check engine SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1095 of 2053

SECTION 5A

AUTOMATIC TRANSMISSION

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless

otherwise noted.

TABLE OF CONTENTS

Description and Operation . . . . . . . . . . . . . . . . . 5A-2

BTRA M74 4WD Automatic Transmission . . . . . . 5A-2

Operators Interfaces . . . . . . . . . . . . . . . . . . . . . 5A-2

Control Systems . . . . . . . . . . . . . . . . . . . . . . . . 5A-3

Electronic Control System . . . . . . . . . . . . . . . . . 5A-3

Hydraulic Control System . . . . . . . . . . . . . . . . . . 5A-9

Hydraulic Control Circuit . . . . . . . . . . . . . . . . . . 5A-10

Power Train System . . . . . . . . . . . . . . . . . . . . . 5A-14

Power Flows . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-18

Park and Neutral . . . . . . . . . . . . . . . . . . . . . . . 5A-20

Reverse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-22

Manual 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-24

Drive 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-26

Drive 2 and Manual 2 . . . . . . . . . . . . . . . . . . . . 5A-28

Drive 3 and Manual 3 . . . . . . . . . . . . . . . . . . . . 5A-30

Drive 3 Lock Up and Manual 3 Lock Up . . . . . . 5A-32

Drive 4 (Overdrive) . . . . . . . . . . . . . . . . . . . . . 5A-34

Drive 4 Lock Up . . . . . . . . . . . . . . . . . . . . . . . . 5A-36

Diagnostic Information and Procedures . . . . . 5A-38

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-38

Basic Knowledge Required . . . . . . . . . . . . . . . 5A-38

Functional Check Procedure . . . . . . . . . . . . . . . 5A-38

Transmission Fluid Level Service Procedure . . . 5A-38

Fluid Leak Diagnosis and Repair . . . . . . . . . . . 5A-39

Electrical / Garage Shift Test . . . . . . . . . . . . . . 5A-40

Road Test Procedure . . . . . . . . . . . . . . . . . . . . 5A-40

Electronic Adjustments . . . . . . . . . . . . . . . . . . 5A-40

Symptom Diagnosis . . . . . . . . . . . . . . . . . . . . . 5A-41

Drive Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-41

Faulty Shift Pattern . . . . . . . . . . . . . . . . . . . . . . 5A-42Shift Quality Faults . . . . . . . . . . . . . . . . . . . . . . 5A-44

After Teardown Faults . . . . . . . . . . . . . . . . . . . 5A-46

Trouble Code Diagnosis - Gasoline Vehicle . . 5A-48

TCM Diagnostic System Overview . . . . . . . . . . 5A-48

Clearing Trouble Codes . . . . . . . . . . . . . . . . . . 5A-48

Diagnostic Trouble Codes . . . . . . . . . . . . . . . . 5A-48

Trouble Code Diagnosis - Diesel Vehicle . . . . . 5A-50

TCM Diagnostic System Overview . . . . . . . . . . 5A-50

Clearing Trouble Codes . . . . . . . . . . . . . . . . . . 5A-50

Diagnostic Trouble Codes . . . . . . . . . . . . . . . . 5A-50

Repair Instructions . . . . . . . . . . . . . . . . . . . . . . 5A-157

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . . . 5A-157

Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-157

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-160

Rebuild Warnings . . . . . . . . . . . . . . . . . . . . . . 5A-160

Disassembly Procedure . . . . . . . . . . . . . . . . . . 5A-161

Assembly Procedure . . . . . . . . . . . . . . . . . . . . 5A-171

Front and Rear Band Adjustment . . . . . . . . . . . 5A-199

Gear Shift Control Lever . . . . . . . . . . . . . . . . . . 5A-202

Kickdown Switch . . . . . . . . . . . . . . . . . . . . . . . 5A-202

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-203

General Specification . . . . . . . . . . . . . . . . . . . . 5A-203

Fastener Tightening Specifications . . . . . . . . . . 5A-205

Schematic and Routing Diagrams . . . . . . . . . . 5A-206

TCM Wiring Diagrams (Gasoline Engine) . . . . . 5A-206

TCM Wiring Diagrams (Diesel Engine) . . . . . . . 5A-208

Connector End View . . . . . . . . . . . . . . . . . . . . . 5A-210

Special Tools and Equipment . . . . . . . . . . . . . 5A-211

Special Tools Table . . . . . . . . . . . . . . . . . . . . . 5A-211

Page 1132 of 2053

5A-38 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

DIAGNOSIS

BASIC KNOWLEDGE REQUIRED

You must be familliar with some basic electronics to

use this section of the Service Manual. They will help

you to follow diagnostic procedures.

