head SSANGYONG KORANDO 1997 Service User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 58 of 2053

1B1 -- 26 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

CYLINDER HEAD FRONT COVER

Preceding Work: Removal of cylinder head cover

Removal of coolant connection fitting

1 Camshaft Position Sensor

2 Magnet Assembly

3 Upper Guide Rail

4 Bolt (M6 x 60, 3 pieces)

22.5-- 27.5 NSm (16.6-- 20.3 lb-ft) .............5 Bolt (M8 x 80, 3 pieces)

22.5-- 27.5 NSm (16.6--20.3 lb-ft) .............

6 Front Cover

7 Rubber Gasket Replace....................

8 Bolt (M6 x 16, 3 pieces)

9--11 NSm (80-- 97 lb-in) .....................

Page 59 of 2053

M162 ENGINE MECHANICAL 1B1 -- 27

D AEW OO M Y_2000

Removal & Installation Procedure

1. Remove the magnet assembly.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

2. Remove the cylinder head front cover (6).

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

Apply the sealant at the mating surface of the cylinder

head and the front cover.

3. Remove the upper guide rail pin and the guide rail (3).

Installation Notice

Install it while the chain tensioner is loose.

4. Remove the gasket (arrow).

Installation Notice

Replace the gasket with new one and apply the sea-

lant.

5. Installation should follow the removal procedure in

the reverse order.

