SSANGYONG KORANDO 1997 Service Repair Manual

KORANDO 1997

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57502/w960_57502-0.png

SSANGYONG KORANDO 1997 Service Repair Manual

Trending: fuel pump, fuses, steering wheel adjustment, washer fluid, brake rotor, fuel additives, charging

Page 281 of 2053

M162 ENGINE INTAKE & EXHAUST 1G1 -- 13

D AEW OO M Y_2000

Removal and Installation of Exhaust System

1 Exhaust Pipe

2 Oxygen Sensor

3 Gasket

4 Catalytic Converter

5 Front Muffler

6 Rear Muffler7 Exhaust Pipe--to--Catalytic Converter

Flange Nuts 28 -- 47 NSm (21--35 lb-ft) .......

8 Front Muffler Pipe--to--Catalytic Converter

Flange Nuts 28 -- 47 NSm (21--35 lb-ft) .......

9 Rear Muffler Pipe Flange -- to -- Front Muffler

Pipe Flange Nuts 28 -- 47 NSm (21--35 lb-ft) ...

Page 282 of 2053

D AEW OO M Y_2000

SECTION 1

ENGINE

SECTION 1A2 (M161 ENGINE)

GENERAL ENGINE INFORMATION

TABLE OF CONTENTS

Specifications 1A2 -- 2............................

Engine Specifications 1A2-- 2.....................

Component Locator 1A2 -- 3.......................

Front View 1A2 -- 3...............................

Side View 1A2-- 4...............................

Performance Curve 1A2-- 5........................

E23 Engine 1A2-- 5..............................

E20 Engine 1A2-- 6..............................

Diagnosis 1A2 -- 7.................................Oil Leak Diagnosis 1A2-- 7........................

Engine Cranking At The

FrontofCrankshaft 1A2--8.....................

Compression Pressure Test 1A2-- 9...............

Cylinder Pressure Leakage Test 1A2-- 11...........

General Information 1A2 -- 13......................

Cleanliness and Care 1A2 -- 13....................

On-- Engine Service 1A2-- 13......................

Page 283 of 2053

GENERAL ENGINE INFORMATION 1A2 -- 11

D AEW OO M Y_2000

CYLINDER PRESSURE LEAKAGE TEST

3 Engine Oil Filler Cap

5 Vibration Damper6 Cylinder Pressure Leakage Tester with

Connecting Hose

Permissible Pressure Leakage

At Whole EngineMax. 25 %

At Valve and Cylinder Head GasketMax. 10 %

At Piston and Piston RingMax. 20 %

Cylinder Number By Mark On Vibration Damper At TDC

TDC MarkOT (TDC)UT (BDC : 180°)