Notice: Lack of the basic knowledge of this transmis-

sion when performing diagnostic procedures could re-

sult in incorrect diagnostic performance or damage to

transmission components. Do not, under any circum-

stances, attempt to diagnose a transmission problem

without this basic knowledge.

Notice: If a wire is probed with a sharp instrument

and not properly sealed afterward, the wire will corrode

and an open circuit will result.

Diagnostic test probes are now available that allow

you to probe individual wires without leaving the wire

open to the environment. These probe devices are

inexpensive and easy to install, and they permanently

seal the wire from corrosion.

Special Tools

You should be able to use a Digital Volt Meter (DVM),

a circuit tester, jumper wires or leads and a line

pressure gauge set. The functional check procedure

is designed to verify the correct operation of electronic

components in the transmission. This will eliminate the

unnecessary removal of transmission components.

FUNCTIONAL CHECK

PROCEDURE

Begin with the Functional Check Procedure which pro-

vides a general outline of how to diagnose automatic

transmission. The following functional check procedure

will indicate the proper path of diagnosing the transmis-

sion by describing the basic checks and then referenc-

ing the locations of the specific checks.

Check the fluid level according to the Fluid Level

Service Procedure.

Check the transmission fluid leak.

Check if the transmission fluid is not burnt by smell.

Notice: The specific fluid used in this transmission

turns brown during normal operation. Brown fluid

does not indicate a transmission fault.

Ensure that the transmission is not in Limp Home

Mode (LHM).

Check the battery terminals and the earth connec-

tions for corrosion or looseness.

Check that the cooler flow is not restricted.

Check all electrical plug connections for tightness.

Use on-board diagnostic tool or a scan tool to see

if any transmission trouble codes have been set.

DIAGNOSTIC INFORMATION AND PROCEDURES

Refer to the appropriate “Diagnostic Trouble Code

(DTC)” information and repair the vehicle as

directed. After repairing the vehicle, perform the

road test and verify that the code has not set again.

Perform the Electrical/Garage Shift Tests.

Perform the Road Test Procedure in this section.

Inspect the oil and check for metal or other contami-

nants in the oil pan.

TRANSMISSION FLUID LEVEL

SERVICE PROCEDURE

This procedure is to be used when checking a concern

with the fluid level in a vehicle. A low fluid level will

result in slipping and loss of drive/ reverse or delay on

engagement of drive/ reverse when the vehicle is cold.

The vehicle is first checked for transmission diagnostic

messages on the scan tool. If the oil level is low, it is

possible to register a vehicle speed signal fault.

The vehicle is to be test driven to determine if there is

an abnormal delay when selecting drive or reverse, or

loss of drive. One symptom of low fluid level is a

momentary loss of drive when driving the vehicle around

a corner. Also when the transmission fluid level is low,

a loss of drive may occur when the transmission fluid

temperature is low.

If there is no loss of drive when the vehicle is driven

warm and a vehicle speed signal fault is registered,

then fluid should be added to the transmission.

When adding or changing transmission fluid use only

Castrol TQ 95 automatic transmission fluid. The use of

incorrect fluid will cause the performance and durability

of the transmission to be severely degraded.

Fluid Level Diagnosis procedure

1. If the vehicle is at operating temperature allow the

vehicle to cool down for two hours, but no greater

than four hours. Or if the vehicle is at cool status,

start the engine and allow the engine to idle for

approximately 5 minutes or, if possible, drive the

vehicle for a few kilometers. This will allow the

transmission to be within the correct temperature

range. Transmission fluid level should be checked

at temperature 50 - 60 °C (82 - 140 °F).

Caution: Removal of the fluid filler plug when

the transmission fluid is hot may cause injury if

fluid drains from the filler hole.

2. With the brake pedal pressed, move the gear shift

control lever through the gear ranges, pausing a

few seconds in each range. Return the gear shift

control lever to P (Park). Turn the engine OFF.

3. Park the vehicle on a hoist, inspection pit or similar

raised level surface. The vehicle must be control

level to obtain a correct fluid level measurement.

Page 1133 of 2053

AUTOMATIC TRANSMISSION 5A-39

SSANGYONG MY2002

4. Place a fluid container below the fluid filler plug.

5. Clean all dirt from around the fluid filler plug.

Remove the fluid filler plug. Clean the filler plug

and check that there is no damage to the ‘O’ ring.

If fluid drains through the filler hole the transmis-

sion may have been overfilled. When the fluid

stops draining the fluid level is correct. Install

the fluid filler plug and tighten it to 33 Nm (24

lb-ft).

If fluid does not drain through the filler hole, the

transmission fluid level may be low. Install the

filler pump into the filler hole. Lower the vehicle

with the filler pump still connected and partially

fill the fluid through the filler hole.

