SSANGYONG KORANDO 1997 Service Repair Manual

KORANDO 1997

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57502/w960_57502-0.png

SSANGYONG KORANDO 1997 Service Repair Manual

Trending: coolant temperature, open hood, technical specifications, STARTER MOTOR WIRING, STARTING, oil filter, STARTER MOTOR

Page 271 of 2053

M162 ENGINE INTAKE & EXHAUST 1G1 -- 3

D AEW OO M Y_2000

MAINTENANCE AND REPAIR

ON -- VEHICLE SERVICE

AIR CLEANER

1 Element Assembly

2 Cleaner Assembly -- Air

3 Shield Cover -- Air Intake4 Shield Assembly -- Air Intake

5 Braket Assembly -- Air Cleaner Mounting

6 Braket Assembly -- Shield Surport

Page 272 of 2053

1G1 -- 4 M162 ENGINE INTAKE & EXHAUST

D AEW OO M Y_2000

Removal and Installation Procedure

1. Disconnect the HFM sensor and the air cleaner by

prying up the clamp.

2. Remove the air cleaner mounting bolt.

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

3. Remove air intake shield upper cover, and then re-

move the air cleaner from rubber bearing on bracket.

Notice:For installation, exactly seat the air cleaner into

the rubber bearing.

4. Installation should follow the removal procedure in

the reverse order.

Page 273 of 2053

M162 ENGINE INTAKE & EXHAUST 1G1 -- 5

D AEW OO M Y_2000

INTAKE AIR DUCT

1 Clamp

2 Sleeve

3Nut4 Clamp

5 Intake Air Duct

Page 274 of 2053

1G1 -- 6 M162 ENGINE INTAKE & EXHAUST

D AEW OO M Y_2000

Removal & Installation Procedure

1. Remove the clamp (1) and disconnect the HFM sen-

sor.

2. Remove the nut (3) (arrow).

3. Remove the clamp (4).

4. Remove the intake air duct (5) carefully.

Installation Notice

Exactly seat the pin of intake air duct onto the crank-

case ventilation rubber mount.

5. Installation should follow the removal procedure in

the reverse order.

Page 275 of 2053

M162 ENGINE INTAKE & EXHAUST 1G1 -- 7

D AEW OO M Y_2000

INTAKE MANIFOLD

Preceding Work: Removal of fuel rail

Removal of battery

Removal of canister

1 Bolt (M6 X 40, 4 pieces)

9--11 NSm (80-- 97 lb-in) .....................

2 Softcap

3 Resonance Flap

4 Gasket Replace...........................

5 Upper Intake Manifold

6 Bolt (M8 x 50, 9 pieces)

22.5-- 27.5 NSm (16.6-- 20.3 lb-ft) .............

7 Gasket Replace...........................

8Blow--byHose

9Blow--byHose

10 Clamp

11 Blow-- by Nipple

12 Inlet Air Housing13 Bolt (M6 x 40, 4 pieces)

9--11 NSm (80-- 97 lb-in) .....................

14 Throttle Body -- Electric

15 Gasket Replace...........................

16 Lower Intake Manifold

17 Bolt (M8 x 40, 4 pieces)

22.5-- 27.5 NSm (16.6--20.3 lb-ft) .............

