SSANGYONG KORANDO 1997 Service Repair Manual

Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 391 of 2053

M161 ENGINE MECHANICAL 1B2 -- 103

D AEW OO M Y_2000

Group Code Letter of CylinderGroup Code Letter 1)Cylinder Bore Size (mm)

Standard SizeAφ89.900 --φ89.906

E20 :φ89.9

E23φ909Xφ89.906 --φ89.912E23 :φ90.9Bφ89.912 --φ89.918

1st Repair Size

(StddSi025)

Aφ90.150 --φ90.156p

(Standard Size + 0.25)Xφ89.156 --φ90.162

Bφ90.162 --φ90.168

2nd Repair Size

(StddSi05)

Aφ90.400 --φ90.406p

(Standard Size + 0.5)Xφ90.406 --φ90.412

Bφ90.412 --φ90.418

1) The group code letters are carved on the surface of the piston crown and in the mating surface of the crankcase.

ServiceDataStandard

Wear Limit in Longitudinal and Transverse Direction0.1 mm

Permissible Deviation of Cylinder Out -- of -- roundWhen new0.007 mmy

Wear limit0.05 mm

Permissible Deviation of Rectangular Cylinder Height (Except Chamfered Area)0.05 mm

Basic Peak -- to-- valley Height After Final Honing and Brushing0.003 -- 0.006 mm

