check engine SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 710 of 2053

OM600 ENGINE MECHANICAL 1B3 -- 161

D AEW OO M Y_2000

Installation Procedure

1. Put the same alignment mark on the new crankshaft

sprocket as in the old sprocket.

Notice

Check the timing chain, camshaft sprocket, injection

pump timing sprocket, oil pump chain and oil pump

sprocket for wear and replace if necessary.

2. Install the new crankshaft sprocket (12) by using a

drift (21).

Notice

Align the groove of sprocket and woodruff key (ar-

row) exactly.

Drift 116 589 07 15 00

3. Fit the timing chain (4) on the crankshaft sprocket

(12).

Notice

Align the alignment marks (arrow) on the chain and

sprocket.

4. Install the camshaft sprocket (3).

Tightening Torque25 N∙m (18 lb-ft) + 90_

Notice

Pay attention on the alignment marks and dowel pin

(arrow).

Page 712 of 2053

OM600 ENGINE MECHANICAL 1B3 -- 163

D AEW OO M Y_2000

PISTON

Preceding Work : Removal of cylinder head

Removal of the oil pump

1 Oil Ring

2 2nd Ring

3 Top Ring

4 Snap Ring Replace........................

5 Piston Pin

6Piston

7 Connecting Rod Bushing Check............8 Connecting Rod

9 Connecting Rod Upper Bearing Shell

10 Connecting Rod Lower Bearing Shell

11 Connecting Rod Bearing Cap

12 Connecting Rod Bolt 35N∙m (26 lb-ft)+90_ ...

13 Crankcase

14 Cylinder Bore

Notice

There are two kinds of connecting rods (for machining) and they are different in weight approx. 15g. When replac-

ing the connecting rod, measure its weight and ensure that a engine has the same weight of connecting rods. If

not, there would be a unbalancing of engine.

Page 715 of 2053

1B3 -- 166 OM600 ENGINE MECHANICAL

D AEW OO M Y_2000

Installation Procedure

1. Fit the piston onto the connecting rod so that the ar-

row (15) and the locking slot (16) are facing in direc-

tion of the vehicle.

2. Coat the piston pin (15) with engine oil and insert it

by hand.

Notice

Do not heat up the piston.

3. Install the new snap ring (4) into the grooves (ar-

row).

4. Check the piston rings (1, 2, 3) and replace them if

necessary.

5. Install and arrange the piston rings to be evenly

120_from each ends gap.

Page 717 of 2053

1B3 -- 168 OM600 ENGINE MECHANICAL

D AEW OO M Y_2000

12. Coat the bolts (12) with oil and then tighten the bolts.

Tightening Torque40 N∙m (30 lb-ft) + 90_

13. Rotate the crankshaft and check axial clearance be-

tween the connecting rod and crankshaft.

14. Measure clearance between the piston crown and

cylinder

StandardMax. 0.12mm

15. Position the piston at TDC and measure the dis-

tance between the piston crown and the crankcase

surface.

StandardMax. 0.965 mm

Notice

Measure at points marked.

Dial Gauge 001 589 00 53 21

Dial Gauge Holder 363 589 02 21 00

Page 728 of 2053

OM600 ENGINE MECHANICAL 1B3 -- 179

D AEW OO M Y_2000

Measurement Procedure

1. Measure height ’A’.

Limit142.5 mm

Notice

If the height is less than 142.5mm, replace the cylin-

der head.

2. Insert the valve (1) and measure valve arrears ’a’.

Valve Arrears ’a’0.1 -- 0.7 mm

Notice

If out of standard, machine the valve seat.

3. Install the prechamber and measure protrusion ’C’.

Protrusion ’C’7.6 -- 8.1mm

4. Assemble the engine and check the valve timing.

Page 730 of 2053

OM600 ENGINE MECHANICAL 1B3 -- 181

D AEW OO M Y_2000

Tools Required

102589001500 Drift

102589121500 Drift

Replacement Procedure

1. Completely drain the coolant.

2. Remove any parts which impede access.

(Example : transmission, injection pump)

3. Place the screwdriver to the deepdrawn edge of the

core plug and pull forward and then rotate 90_.