Start the vehicle in P (Park) with the parking

brake and the brake applied. With the engine

idling, move the gear shift. control lever through

the gear ranges, pausing a few seconds in each

range and adding the fluid until gear application

is felt.

Return the gear shift lever to P (Park).

Turn the engine OFF and raise the vehicle. When

the three minutes passed after the engine

stopped, remove the filler pump.

Check if the fluid level is aligned with the bottom

of the filler hole. If not, add a small quantity of

fluid to the correct level. Install the fluid filler

plug and tighten it to 33 Nm (24 lb-ft).

If fluid does not drain through the filler hole al-

though adding a total of 1.5 liters, the transmission

should be inspected for fluid leaks and any leaks

should be fixed before setting the transmission

fluid level.

6. When the fluid level checking procedure is com-

pleted, wipe any fluid around the filler plug with a

rag or shop towel.

Fluid Level Set After Service

1. Depending on the service procedure performed,

add the following amounts of fluid through the filler

plug hole prior to adjusting the fluid level:

Converter empty 8.0 liters (8.5 quarts)

Converter full 3.8 liters (4.0 quarts)

2. Follow steps 1 through 4 of the Fluid Level Diagnosis

Procedure.

3. Clean all dirt from around the fluid filler plug.

Remove the fluid filler plug. Clean the filler plug

and check that there is no damage to the ‘O’ ring.

4. Lower the vehicle with the filler pump still connected

and start the vehicle in P (Park) with the parking

brake and the brake applied. With the engine idling,

move the gear shift control lever through the gear

ranges, pausing a few seconds in each range and

adding the fluid until gear application is felt.Then add an additional 0.5 litres of fluid. Return

the gear shift lever to P (Park). Turn the engine OFF

and raise the vehicle. Install the fluid filler plug and

tighten it to 33 Nm (24 lb-ft).

5. Drive the vehicle at 3.5 to 4.5 kilometers with light

throttle so that the engine does not exceed 2500

rpm.

This should result in the transmission temperature

being in the range 50 - 60 °C (82 - 140 °F). With the

brake applied, move the shift lever through the gear

ranges, pausing a few seconds in each range at

the engine idling.

6. Return the gear shift lever to P (Park).

Turn the en-gine OFF and raise the vehicle on the

hoist, if applicable, ensuring the vehicle is level.

When the three minutes passed after the engine

stopped, remove the filler plug.

Check if the fluid level is aligned with the bottom of

the filler hole. If not, add a small quantity of fluid to

the correct level. Install the fluid filler plug and

tighten it to 33 Nm (24 lb-ft).

7. Wipe any fluid around the filler plug with a rag or

shop towel.

FLUID LEAK DIAGNOSIS AND

REPAIR

The cause of most external leaks can generally be lo-

cated and repaired with the transmission in the vehicle.

Methods for Locating Leaks

General Method

1. Verify that the leak is transmission fluid.

2. Thoroughly clean the suspected leak area.

3. Drive the vehicle for approximately 25 km (15 miles)

or until the transmission reaches normal operating

temperature (88 °C, 190 °F).

4. Park the vehicle over clean paper or cardboard.

5. Turn the engine OFF and look for fluid spots on the

paper.

6. Make the necessary repairs to correct the leak.

Powder Method

1. Thoroughly clean the suspected leak area.

2. Apply an aerosol type powder (foot powder) to the

suspected leak area.

3. Drive the vehicle for approximately 25 km (15 miles)

or until the transmission reaches normal operating

temperature (88 °C, 190 °F).

4. Turn the engine OFF.

5. Inspect the suspected leak area and trace the leak

path through the powder to find the source of the

leak.

6. Make the necessary repairs.

Page 1134 of 2053

5A-40 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Dye and Black Light Method

1. Add dye to the transmission through the transmission

fluid filler plug. Follow the manufacturer’s recommen-

dation for the amount of dye to be used.

2. Use the black light to find the fluid leak.

3. Make the necessary repairs.

Repairing the Fluid Leak

Once the leak point is found the source of the leak

must be determined. The following list describes the

potential causes for the leak:

Fasteners are not torqued to specification.

Fastener threads and fastener holes are dirty or

corroded.

Gaskets, seals or sleeves are misaligned, damaged

or worn.

Damaged, warped or scratched seal bore or gasket

surface.

Loose or worn bearing causing excess seal or sleeve

wear.

Case or component porosity.

Fluid level is too high.

Plugged vent or damaged vent tube.

Water or coolant in fluid.

Fluid drain back holes plugged.

