SSANGYONG KORANDO 1997 Service Repair Manual

KORANDO 1997

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57502/w960_57502-0.png

SSANGYONG KORANDO 1997 Service Repair Manual

Trending: open gas tank, air bleeding, brake, battery location, jack points, technical data, tailgate

Page 361 of 2053

1B2 -- 68 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

CHAIN TENSIONER

1 Screw Plug 40 NSm (30 lb-ft) ................

2 Seal

3 Filler Pin

4 Compression Spring

5 Snap Ring6 Thrust Pin

7 Chain Tensioner Housing

72-- 88 NSm (53-- 65 lb-ft) ....................

8Seal

Removal Procedure

1. Position the number 1 cylinder to ATDC 20°.

Notice:Remove the oil filler cap at adjustment position,

and check whether the intake camshaft cam’s lobe (ar-

row) stays in the upper side.

2. Cover the generator with a clean cloth.

3. Release the tension by unscrewing the screw plug

once.

Notice:In case that the tension is reduced by unscrew-

ing the screw plug, reinstall after completely removing

the chain tensioner. If the chain tensioner is tightened

again without completely reducing its tension, then the

snap ring doesn’t return to the original position and the

tension gets exceeded.

Page 362 of 2053

M161 ENGINE MECHANICAL 1B2 -- 69

D AEW OO M Y_2000

4. Carefully unscrew the screw plug (1), and remove the

seal (2).

Notice

DFor the removal of screw plug, be careful that it can

be jumped out due to the force of compression

spring.

DRemove the screw plug only when the seal and com-

pression spring are damaged.

5. Carefully remove the filler pin (3), compression spring

(4), snap ring (5), and the thrust pin (6).

6. Remove the chain tensioner housing (7) and the seal

(8).

Installation Procedure

1. Connect the thrust pin (6) and the snap ring (5) to the

chain tensioner housing (7).

Notice:When connecting the thrust pin, push in the

thrust pin far enough so that it doesn’t protrude at the

chain tensioner housing.

2. Install the chain tensioner housing (7), thrust pin (6),

snap ring (5), and the seal (8).

Installation Notice

Tightening Torque

72 -- 88 NSm (53 -- 65 lb-ft)

3. Insert the compression spring (4) with the filler pin (3)

into chain tensioner housing.

