SSANGYONG KORANDO 1997 Service Workshop Manual

KORANDO 1997

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57502/w960_57502-0.png

SSANGYONG KORANDO 1997 Service Workshop Manual

Page 351 of 2053

1B2 -- 58 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

CAMSHAFT

Preceding Work: Removal of cylinder head cover

Removal of camshaft adjust actuator and cylinder head front cover

1 Bolt (M7 X 13, 3 pieces)

1stStep18--22NSm (13-- 16 lb-ft) ..........

2nd Step 60°±5°Rotation Added

2 Exhaust Camshaft Sprocket

3 Timing Chain

4a Intake Camshaft Spocket (E20)4b Camshaft Adjuster and Camshaft

Sprocket (E23)

5 Bearing Cap Bolt (20 pieces)

22.5-- 27.5 NSm (16.6--20.3 lb-ft) .............

6 Camshaft Bearing Cap

7 Wrench

Page 353 of 2053

1B2 -- 60 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

7. Remove the bearing cap, and remove the intake

and the exhaust camshaft.

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

Notice:Check the numbers on the bearing cap not to be

mixed up.

8. Apply the engine oil on the valve tappet and cam-

shaft bearing.

9. Installation should follow the removal procedure in

the reverse order.

Notice:

DBase circle of cam should cantact with the valve tap-

pet.

DInstall the camshaft bearing caps according to the

numbers on the cylinder head cast and bearing cap.

10. Check the camshaft timing position.

Page 354 of 2053

M161 ENGINE MECHANICAL 1B2 -- 61

D AEW OO M Y_2000

CAMSHAFT TIMING POSITION

Preceding Work: Removal of cylinder head cover

Removal of cylinder head front cover

1 Holding Pin 111 589 03 15 00

2 Intake Camshaft Sprocket

3 Camshaft Bearing Cap

4 Timing Chain

5 Exhaust Camshaft Sprocket6 Bolt (M7 X 13, 3 pieces)

1ststep18--22NSm (13-- 16 lb-ft) ...........

2ndstep60°±5°rotation added

7StratePin

Page 364 of 2053

M161 ENGINE MECHANICAL 1B2 -- 71

D AEW OO M Y_2000

Sectional View

1 Screw Plug

2 Ball (Nonreturn Valve)

3 Compression Spring

4 Ball Guide

5 Seal (Aluminum)

6 Filler Pin

7 Compression Spring

8 Snap Ring

9 Thrust Pin

10 Ball (Nonreturn Valve)

11 Compression Spring

12 Thrust Piece13 Chain Tensioner Housing

14 Seal

15 Timing Gear Case Cover

16 Cylinder Head

17 Bolt / Washer

18 Tensioning Rail

19 Cylinder Head Gasket

20 Timing Chain

21 Tensioning Rail Base (Sliding Surface)

A Oil Supply Hole

B Chain Tensioner Oil Storage Hole

Page 365 of 2053

1B2 -- 72 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

TIMING CHAIN

Preceding Work: Removal of cylinder head cover

Removal of spark plug

1Pin

2 New Timing Chain

3 Timing Chain (Used)

4 Wedge5Link

6 Center Plate

7 Outer Plate

Page 370 of 2053

M161 ENGINE MECHANICAL 1B2 -- 77

D AEW OO M Y_2000

TENSIONING RAIL

Preceding Work: Removal of cylinder head

1 Sliding Rail Pin

2 Sliding Rail3 Timing Gear Case Cover

Removal & Installation Procedure

1. Remove the timing gear case cover (3).

Notice:Be careful not to damage the gasket.

2. Remove the sliding rail (1) from the sliding rail pin (2).

Notice

DReplace the plastic guide (2) if it is damaged.

DFor installation, exactly align the plastic guide (2) with

the sliding rail (1).

3. Installation should follow the removal procedure in

the reverse order.

