head SSANGYONG KORANDO 1997 Service Owner's Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 183 of 2053

1F1 -- 20 M162 ENGINE CONTROLS

D AEW OO M Y_2000

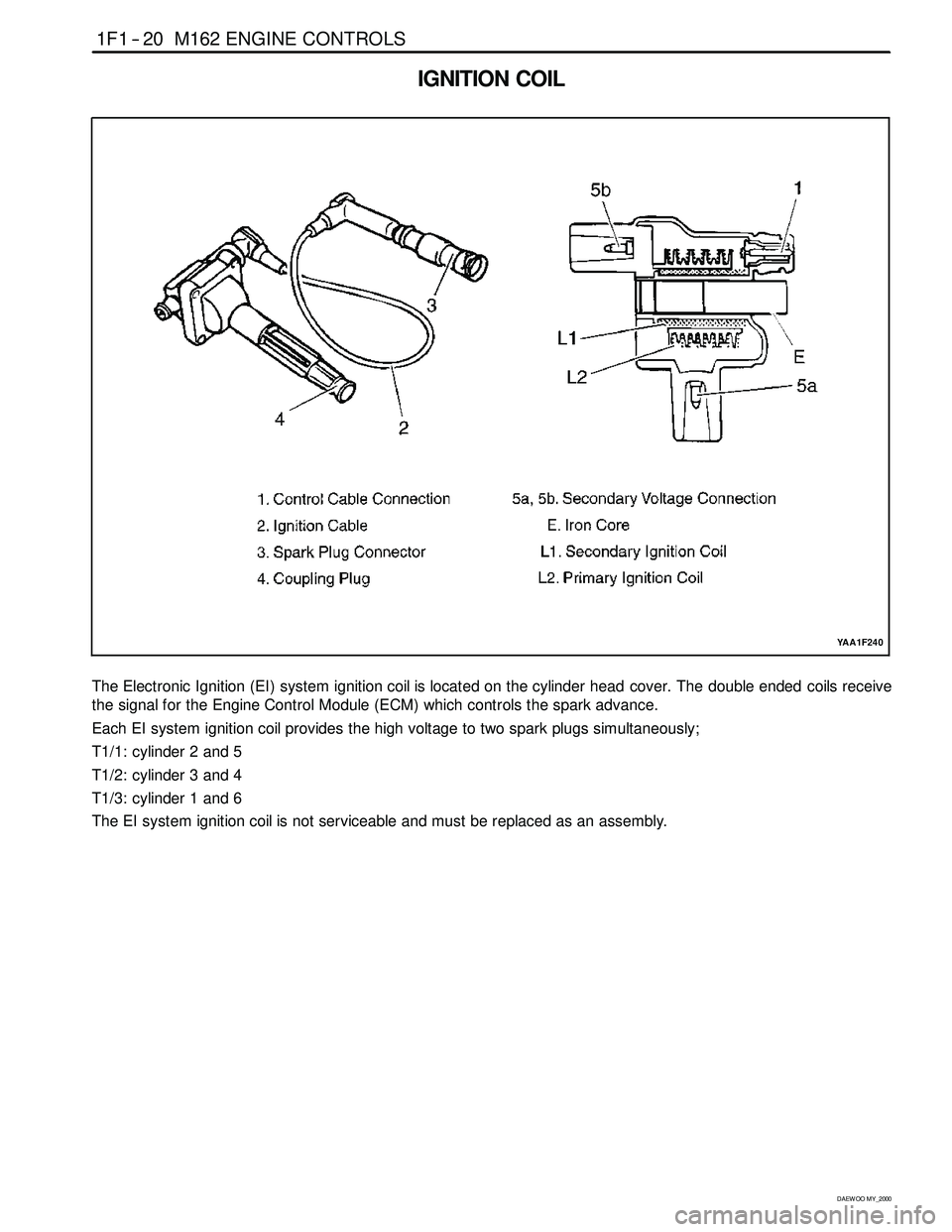

IGNITION COIL

YAA1F240

The Electronic Ignition (EI) system ignition coil is located on the cylinder head cover. The double ended coils receive

the signal for the Engine Control Module (ECM) which controls the spark advance.