Cylinder Number1, 42, 3

Universal Tool

Cylinder Pressure Leakage TesterBosch, EFAW 210A

Sun, CLT 228

Page 284 of 2053

1A2 -- 12 GENERAL ENGINE INFORMATION

D AEW OO M Y_2000

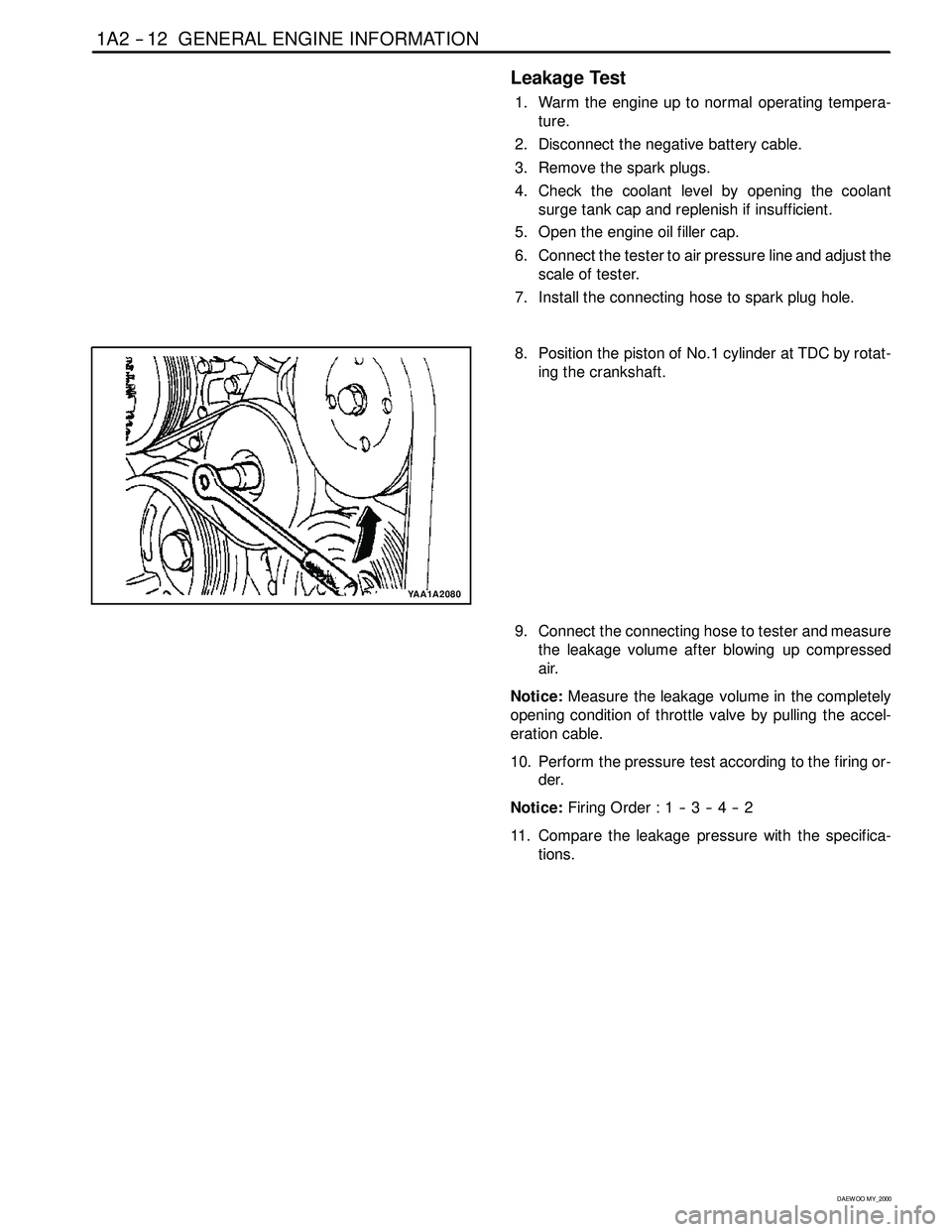

Leakage Test

1. Warm the engine up to normal operating tempera-

ture.

2. Disconnect the negative battery cable.

3. Remove the spark plugs.

4. Check the coolant level by opening the coolant

surge tank cap and replenish if insufficient.

5. Open the engine oil filler cap.

6. Connect the tester to air pressure line and adjust the

scale of tester.

7. Install the connecting hose to spark plug hole.

YAA1A2080

8. Position the piston of No.1 cylinder at TDC by rotat-

ing the crankshaft.

9. Connect the connecting hose to tester and measure

the leakage volume after blowing up compressed

air.

Notice:Measure the leakage volume in the completely

opening condition of throttle valve by pulling the accel-

eration cable.

10. Perform the pressure test according to the firing or-

der.

Notice:Firing Order : 1 -- 3 -- 4 -- 2

11. Compare the leakage pressure with the specifica-

tions.

Page 285 of 2053

GENERAL ENGINE INFORMATION 1A2 -- 13

D AEW OO M Y_2000

GENERAL INFORMATION

CLEANLINESS AND CARE

An automobile engine is a combination of many ma-

chined, honed, polished and lapped surfaces with toler-

ances that are measured in the ten-thousandths of an

inch. When any internal engine parts are serviced, care

and cleanliness are important. A liberal coating of enigne

oil should be applied to friction areas during assembly, to

protect and lubricate the surfaces on initial operation.