Page 60 of 2053

1B1 -- 28 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

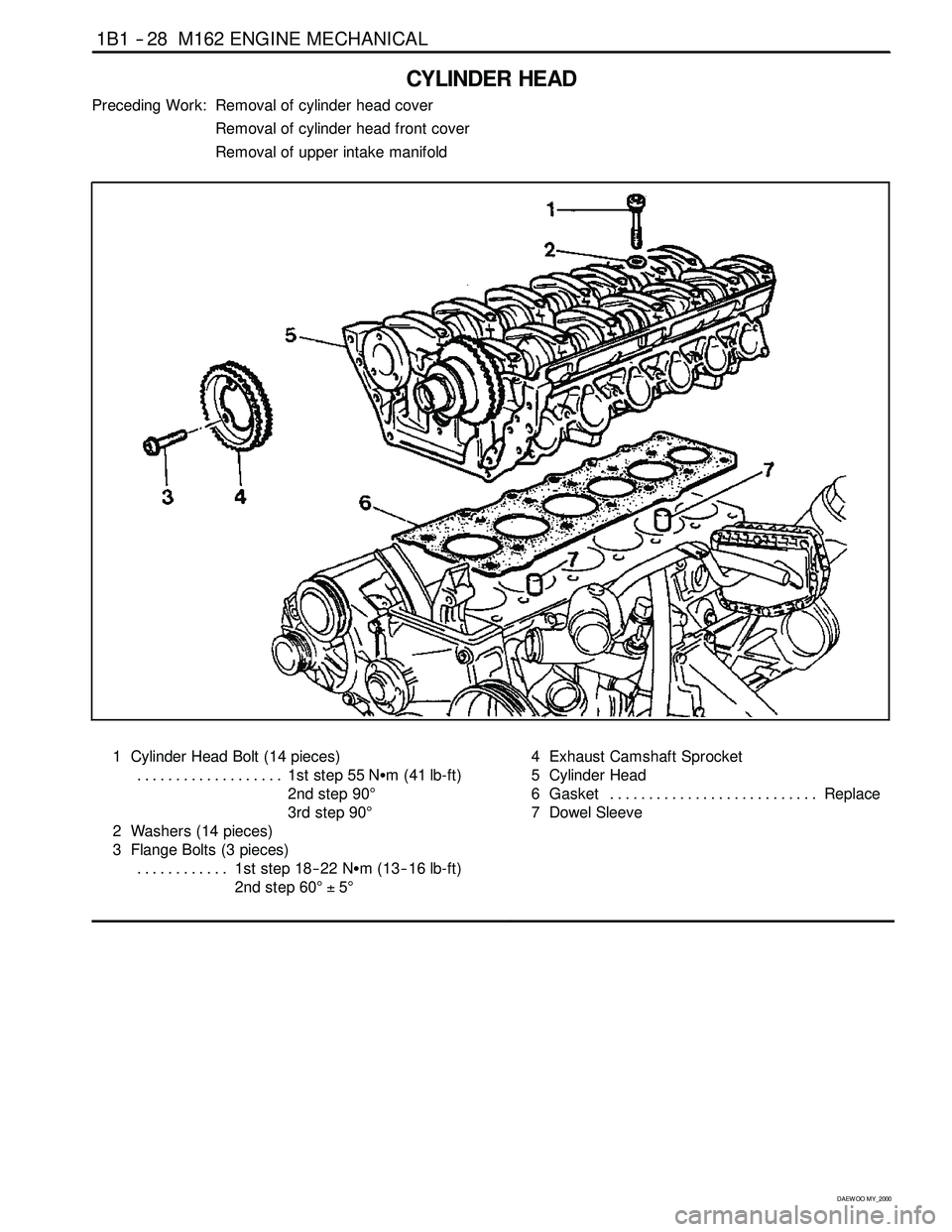

CYLINDER HEAD

Preceding Work: Removal of cylinder head cover

Removal of cylinder head front cover

Removal of upper intake manifold

1 Cylinder Head Bolt (14 pieces)

1st step 55 NSm (41 lb-ft) ...................

2nd step 90°

3rdstep90°

2 Washers (14 pieces)

3 Flange Bolts (3 pieces)

1ststep18--22NSm (13-- 16 lb-ft) ............