ELECTRICAL / GARAGE SHIFT

TEST

This preliminary test should be performed before a hoist

or road test to make sure electronic control inputs are

connected and operating. If the inputs are not checked

before operating the transmission, a simple electrical

condition could be misdiagnosed as a major

transmission condition.

A scan tool provides valuable information and must

be used on the automatic transmission for accurate

diagnosis.

1. Move gear shift control lever to P (Park) and set

the parking brake.

2. Connect scan tool to Data Link Connector (DLC)

terminal.

3. Start engine.

4. Turn the scan tool ON.

5. Verify that the appropriate signals are present.

These signals may include:

ENGINE SPEED

VEHICLE SPEED

THROTTLE POSITION

ACCEL. PEDAL POSITION

TRANSMISSION GEAR STATE

GEAR SHIFT LEVER POSITION

TRANSMISSION FLUID TEMPERATURE

CLOSED THROTTLE POSITION LEARN

OPEN THROTTLE POSITION LEARNT

CLOSED ACCEL. PEDAL POSITION LEARNT

OPEN ACCEL. PEDAL POSITION LEARNT

A/C COMPRESSOR STATUS

KICKDOWN SWITCH STATUS

4WD STATUS

MODE SWITCH

THROTTLE POSITION VOLTAGE

GEAR SHIFT LEVER POSITION VOLTAGE

TRANS. FLUID TEMPERATURE VOLTAGE

A/C SWITCH

KICKDOWN SWITCH VOLTAGE

4WD LAMP LOW VOLTAGE

4WD LAMP HIGH VOLTAGE

MODE SWITCH VOLTAGE

BATTERY VOLTAGE

6. Monitor the A/C COMPRESSOR STATUS signal

while pushing the A/C switch.

The A/C COMPRESSOR STATUS should come

ON when the A/C switch is pressed, and turn

OFF when the A/C switch is repushed.

7. Monitor the GEAR SHIFT LEVER POSITION signal

and move the gear shift control lever through all

the ranges.

Verify that the GEAR SHIFT LEVER POSITION

value matches the gear range indicated on the

instrument panel or console.

Gear selections should be immediate and not

harsh.

8. Move gear shift control lever to neutral and monitor

the THROTTLE POSITION signal while increasing

and decreasing engine speed with the accelerator

pedal.

THROTTLE POSITION should increase with en-

gine speed.

ROAD TEST PROCEDURE

Perform the road test using a scan tool.

This test should be performed when traffic and road

conditions permit.

Observe all traffic regulations.

ELECTRONIC ADJUSTMENTS

Idle Speed Adjustments

Carry out the adjustments to the idle speed as detailed

in the workshop manual.

Vehicle Coding

The vehicle coding is integrated as part of the

diagnostic software. A scan tool has the function to

code the ve-hicle through the K-line.

Page 1135 of 2053

5A-40 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Dye and Black Light Method

1. Add dye to the transmission through the transmission

fluid filler plug. Follow the manufacturer’s recommen-

dation for the amount of dye to be used.

2. Use the black light to find the fluid leak.

3. Make the necessary repairs.

Repairing the Fluid Leak

Once the leak point is found the source of the leak

must be determined. The following list describes the

potential causes for the leak:

Fasteners are not torqued to specification.

Fastener threads and fastener holes are dirty or

corroded.

Gaskets, seals or sleeves are misaligned, damaged

or worn.

Damaged, warped or scratched seal bore or gasket

surface.

Loose or worn bearing causing excess seal or sleeve

wear.

Case or component porosity.

Fluid level is too high.

Plugged vent or damaged vent tube.

Water or coolant in fluid.

Fluid drain back holes plugged.

ELECTRICAL / GARAGE SHIFT

TEST

This preliminary test should be performed before a hoist

or road test to make sure electronic control inputs are

connected and operating. If the inputs are not checked

before operating the transmission, a simple electrical

condition could be misdiagnosed as a major

transmission condition.

A scan tool provides valuable information and must

be used on the automatic transmission for accurate

diagnosis.

1. Move gear shift control lever to P (Park) and set

the parking brake.

2. Connect scan tool to Data Link Connector (DLC)

terminal.

3. Start engine.

4. Turn the scan tool ON.

5. Verify that the appropriate signals are present.

These signals may include:

ENGINE SPEED

VEHICLE SPEED

THROTTLE POSITION

ACCEL. PEDAL POSITION

TRANSMISSION GEAR STATE

GEAR SHIFT LEVER POSITION

TRANSMISSION FLUID TEMPERATURE

CLOSED THROTTLE POSITION LEARN

OPEN THROTTLE POSITION LEARNT

CLOSED ACCEL. PEDAL POSITION LEARNT

OPEN ACCEL. PEDAL POSITION LEARNT

A/C COMPRESSOR STATUS

KICKDOWN SWITCH STATUS

4WD STATUS

MODE SWITCH

THROTTLE POSITION VOLTAGE

GEAR SHIFT LEVER POSITION VOLTAGE

TRANS. FLUID TEMPERATURE VOLTAGE

A/C SWITCH

KICKDOWN SWITCH VOLTAGE

4WD LAMP LOW VOLTAGE

4WD LAMP HIGH VOLTAGE

MODE SWITCH VOLTAGE

BATTERY VOLTAGE

6. Monitor the A/C COMPRESSOR STATUS signal

while pushing the A/C switch.

