SSANGYONG KORANDO 1997 Service Repair Manual

KORANDO 1997

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57502/w960_57502-0.png

SSANGYONG KORANDO 1997 Service Repair Manual

Trending: service indicator, jacking, tire pressure, fuse chart, seat memory, tow bar, radio

Page 311 of 2053

1B2 -- 18 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

GENERATOR

1 Bolt (M8 X 40, 3 pieces)

22.5-- 27.5 NSm (16.6-- 20.3 lb-ft) .............

2 Bolt (M8 X 70, 2 pieces)

22.5-- 27.5 NSm (16.6-- 20.3 lb-ft) .............3 Bolt (M8 X 85, 1 piece)

22.5-- 27.5 NSm (16.6--20.3 lb-ft) .............

4 Generator Bracket

Removal & Installation Procedure

1. Disconnect the negative battery cable.

2. Remove the drive belt.

3. Remove the generator.

4. Unscrew the generator carrier bolts and remove the

carrier.

Installation Notice

Tightening Torque

25 NSm (18 lb-ft)

Notice:Apply 3 Nm of torque when mounting the bolt

(1) ; apply 25 Nm of torque when mounting the bolts (2),

and (3) ; and then tighten the bolt (1) with 25 Nm of

torque.

5. Installation should follow the removal procedure in

the reverse order.

Page 312 of 2053

M161 ENGINE MECHANICAL 1B2 -- 19

D AEW OO M Y_2000

ENGINE MOUNT

Removal & Installation Procedure

1. Unscrew the upper engine mount nuts and remove

the engine.

Installation Notice

Tightening Torque

70 NSm (52 lb-ft)

2. Unscrew the lower nuts.

Installation Notice

Tightening Torque

38 NSm (28 lb-ft)

3. Remove the hydraulic engine mounting insulator.

4. Installation should follow the removal procedure in

the reverse order.