2nd step 60°±5°4 Exhaust Camshaft Sprocket

5 Cylinder Head

6 Gasket Replace...........................

7 Dowel Sleeve

Page 62 of 2053

1B1 -- 30 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

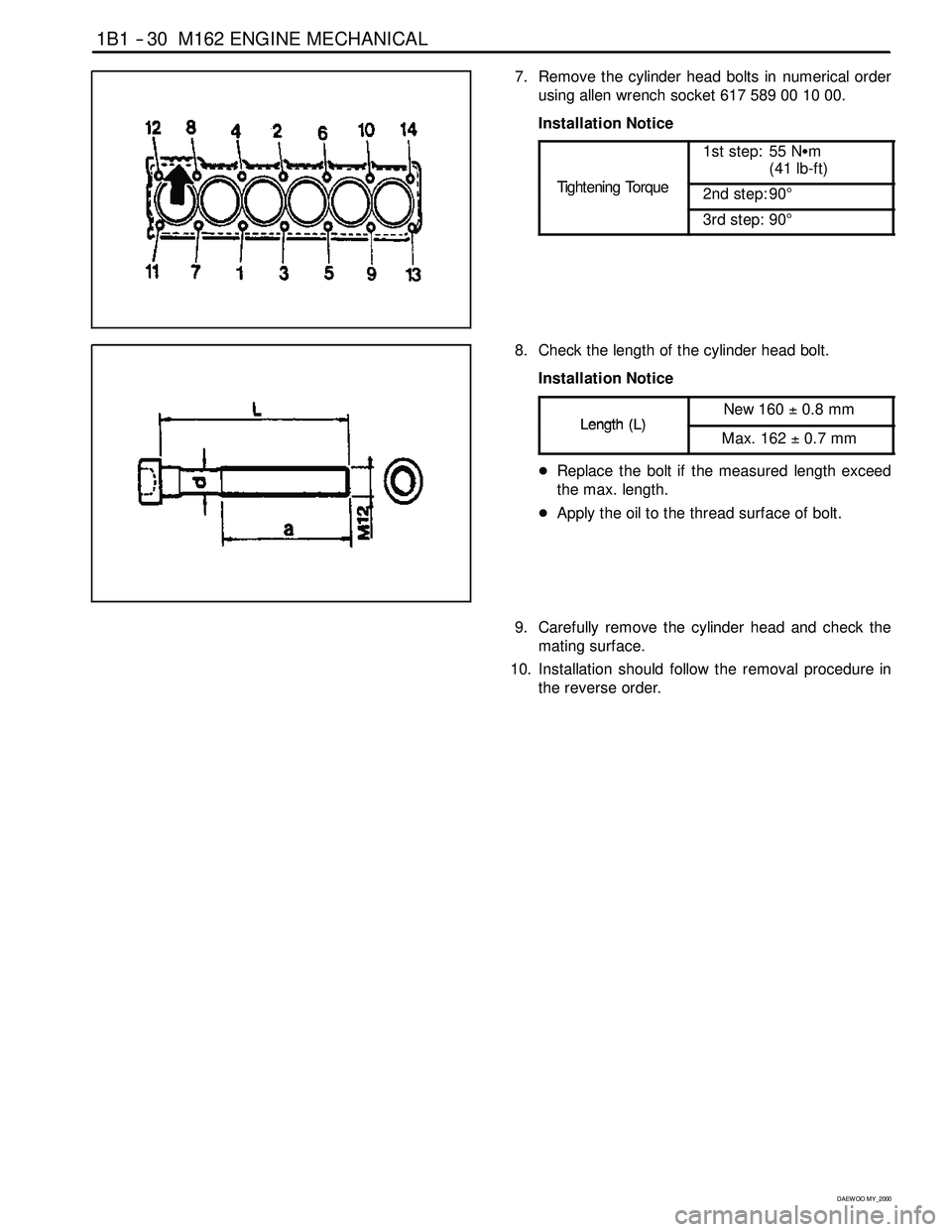

7. Remove the cylinder head bolts in numerical order

usingallenwrenchsocket617589001000.

Installation Notice

TihtiT

1st step: 55 NSm

(41 lb-ft)

Tightening Torque2nd step: 90°

3rd step: 90°

8. Check the length of the cylinder head bolt.

Installation Notice

Length(L)New 160±0.8 mmLength(L)Max. 162±0.7 mm

DReplace the bolt if the measured length exceed

the max. length.

DApply the oil to the thread surface of bolt.

9. Carefully remove the cylinder head and check the

mating surface.

10. Installation should follow the removal procedure in

the reverse order.

Page 63 of 2053

M162 ENGINE MECHANICAL 1B1 -- 31

D AEW OO M Y_2000

TIMING GEAR CASE COVER

Preceding Work: Removal of cylinder head front cover

Removal of generator bracket

Removal of tensioning device

Removal of belt pulley and vibration damper

1 Bolt (M8 x 60, 3 pieces)

22.5-- 27.5 NSm (16.6-- 20.3 lb-ft) .............

2 A/C Bracket

3 Bolt (M8 x 65, 3 pieces)

22.5-- 27.5 NSm (16.6-- 20.3 lb-ft) .............

4 Bolt (M8 x 40, 1 piece)

22.5-- 27.5 NSm (16.6-- 20.3 lb-ft) .............5 Bolt (M8 x 60, 1 piece)

22.5-- 27.5 NSm (16.6--20.3 lb-ft) .............

6Seal

7 Timing Gear Case Cover

8RollPin

9 Bolt (M6 x 22, 6 pieces)

9--11 NSm (80-- 97 lb-in) .....................