Chamfer Angle75°

Honing Angle50°±10°

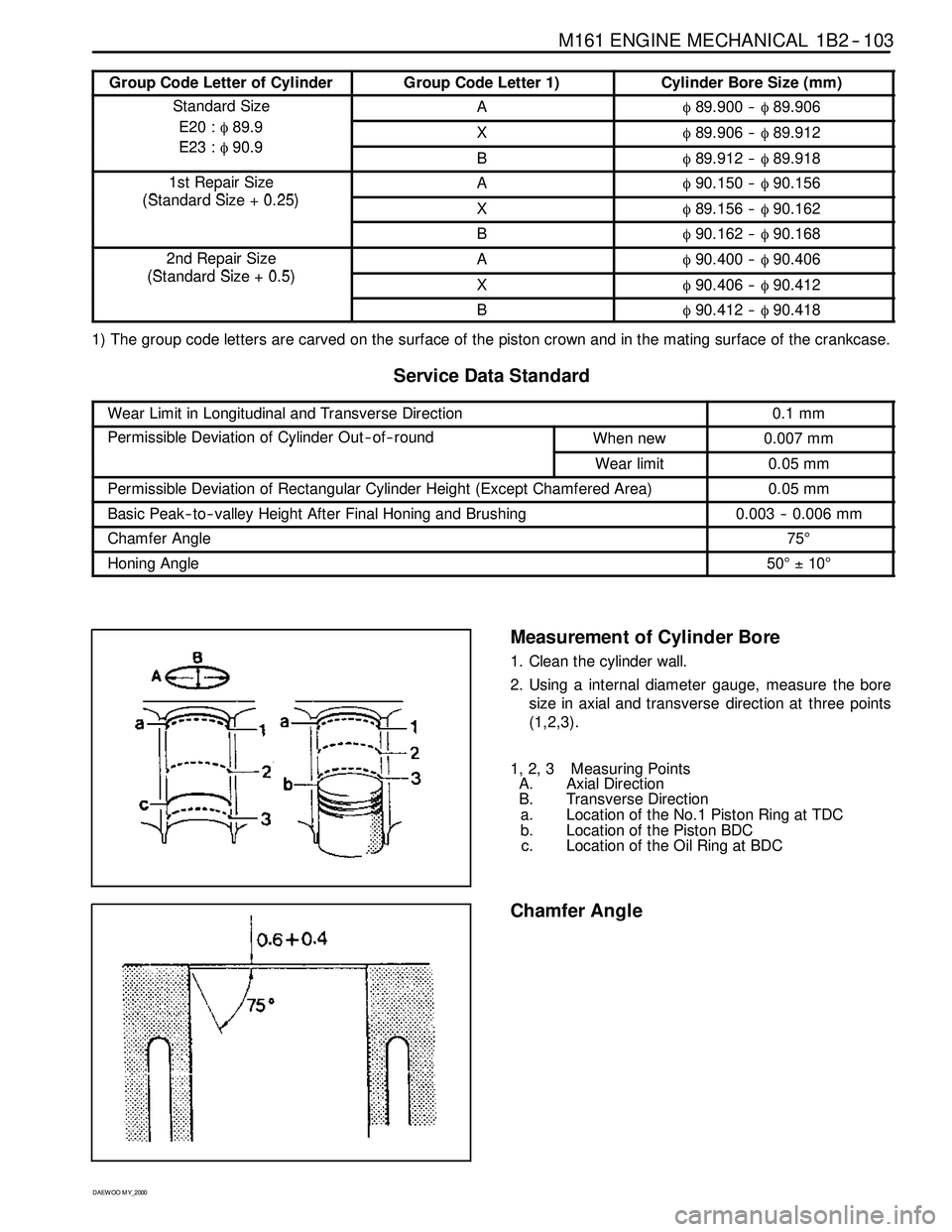

Measurement of Cylinder Bore

1. Clean the cylinder wall.

2. Using a internal diameter gauge, measure the bore

size in axial and transverse direction at three points

(1,2,3).