Page 313 of 2053

1B2 -- 20 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

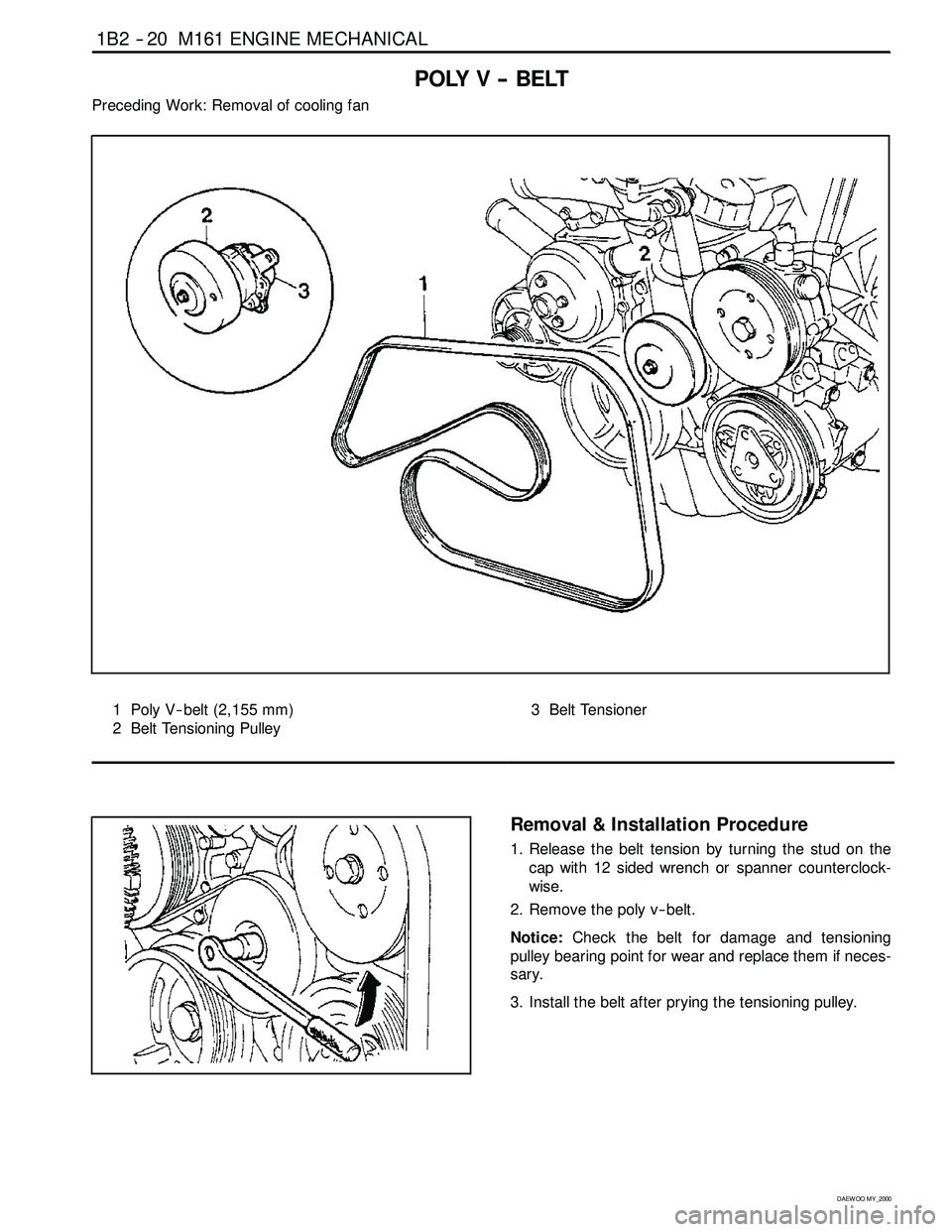

POLY V -- BELT

Preceding Work: Removal of cooling fan

1 Poly V-- belt (2,155 mm)

2 Belt Tensioning Pulley3 Belt Tensioner

Removal & Installation Procedure

1. Release the belt tension by turning the stud on the

cap with 12 sided wrench or spanner counterclock-

wise.

2. Remove the poly v -- belt.

Notice:Check the belt for damage and tensioning

pulley bearing point for wear and replace them if neces-

sary.

3. Install the belt after prying the tensioning pulley.

Page 314 of 2053

1B2 -- 22 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

TENSIONING DEVICE

Preceding Work: Removal of tensioning device shock absorber

1 Bolt (M8 x 75, 2 pieces) +

Washer 22.5-- 27.5 NSm (16.6-- 20.3 lb-ft) ......

2 Bolt (M8 x 25, 1 pieces) +

Washer 22.5-- 27.5 NSm (16.6-- 20.3 lb-ft) ......3 Tensioning Device

4 Stud bolt

5 Tensioning Arm

Removal & Installation Procedure

1. Turn the stud bolt to counterclockwise.

2. Insert the pin (111 589 01 15 00) into the hole in ten-

sioning arm.

3. Unscrew the bolts (1, 2) and remove the tensioning

device.

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

4. Installation should follow the removal procedure in

the reverse order.

Page 315 of 2053

M161 ENGINE MECHANICAL 1B2 -- 21

D AEW OO M Y_2000

Poly V - Belt Arrangement

1 Belt Tensioning Pulley

2 Crankshaft Belt Pulley

3 A/C Compressor Pulley5 Generator Pulley

7 Power Steering Pump Pulley

8 Water Pump Pulley

Page 316 of 2053

M161 ENGINE MECHANICAL 1B2 -- 23

D AEW OO M Y_2000

TENSIONING DEVICE SHOCK ABSORBER

1 End Cover

2 Bolt 40.5-- 49.5 NSm (29.9-- 36.5 lb-ft) .........

3 Tensioning Pulley

4 Bolt (M8 X 25) + Washer

22.5-- 27.5 NSm (16.6-- 20.3 lb-ft) .............5 Tensioning Device

6 Bolt (M8 X 35) + Washer

22.5-- 27.5 NSm (16.6--20.3 lb-ft) .............

7 Shock Absorber

Removal & Installation Procedure

1. Remove the end cover (1).

2. Remove the bolt (2) and remove the tensioning pulley

(3).

Installation Notice

Tightening Torque

40.5 -- 49.5 NSm

(29.9 -- 36.5 lb-ft)

3. Unscrew the bolts (4,6) and remove the shock ab-

sorber (7).