Page 73 of 2053

M162 ENGINE MECHANICAL 1B1 -- 41

D AEW OO M Y_2000

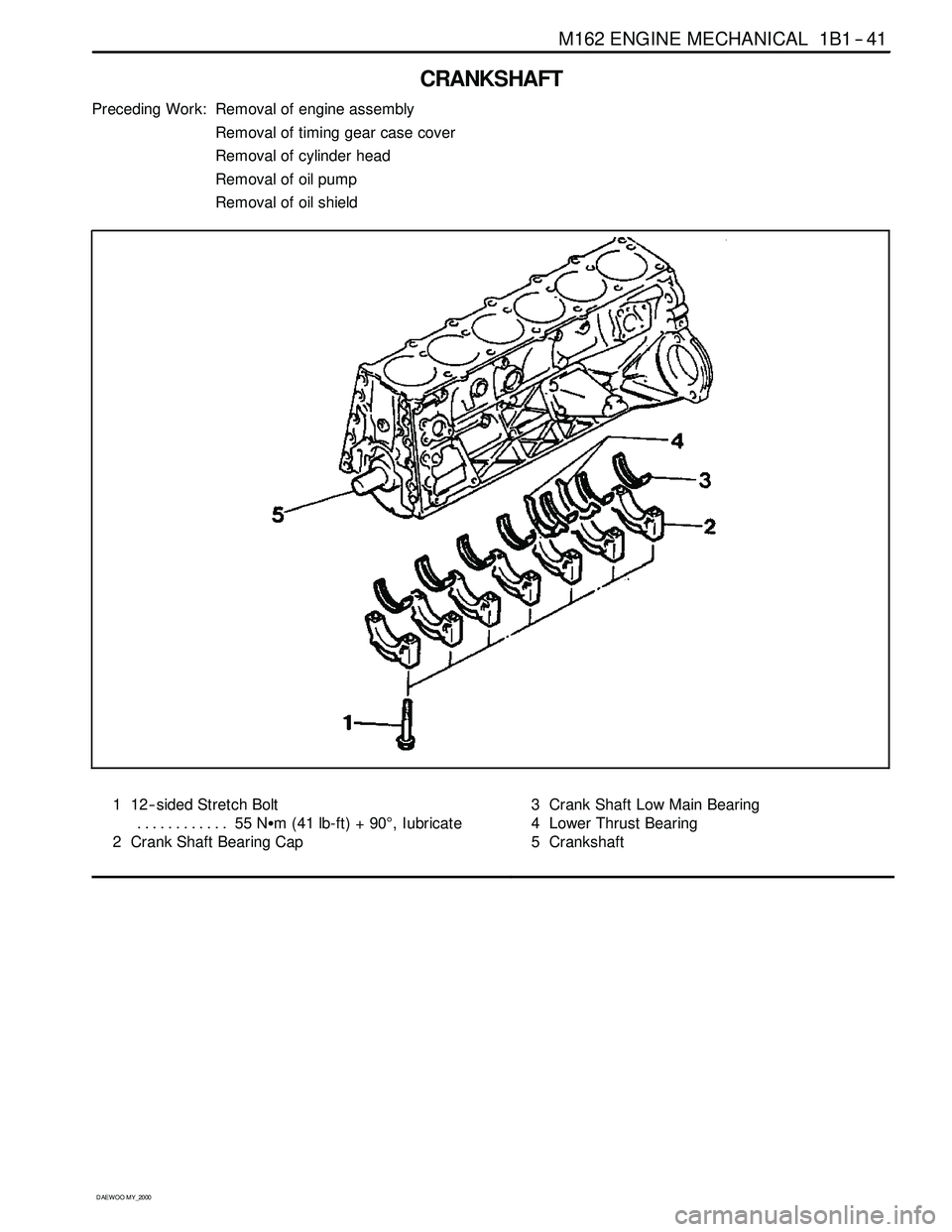

CRANKSHAFT

Preceding Work: Removal of engine assembly

Removal of timing gear case cover

Removal of cylinder head

Removal of oil pump

Removal of oil shield

1 12-- sided Stretch Bolt

55 NSm (41 lb-ft) + 90°, Iubricate ............

2 Crank Shaft Bearing Cap3 Crank Shaft Low Main Bearing

4 Lower Thrust Bearing

5 Crankshaft

Page 82 of 2053

1B1 -- 50 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

CAMSHAFT ADJUSTER

Preceding Work: Removal of cylinder head cover

Removal of cylinder head front cover

1 Bolt (M6 x 16, 3 pieces)

9--11 NSm (80-- 97 lb-in) .....................

2 Magnet Assembly (2 Pin Connector)

3Bolt 35NSm (26 lb-ft) ......................

4 Armature

5RollPin

6 Nut (M20 x 1.5) 60-- 70 NSm (44-- 52 lb-ft) ......

7 Front Cover

8 Seal

9 Camshaft Position Sensor

10 Bolt (M6 x 16, 2 pieces)

9--11 NSm (80-- 97 lb-in) .....................