1, 2, 3 Measuring Points

A. Axial Direction

B. Transverse Direction

a. Location of the No.1 Piston Ring at TDC

b. Location of the Piston BDC

c. Location of the Oil Ring at BDC

Chamfer Angle

Page 392 of 2053

1B2 -- 104 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

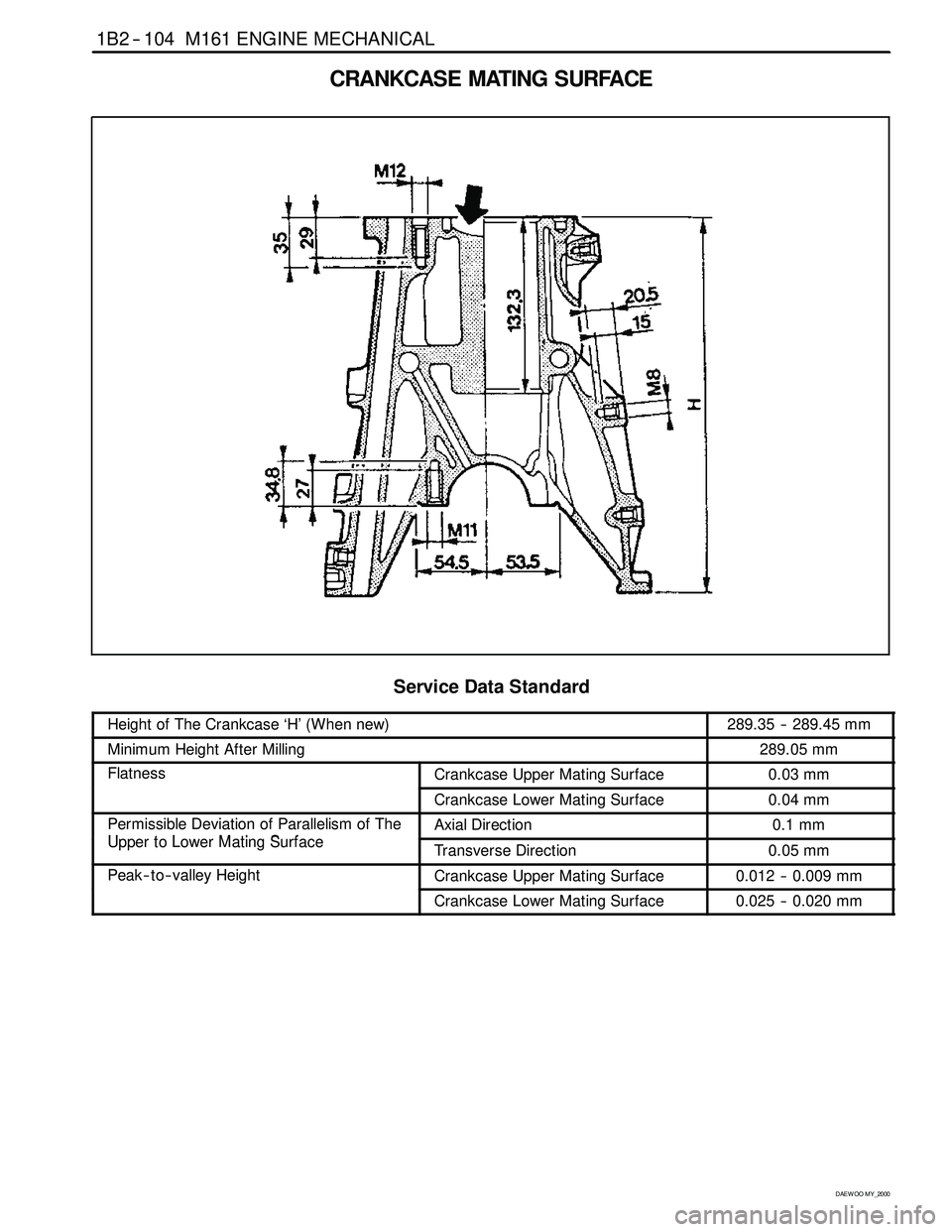

CRANKCASE MATING SURFACE

ServiceDataStandard

Height of The Crankcase ‘H’ (When new)289.35 -- 289.45 mm

Minimum Height After Milling289.05 mm

FlatnessCrankcase Upper Mating Surface0.03 mm

Crankcase Lower Mating Surface0.04 mm

Permissible Deviation of Parallelism of The

UtLMtiSf

Axial Direction0.1 mm

Upper to Lower Mating SurfaceTransverse Direction0.05 mm

Peak -- to-- valley HeightCrankcase Upper Mating Surface0.012 -- 0.009 mmyg

Crankcase Lower Mating Surface0.025 -- 0.020 mm

Page 393 of 2053

M161 ENGINE MECHANICAL 1B2 -- 105

D AEW OO M Y_2000

Chamfering Procedure

1. Chamfer angle : 75°

2. Polish the lower chamfered area evenly with a grinder

after finishing the chamfering with a suitable tool

(e.g., hand milling cutter).