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

Page 317 of 2053

1B2 -- 24 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

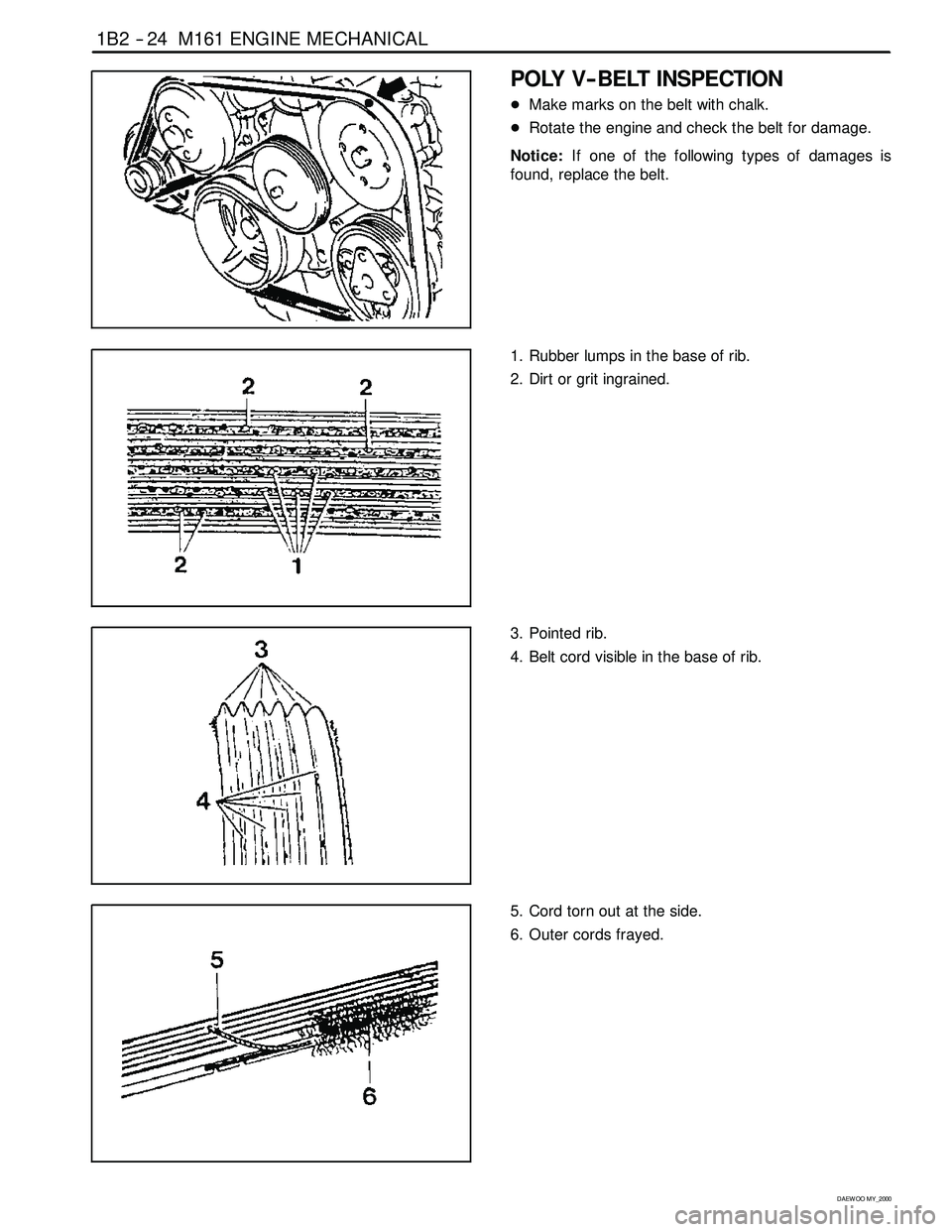

POLY V-- BELT INSPECTION

DMake marks on the belt with chalk.

DRotate the engine and check the belt for damage.

Notice:If one of the following types of damages is

found, replace the belt.

