SSANGYONG KORANDO 1997 Service Repair Manual

KORANDO 1997

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57502/w960_57502-0.png

SSANGYONG KORANDO 1997 Service Repair Manual

Trending: tires, technical data, bulb, ecm, alarm, air filter, 5D2-1

Page 561 of 2053

1B3 -- 12 OM600 ENGINE MECHANICAL

D AEW OO M Y_2000

MAINTENANCE AND REPAIR

ON -- VEHICLE SERVICE

ENGINE ASSEMBLY

Page 562 of 2053

OM600 ENGINE MECHANICAL 1B3 -- 13

D AEW OO M Y_2000

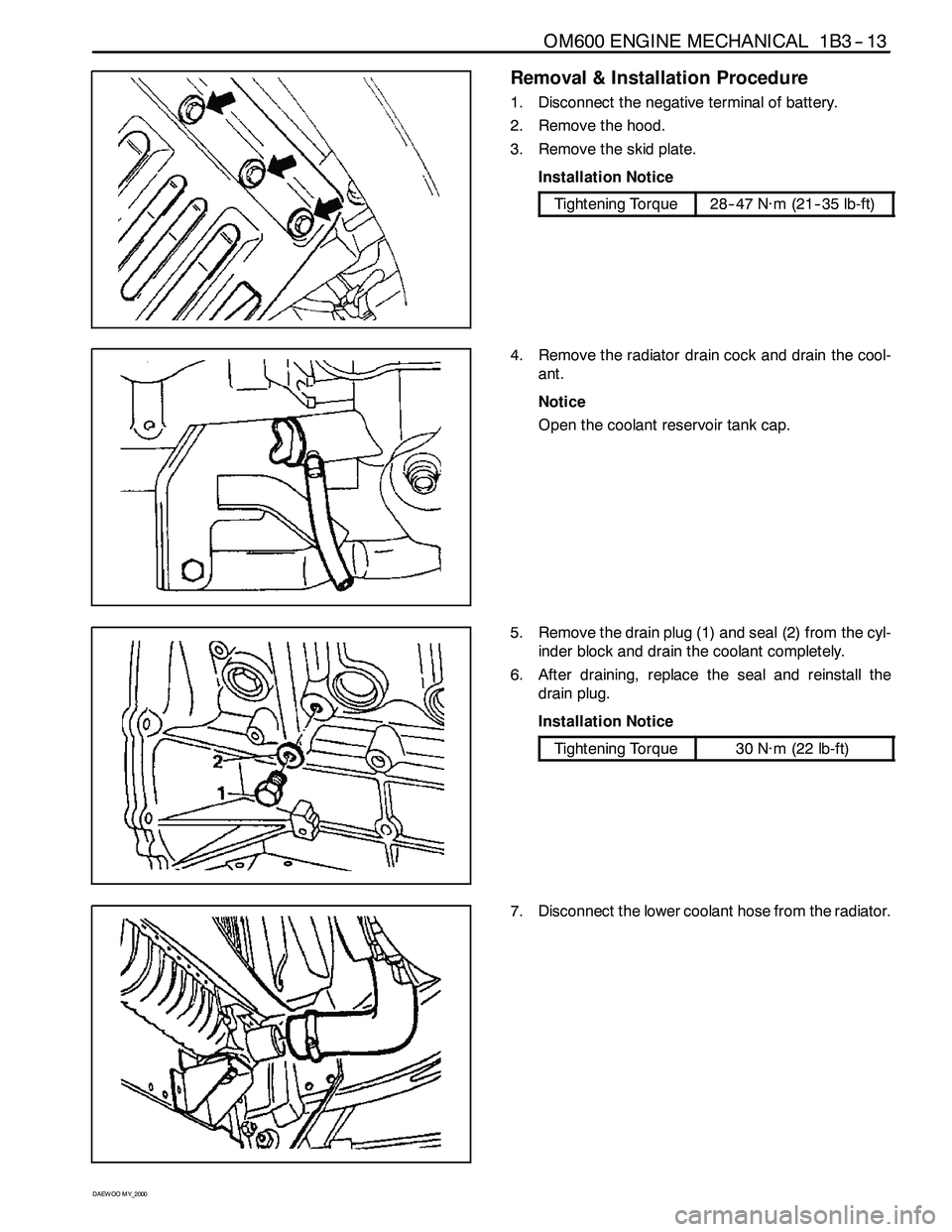

Removal & Installation Procedure

1. Disconnect the negative terminal of battery.

2. Remove the hood.

3. Remove the skid plate.

Installation Notice

Tightening Torque28-- 47 N∙m (21-- 35 lb-ft)

4. Remove the radiator drain cock and drain the cool-

ant.