Page 394 of 2053

1B2 -- 106 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

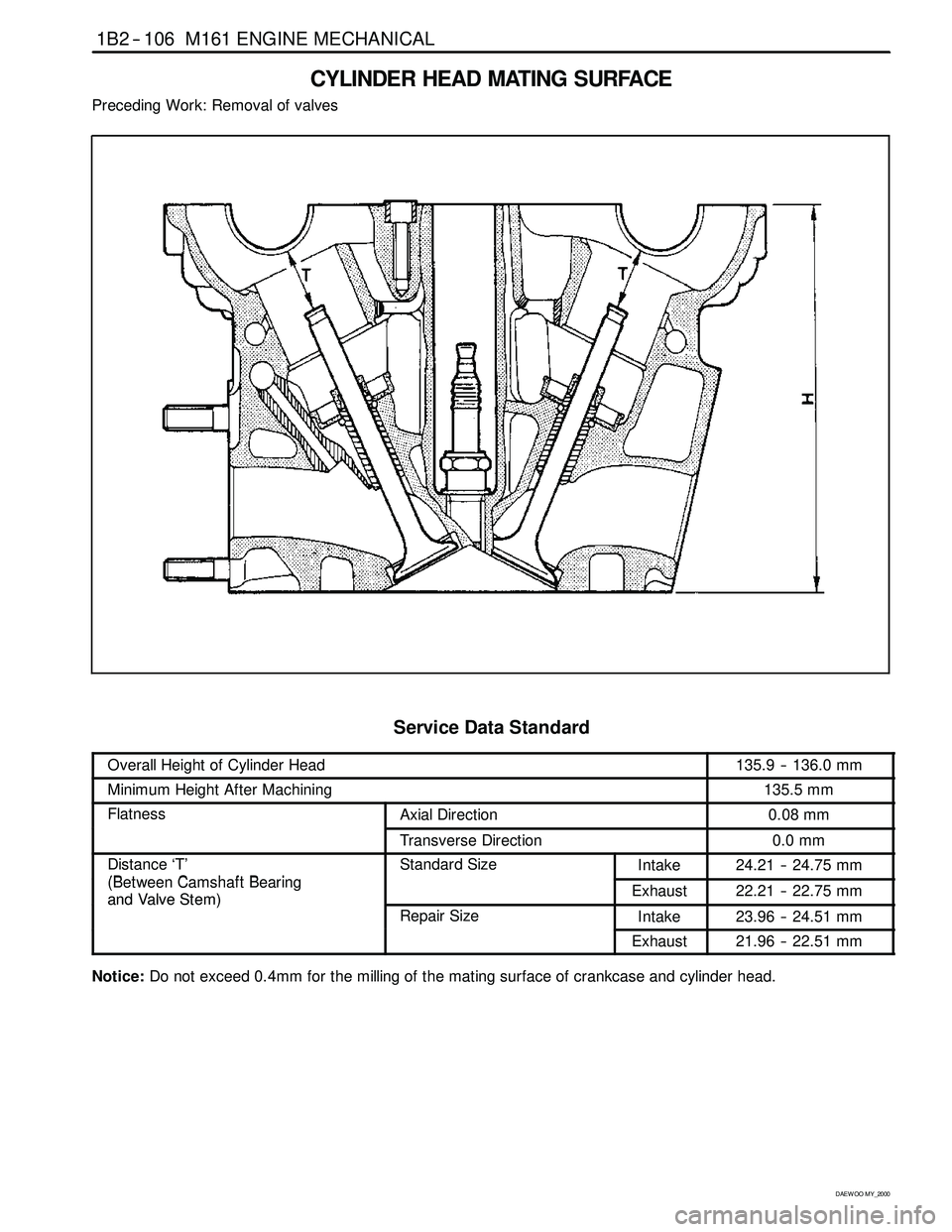

CYLINDER HEAD MATING SURFACE

Preceding Work: Removal of valves

ServiceDataStandard

Overall Height of Cylinder Head135.9 -- 136.0 mm

Minimum Height After Machining135.5 mm

FlatnessAxial Direction0.08 mm

Transverse Direction0.0 mm

Distance ‘T’

(BtChftBi

Standard SizeIntake24.21 -- 24.75 mm

(Between Camshaft Bearing

andValveStem)Exhaust22.21 -- 22.75 mmandValveStem)

Repair SizeIntake23.96 -- 24.51 mmp

Exhaust21.96 -- 22.51 mm

Notice:Do not exceed 0.4mm for the milling of the mating surface of crankcase and cylinder head.

Page 395 of 2053

M161 ENGINE MECHANICAL 1B2 -- 107

D AEW OO M Y_2000

Measurement of Mating Surfac

1. Measure the height (H) of the cylinder head(refer to

Service data standard).

2. Check the mating surface of the cylinder head.

3. Mill the sharp edge of the combustion chamber.

4. Re-- measure the height (H) of the cylinder head.

5. Seal the intake and exhaust valves.

6. Measure the dimension (T) between the camshaft

bearing and the valve system(refer to Service data

standard).

7. Mill the cylinder head valve seat(refer to Service data

standard).

Universal Tool

Surface Grinding Machine

Sceledum, Type RTY

Roaro

Schio/Italy

Page 396 of 2053

D AEW OO M Y_2000

SECTION 1D2

M161 ENGINE COOLING

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless other -

wise noted.

TABLE OF CONTENTS

Specifications 1D2 -- 2............................

General Specifications 1D2-- 2....................

Fastener Tightening Specifications 1D2 -- 2..........

Special Tools 1D2 -- 3.............................

Special Tools Table 1D2-- 3.......................

Diagnosis 1D2 -- 4.................................