Proper cleaning and protection of machined surfaces and

friction areas is part of the repair procedure. This is con-

sidered standard shop practice even if not specifically

stated.

Whenever valve train components are removed for ser-

vice, they should be kept in order. They should be

installed in the same locations, and with the same mating

surfaces, as when they were removed.

Battery cables should be disconnected before any major

work is performed on the engine. Failure to disconnect

cables may result in damage to wire harness or other

electrical parts.

ON-ENGINE SERVICE

Caution: Disconnect the negative battery cable be -

fore removing or installing any electrical unit, or

when a tool or equipment could easily come in con-

tact with exposed electrical terminals. Disconnect -

ing this cable will help prevent personal injury and

damage to the vehicle. The ignition must also be in

LOCK unless otherwise noted.

Notice:Any time the air cleaner is removed, the intake

opening should be covered. Thiswill protect against ac-

cidental entrance of foreign material, which could follow

the intake passage into the cylinder and cause exten-

sive damage when the engine is started.

Page 286 of 2053

1A2 -- 2 GENERAL ENGINE INFORMATION

D AEW OO M Y_2000

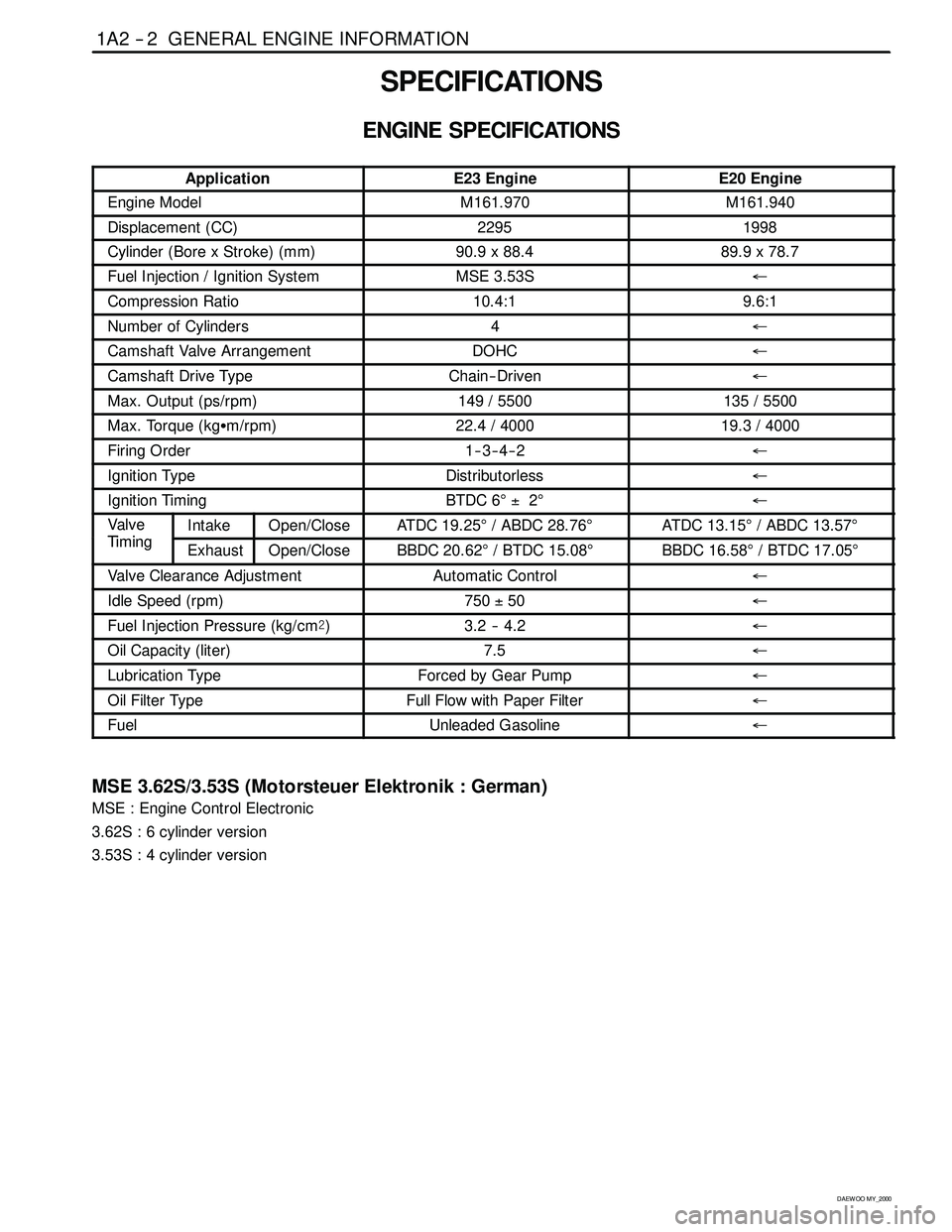

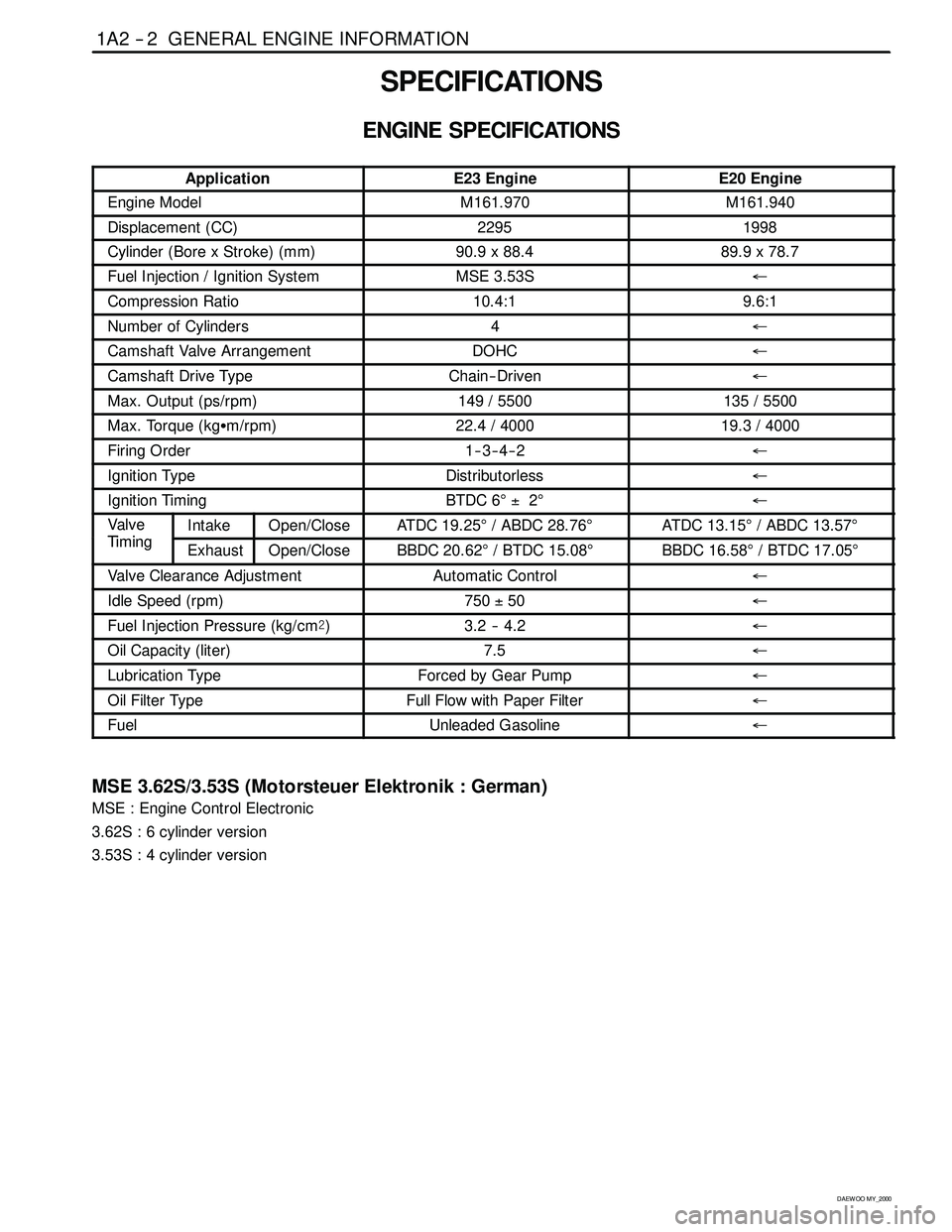

SPECIFICATIONS

ENGINE SPECIFICATIONS

ApplicationE23 EngineE20 Engine

Engine ModelM161.970M161.940

Displacement (CC)22951998

Cylinder (Bore x Stroke)(mm)90.9 x 88.489.9 x 78.7

Fuel Injection / Ignition SystemMSE 3.53S←

Compression Ratio10.4:19.6:1

Number of Cylinders4←

Camshaft Valve ArrangementDOHC←

Camshaft Drive TypeChain-- Driven←

Max. Output (ps/rpm)149 / 5500135 / 5500

Max. Torque (kgSm/rpm)22.4 / 400019.3 / 4000

Firing Order1--3--4--2←

Ignition TypeDistributorless←

Ignition TimingBTDC 6°±2°←

Va lv e

Tii

IntakeOpen/CloseATDC 19.25°/ ABDC 28.76°ATDC 13.15°/ ABDC 13.57°

Tim in gExhaustOpen/CloseBBDC 20.62°/ BTDC 15.08°BBDC 16.58°/ BTDC 17.05°

Valve Clearance AdjustmentAutomatic Control←

Idle Speed (rpm)750±50←

Fuel Injection Pressure (kg/cm@)3.2 -- 4.2←

Oil Capacity (liter)7.5←

Lubrication TypeForced by Gear Pump←

Oil Filter TypeFull Flow with Paper Filter←

FuelUnleaded Gasoline←

MSE 3.62S/3.53S (Motorsteuer Elektronik : German)