The A/C COMPRESSOR STATUS should come

ON when the A/C switch is pressed, and turn

OFF when the A/C switch is repushed.

7. Monitor the GEAR SHIFT LEVER POSITION signal

and move the gear shift control lever through all

the ranges.

Verify that the GEAR SHIFT LEVER POSITION

value matches the gear range indicated on the

instrument panel or console.

Gear selections should be immediate and not

harsh.

8. Move gear shift control lever to neutral and monitor

the THROTTLE POSITION signal while increasing

and decreasing engine speed with the accelerator

pedal.

THROTTLE POSITION should increase with en-

gine speed.

ROAD TEST PROCEDURE

Perform the road test using a scan tool.

This test should be performed when traffic and road

conditions permit.

Observe all traffic regulations.

ELECTRONIC ADJUSTMENTS

Idle Speed Adjustments

Carry out the adjustments to the idle speed as detailed

in the workshop manual.

Vehicle Coding

The vehicle coding is integrated as part of the

diagnostic software. A scan tool has the function to

code the ve-hicle through the K-line.

Page 1136 of 2053

AUTOMATIC TRANSMISSION 5A-41

SSANGYONG MY2002

SYMPTOM DIAGNOSIS

DRIVE FAULTS

Condition

No Drive in DPossible Causes

Insufficient auto transmission

fluid.

Blocked feed in C1/C2 cylinder.

‘Z’ link displaced.

Primary Regulator Valve (PRV)

jammed open.

Overdrive shaft or input shaft

seal rings failed.

3-4 or 1-2 One Way Clutch

(OWC) installed backwards or

failed.

C2 piston broken or cracked.

Rear band or servo faulty.

Failure in C3, C3 hub or C1/C2

cylinder.

Damaged input shaft sealing rings.

Jammed Primary Regulator

Valve (PRV).

Damaged/broken pump gears.

Dislodged output shaft snap ring.Action

Check the fluid level. Top up as

necessary.

Inspect and clean C1/C2 feed.

Reinstall/renew the ‘z’ link.

Remove, clean and re-install the

PRV.

Inspect and replace as necessary.

Inspect and replace as necessary.

Inspect and replace as necessary.

Check servo adjustment or

replace rear band as necessary.

Check for failure in C3, C3 hub

or C1/C2 cylinder. Repair as

necessary.

Inspect and replace as necessary.

Inspect and clean PRV.

Inspect and replace pump

gears as necessary.

Inspect and repair as necessary.