1. Rubber lumps in the base of rib.

2. Dirt or grit ingrained.

3. Pointed rib.

4. Belt cord visible in the base of rib.

5. Cord torn out at the side.

6. Outer cords frayed.

Page 318 of 2053

M161 ENGINE MECHANICAL 1B2 -- 25

D AEW OO M Y_2000

7. Rib detached from the base of belt.

8. Splits across the rib.

9. Sections of rib torn out.

10. Splits across several ribs.

11. Splits across the back of the belt.

Page 319 of 2053

1B2 -- 26 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

CYLINDER HEAD COVER

1 Spark Plug Cover

2 Spark Plug Connector

3 Bolt(M6X45:4pieces,M6X60:6pieces)

9--11 NSm (80-- 97 lb-in) .....................4 Cylinder Head Cover

5 Gasket Replace...........................

Page 320 of 2053

M161 ENGINE MECHANICAL 1B2 -- 27

D AEW OO M Y_2000

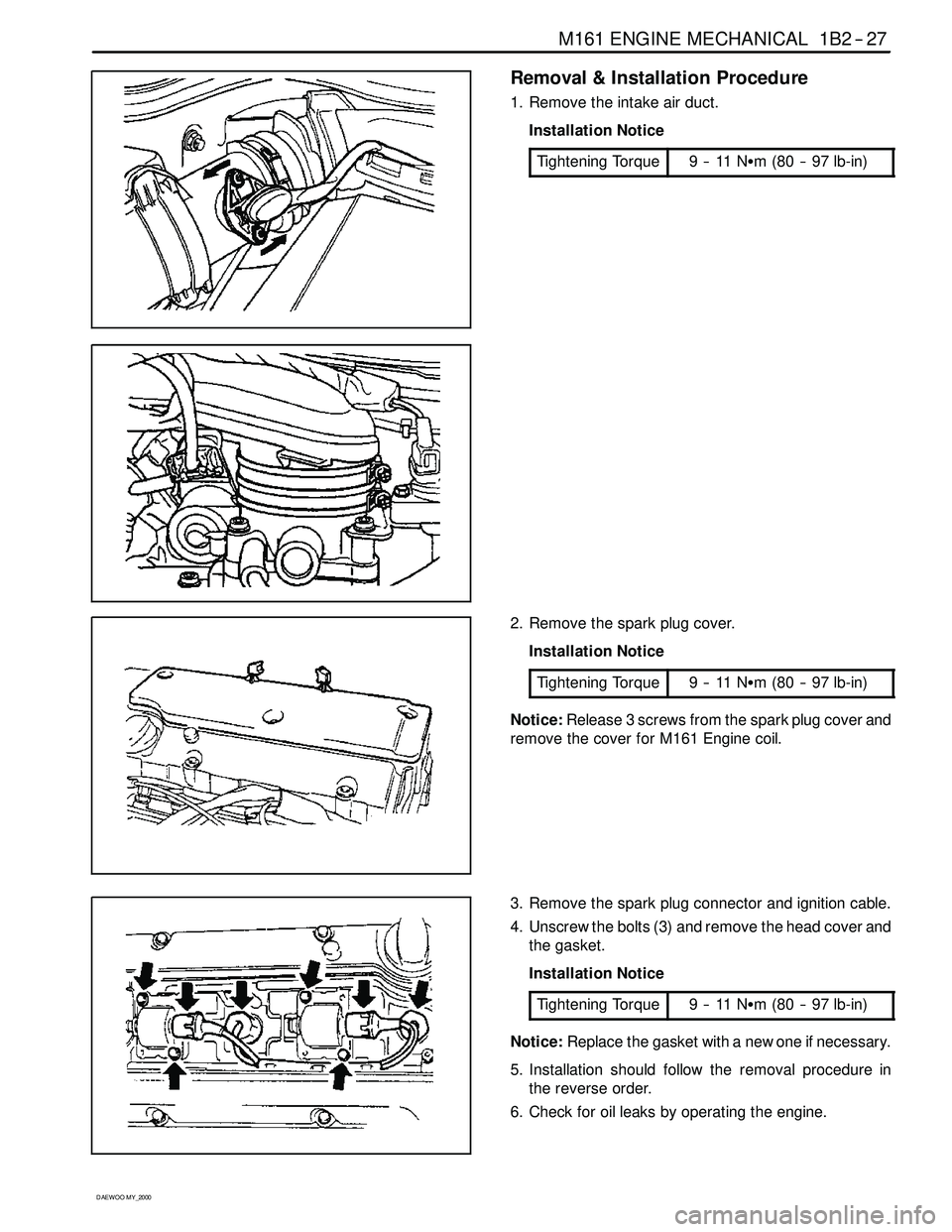

Removal & Installation Procedure

1. Remove the intake air duct.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

2. Remove the spark plug cover.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

Notice:Release 3 screws from the spark plug cover and

remove the cover for M161 Engine coil.

3. Remove the spark plug connector and ignition cable.

4. Unscrew the bolts (3) and remove the head cover and

the gasket.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

Notice:Replace the gasket with a new one if necessary.

5. Installation should follow the removal procedure in

the reverse order.

6. Check for oil leaks by operating the engine.

Trending: tow bar, battery, cabi, boot, STARTER MOTOR, height adjustment, key