ignition switch SSANGYONG KORANDO 1997 Service Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 999 of 2053

SSANGYONG MY2002

4F-16 ABS AND TCS

1. Install the scan tool.

2. Turn ignition switch to ON.

3. Select the Data List mode.

Is the scan tool receiving data from the electronic

brake control module (EBCM)?

Check the display.

Are there any current DTCs displayed?

1. Turn the ignition to LOCK for 10 seconds.

2. Turn the ignition to ON and observe the ABS

indicator.

Does the indicator light for 2 seconds and then go off?

Check the ABS indicator.

Did the ABS indicator turn on and stay on?

Check whether the vehicle is equipped with traction

control.

Is the vehicle equipped with traction control?

1. Turn the ignition to LOCK for 10 seconds.

2. Turn the ignition to ON and observe the TCS

indicator.

Does the indicator light for 2 seconds and then go off?

1. Turn the ignition to LOCK.

2. Disconnect the EBCM harness connector.

3. Turn the ignition to ON.

4. Use a digital voltmeter (DVM) to measure the

voltage from ground to terminal 1 and 50 of the

EBCM harness connector.

Is the voltage equal to the specified value?

1. Turn the ignition to LOCK.

2. Use a DVM to measure the resistance from the EBCM

harness connector, terminals 28 and 29 to ground.

Is the resistance equal to the specified value?

Repair the open in the circuit that failed.

Is the repair complete?

Use a DVM to measure the resistance between

terminal 46 of the EBCM harness connector and

terminal 8 of the data link connector (DLC).

Is the resistance below the specified value?

Replace the ABS unit.

Is the repair complete?

Repair the open or high resistance in circuit BrG

between terminal 11 of the EBCM harness connector

and terminal 13 of the DLC.

Is the repair complete?

Perform the road test described above.

Are any DTCs set? Step

1

2

3

4

5

6

7

8

9

10

11

12

13

Diagnostic Circuit Check

Action Yes

Go to Step 2

Refer to the

applicable DTC

table

Go to Step 5

Go to “ABS

Indicator Lamp

Illuminated

Constantly”

Go to Step 6

Go to Step 13

Go to Step 8

Go to Step 10

System OK

Go to Step 11

System OK

Go to Step 1

Go to the table

for the DTCNo

Go to Step 7

Go to Step 3

Go to Step 4

Go to

“ABS Indicator

Lamp Inopera-

tive

Go to Step 13

Go to “Traction

Control System

Indicator Lamp

Inoperative”

Go to “Power

Supply to

Control Mod-

ule, No DTCs

Stored

Go to Step 9

-

Go to Step 12

-

-

System OK Value(s)

-

-

-

-

-

-

11 - 14 v

≈ 0 Ω

-

2 Ω

-

-

-

Page 1001 of 2053

SSANGYONG MY2002

4F-18 ABS AND TCS

ABS INDICATOR LAMP INOPERATIVE

KAA4F120

Circuit Description

Battery voltage is supplied to the ABS warning lamp

with the ignition switch in the ON or START positions.

The warning lamp can be activated only by the ABS

control module internally supplying ground to terminal

20 or by the shorting bar in the ABS module connector

if the connector is disconnected from the module.

Diagnosis

This procedure checks for a problem in the wiring, a

faulty ground, a voltage supply problem, a burned out

indicator lamp, or a contact problem in a connector.

Cause(s)

A fuse has blown.

The indicator lamp has burned out.

There is a corroded or broken connector terminal.

There is a faulty ground connection.

There is a broken wire in a wiring harness.

The EBCM is faulty.Test Description

The number(s) below refer to step(s) on the diagnostic

table.

1. This test checks for any DTCs that may cause

the ABS indicator lamp to be inoperative.

2. This test verifies an inoperative lamp condition.

3. This test checks for voltage on the lamp circuit.

4. This begins a series of tests of the circuit from

the indicator lamp to the EBCM and ground.

19. This begins a series of tests of the voltage supply

circuits that power the indicator lamp.