4. Pull out the core plug with pliers.

5. Thoroughly clean the sealing surface and apply Loc-

tite 241.

6. Install the new core plug by using a drift.

Drift 102 589 00 15 00 (F34)

Drift 102 589 12 15 00 (F17)

7. Install the removed parts and fill the coolant.

Notice

The adhesive must be allowed to harden for about

45 minutes before filling of coolant.

8. Warm up the engine and check the coolant for leaks.

Page 734 of 2053

OM600 ENGINE MECHANICAL 1B3 -- 185

D AEW OO M Y_2000

Removal & Installation Procedure

1. Remove the timing case cover.

2. By inserting a round bar (6) approx. 0.7m from the

back to the front side through the oil gallery, knock

out the steel balls (1,3).

Notice

Be careful not to damage the bores of the steel

balls.

6 Shop -- made tool

3. Thoroughly clean the bores of steel balls.

4. Place the steel ball (3) onto the drift (7) with a little

grease and position to the bore and then tap until the

drift stops.

Drift 601 589 08 15 00

5. Place the steel ball (1) onto the drift (7) with a little

grease and position to the bore and then tap until the

drift stops.

Drift 601 589 08 1500

6. Warm up the engine and check the oil for leaks.

Page 739 of 2053

1D3 -- 4 OM600 ENGINE COOLING

D AEW OO M Y_2000

COOLING SYSTEM LEAKAGE TEST

Tools Required

124589152100Tester

Test

1. Loosen the pressure cap by 1 notch and remove the

cap after.

Notice

Do not remove radiator cap when coolant is above

90°C.

2. Add the coolant to the arrow mark of coolant reser-

voir.

3. Connect the special tool to the injector of reservoir

and apply 1.4bar pressure.

Tester 124 589 15 21 00

4. If the pressure on the tester drops, check the hose,

pipe and leakage and, replace or retighten.

Page 740 of 2053

OM600 ENGINE COOLING 1D3 -- 5

D AEW OO M Y_2000

MAINTENANCE AND REPAIR

ON -- VEHICLE SERVICE

DRAIN AND FILLING OF COOLANT

Preceding Work : Removal of skid plate

Drain / Filling

1. Loosen the pressure cap of reservoir by 1 notch and

remove pressure and then loosen the cap.

Notice

Do not remove radiator cap when coolant is above

90°C.

2. Open the drain plug and drain the coolant.

Notice

Collect the coolant by using the proper bottle.

3. Remove the drain plug(1) and seal(2) of cylinder

block and drain the coolant.

4. Replace the seal to new one and tighten the drain

plug.

Installation Notice

Tightening Torque30 N∙m (22 lb-ft)

5. Tighten the drain plug of the lower radiator.

6. Fill the coolant through coolant reservoir -- tank.

Notice

DA proportion of 50% by volume of water / anticor-

rosion must be ensured.

7. After engine is running at idle speed, check the level

of coolant. If necessary, add enough specified cool-

ant.