Each EI system ignition coil provides the high voltage to two spark plugs simultaneously;

T1/1: cylinder 2 and 5

T1/2: cylinder 3 and 4

T1/3: cylinder 1 and 6

The EI system ignition coil is not serviceable and must be replaced as an assembly.

Page 263 of 2053

1F1 -- 100 M162 ENGINE CONTROLS

D AEW OO M Y_2000

KAA1F090

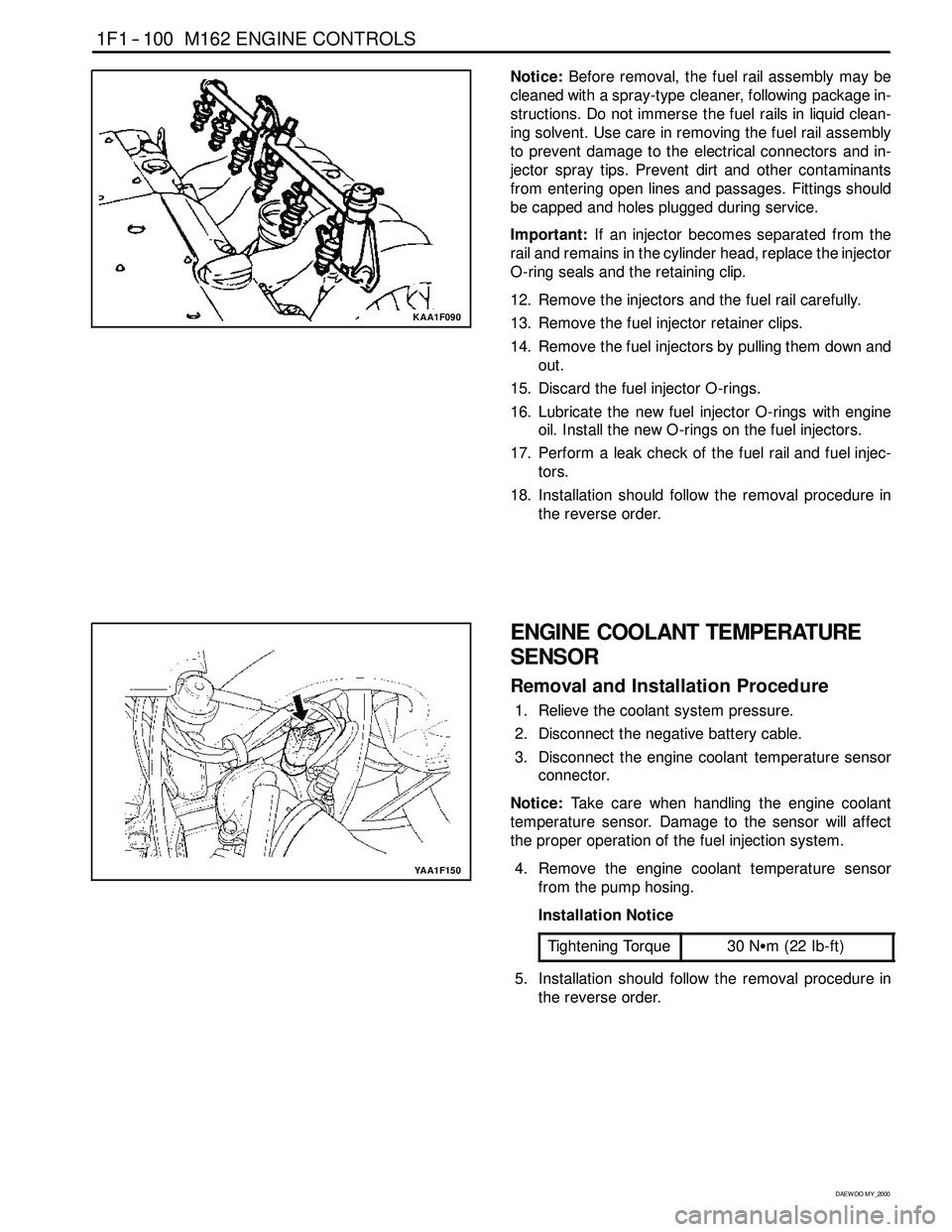

Notice:Before removal, the fuel rail assembly may be

cleaned with a spray-type cleaner, following package in-

structions. Do not immerse the fuel rails in liquid clean-

ing solvent. Use care in removing the fuel rail assembly

to prevent damage to the electrical connectors and in-

jector spray tips. Prevent dirt and other contaminants

from entering open lines and passages. Fittings should

be capped and holes plugged during service.

Important:If an injector becomes separated from the

rail and remains in the cylinder head, replace the injector

O-ring seals and the retaining clip.

12. Remove the injectors and the fuel rail carefully.

13. Remove the fuel injector retainer clips.

14. Remove the fuel injectors by pulling them down and

out.

15. Discard the fuel injector O-rings.

16. Lubricate the new fuel injector O-rings with engine