No Drive in Reverse

No engine braking in Manual 1

Engine braking in Manual 1 is OK

No drive in Drive and Reverse

Page 1143 of 2053

5A-48 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

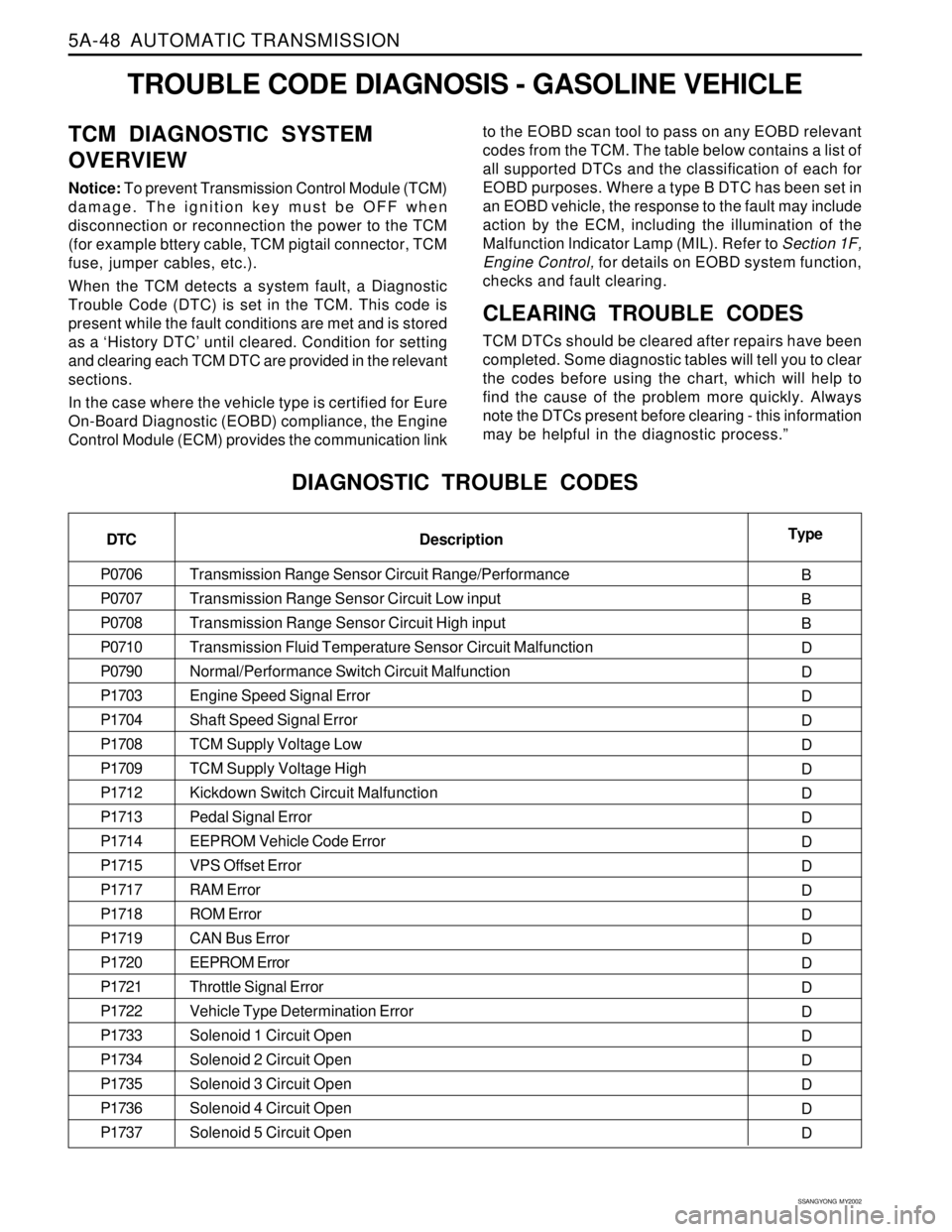

TROUBLE CODE DIAGNOSIS - GASOLINE VEHICLE

TCM DIAGNOSTIC SYSTEM

OVERVIEW

Notice: To prevent Transmission Control Module (TCM)

damage. The ignition key must be OFF when

disconnection or reconnection the power to the TCM

(for example bttery cable, TCM pigtail connector, TCM

fuse, jumper cables, etc.).

When the TCM detects a system fault, a Diagnostic

Trouble Code (DTC) is set in the TCM. This code is

present while the fault conditions are met and is stored

as a ‘History DTC’ until cleared. Condition for setting

and clearing each TCM DTC are provided in the relevant

sections.

In the case where the vehicle type is certified for Eure

On-Board Diagnostic (EOBD) compliance, the Engine

Control Module (ECM) provides the communication linkto the EOBD scan tool to pass on any EOBD relevant

codes from the TCM. The table below contains a list of

all supported DTCs and the classification of each for

EOBD purposes. Where a type B DTC has been set in

an EOBD vehicle, the response to the fault may include

action by the ECM, including the illumination of the

Malfunction lndicator Lamp (MIL). Refer to Section 1F,

Engine Control, for details on EOBD system function,

checks and fault clearing.

CLEARING TROUBLE CODES

TCM DTCs should be cleared after repairs have been

completed. Some diagnostic tables will tell you to clear

the codes before using the chart, which will help to

find the cause of the problem more quickly. Always

note the DTCs present before clearing - this information

may be helpful in the diagnostic process.”

DIAGNOSTIC TROUBLE CODES

DTC

P0706

P0707

P0708

P0710

P0790

P1703

P1704

P1708

P1709

P1712

P1713

P1714

P1715

P1717

P1718

P1719

P1720

P1721

P1722

P1733

P1734

P1735

P1736

P1737Type

B

B

B

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D Description

Transmission Range Sensor Circuit Range/Performance

Transmission Range Sensor Circuit Low input

Transmission Range Sensor Circuit High input

Transmission Fluid Temperature Sensor Circuit Malfunction

Normal/Performance Switch Circuit Malfunction

Engine Speed Signal Error

Shaft Speed Signal Error

TCM Supply Voltage Low

TCM Supply Voltage High

Kickdown Switch Circuit Malfunction

Pedal Signal Error

EEPROM Vehicle Code Error

VPS Offset Error

RAM Error

ROM Error

CAN Bus Error

EEPROM Error

Throttle Signal Error

Vehicle Type Determination Error

Solenoid 1 Circuit Open

Solenoid 2 Circuit Open

Solenoid 3 Circuit Open

Solenoid 4 Circuit Open

Solenoid 5 Circuit Open

Page 1147 of 2053

5A-52 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Circuit Description

The Transmission Control Module (TCM) Diagnistic

System Check is the starting point for any driveability

complaint diagnosis. Before using this procedure,

perform a careful visual/physical check of the

Transmission Control Module (TCM) and the

transmission grounds for cleanliness and tightness.

