SSANGYONG KORANDO 1997 Service Repair Manual

KORANDO 1997

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57502/w960_57502-0.png

SSANGYONG KORANDO 1997 Service Repair Manual

Trending: automatic transmission, odometer, instrument panel, maintenance schedule, engine, manual transmission, stop start

Page 381 of 2053

1B2 -- 88 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

PISTON RING

Preceding Work: Removal of piston

1 Piston Compression Ring (Top Ring)

2 Piston Compression Ring (2nd Ring)

3 Piston Oil Ring4--

5 Spacer

6SideRail

Page 382 of 2053

M161 ENGINE MECHANICAL 1B2 -- 89

D AEW OO M Y_2000

Replacement Procedure

1. Measure the piston ring’s gap.

EdGfTh

Groove 1 0.20 -- 0.40 mm

End Gap of The

PistonRingGroove 2 0.20 -- 0.40 mmPistonRing

Groove 3 0.20 -- 0.45 mm

GapBetweenGroove 1 0.028 -- 0.060 mmGapBetween

ThePistonand

ThPitRi

Groove 2 0.010 -- 0.045 mm

The Piston RingGroove 3 0.010 -- 0.045 mm

Notice:If out of specification, replace the piston ring.

2. Remove the piston ring with a pliers.

3. For installation, position the piston ring to be the

‘TOP’ mark on the piston ring upward and arrange the

piston ring ends to be 120°apart.

4. Adjust the hook spring joint in the oil ring 180°away

from the ring end.

Page 383 of 2053

1B2 -- 90 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

OIL PAN

1Bolt

2Bolt

3Bolt

4Bolt5Bolt

6OilPan

7 Gasket

Removal & Installation Procedure

1. Remove the drain plug and drain the oil completely.

2. Unscrew the bolts and remove the oil pan and gasket.

Notice:Arrange the bolts according to each size.

3. Clean the inside of oil pan and sealing surface, then

apply the sealant.

4. Replace the gasket with new one.

5. Install the oil pan with gasket, and tighten each bolt in

specified torque.

6. Check for oil leaks while running the engine.

Page 384 of 2053

M161 ENGINE MECHANICAL 1B2 -- 91

D AEW OO M Y_2000

Oil Circulation

1 Oil Strainer

2OilPump

3OilPan

4 Oil Non-- Return Valve

5 Oil Filter

6 Oil Filter Bypass Valve

7 Main Oil Gallery

8 Closing Ball (φ15mm)

9 Crankshaft

10 Connecting Rod Bearing

11 Crankshaft Bearing

12 Connecting Rod

13 Piston

14 Oil Spray (Piston Crown Area)

15 Non-- Return Valve (Crankcase)16 Oil Supply (To Chain Tensioner)

17 Camshaft

18 Cam Bearing

19 Valve

20 Oil Gallery (Supply Oil to Intake Tappet)

21 Oil Gallery (Supply Oil to Exhaust Tappet)

22 Ball (φ8mm)

23 Camshaft Plug

24 Seal

25 Screw Plug

26 Oil Return Gallery

(Cylinder Head and Crankcase)

27 Oil Return Gallery (Crankcase)

28 End Cover (φ20mm)

29 Oil Return Pipe

Page 385 of 2053

M161 ENGINE MECHANICAL 1B2 -- 97

D AEW OO M Y_2000

OIL PRESSURE RELIEF VALVE

Preceding Work: Removal of oil pan

1 Screw Plug 50 NSm (37 lb-ft) ................

2 Compression Spring3 Guide Pin

4Piston

Removal & Installation Procedure

1. Remove the screw plug (1).

Installation Notice

Tightening Torque

50 NSm (37 lb-ft)

2. Remove the spring (2), guide pin (3) and the piston

(4).

3. Installation should follow the removal procedure in

the reverse order.

Notice:Don’t use the seal for the screw plug.

Page 386 of 2053

1B2 -- 98 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

OIL NON-- RETURN VALVE

Preceding Work: Removal of timing gear case cover

1 Oil Non-- return Valve

Functions

The non -- return valve prevents the oil in the chain ten-

sioner from drying up. In other words, it stops oil-- return-

ing in order to prevent the oil in the chain tensioner from

getting dry. As a result, the chain tensioner can be acti-

vated with oil in itself.