oil. Install the new O-rings on the fuel injectors.

17. Perform a leak check of the fuel rail and fuel injec-

tors.

18. Installation should follow the removal procedure in

the reverse order.

YAA1F150

ENGINE COOLANT TEMPERATURE

SENSOR

Removal and Installation Procedure

1. Relieve the coolant system pressure.

2. Disconnect the negative battery cable.

3. Disconnect the engine coolant temperature sensor

connector.

Notice:Take care when handling the engine coolant

temperature sensor. Damage to the sensor will affect

the proper operation of the fuel injection system.

4. Remove the engine coolant temperature sensor

from the pump hosing.

Installation Notice

Tightening Torque

30 NSm (22 Ib-ft)

5. Installation should follow the removal procedure in

the reverse order.

Page 283 of 2053

GENERAL ENGINE INFORMATION 1A2 -- 11

D AEW OO M Y_2000

CYLINDER PRESSURE LEAKAGE TEST

3 Engine Oil Filler Cap

5 Vibration Damper6 Cylinder Pressure Leakage Tester with

Connecting Hose

Permissible Pressure Leakage

At Whole EngineMax. 25 %

At Valve and Cylinder Head GasketMax. 10 %

At Piston and Piston RingMax. 20 %

Cylinder Number By Mark On Vibration Damper At TDC

TDC MarkOT (TDC)UT (BDC : 180°)