The TCM Diagnostic System Check is an organized

approach to identifying a problem created by an

electronic transmission control system malfunction.

TCM DIAGNOSTIC SYSTEM CHECK

Diagnostic Aids

An intermittent fault may be caused by a poor connec-

tion, rubbed-through wire insulation or a wire broken

inside the insulation. Check for poor connections or a

damaged harness. Inspect the TCM harness and con-

nections for improper mating, broken locks, improperly

formed or damaged terminals, poor terminal-to-wire

connection, and damaged harness.

TCM Diagnostic System Check

1

StepAction Value(s) Yes No

21 Turn the ignition OFF.

2. Install the scan tool.

3. Turn the ignition ON, with the engine OFF.

4. Attempt to display the Transmission Control

Module (TCM) Data List with the scan tool.

Does the scan tool display the TCM data?

Select the Trouble Code with the scan tool.

Are any Diagnostic Trouble Codes (DTCs) stored?

- Go to Step 2 Go to Step 3

Go to

applicable

DTC table -System OK,

Check

Complete

KAA5A5KA

Page 1149 of 2053

5A-54 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

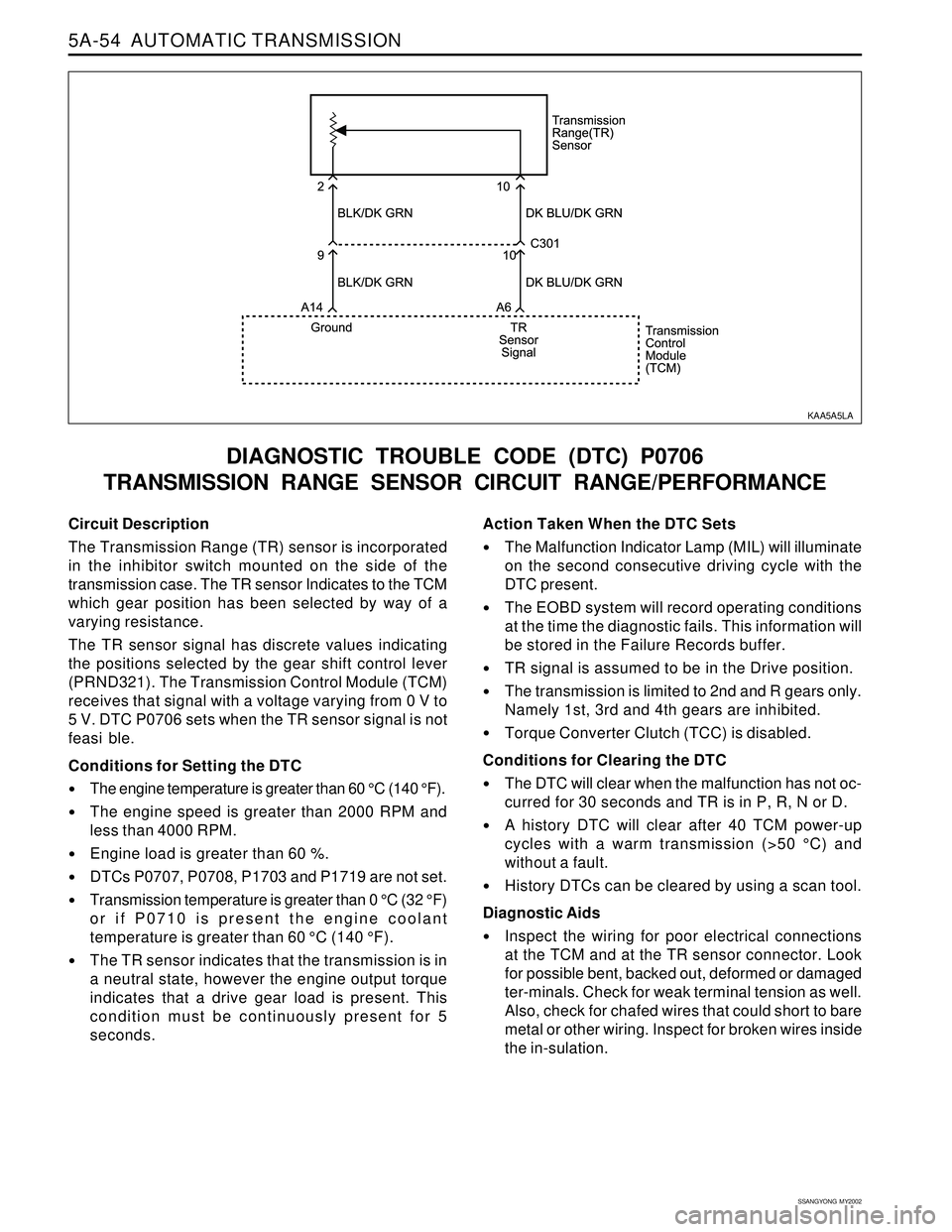

Circuit Description

The Transmission Range (TR) sensor is incorporated

in the inhibitor switch mounted on the side of the

transmission case. The TR sensor Indicates to the TCM

which gear position has been selected by way of a

varying resistance.

The TR sensor signal has discrete values indicating

the positions selected by the gear shift control lever

(PRND321). The Transmission Control Module (TCM)

receives that signal with a voltage varying from 0 V to

5 V. DTC P0706 sets when the TR sensor signal is not

feasi ble.

Conditions for Setting the DTC

•The engine temperature is greater than 60 °C (140 °F).

The engine speed is greater than 2000 RPM and

less than 4000 RPM.

Engine load is greater than 60 %.

DTCs P0707, P0708, P1703 and P1719 are not set.

Transmission temperature is greater than 0 °C (32 °F)

or if P0710 is present the engine coolant

temperature is greater than 60 °C (140 °F).

The TR sensor indicates that the transmission is in

a neutral state, however the engine output torque

indicates that a drive gear load is present. This

condition must be continuously present for 5

seconds.

DIAGNOSTIC TROUBLE CODE (DTC) P0706

TRANSMISSION RANGE SENSOR CIRCUIT RANGE/PERFORMANCE

Action Taken When the DTC Sets

The Malfunction Indicator Lamp (MIL) will illuminate

on the second consecutive driving cycle with the

DTC present.