Replacement Procedure

1. Remove the non--return valve using a pliers.

2. Insert new non-- return valve with hand.

Page 387 of 2053

M161 ENGINE MECHANICAL 1B2 -- 99

D AEW OO M Y_2000

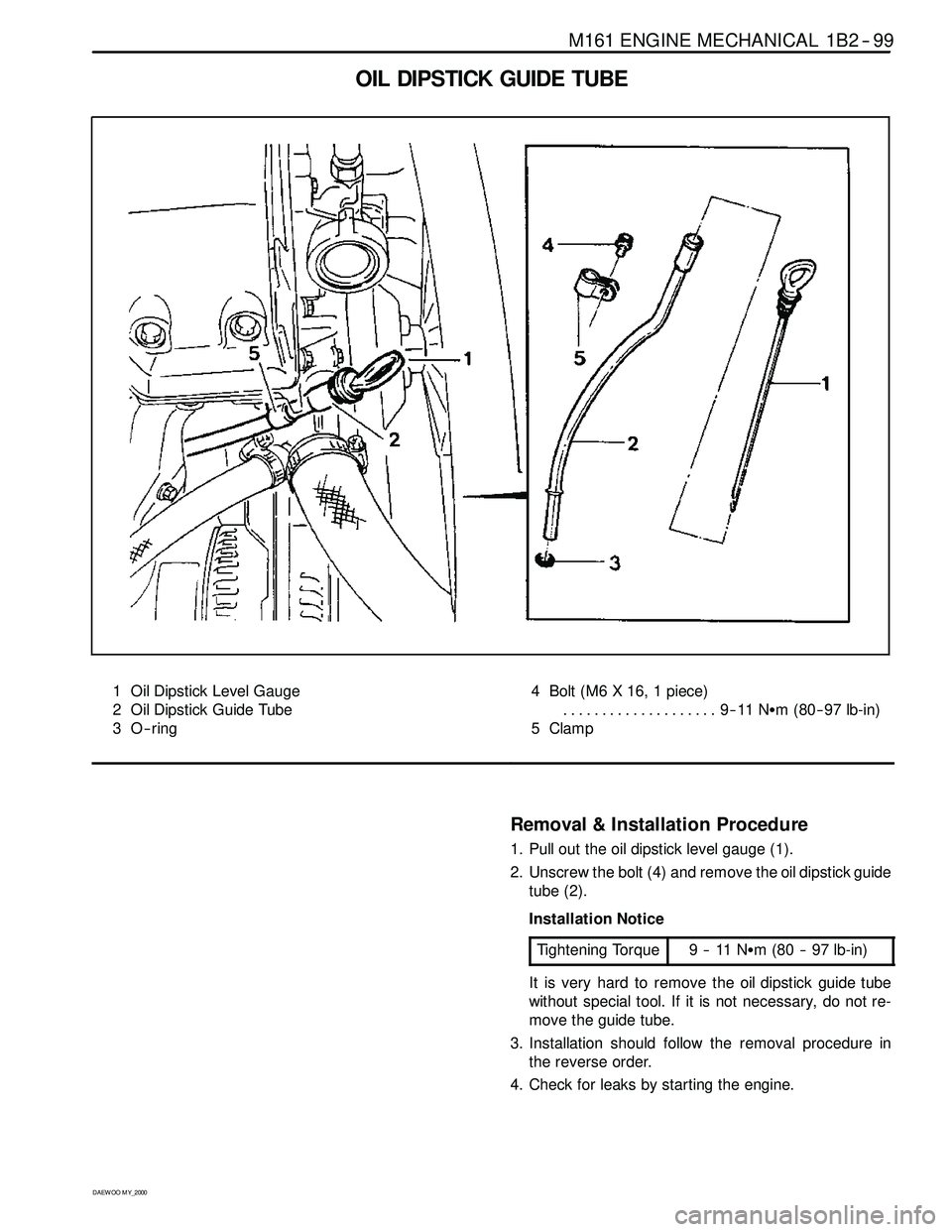

OIL DIPSTICK GUIDE TUBE

1 Oil Dipstick Level Gauge

2 Oil Dipstick Guide Tube

3O--ring4 Bolt (M6 X 16, 1 piece)

9--11 NSm (80-- 97 lb-in) ....................

5 Clamp

Removal & Installation Procedure

1. Pull out the oil dipstick level gauge (1).

2. Unscrew the bolt (4) and remove the oil dipstick guide

tube (2).

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

It is very hard to remove the oil dipstick guide tube

without special tool. If it is not necessary, do not re-

move the guide tube.

3. Installation should follow the removal procedure in

the reverse order.

4. Check for leaks by starting the engine.

Page 388 of 2053

1B2 -- 100 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

UNIT REPAIR

CORE PLUGS IN CRANKCASE

Preceding Work: Draining of the coolant

1 Core Plug Replace.........................

Page 389 of 2053

M161 ENGINE MECHANICAL 1B2 -- 101

D AEW OO M Y_2000

Tools Required

102589001500 Drift

Replacement Procedure

1. Remove the intake and exhaust manifolds.

2. Pull back the core plug until the end of one side

comes out using the screw driver.

3. Pull out the plug carefully using a pliers.

4. Clean the sealing surface and apply Loctite 241.

5. Press in new plug using a drift.

Notice:Wait for about 45minutes before filling the cool-

ant so that the Loctite 241 hardens.

6. Warm up the engine and check the coolant for leaks.

Page 390 of 2053

1B2 -- 102 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

CYLINDER BORE

Group Code Letter and Cylinder Bore Size

EngineGroup Code Letter of CylinderPiston Type to be UsedCylinder Bore Size (mm)

AAorXφ90.906 --φ90.912

XA, X or Bφ90.906 --φ90.912

E23BXorBφ90.912 --φ90.918

X+5X+5φ90.950 --φ90.968

X+10X+10φ91.000 --φ91.018

AAorXφ89.900 --φ90.906

XA, X or Bφ89.906 --φ89.912

E20BXorBφ89.912 --φ89.918

X+5X+5φ89.950 --φ89.968

X+10X+10φ90.000 --φ90.018

Trending: refrigerant type, open gas tank, 2c-2, CD player, jump start terminals, air filter, child restraint