Cylinder Number1, 42, 3

Universal Tool

Cylinder Pressure Leakage TesterBosch, EFAW 210A

Sun, CLT 228

Page 287 of 2053

GENERAL ENGINE INFORMATION 1A2 -- 3

D AEW OO M Y_2000

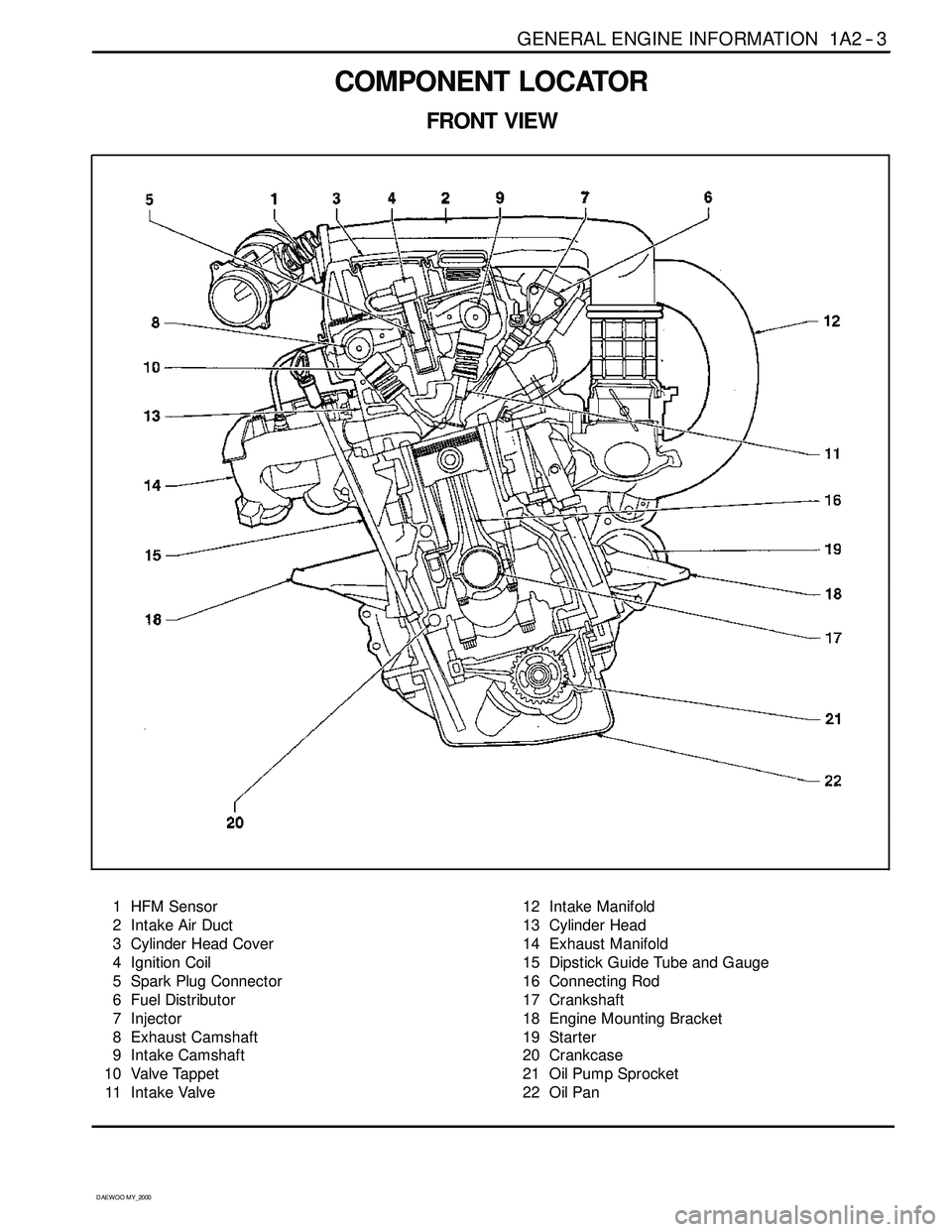

COMPONENT LOCATOR

FRONT VIEW

1 HFM Sensor

2 Intake Air Duct

3 Cylinder Head Cover

4 Ignition Coil

5 Spark Plug Connector

6 Fuel Distributor

7 Injector

8 Exhaust Camshaft

9 Intake Camshaft

10 Valve Tappet

11 Intake Valve12 Intake Manifold

13 Cylinder Head

14 Exhaust Manifold

15 Dipstick Guide Tube and Gauge

16 Connecting Rod

17 Crankshaft

18 Engine Mounting Bracket

19 Starter