The EOBD system will record operating conditions

at the time the diagnostic fails. This information will

be stored in the Failure Records buffer.

TR signal is assumed to be in the Drive position.

The transmission is limited to 2nd and R gears only.

Namely 1st, 3rd and 4th gears are inhibited.

Torque Converter Clutch (TCC) is disabled.

Conditions for Clearing the DTC

The DTC will clear when the malfunction has not oc-

curred for 30 seconds and TR is in P, R, N or D.

A history DTC will clear after 40 TCM power-up

cycles with a warm transmission (>50 °C) and

without a fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

Inspect the wiring for poor electrical connections

at the TCM and at the TR sensor connector. Look

for possible bent, backed out, deformed or damaged

ter-minals. Check for weak terminal tension as well.

Also, check for chafed wires that could short to bare

metal or other wiring. Inspect for broken wires inside

the in-sulation.

KAA5A5LA

Page 1150 of 2053

AUTOMATIC TRANSMISSION 5A-55

SSANGYONG MY2002

Perform a Transmission Control Module (TCM)

Diagnostic System Check.

Is the check performed?

1. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

3. Record and then clear DTCs.

4. Operate the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool display P0706?

1. Select Gear Lever Position on scan tool Data List.

2. Move the gear shift control lever through all of the

gear ranges (P, R, N, D, 3, 2, 1).

Does the scan tool display the correct gear lever

positions?

1. Inspect the TR sensor for damage to its rotating

part or its mountings.

2. Inspect the shaft driving the TR sensor for damage.

Is a repair necessary?

Replace the TR sensor or driving shaft as appropriate.

Is the acting complete?

Check for damage to the z-link within the transmission

and repair as necessary.

Is a repair necessary?

1. Using the scan tool, clear the DTCs.

2. Road test the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool indicate that this diagnostic has

run and passed?

Check if any DTCs are set.

Are there any DTCs displayed or previously recorded

at Step 2 that have not been diagnosed?

DTC P0706 Transmission Range Sensor Circuit Range/Performance

1

StepAction Value(s) Yes No

2

3

4

5

6

- Go to Step 2Go to “TCM

Diagnostic

System Check”

- Go to Step 6 Go to Step 4

- Go to Step 5 Go to Step 6

- Go to Step 7 -

8 7

- Go to Step 8 Go to Step 2

- Go to Step 7 -

- Go to Step 3 Go to

“Diagnostic

Aids”

-Go to

applicable

DTC tableSystem OK,

Check

Complete