18 Nipple Replace............................

19 Seal Ring

20 Connection House

21 Clamp

22 Noise Damper Assembly

23 Tapping Screw

Page 276 of 2053

1G1 -- 8 M162 ENGINE INTAKE & EXHAUST

D AEW OO M Y_2000

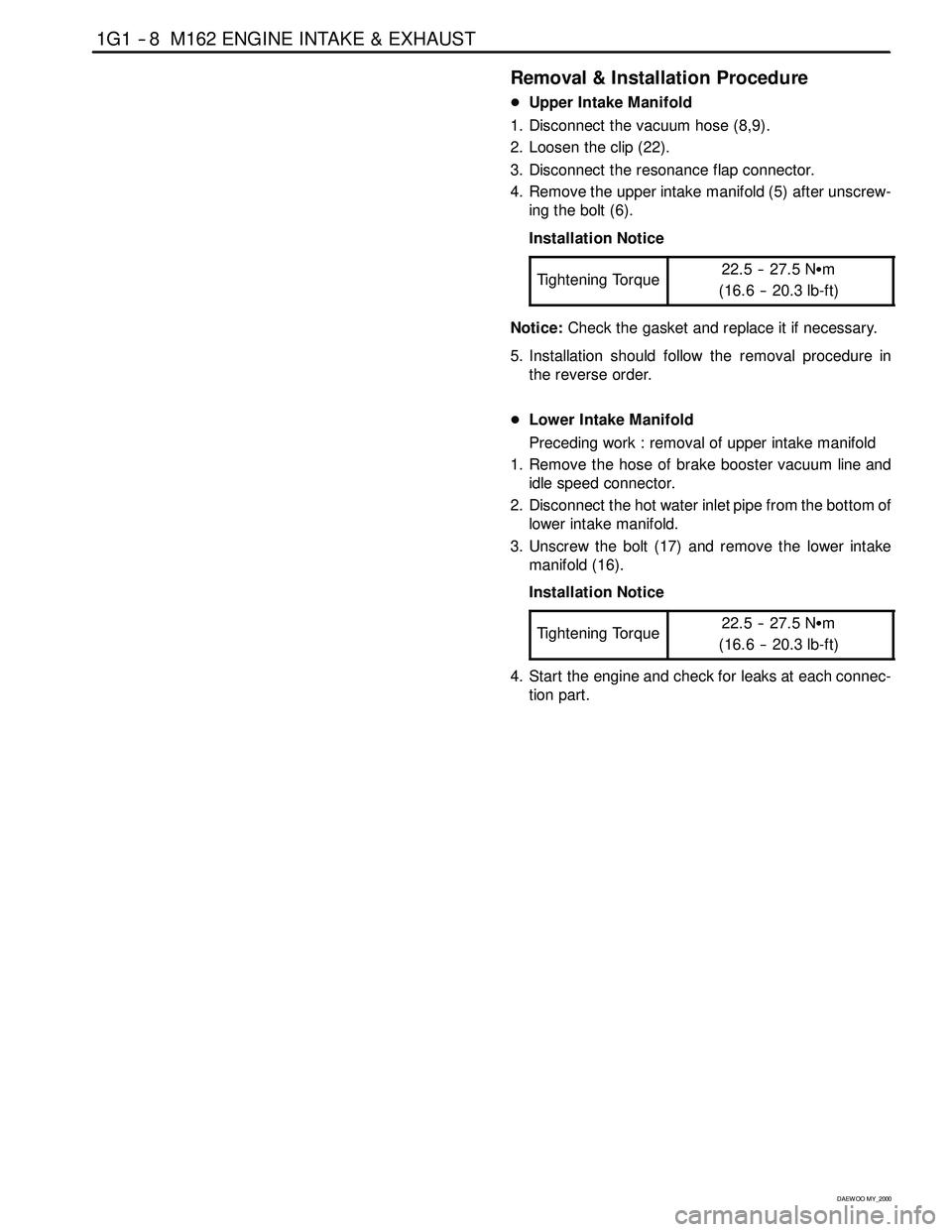

Removal & Installation Procedure

DUpper Intake Manifold

1. Disconnect the vacuum hose (8,9).

2. Loosen the clip (22).

3. Disconnect the resonance flap connector.

4. Remove the upper intake manifold (5) after unscrew-

ing the bolt (6).

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

Notice:Check the gasket and replace it if necessary.

5. Installation should follow the removal procedure in

the reverse order.

DLower Intake Manifold

Preceding work : removal of upper intake manifold

1. Remove the hose of brake booster vacuum line and

idle speed connector.

2. Disconnect the hot water inlet pipe from the bottom of

lower intake manifold.

3. Unscrew the bolt (17) and remove the lower intake

manifold (16).

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

4. Start the engine and check for leaks at each connec-

tion part.