Notice

Open the coolant reservoir tank cap.

5. Remove the drain plug (1) and seal (2) from the cyl-

inder block and drain the coolant completely.

6. After draining, replace the seal and reinstall the

drain plug.

Installation Notice

Tightening Torque30 N∙m (22 lb-ft)

7. Disconnect the lower coolant hose from the radiator.

Page 563 of 2053

1B3 -- 14 OM600 ENGINE MECHANICAL

D AEW OO M Y_2000

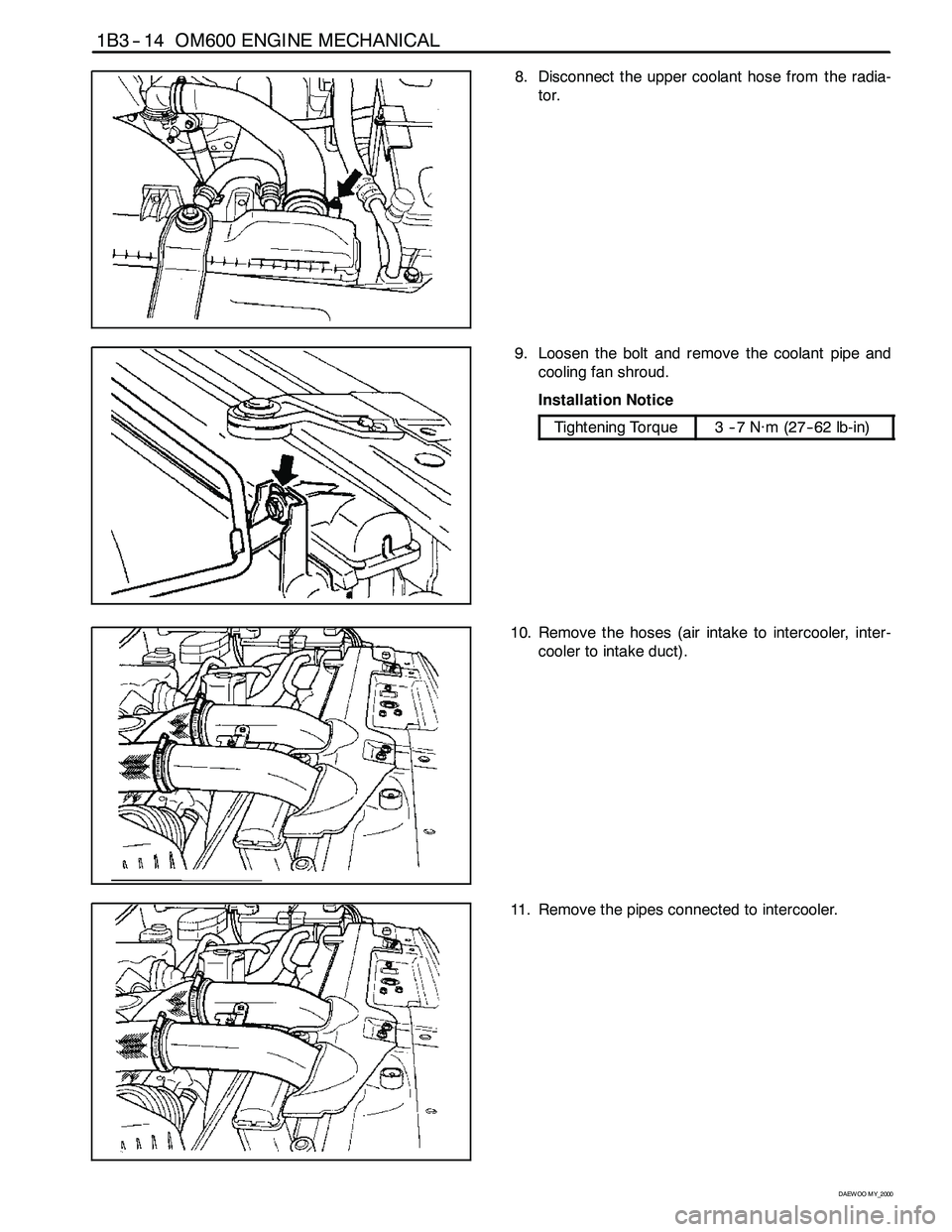

8. Disconnect the upper coolant hose from the radia-

tor.

9. Loosen the bolt and remove the coolant pipe and

cooling fan shroud.

Installation Notice

Tightening Torque3--7N∙m (27-- 62 lb-in)

10. Remove the hoses (air intake to intercooler, inter-

cooler to intake duct).