System Leakage Test 1D2-- 4.....................

Maintenance and Repair 1D2 -- 5...................

On-- Vehicle Service 1D2-- 5.........................Coolant Drain and Fill Up 1D2 -- 5..................

Cooling Fan and Viscous Clutch 1D2 -- 7............

Wat er Pum p 1D2 -- 9.............................

Thermostat 1D2 -- 11.............................

Thermostat Housing Assembly 1D2 -- 12............

Removal and Installation of Cooling

Fan Shroud 1D2 -- 14...........................

Removal and Installation of Radiator 1D2-- 15.......

Page 397 of 2053

1D2 -- 2 M161 ENGINE COOLING

D AEW OO M Y_2000

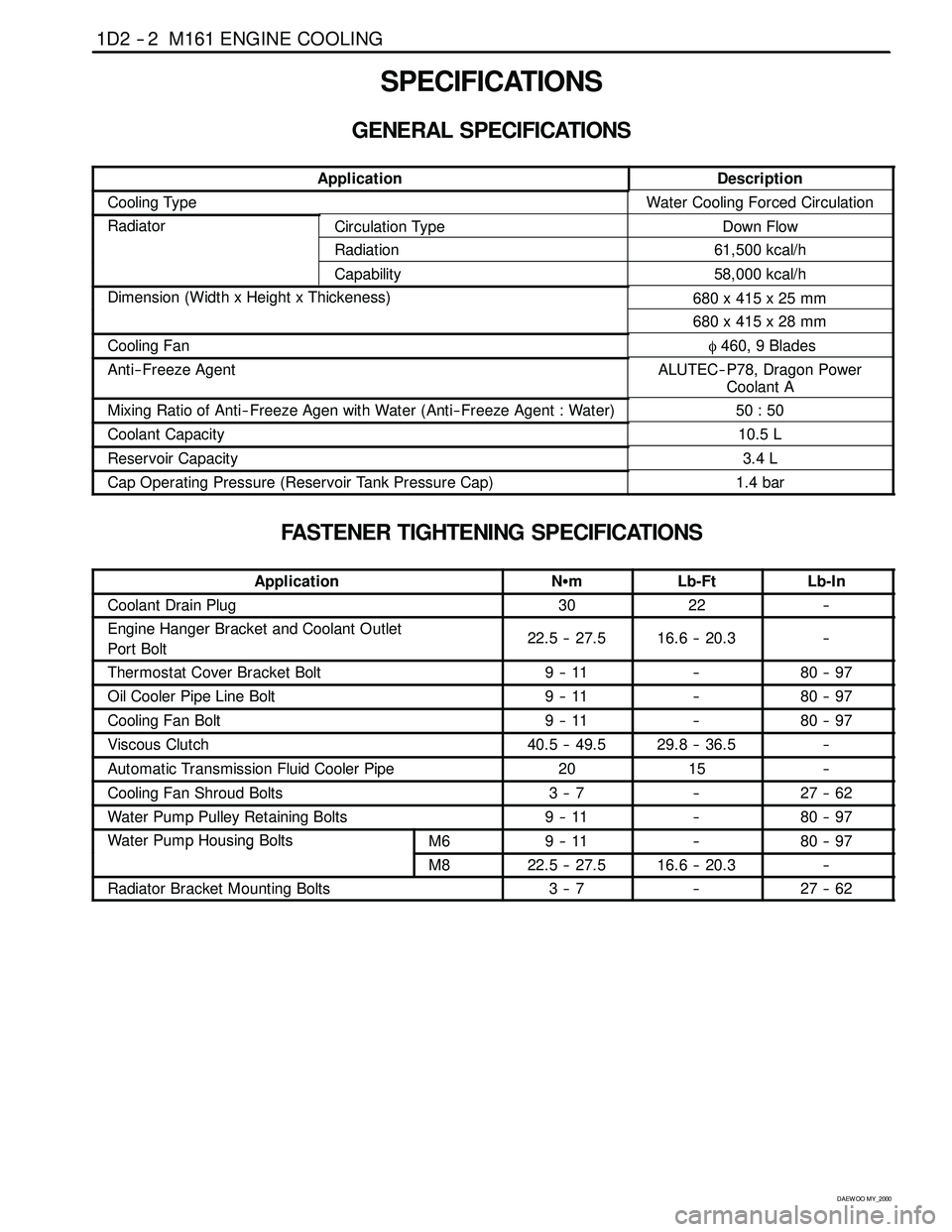

SPECIFICATIONS

GENERAL SPECIFICATIONS

ApplicationDescription

Cooling TypeWater Cooling Forced Circulation

RadiatorCirculation TypeDown Flow

Radiation61,500 kcal/h

Capability58,000 kcal/h

Dimension (Width x Height x Thickeness)680 x 415 x 25 mm(g)

680 x 415 x 28 mm

Cooling Fanφ460, 9 Blades

Anti-- Freeze AgentALUTEC-- P78, Dragon Power

Coolant A

Mixing Ratio of Anti-- Freeze Agen with Water (Anti-- Freeze Agent : Water)50 : 50

Coolant Capacity10.5 L

Reservoir Capacity3.4 L

Cap Operating Pressure (Reservoir Tank Pressure Cap)1.4 bar

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb-FtLb-In

Coolant Drain Plug3022--

Engine Hanger Bracket and Coolant Outlet

Port Bolt22.5 -- 27.516.6 -- 20.3--

Thermostat Cover Bracket Bolt9--11--80 -- 97

Oil Cooler Pipe Line Bolt9--11--80 -- 97

Cooling Fan Bolt9--11--80 -- 97

Viscous Clutch40.5 -- 49.529.8 -- 36.5--

Automatic Transmission Fluid Cooler Pipe2015--

Cooling Fan Shroud Bolts3--7--27 -- 62

Water Pump Pulley Retaining Bolts9--11--80 -- 97

Water Pump Housing BoltsM69--11--80 -- 97pg

M822.5 -- 27.516.6 -- 20.3--