Page 371 of 2053

1B2 -- 78 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

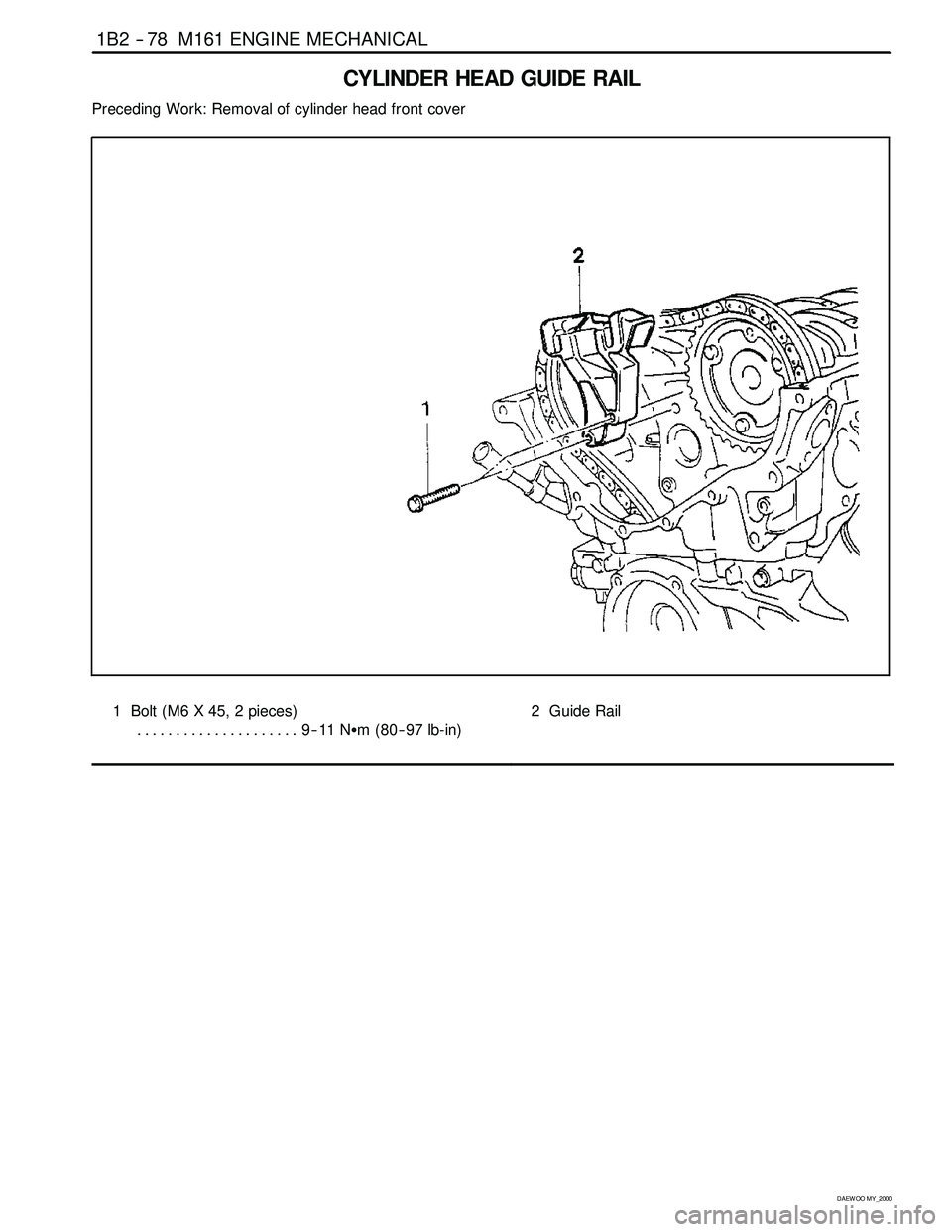

CYLINDER HEAD GUIDE RAIL

Preceding Work: Removal of cylinder head front cover

1 Bolt (M6 X 45, 2 pieces)

9--11 NSm (80-- 97 lb-in) .....................2 Guide Rail

Page 376 of 2053

M161 ENGINE MECHANICAL 1B2 -- 83

D AEW OO M Y_2000

PISTON

Preceding Work: Removal of engine

Removal of cylinder head

Removal of oil pan

Removal of oil pump

Removal of baffle plate

1 Connecting Rod Bearing Cap

2 Connecting Rod

3 Connecting Rod Bolt (M9 x 52, 8 pieces)

1ststep40NSm (30 lb-ft) ..................

2nd step 90°4Piston

5 Snap Ring

6 Piston Pin

Page 378 of 2053

M161 ENGINE MECHANICAL 1B2 -- 85

D AEW OO M Y_2000

1. Check the piston ring gap and apply the engine oil to

the piston pin and the connecting rod bushing.

2. Connect the piston and the connecting rod by press-

ing in the piston pin (6) and install the snap ring to the

groove.

3. Clean the cylinder bore, connecting rod bearing jour-

nal, connecting rod bearing shell and the piston and

coat them with engine oil.

4. Install the piston ring.

5. Install the piston so that the arrow on the piston head

faces to the forward of the vehicle.

6. After aligning the connecting rod and the bearing cap

mark (// or a number), tighten the bolts.

Installation Notice

TighteningTorque1st step: 40 NSm (30 lb-ft)TighteningTorque2nd step: 90°

Apply the engine oil to the bearing cap upper and low-

er bearing shells.

7. Check if the crankshaft rotates without any trouble by

rotating it.

Page 384 of 2053

M161 ENGINE MECHANICAL 1B2 -- 91

D AEW OO M Y_2000

Oil Circulation

1 Oil Strainer

2OilPump

3OilPan

4 Oil Non-- Return Valve

5 Oil Filter

6 Oil Filter Bypass Valve

7 Main Oil Gallery

8 Closing Ball (φ15mm)

9 Crankshaft

10 Connecting Rod Bearing

11 Crankshaft Bearing

12 Connecting Rod

13 Piston

14 Oil Spray (Piston Crown Area)

15 Non-- Return Valve (Crankcase)16 Oil Supply (To Chain Tensioner)

17 Camshaft

18 Cam Bearing

19 Valve

20 Oil Gallery (Supply Oil to Intake Tappet)

21 Oil Gallery (Supply Oil to Exhaust Tappet)

22 Ball (φ8mm)

23 Camshaft Plug

24 Seal

25 Screw Plug

26 Oil Return Gallery

(Cylinder Head and Crankcase)

27 Oil Return Gallery (Crankcase)

28 End Cover (φ20mm)

29 Oil Return Pipe