11. Remove the pipes connected to intercooler.

Page 564 of 2053

OM600 ENGINE MECHANICAL 1B3 -- 15

D AEW OO M Y_2000

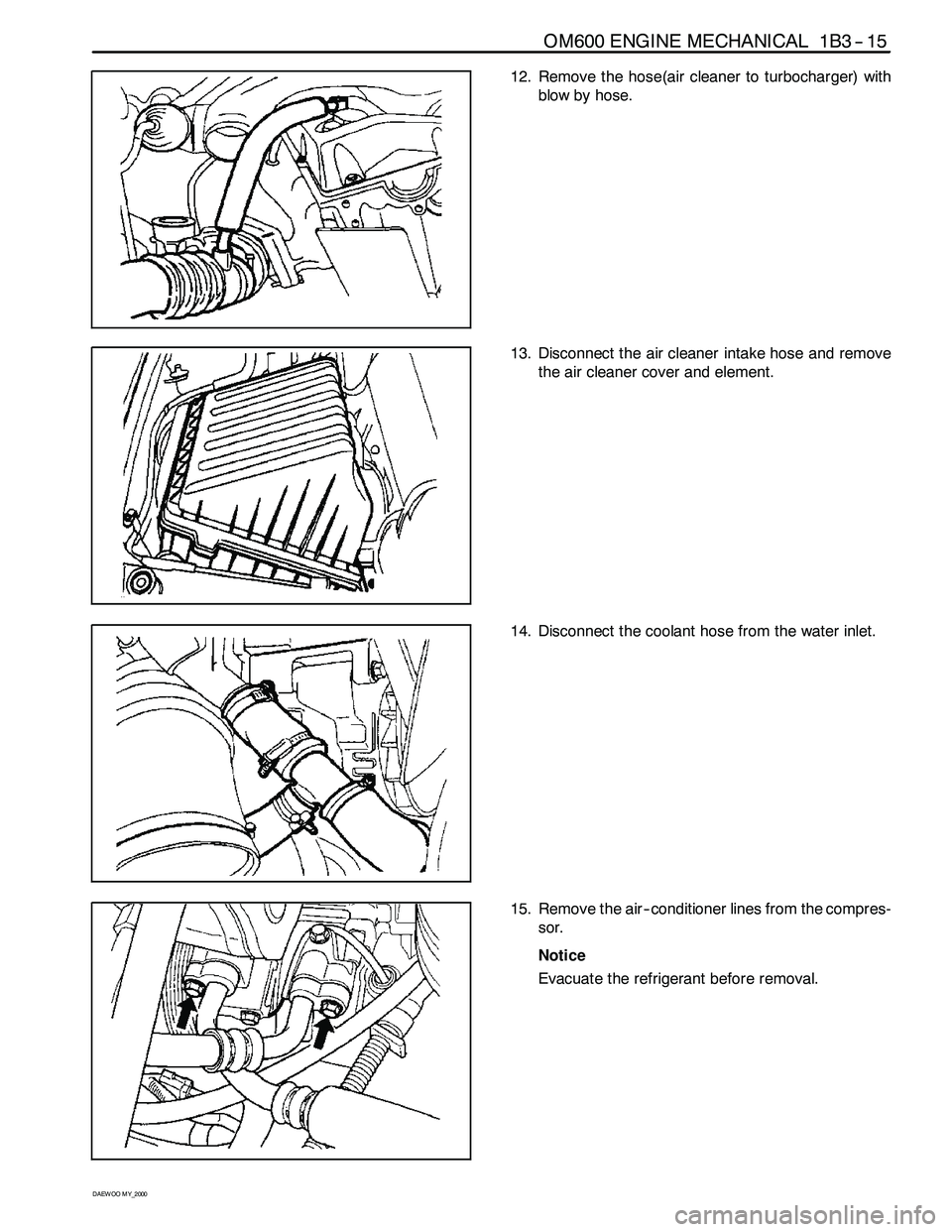

12. Remove the hose(air cleaner to turbocharger) with

blow by hose.

13. Disconnect the air cleaner intake hose and remove

the air cleaner cover and element.

14. Disconnect the coolant hose from the water inlet.

15. Remove the air -- conditioner lines from the compres-

sor.

Notice

Evacuate the refrigerant before removal.

Page 565 of 2053

1B3 -- 16 OM600 ENGINE MECHANICAL

D AEW OO M Y_2000

16. Remove the power steering pump lines.

Notice

Completely drain the fluid.

17. Disconnect the fuel feed line with prefilter from the

feed pump on injection pump.

18. Vehicle with automatic transmission.

Remove the hydraulic lines (19, 20) from oil cooler

(2).

19. Disconnect the engine harness.

20. Disconnect the preheating time relay cable.

Page 566 of 2053

OM600 ENGINE MECHANICAL 1B3 -- 17

D AEW OO M Y_2000

21. Remove the fuel lines from the fuel filter and cover

the filter with plug.

22. Disconnect the brake booster hose from vacuum

pump.

23. Disconnect the other vacuum lines.

24. Disconnect the ground cable.

25. Disconnect the generator wires.

26. Disconnect the starter motor wires and remove the

starter motor.

Page 567 of 2053

1B3 -- 18 OM600 ENGINE MECHANICAL

D AEW OO M Y_2000

27. Disconnect the preheating time relay sensor plug.

28. Disconnect the coolant temperature sensor plug.

29. Disconnect the accelerator cable from the control

