the ignition feed circuit to determine if the

voltage falls below a minimum level.

Diagnosis

This test checks for battery output, proper grounding,

blown fuses, faulty ignition switch, and problems in the

circuitry.

Cause(s)

The battery is defective.

There is a defective ground connection.

A connector is damaged.

A wire is broken or shorted.

A fuse is blown.

The ignition switch is malfunctioning.Fail Action

ABS action is disabled during the period of low voltage,

and the ABS warning lamp is ON for the remainder of

the ignition cycle. If the failure is intermittent, the EBCM

will enable the system at the next ignition cycle and

set a history DTC 28.

Test Description

The number(s) below refer to step(s) on the diagnostic

table.

1. This step determines whether there is voltage at

the battery and at the high current source.

7. This step checks for voltage at the ignition 1

source.

15. This step begins the check for voltage at the EBCM

end of the ABS harness.

Diagnostic Aids

It is very important to perform a thorough inspection of

the wiring and the connectors. Failure to do so may re-

sult in misdiagnosis, causing part replacement with the

reappearance of the malfunction.

Step

1

2

3

Action

Go to Step 3

System OK

Go to Step 4Go to Step 2

-

Go to Step 7 11 - 14v

-

-

Check the voltage at the battery.

Is the voltage within the specified value?

Charge or replace the battery, as required.

Is the repair complete?

Check fuse EF11 in the engine fuse block.

Is the fuse blown?

DTC 28 - Low Voltage Fault

Value(s) Yes No

Page 1068 of 2053

ABS AND TCS 4F-85

SSANGYONG MY2002

Step

4

5

6

7

8

9

10

11

12

13

DTC 28 - Low Voltage Fault (Cont’d)

Action

Go to Step 5

System OK

System OK

Go to Step 8

Go to Step 9

System OK

System OK

Go to Step 12

Go to Step 13

System OKGo to Step 6

-

-

Go to Step 11

Go to Step 10

-

-

Go to Step 15

Go to Step 14

- -

-

-

-

-

-

-

-

-

-

1. Replace fuse EF11.

2. Turn the ignition to ON.

Does the fuse blow again?

1. Turn the ignition to OFF.

2. Trace the BLK/WHT wires in the ABS wiring

harness from terminal 8 of C104 at the engine fuse

block to F19 in the I/P fuse block.

3. Repair any short circuit found along this path.

Is the repair complete?

1. Turn the ignition to OFF.

2. Install the scan tool.

3. Clear all DTCs.

4. Road test the vehicle.

Does DTC 28 reset?

Check fuse F19 in the I/P fuse block.

Is the fuse blown?

1. Replace fuse F19.

2. Turn the ignition to ON.

Does the fuse blow again?

1. Turn the ignition to OFF.

2. Trace the WHT/RED wires in the ABS Wiring

harness from fuse F19 to terminal 50 of the EBCM

connector.

3. Repair any short circuit found along this path.

Is the repair complete?

1. Turn the ignition to OFF.

2. Install the scan tool.

3. Clear all DTCs.

4. Rood test the vehicle.

Does DTC 28 reset?

Check fuse F29 in the I/P fuse block.

Is fuse F29 blown?

1. Replace fuse F29.

2. Turn the ignition to ON.

Does fuse F29 blow again?

1. Turn the ignition to OFF.

2. Trace the WHT/RED wire from fuse F19 to terminal

1 of the EBCM connector.

3. Repair any short circuit found along this path.

Is the repair complete?

Value(s) Yes No

Page 1089 of 2053

SSANGYONG MY2002

4G-2 PARKING BRAKE

DESCRIPTION AND OPERATION

BRAKE CALIPER

This braking system uses a BRAKE warning light lo-

cated in the instrument panel cluster.

The following conditions will activate the BRAKE lamp:

•The parking brake is applied when the ignition is

ON. The lamp will turn off when the parking brake

is released.

The fluid level is below the minimum mark in the

master cylinder reservoir. The lamp will turn off when

the fluid level is above the minimum.

As a test of the lamp circuit, the BRAKE lamp will

glow dimly when the ignition is ON, even if the

parking brake is off and fluid level is above the

minimum. The lamp will turn off when the engine is

started. When the brake is firmly applied, the parking

brake should hold the vehicle with ample pedal

travel remaining.

Check for frayed cables, rust, etc. or any condition

that may inhibit present (or future) free movement of

the parking brake lever assembly.