Page 1002 of 2053

ABS AND TCS 4F-19

SSANGYONG MY2002

Step

1

2

3

4

5

6

7

8

9

10

11

12

13

ABS Indicator Lamp Inoperative

Action Yes

Go to the chart

for the DTC

Go to

“Intermittents

and Poo Con-

nections”

Go to Step 4

Go to Step 5

Go to Step 6

System OK

System OK

Go to Step 10

System OK

Go to Step 11

System OK

Go to Step 14

System OKNo

Go to Step 2

Go to Step 3

Go to Step 19

Go to Step 8

Go to Step 7

-

-

Go to Step 9

-

Go to Step 12

-

Go to Step 13

- Value(s)

Install the scan tool and check for any DTCs.

Is any DTC set?

1. Turn the ignition to LOCK.

2. Disconnect the scan tool.

3. Turn the ignition to ON.

4. Observe the ABS indicator lamp.

Does the lamp illuminate for about 2 seconds, then

turn off?

With the ignition still ON, observe the oil pressure

lamp.

Is the oil pressure lamp illuminated?

1. Turn the ignition to LOCK.

2. Disconnect the connector from the electronic brake

control module (EBCM).

3. Turn the ignition switch to ON.

Does the ABS indicator illuminate?

1. Turn the ignition to LOCK.

2. Examine terminals 19 and 31 at the EBCM connec-

tor on both the ABS wiring harness and on the

EBCM.

Is there a poor connection at any of these terminals?

Repair the faulty terminals or replace the ABS unit, as

required.

Is the repair complete?

Replace the ABS unit.

Is the repair complete?

1. Turn the ignition to LOCK.

2. Disconnect the wire from the negative battery

terminal.

3. Measure the resistance between the negative

battery wire, which is attached to ground, and the

shorting bar in the EBCM connector.

Is the resistance equal to the specified value?

Repair the open or high resistance in the circuit from

EBCM connector, terminal 19 to ground G205.

Is the repair complete?

1. Remove the I/P cluster.

2. Remove and check the ABS indicator bulb. Is the

bulb burned out?

1. Replace the ABS indicator bulb.

2. Install the I/P cluster.

Is the repair complete?

Check the continuity at the I/P cluster connector

terminal D7.

Is the continuity equal to the specified value?

Repair the contact at the I/P cluster connector terminal

D7.

Is the repair complete?