20 Crankcase

21 Oil Pump Sprocket

22 Oil Pan

Page 294 of 2053

D AEW OO M Y_2000

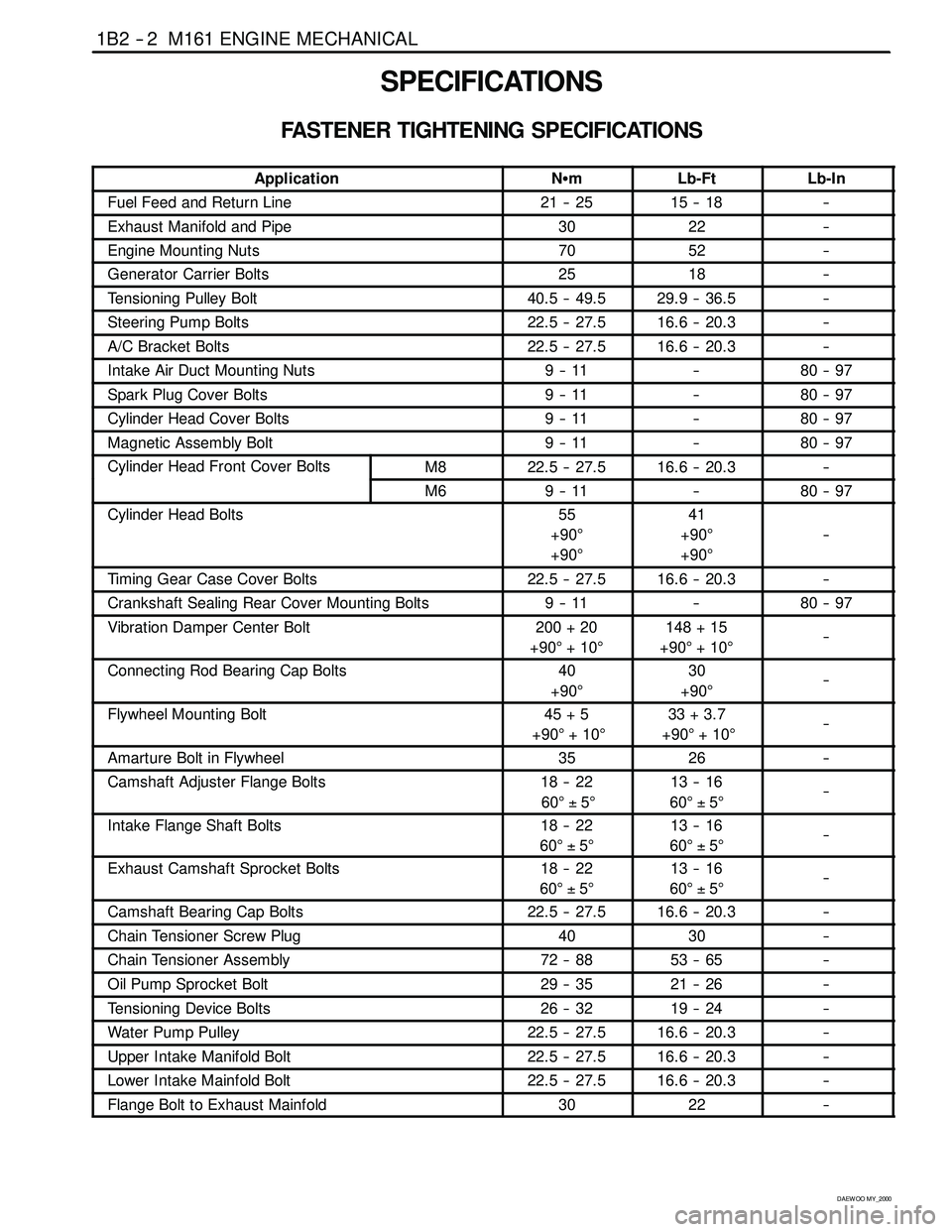

SECTION 1B2

M161 ENGINE MECHANICAL

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless other -

wise noted.

TABLE OF CONTENTS

Specifications 1B2 -- 2............................

Fastener Tightening Specifications 1B2 -- 2..........

Special Tools 1B2 -- 4.............................

Special Tools Table 1B2-- 4.......................

Maintenance and Repair 1B2 -- 7...................

On-- Vehicle Service 1B2-- 7.........................

Engine Assembly 1B2-- 7.........................