MSE : Engine Control Electronic

3.62S : 6 cylinder version

3.53S : 4 cylinder version

Page 287 of 2053

GENERAL ENGINE INFORMATION 1A2 -- 3

D AEW OO M Y_2000

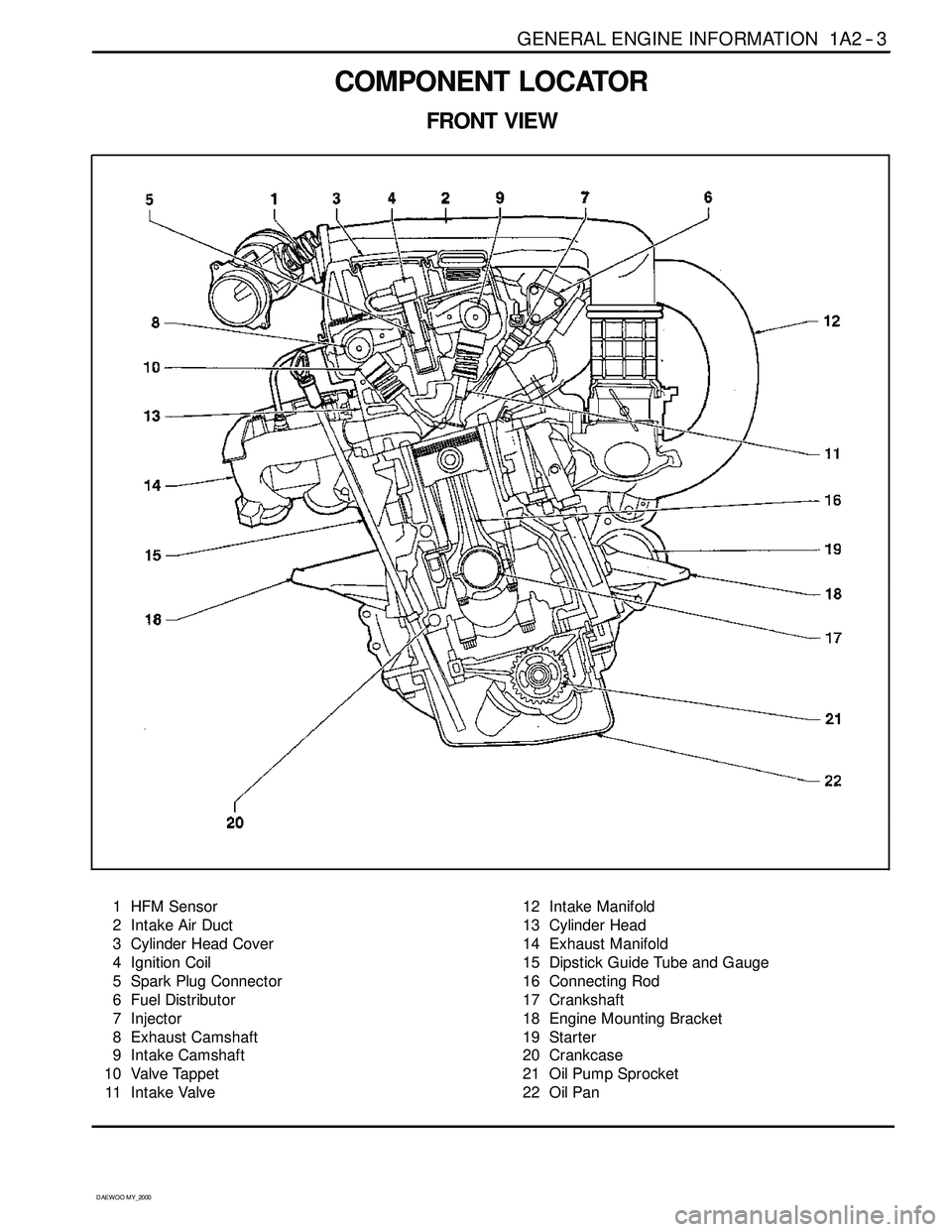

COMPONENT LOCATOR

FRONT VIEW

1 HFM Sensor

2 Intake Air Duct

3 Cylinder Head Cover

4 Ignition Coil

5 Spark Plug Connector

6 Fuel Distributor

7 Injector

8 Exhaust Camshaft

9 Intake Camshaft

10 Valve Tappet

11 Intake Valve12 Intake Manifold

13 Cylinder Head

14 Exhaust Manifold

15 Dipstick Guide Tube and Gauge

16 Connecting Rod

17 Crankshaft

18 Engine Mounting Bracket

19 Starter

20 Crankcase

21 Oil Pump Sprocket

22 Oil Pan

Page 288 of 2053

1A2 -- 4 GENERAL ENGINE INFORMATION

D AEW OO M Y_2000

SIDE VIEW

23 Camshaft Adjuster

24 Oil Filler Cap

25 Engine Hanger Bracket

26 Cooling Fan and Viscous Clutch

27 Oil Filter

28 Timing Chain29 Oil Pump Drive Chain

30 Oil Strainer

31 Oil Pump

32 Ring Gear and Flywheel of Drive Plate

33 Piston

Page 289 of 2053

GENERAL ENGINE INFORMATION 1A2 -- 5

D AEW OO M Y_2000

PERFORMANCE CURVE

E32 ENGINE

Page 290 of 2053

1A2 -- 6 GENERAL ENGINE INFORMATION

D AEW OO M Y_2000

E20 ENGINE

Trending: brake, cooling, steering wheel, airbag off, STARTER, Timing sign, check oil