-

-

-

-

-

-

-

≈ 0 Ω

-

-

-

≈ 0 Ω

-

Page 1013 of 2053

SSANGYONG MY2002

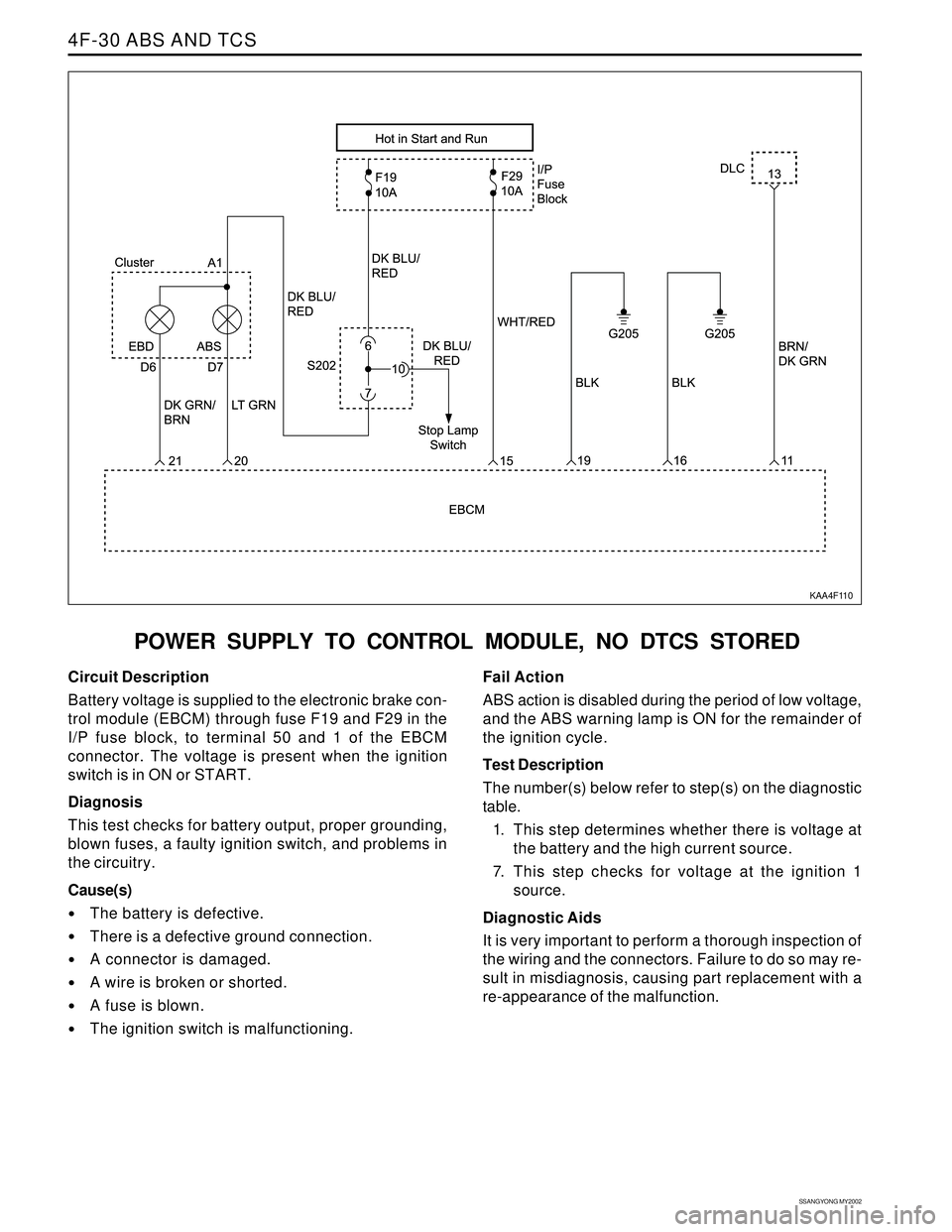

4F-30 ABS AND TCS

POWER SUPPLY TO CONTROL MODULE, NO DTCS STORED

KAA4F110

Circuit Description

Battery voltage is supplied to the electronic brake con-

trol module (EBCM) through fuse F19 and F29 in the

I/P fuse block, to terminal 50 and 1 of the EBCM

connector. The voltage is present when the ignition

switch is in ON or START.

Diagnosis

This test checks for battery output, proper grounding,

blown fuses, a faulty ignition switch, and problems in

the circuitry.

Cause(s)

The battery is defective.

There is a defective ground connection.

A connector is damaged.

A wire is broken or shorted.

A fuse is blown.

The ignition switch is malfunctioning.Fail Action

ABS action is disabled during the period of low voltage,

and the ABS warning lamp is ON for the remainder of

the ignition cycle.

Test Description

The number(s) below refer to step(s) on the diagnostic

table.

1. This step determines whether there is voltage at

the battery and the high current source.

7. This step checks for voltage at the ignition 1

source.

Diagnostic Aids

It is very important to perform a thorough inspection of

the wiring and the connectors. Failure to do so may re-

sult in misdiagnosis, causing part replacement with a

re-appearance of the malfunction.

Page 1015 of 2053

SSANGYONG MY2002

4F-32 ABS AND TCS

Step

15

16

17

18

19

20

21

22

23

Power Supply to Control Module, No DTCs Stored (Cont’d)

Action

Go to Step 17

System OK

Go to Step 19

System OK

Go to Step 20

Go to Step 21

System OK

System OK

System OKGo to Step 16

-

Go to Step 18

-

Go to Step 23

Go to Step 22

-

-

- 11 - 14v

-

11 - 14v

-

≈ 0 Ω

-

-

-

-

1. Disconnect the EBCM connector from the EBCM.

2. Turn the ignition to ON.

3. Check for the presence of battery voltage between

ground and terminal 20 and 21.

Is the voltage equal to the specified value?

1. Turn the ignition switch to OFF.

2. Trace the RW wires between terminal 20 and 21 of

the EBCM connector to fuse F30 of the I/P fuse

block.

3. Repair the open in this circuit.

Is the repair complete?

Check the voltage between ground and terminal 1 of

the EBCM connector.

Is the voltage equal to the specified value?

1. Turn the ignition switch to OFF.

2. Repair the circuit RW between terminal 1 of the

ABS harness EBCM connector to fuse F29 in the I/

P fuse block.

Is the repair complete?

1. Turn the ignition to OFF.

2. Check the resistance between ground and terminals

16 and 19 of the EBCM connector.