Crankcase Ventilation System 1B2-- 14.............

Generator 1B2-- 18..............................

Engine Mount 1B2-- 19...........................

Poly V-- Belt 1B2 -- 20.............................

Tensioning Device 1B2-- 22.......................

Tensioning Device Shock Absorber 1B2-- 23........

Poly V-- Belt Inspection 1B2-- 24...................

Cylinder Head Cover 1B2-- 26.....................

Cylinder Head Front Cover 1B2 -- 28...............

Cylinder Head 1B2-- 30...........................

Timing Gear Case Cover 1B2-- 34.................

Crankshaft Sealing Rear Cover 1B2-- 37...........

Belt Pulley and Vibration Damper 1B2-- 39..........

Crankshaft Front Radial Seal 1B2-- 42.............

Crankshaft Rear Radial Seal 1B2-- 44..............

Crankshaft 1B2-- 45.............................

Flywheel / Driven Plate 1B2 -- 51...................

Camshaft Adjuster 1B2-- 54.......................Camshaft Sprocket Bolt 1B2-- 57..................

Camshaft 1B2-- 58..............................

Camshaft Timing Position 1B2 -- 61................

Valve Spring 1B2 -- 63............................

Valve Stem Seal 1B2-- 67........................

Chain Tensioner 1B2-- 68.........................

Timing Chain 1B2-- 72............................

Tensioning Rail 1B2-- 77..........................

Cylinder Head Guide Rail 1B2-- 78.................

Crankcase Guide Rail 1B2-- 80....................

Crankshaft Sprocket 1B2-- 81.....................

Piston 1B2-- 83..................................

Connecting Rod 1B2-- 86.........................

Piston Ring 1B2 -- 88.............................

Oil Pan 1B2-- 90.................................

Engine Oil and Oil Filter Element 1B2-- 92..........

Oil Pump 1B2-- 95...............................

Oil Pressure Relief Valve 1B2-- 97.................

Oil Non-Return Valve 1B2-- 98....................

Oil Dipstick Guide Tube 1B2-- 99..................

Unit Repair 1B2 -- 100............................

Core Plugs in Crankcase 1B2-- 100................

Cylinder Bore 1B2-- 102..........................

Crankcase Mating Surface 1B2-- 104..............

Cylinder Head Mating Surface 1B2-- 106...........