Radiator Bracket Mounting Bolts3--7--27 -- 62

Page 398 of 2053

M161 ENGINE COOLING 1D2 -- 3

D AEW OO M Y_2000

SPECIAL TOOLS AND EQUIPMENT

SPECIAL TOOLS TABLE

124 589 15 21 00

Tester

111 589 02 01 00

Open End Wrench

603 589 00 40 00

Fan Clutch Holder

111 589 00 40 00

Open End Wrench

Page 399 of 2053

1D2 -- 4 M161 ENGINE COOLING

D AEW OO M Y_2000

DIAGNOSIS

SYSTEM LEAKAGE TEST

Tools Required

124 589 15 21 00 Tester

Test Procedure

1. Loosen the cap a little and release pressure and re-

move the cap.

Notice:For the risk of scalding, cap must not be opened

unless the coolant temperature is below 90°C.

2. Fill coolant up to upper edge (arrow) of reservoir.

3. Connect the special tool to the reservoir filler cap and

apply 1.4 bar of pressure.

Tester 124 589 15 21 00

4. If the pressure on the tester drops, check leakage at

the all coolant hoses and pipes and each connec-

tions. Replace or retighten if necessary.

Page 400 of 2053

M161 ENGINE COOLING 1D2 -- 5

D AEW OO M Y_2000

MAINTENANCE AND REPAIR

ON -- VEHICLE SERVICE

COOLANT DRAIN AND FILL UP

Draning & Filling up Procedure

1. Loosen the cap a little and release pressure and re-

move the cap.

Notice:For the risk of scalding, the cap must not be

opened unless the coolant temperature is below 90°C.

2. Loosen the radiator lower drain cock and drain the

coolant.

Notice:Collect the coolant by using a proper container.

3. Drain the coolant from the crankcase by inserting a

hose (dia. 14mm) onto the drain bolt on the side of

crankcase (exhaust manifold) and by loosening the

plug.

Notice

DJust loosen the drain plug to drain the coolant and do

not remove the plug completely.

DCollect the coolant by using the proper container.