Is the resistance equal to the specified value?

Examine terminals 20, 21, 1, 19 and 16 of the EBCM

connector.

Is there a defective terminal?

Repair the defective terminal or replace the connector

or wiring harness, as required.

Is the repair complete?

Replace the ABS unit.

Is the repair complete?

Repair the defective ground connection.

Is the repair complete?

Value(s) Yes No

Page 1019 of 2053

SSANGYONG MY2002

4F-36 ABS AND TCS

SELF-DIAGNOSTICS

Important: The electronic brake control module (EBCM)

turns the valve relay off when a diagnostic trouble code

(DTC) is set. The scan tool will indicate that the valve

relay is off when it is used to monitor the data list. This

is normal and should not be considered a mal-function.

The EBCM performs system self-diagnostics and can

detect and often isolate system malfunctions. When it

detects a malfunction, the EBCM sets a DTC that repre

sents the malfunction, turns on the ABS and/or the

TCS indicators in most instances, and may disable the

ABS and/or the TCS functions, as necessary, for the

duration of the ignition cycle.

Once each ignition cycle, the EBCM performs an auto-

matic test when the vehicle reaches 2.75 km/h (1.7

mph). In the course of this test, the system cycles

each valve solenoid and the pump motor, along with

the necessary relays, to check component operation.

If the EBCM detects any malfunctions, it will set a

DTC as described above.

DISPLAYING DTCs

Tools Required

Scan Tool

DTCs can be read through the use of the scan tool.

CLEARING DTCs

Tools Required

Scan Tool

The diagnostic trouble codes (DTCs) in the electronic

brake control module (EBCM) memory are erased in

one of two ways:

Use the scan tool “Clear DTCs” selection.

After 249 DTC-free ignition cycles.

These two methods are detailed below. Be sure to verify

the proper system operation and, the absence of DTCs

when the clearing procedure is completed.The EBCM will not permit DTC clearing until all DTCs

have been displayed. Also, DTCs cannot be cleared

by disconnecting the EBCM, disconnecting the battery

cables, or turning the ignition switch to LOCK.

Scan Tool Method

The scan tool can clear ABS/TCS system DTCs using

the mass storage cartridge.

1. Install the scan tool and the mass storage

cartridge.

2. Select “Fault Memory”.

3. Select “Clear Fault Memory”.

Clearing the fault memory cannot reset a valve relay

which was shut down when the fault was recognized.

Changes are possible only after the fault has been elimi-

nated and the next ignition cycle has begun.

Ignition Cycle Default

A DTC is erased from memory after 249 ignition cycles

without any reappearance of that malfunction.

INTERMITTENTS AND POOR

CONNECTIONS

As with most electronic systems, intermittent malfunc

tions may be difficult to diagnose accurately. The follow-

ing is a method to try to isolate an intermittent

malfunction, especially in wheel speed circuitry.

If an ABS malfunction occurs, the ABS indicator will

illuminate during the ignition cycle in which the

malfunction was detected. If it is an intermittent problem

which seems to have corrected itself (ABS indicator

OFF), a history DTC will be stored. Also stored will be

the history data of the DTC at the time the malfunction

occurred. Use the scan tool modular diagnostic system

to read ABS history data.

Most intermittents are caused by faulty electrical con

nections or wiring, although a sticking relay or solenoid

can occasionally be at fault.

Page 1022 of 2053

ABS AND TCS 4F-39

SSANGYONG MY2002

Step

2

3

4

5

6

7

8

9

10

11

12

DTC 03 - Left Front Wheel Speed Sensor Fault (Cont’d)

Action

Go to Step 4

System OK

Go to Step 6

System OK

Go to Step 7

System OK

Go to Step 9

System OK

Go to Step 11

System OK

System OKGo to Step 3

-

Go to Step 5

-

Go to Step 8

-

Go to Step 10

-

Go to Step 12

-

- 1280 - 1920 Ω

-

≈ 70 mv

-

>1v

-

∞

-

>5 Ω

-

-

1. Turn the ignition to LOCK.

2. Disconnect the left rear wheel speed sensor

connector.

3. Use a digital voltmeter (DVM) to measure resis-

tance between the sensor terminals.

Is the resistance within the specified value at approxi-

mately 25-C (77-F)?

Replace the wheel speed sensor.

Is the repair complete?