linkage.

Installation Notice

Tightening Torque8--18 N∙m (6 -- 13 lb-ft)

30. Loosen the connection of control pressure cable (an

arrow) used in auto transmisson.

Page 568 of 2053

OM600 ENGINE MECHANICAL 1B3 -- 19

D AEW OO M Y_2000

31. Separate the exhaust pipe flange from the turbo

charger.

Installation Notice

Tightening Torque30 N∙m (22 lb-ft)

32. Loosen the installing bolt of clutch release cylinder

and remove the clutch release cylinder.

Installation Notice

Tightening Torque20-- 34 N∙m (15-- 25 lb-ft)

33. Disconnect the exhaust pipe flange from the ex-

haust manifold.

Installation Notice

Tightening Torque30 N∙m (22 lb-ft)

34. Remove the propeller shaft from the transmission.

Installation Notice

TighteningTorque

Axle 70-- 80 N∙m

(52--59 lb-ft)

TighteningTorqueT/C 81 -- 89 N∙m

(60--66 lb-ft)

35. Remove the shift control cable.

36. Remove the transmission.

Page 569 of 2053

1B3 -- 20 OM600 ENGINE MECHANICAL

D AEW OO M Y_2000

37. Loosen the engine mounting bracket nut.

Installation Notice

Tightening Torque50-- 75 N∙m (37-- 55 lb-ft)

38. Remove the engine assembly from the vehicle by

using a hoist or crane.

39. Installation should follow the removal procedure in

the reverse order.

Page 570 of 2053

OM600 ENGINE MECHANICAL 1B3 -- 21

D AEW OO M Y_2000

POLY V-- BELT

1 Nut 23N∙m (17 lb-ft) .......................

2 Tensioning Lever

3Bolt4Spring

5 Tensioning Lever

6PolyV--Belt

Trending: washer fluid, technical specifications, service reset, remote start, jack points, START CIRCUIT, oil dipstick