Page 277 of 2053

M162 ENGINE INTAKE & EXHAUST 1G1 -- 9

D AEW OO M Y_2000

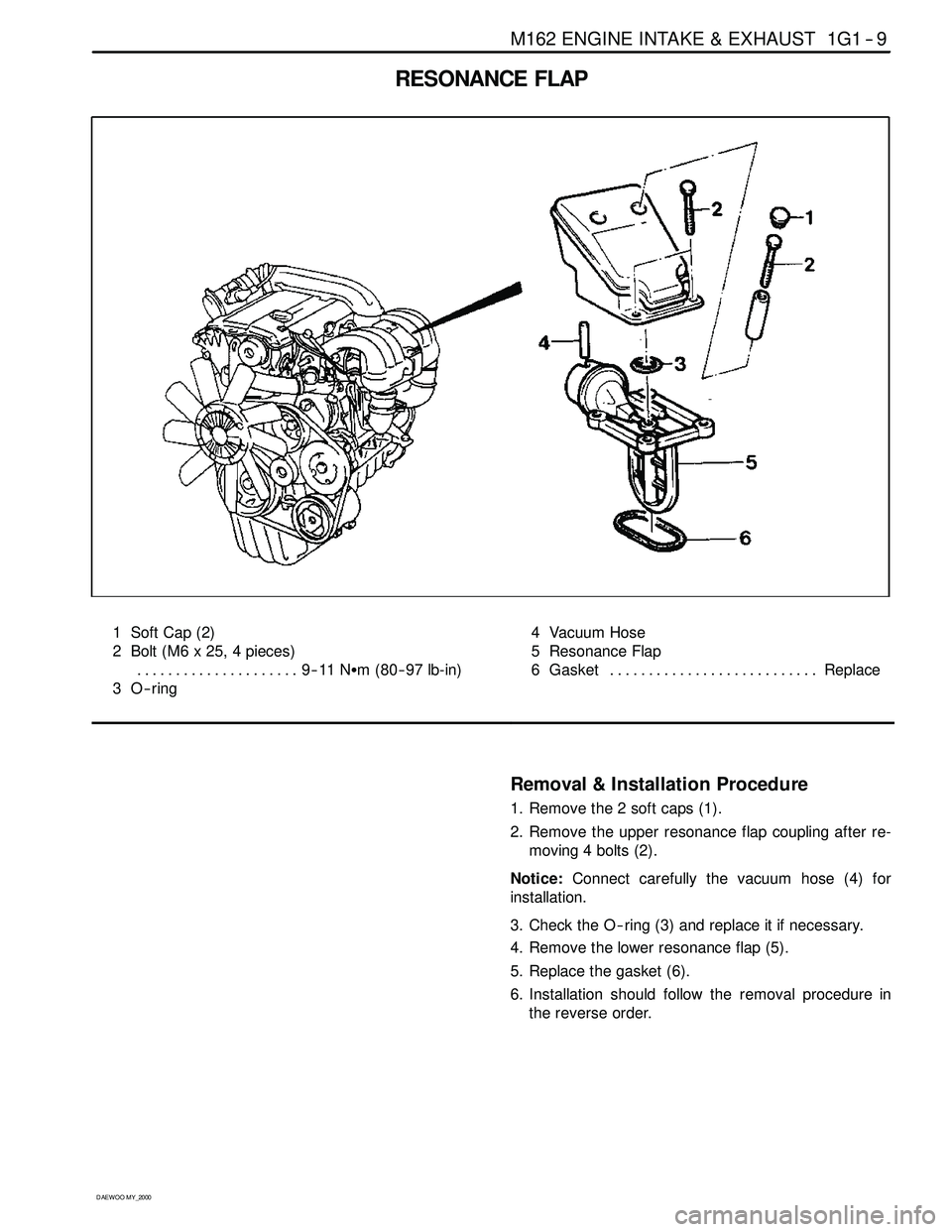

RESONANCE FLAP

1 Soft Cap (2)

2 Bolt (M6 x 25, 4 pieces)

9--11 NSm (80-- 97 lb-in) .....................

3O--ring4 Vacuum Hose

5 Resonance Flap

6 Gasket Replace...........................

Removal & Installation Procedure

1. Remove the 2 soft caps (1).

2. Remove the upper resonance flap coupling after re-

moving 4 bolts (2).

Notice:Connect carefully the vacuum hose (4) for

installation.

3. Check the O -- ring (3) and replace it if necessary.

4. Remove the lower resonance flap (5).

5. Replace the gasket (6).

6. Installation should follow the removal procedure in

the reverse order.

Page 278 of 2053

1G1 -- 10 M162 ENGINE INTAKE & EXHAUST

D AEW OO M Y_2000

Function Description

A pneumatically actuated resonance flap (5) is located

on the intake manifold, and will be opened and closed by

load, which operates resonance flap according to engine

and controlled by ECU and rpm.

1. Resonance flap closed (at idle/partial load : less

than 3,800/rpm)

The switch valve (7) will be adjusted by ECU and res-

onance flapwill be closed. By increasing air flow pas-

sage through dividing intaking air flow toward both air

collection housing (8). This leads to a signficant in-

crease in the torque in the lower speed range.

2. Resonance flap open (at full load:over 3,800/rpm)

The switch valve (7) will not be adjusted by ECU and

resonance flap (5) will beopen. The colllected air in

the air collection housing (8)will not be divided and

intaking air passage will be shorten.