1. Switch the DVM to the ac millivolt range.

2. Measure the voltage output between the wheel

speed sensor terminals while rotating the wheel

about 1 revolution per second.

Is the output within the specified value?

Replace the speed sensor or the toothed wheel, as

required.

Is the repair complete?

1. Disconnect the harness from the EBCM.

2. Connect a DVM between ground and one terminal of

the wheel speed connector.

3. Turn the ignition to ON.

4. Repeat the above test for the other terminal of the

wheel speed connector.

Is the voltage for either of these terminals within the

specified value?

Repair the short to voltage in the affected circuit.

Is the repair complete?

1. Turn the ignition to LOCK.

2. Measure the resistance to ground from terminal at

the harness EBCM connector.

3. Measure the resistance to ground from terminal 36

at the harness EBCM connector.

Is the resistance at either circuit less than the speci-

fied value?

Repair the short to ground in the affected circuit.

Is the repair complete?

1. Measure the resistance between terminal 10 at the

harness EBCM connector and the harness wheel

speed sensor connector.

2. Measure the resistance between terminal 36 at the

harness EBCM connector and the harness wheel

speed sensor connector.

Is the resistance on either circuit within the specified

value?

Repair the open or the high resistance in the affected

circuit, as required. Be sure to check terminals 2 and 8

of connector C113 and junction J101 and J102.

Is the repair complete?

Replace the ABS unit.

Is the repair complete?

Value(s) Yes No

Page 1026 of 2053

ABS AND TCS 4F-43

SSANGYONG MY2002

Step

2

3

4

5

6

7

8

9

10

11

12

DTC 04 - Right Front Wheel Speed Sensor Fault (Cont’d)

Action

Go to Step 4

System OK

Go to Step 6

System OK

Go to Step 7

System OK

Go to Step 9

System OK

Go to Step 11

System OK

System OKGo to Step 3

-

Go to Step 5

-

Go to Step 8

-

Go to Step 10

-

Go to Step 12

-

- 1280 - 1920 Ω

-

≈ 70 mv

-

>1v

-

∞

-

>5 Ω

-

-

1. Turn the ignition to LOCK.

2. Disconnect the left rear wheel speed sensor

connector.

3. Use a digital voltmeter (DVM) to measure resis-

tance between the sensor terminals.

Is the resistance within the specified value at approxi-

mately 25-C (77-F)?

Replace the wheel speed sensor.

Is the repair complete?

1. Switch the DVM to the ac millivolt range.

2. Measure the voltage output between the wheel

speed sensor terminals while rotating the wheel

about 1 revolution per second.

Is the output within the specified value?

Replace the speed sensor or the toothed wheel, as

required.

Is the repair complete?

1. Disconnect the harness from the EBCM.

2. Connect a DVM between ground and one terminal of

the wheel speed connector.

3. Turn the ignition to ON.

4. Repeat the above test for the other terminal of the

wheel speed connector.

Is the voltage for either of these terminals within the

specified value?

Repair the short to voltage in the affected circuit.

Is the repair complete?

1. Turn the ignition to LOCK.

2. Measure the resistance to ground from terminal 14

at the harness EBCM connector.

3. Measure the resistance to ground from terminal 15

at the harness EBCM connector.

Is the resistance at either circuit less than the speci-

fied value?

Repair the short to ground in the affected circuit.

Is the repair complete?

1. Measure the resistance between terminal 14 at the

harness EBCM connector and the harness wheel

speed sensor connector.

2. Measure the resistance between terminal 15 at the

harness EBCM connector and the harness wheel

speed sensor connector.

Is the resistance on either circuit within the specified

value?

Repair the open or the high resistance in the affected

circuit, as required. Be sure to check terminals 7 and 1

of connector C113 and junction J103 and J104.

Is the repair complete?

Replace the ABS unit.

Is the repair complete?

Value(s) Yes No

Page 1030 of 2053

ABS AND TCS 4F-47

SSANGYONG MY2002

Step

2

3

4

5

6

7

8

9

10

11

12

DTC 05 - Left Rear Wheel Speed Sensor Fault (Cont’d)

Action

Go to Step 4

System OK

Go to Step 6

System OK

Go to Step 7

System OK

Go to Step 9

System OK

Go to Step 11

System OK

System OKGo to Step 3

-

Go to Step 5

-

Go to Step 8

-

Go to Step 10

-

Go to Step 12

-

- 1280 - 1920 Ω

-

≈ 70 mv

-

>1v

-

∞

-

>5 Ω

-

-

1. Turn the ignition to LOCK.

2. Disconnect the left rear wheel speed sensor

connector.