Page 295 of 2053

1B2 -- 2 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb-FtLb-In

Fuel Feed and Return Line21 -- 2515 -- 18--

Exhaust Manifold and Pipe3022--

Engine Mounting Nuts7052--

Generator Carrier Bolts2518--

Tensioning Pulley Bolt40.5 -- 49.529.9 -- 36.5--

Steering Pump Bolts22.5 -- 27.516.6 -- 20.3--

A/C Bracket Bolts22.5 -- 27.516.6 -- 20.3--

Intake Air Duct Mounting Nuts9--11--80 -- 97

Spark Plug Cover Bolts9--11--80 -- 97

Cylinder Head Cover Bolts9--11--80 -- 97

Magnetic Assembly Bolt9--11--80 -- 97

Cylinder Head Front Cover BoltsM822.5 -- 27.516.6 -- 20.3--y

M69--11--80 -- 97

Cylinder Head Bolts55

+90°

+90°41

+90°

+90°

--

Timing Gear Case Cover Bolts22.5 -- 27.516.6 -- 20.3--

Crankshaft Sealing Rear Cover Mounting Bolts9--11--80 -- 97

Vibration Damper Center Bolt200 + 20

+90°+10°148 + 15

+90°+10°--

Connecting Rod Bearing Cap Bolts40

+90°30

+90°--

Flywheel Mounting Bolt45 + 5

+90°+10°33 + 3.7

+90°+10°--

Amarture Bolt in Flywheel3526--

Camshaft Adjuster Flange Bolts18 -- 22

60°±5°13 -- 16

60°±5°--

Intake Flange Shaft Bolts18 -- 22

60°±5°13 -- 16

60°±5°--

Exhaust Camshaft Sprocket Bolts18 -- 22

60°±5°13 -- 16

60°±5°--

Camshaft Bearing Cap Bolts22.5 -- 27.516.6 -- 20.3--

Chain Tensioner Screw Plug4030--

Chain Tensioner Assembly72 -- 8853 -- 65--

Oil Pump Sprocket Bolt29 -- 3521 -- 26--

Tensioning Device Bolts26 -- 3219 -- 24--

Water Pump Pulley22.5 -- 27.516.6 -- 20.3--

Upper Intake Manifold Bolt22.5 -- 27.516.6 -- 20.3--

Lower Intake Mainfold Bolt22.5 -- 27.516.6 -- 20.3--

Flange Bolt to Exhaust Mainfold3022--

Page 307 of 2053

1B2 -- 14 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

CRANKCASE VENTILATIONSYSTEM

Operation at Idling and Mid- Load

1 HFM Sensor

2 Cylinder Head Cover

3 Oil Spearation Chamber (Full-- Load or Over

Mid-- Load)

4 Intake Air Duct (Cross Pipe)

5 Vent Line (Full-- Load or Over Mid-- Load)

6 Throttle Valve

7 Restrictor, Diameter 1.1mm

(Mid-- Load at Idling)

8 Intake Manifold

9 Vent Line (Mid-- Load at Idling)

10 Air Conditioner Bracket11 Oil Separation Chamber (Mid-- Load at Idling)

12 Crank Chamber

13 Oil Return Pipe

14 Oil Pan

15 Timing Gear Case Cover

16 Crankcase

17 Chain Housing

A Fresh Air

BBlow--byGas

D Vent Connection

Page 308 of 2053

M161 ENGINE MECHANICAL 1B2 -- 15

D AEW OO M Y_2000

Operation at Idling and Mid- Load

DThe throttle valve (6) is closed or very partially

opened, and the vacuum pressure in intake manifold

is high.

The blow-- by gas and the fresh air that is additionally

supplied through the vent connection (D) in the crank-

case in partial load gets supplied to the combustion

chamber from the crank chamber (12) through the oil

separation chamber (11), air -- conditioner bracket

(10), vent line (9), and restrictor (7) mounted to the

cylinder head.

The circulated engine oil returns to the oil pan through

the oil return pipe (13) at the bottom of oil separation

chamber (11).

The fresh air gets supplied to the crank chamber (12)

through the HFM sensor (1), intake air duct (4), vent

line (5), oil separation chamber (3), chain housing

(17), and the timing gear case cover (15).

The additional supply of the fresh air is needed to pre-

vent from forming the residues of the engine oil.

Page 309 of 2053

1B2 -- 16 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

Operation When Full- Load at Partial Load

1 HFM Sensor

2 Cylinder Head Cover

3 Oil Spearation Chamber (Full-- Load or Over

Mid-- Load)

4 Intake Air Duct (Cross Pipe)

5 Vent Line (Full-- Load or Over Mid-- Load)

6 Throttle Valve

7 Restrictor, Diameter 1.1mm

(Mid-- Load at Idling)

8 Intake Manifold

9 Vent Line (Mid-- Load at Idling)

10 Air Conditioner Bracket11 Oil Separation Chamber (Mid-- Load at Idling)

12 Crank Chamber

13 Oil Return Pipe

14 Oil Pan

15 Timing Gear Case Cover

16 Crankcase

17 Chain Housing

A Fresh Air

CBlow--byGas

D Vent Connection

Page 319 of 2053

1B2 -- 26 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

CYLINDER HEAD COVER

1 Spark Plug Cover

2 Spark Plug Connector

3 Bolt(M6X45:4pieces,M6X60:6pieces)

9--11 NSm (80-- 97 lb-in) .....................4 Cylinder Head Cover

5 Gasket Replace...........................