11 Seal12 Seal Cover

13 Camshaft Sprocket and Position Indicator (b)

14 Adjuster Piston

15 Flange bolt (M7 x 13, 3 pieces)

1ststep18--22NSm (13-- 16 lb-ft) ...........

2ndstep60°±5°

16 Flange Shaft

17 Compression Spring

18 Control Piston

19 Circlip

20 Oil Gallery

21 Pin

22 Intake Camshaft

Page 83 of 2053

M162 ENGINE MECHANICAL 1B1 -- 51

D AEW OO M Y_2000

Removal & Installation Procedure

1. Turn the crankshaft to the direction of engine rotation

and position the no.1 cylinder piston at TDC which the

camshaft is positioned at OT.

2. Remove the cylinder head front cover.

3. Paint the alignment marks (arrows) on the intake and

exhaust camshaft sprocket and the timing chain.

3 Bolt 13 Camshaft Sprocket

4 Amarture 18 Control Piston

6 Nut (M20 x 1.5) 22 Intake Camshaft

12 Seal Cover

4. Unscrew the bolt (3) from the armature (4) and re-

move the armature.

Installation Notice

Tightening Torque

35 NSm (26 lb-ft)

5. Unscrew the nut (6) and remove the ring and seal

cover (11).

Installation Notice

Tightening Torque

60 -- 70 NSm (44 -- 52 lb-ft)

6. Unscrew the sprocket bolt from the exhaust camshaft

and remove the sprocket.

Installation Notice

Ti

ghteningTo rque

1st step: 18 -- 22 NSm

(13 -- 16 lb-ft)

TighteningTorque

2nd step: 60°±5°

The sprocket bolt is designed to be used only once,

so always replace with new one.

Page 86 of 2053

M162 ENGINE MECHANICAL 1B1 -- 59

D AEW OO M Y_2000

CAMSHAFT TIMING POSITION

Preceding Work: Removal of cylinder head cover

Removal of cylinder head front cover

1 Chain Tensioner Assembly

2 Exhaust Camshaft Sprocket

3 Upper Guide Rail4 Cylinder Head Front Cover

5 Wrench

6 Holding Pin DW110-- 120

Page 87 of 2053

1B1 -- 60 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

Tools Required

DW110 -- 120 Holding Pin

Inspection

1. Position the No.1 cylinder piston to TDC (OT) by turn-

ing the crankshaft.

Notice:When the OT mark on vibration damper is

aligned with timing gear case cover, the intake and ex-

haust cam of cylinderwill make the slope to the center

and will face up. In this way, the adjustment hole of the

intake and exhaust camshaftwill match in line with the

cylinder head upper end, at 3 o’clock, and 9 o’clock di-

rection each other.

2. Check the timing as below procedure;

-- Check if the camshaft adjustment hole is posi-

tioned to 3 o’clock direction at the intake side and

to 9 o’clock direction at the exhaust side, respec-

tively and align with the cylinder head mating sur-

face.

-- At this condition, check if the OT mark on vibration

damper aligns with the marker on the timing gear

case.

Adjustment Procedure

1. Position the No.1 cylinder to BTDC 30°.

2. Remove the chain tensioner.

3. Remove the exhaust camshaft sprocket.

4. Align the intake and exhaust camshaft flange hole

with the cylinder head upper surface.

DIntake Side : 3 o’clock direction

DExhaust Side : 9 o’clock direction

5. Align the holes on intake and exhaust camshaft to the

hole on cylinder head. Insert the holding pin

DW110-- 120 into the holes.

6. Secure the intake and exhaust camshaft.

7. Position the piston of No.1 cylinder at TDC (OT) by

turning the crankshaft.

8. Turn the camshaft adjuster of the intake camshaft to

the left as much as possible (cam adjuster ‘retarded’

position).

9. Install the chain to the intake camshaft sprocket.

Notice:Timing chain must be placed on the guide rail in

gear case cover.