3. Use a digital voltmeter (DVM) to measure resis-

tance between the sensor terminals.

Is the resistance within the specified value at ap-

proximately 25-C (77-F)?

Replace the wheel speed sensor.

Is the repair complete?

1. Switch the DVM to the ac millivolt range.

2. Measure the voltage output between the wheel

speed sensor terminals while rotating the wheel

about 1 revolution per second.

Is the output within the specified value?

Replace the speed sensor or the toothed wheel, as

required.

Is the repair complete?

1. Disconnect the harness from the EBCM.

2. Connect a DVM between ground and one terminal

of the wheel speed connector.

3. Turn the ignition to ON.

4. Repeat the above test for the other terminal of the

wheel speed connector.

Is the voltage for either of these terminals within the

specified value?

Repair the short to voltage in the affected circuit.

Is the repair complete?

1. Turn the ignition to LOCK.

2. Measure the resistance to ground from terminal 12

at the harness EBCM connector.

3. Measure the resistance to ground from terminal 13

at the harness EBCM connector.

Is the resistance at either circuit less than the speci-

fied value?

Repair the short to ground in the affected circuit.

Is the repair complete?

1. Measure the resistance between terminal 12 at the

harness EBCM connector and the harness wheel

speed sensor connector.

2. Measure the resistance between terminal 13 at the

harness EBCM connector and the harness wheel

speed sensor connector.

Is the resistance on either circuit within the specified

value?

Repair the open or the high resistance in the affected

circuit, as required. Be sure to check junction J301

and J302.

Is the repair complete?

Replace the ABS unit.

Is the repair complete?

Value(s) Yes No

Page 1034 of 2053

ABS AND TCS 4F-51

SSANGYONG MY2002

Step

2

3

4

5

6

7

8

9

10

11

12

DTC 05 - Left Rear Wheel Speed Sensor Fault (Cont’d)

Action

Go to Step 4

System OK

Go to Step 6

System OK

Go to Step 7

System OK

Go to Step 9

System OK

Go to Step 11

System OK

System OKGo to Step 3

-

Go to Step 5

-

Go to Step 8

-

Go to Step 10

-

Go to Step 12

-

- 1280 - 1920 Ω

-

≈ 70 mv

-

>1v

-

∞

-

>5 Ω

-

-

1. Turn the ignition to LOCK.

2. Disconnect the left rear wheel speed sensor

connector.

3. Use a digital voltmeter (DVM) to measure resis-

tance between the sensor terminals.

Is the resistance within the specified value at ap-

proximately 25-C (77-F)?

Replace the wheel speed sensor.

Is the repair complete?

1. Switch the DVM to the ac millivolt range.

2. Measure the voltage output between the wheel

speed sensor terminals while rotating the wheel

about 1 revolution per second.

Is the output within the specified value?

Replace the speed sensor or the toothed wheel, as

required.

Is the repair complete?

1. Disconnect the harness from the EBCM.

2. Connect a DVM between ground and one terminal

of the wheel speed connector.

3. Turn the ignition to ON.

4. Repeat the above test for the other terminal of the

wheel speed connector.

Is the voltage for either of these terminals within the

specified value?

Repair the short to voltage in the affected circuit.

Is the repair complete?

1. Turn the ignition to LOCK.

2. Measure the resistance to ground from terminal 38

at the harness EBCM connector.

3. Measure the resistance to ground from terminal 11

at the harness EBCM connector.

Is the resistance at either circuit less than the speci-

fied value?

Repair the short to ground in the affected circuit.

Is the repair complete?

1. Measure the resistance between terminal 38 at the

harness EBCM connector and the harness wheel

speed sensor connector.

2. Measure the resistance between terminal 11 at the

harness EBCM connector and the harness wheel

speed sensor connector.

Is the resistance on either circuit within the specified

value?

Repair the open or the high resistance in the affected

circuit, as required. Be sure to check junction J303

and J304.

Is the repair complete?

Replace the ABS unit.

Is the repair complete?

Value(s) Yes No