Page 279 of 2053

M162 ENGINE INTAKE & EXHAUST 1G1 -- 11

D AEW OO M Y_2000

EXHAUST MANIFOLD

Preceding Work: Removal of air cleaner

1 Nut 36-- 44 NSm (27-- 33 lb-ft) .................

2 Gasket Replace...........................3 Exhaust Manifold

Page 280 of 2053

1G1 -- 12 M162 ENGINE INTAKE & EXHAUST

D AEW OO M Y_2000

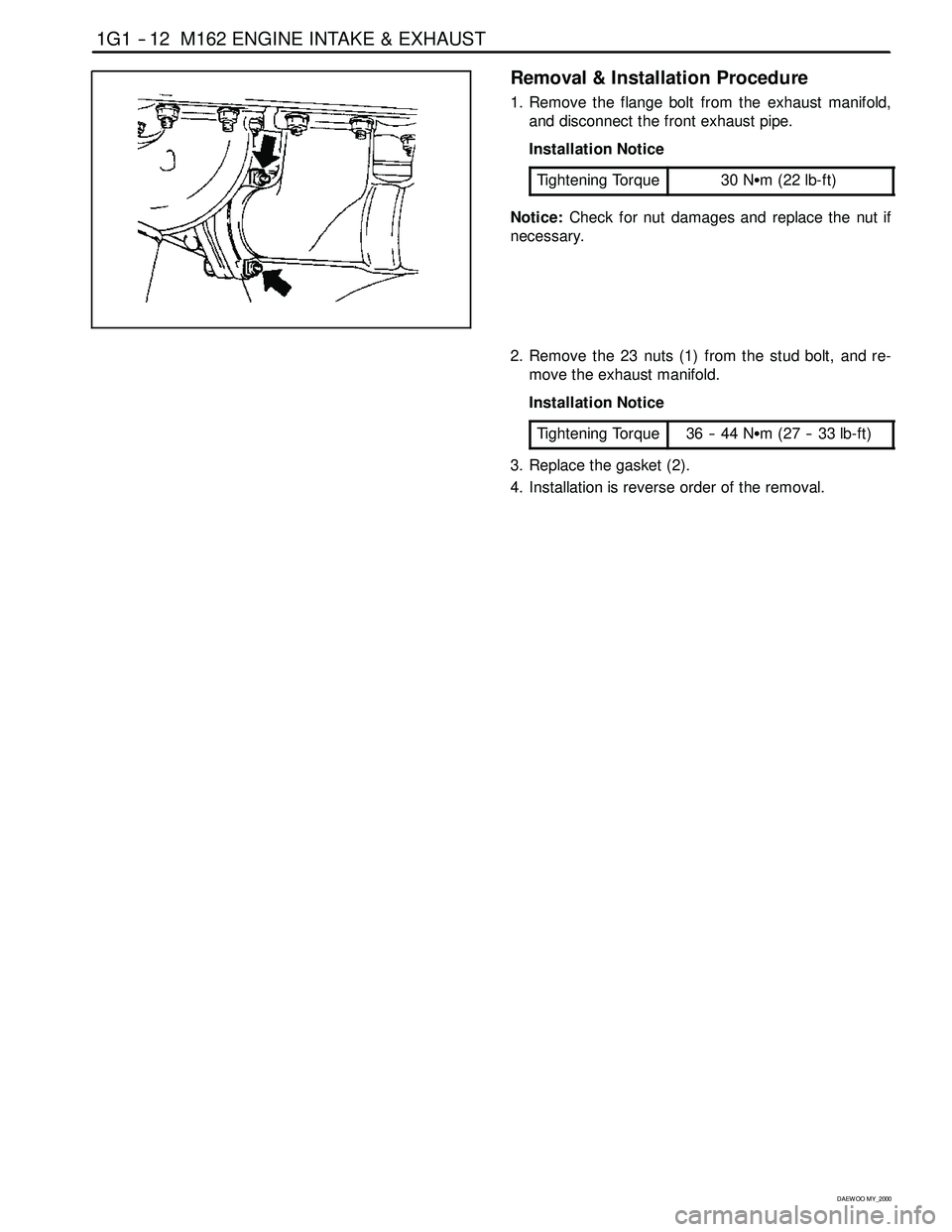

Removal & Installation Procedure

1. Remove the flange bolt from the exhaust manifold,

and disconnect the front exhaust pipe.

Installation Notice

Tightening Torque

30 NSm (22 lb-ft)

Notice:Check for nut damages and replace the nut if

necessary.

2. Remove the 23 nuts (1) from the stud bolt, and re-

move the exhaust manifold.

Installation Notice

Tightening Torque

36 -- 44 NSm (27 -- 33 lb-ft)

3. Replace the gasket (2).

4. Installation is reverse order of the removal.

Trending: wheel, washer fluid, air bleeding, wipers, maintenance, coolant, child restraint