Page 748 of 2053

OM600 ENGINE COOLING 1D3 -- 13

D AEW OO M Y_2000

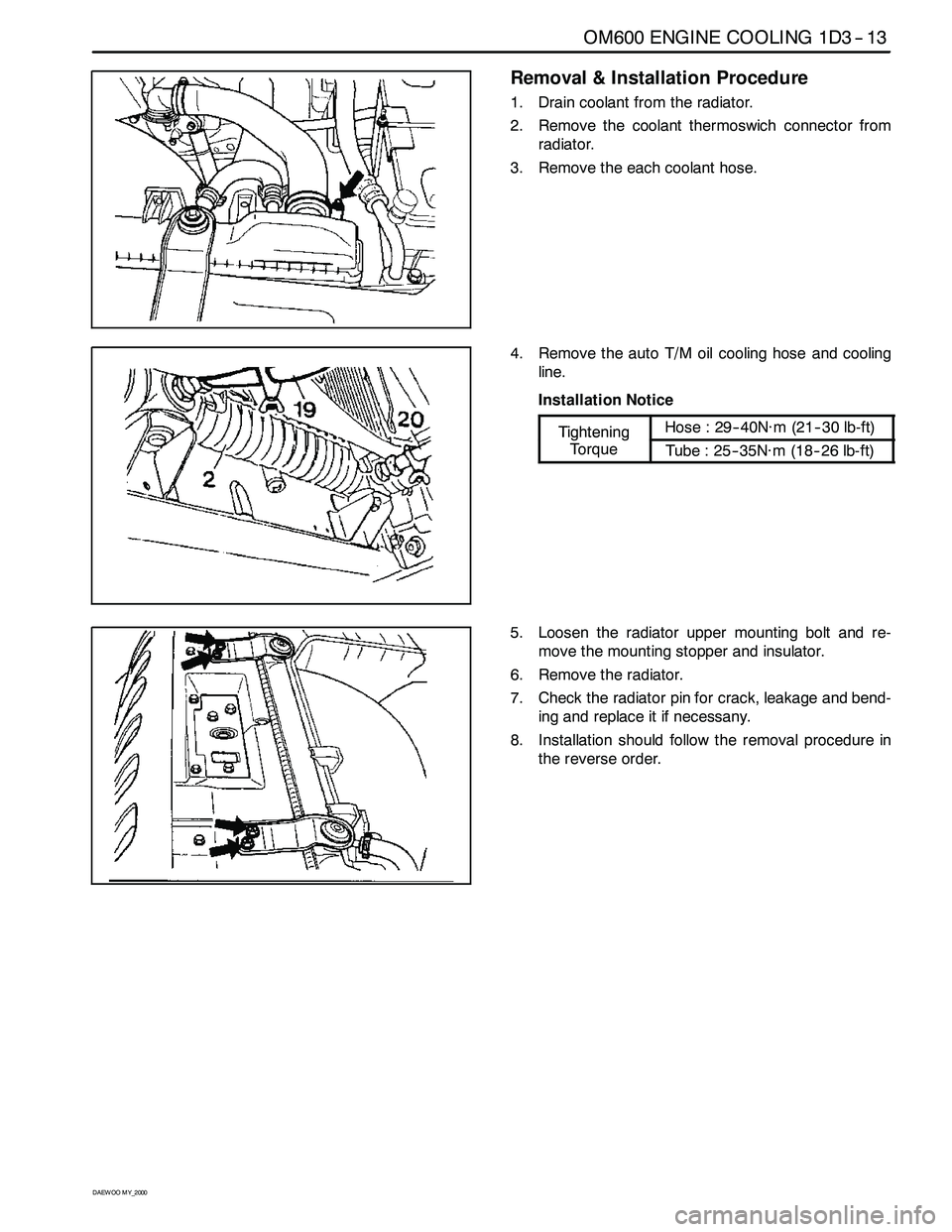

Removal & Installation Procedure

1. Drain coolant from the radiator.

2. Remove the coolant thermoswich connector from

radiator.

3. Remove the each coolant hose.

4. Remove the auto T/M oil cooling hose and cooling

line.

Installation Notice

TighteningHose : 29-- 40N∙m (21-- 30 lb-ft)Tightening

TorqueTube : 25-- 35N∙m (18--26 lb-ft)

5. Loosen the radiator upper mounting bolt and re-

move the mounting stopper and insulator.

6. Remove the radiator.

7. Check the radiator pin for crack, leakage and bend-

ing and replace it if necessany.

8. Installation should follow the removal procedure in

the reverse order.