Page 363 of 2053

1B2 -- 70 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

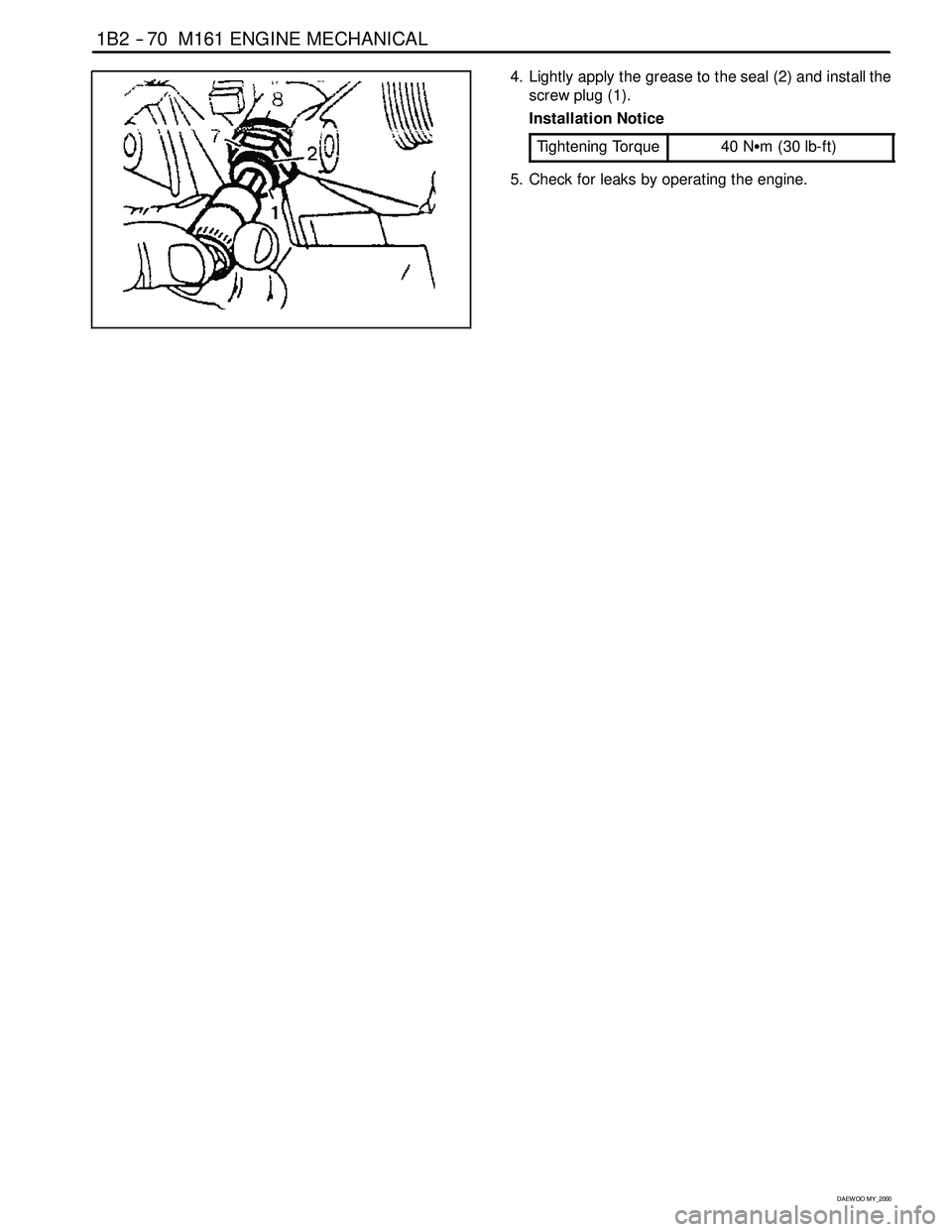

4. Lightly apply the grease to the seal (2) and install the

screw plug (1).

Installation Notice

Tightening Torque

40 NSm (30 lb-ft)

5. Check for leaks by operating the engine.

Page 364 of 2053

M161 ENGINE MECHANICAL 1B2 -- 71

D AEW OO M Y_2000

Sectional View

1 Screw Plug

2 Ball (Nonreturn Valve)

3 Compression Spring

4 Ball Guide

5 Seal (Aluminum)

6 Filler Pin

7 Compression Spring

8 Snap Ring

9 Thrust Pin

10 Ball (Nonreturn Valve)

11 Compression Spring

12 Thrust Piece13 Chain Tensioner Housing

14 Seal

15 Timing Gear Case Cover

16 Cylinder Head

17 Bolt / Washer

18 Tensioning Rail

19 Cylinder Head Gasket

20 Timing Chain

21 Tensioning Rail Base (Sliding Surface)

A Oil Supply Hole

B Chain Tensioner Oil Storage Hole

Page 365 of 2053

1B2 -- 72 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

TIMING CHAIN

Preceding Work: Removal of cylinder head cover

Removal of spark plug

1Pin

2 New Timing Chain

3 Timing Chain (Used)

4 Wedge5Link

6 Center Plate

7 Outer Plate

Page 366 of 2053

M161 ENGINE MECHANICAL 1B2 -- 73

D AEW OO M Y_2000

Tools Required

000589584300 ChainAssembly

111 589 03 15 00 Holding Pin

Replacement Procedure

1. Position the NO.1 cylinder to ATDC 20°.

2. Insert the holding pin 111 589 03 15 00 to the intake

and exhaust camshaft flange not to rotate camshaft.

3. Remove the chain tensioner.

4. Mount the wedges to both sides of the camshaft

sprocket as shown in the figure.

5. Cover the chain housing with a clean cloth, and grind

off the timing chain pin from the intake camshaft

sprocket with the grinder.

Page 367 of 2053

1B2 -- 74 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

6. Remove the outer plate (7) with the screw driver and

remove the link (5).

7. Connect the new timing chain (2) to the used timing

chain (3) with the link (5), center plate (6, thickness

1.6mm), and the outer plate (7).

8. Rotate the crankshaft in the direction if engine revo-

lution by pressing the new timing chain against the

exhaust camshaft sprocket to prevent it to be

tangled.

Notice:Be sure to remove the wedge before cranking

the engine.

9. Take out the used timing chain out from the chain

housing.

10. Connect both separators of the new timing chain

with the link (5) and the center plate (6).

11. Install the jaw (a) and the thrust piece (b) to the as-

sembly tool as shown in the figures.

Page 368 of 2053

M161 ENGINE MECHANICAL 1B2 -- 75

D AEW OO M Y_2000

12. Place the outer plate (7, thickness 1.2mm) inside

the thrust piece (b).

13. Install the chain assembly 000 589 58 43 00 above

the link and tighten the spindle (c) until a block is felt.

14. Place the chain assembly 000 589 58 43 00.

15. Replace the thrust piece (b) as shown in the figure.

16. Install the chain assembly 000 589 58 43 00 to the

link pin and tighten the spindle (c).

Installation Notice

Tightening Torque

30 NSm (22 lb-ft)

Page 369 of 2053

1B2 -- 76 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

17. Rivet the link pin.

Check the condition and it again if necessary.

18. Install the chain tensioner.

Installation Notice

Ti

ghteningScrew Plug40 NSm

(30 lb-ft)

Tightening

TorqueTensioner

Assembly72 -- 88 NSm

(53 -- 65 lb-ft)

19. Check the camshaft timing position.

Page 370 of 2053

M161 ENGINE MECHANICAL 1B2 -- 77

D AEW OO M Y_2000

TENSIONING RAIL

Preceding Work: Removal of cylinder head

1 Sliding Rail Pin

2 Sliding Rail3 Timing Gear Case Cover

Removal & Installation Procedure

1. Remove the timing gear case cover (3).

Notice:Be careful not to damage the gasket.

2. Remove the sliding rail (1) from the sliding rail pin (2).

Notice

DReplace the plastic guide (2) if it is damaged.

DFor installation, exactly align the plastic guide (2) with

the sliding rail (1).

3. Installation should follow the removal procedure in

the reverse order.

Trending: fuel type, air bleeding, traction control, drain bolt, roof, plugs, head