Fuse box SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 157 of 2053

M162 ENGINE ELECTRICAL 1E 1 -- 5

D AEW OO M Y_2000

BATTERY

1 Cable Terminal ( -- )

2 Cable Terminal Cap ( -- )

3 Cable Terminal Cap (+)

4Nut

5 Fuseblink Box

6 Terminal (+)7 Battery holddown Bracket

8 Battery Clamp Bolt

9 Battery

10 Sub Tray

11 Battery Tray

Removal & Installation Procedure

Notice

DDisconnect the battery negative cable first.

DInsert the clamp bolt (8) into the battery tray hole (11)

from inside when installing.

Page 207 of 2053

1F1 -- 44 M162 ENGINE CONTROLS

D AEW OO M Y_2000

Measure the Fuel Delivery from the Fuel Pump

1. Disconnect the return pipe from fuel distributor and insert the appropriate hose into it.

2. Place the hose end into the beaker with the minimum capacity of 1 Liter

3. Turn the ignition switch to “ON” position.

4. Connect the terminal No. 33 and No. 5 of ECM with a service wire.

5. Measure the fuel delivery from the fuel pump

Specified Value

1 Liter/max. 35 sec.

Notice:Check the fuel filter and fuel line when the fuel delivery is not within specified value.

Measure the Current Consumption of Fuel Pump

1. Remove the fuel pump relay from fuse and relay box in trunk, and turn the ignition switch to “ON” position.

2. Using a multimeter, measure the current consumption by connecting the terminal No. 30 and No. 87 of the fuel

pump relay connector.

Specified Value

5~9A

Notice:Replace the fuel pump relay if the measured value is over 9 A.

Page 416 of 2053

M161 ENGINE ELECTRICAL 1E 2 -- 5

D AEW OO M Y_2000

BATTERY

1 Cable Terminal ( -- )

2 Cable Terminal Cap ( -- )

3 Cable Terminal Cap (+)

4Nut

5 Fuseblink Box

6 Terminal (+)7 Battery holddown Bracket

8 Battery Clamp Bolt

9 Battery

10 Sub Tray

11 Battery Tray

Removal & Installation Procedure

Notice

DDisconnect the battery negative cable first.

DInsert the clamp bolt (8) into the battery tray hole (11)

from inside when installing.

Page 462 of 2053

1F2 -- 44 M161 ENGINE CONTROLS

D AEW OO M Y_2000

Measure the Fuel Delivery from the Fuel Pump

1. Disconnect the return pipe from fuel distributor and insert the appropriate hose into it.

2. Place the hose end into the beaker with the minimum capacity of 1 Liter

3. Turn the ignition switch to “ON” position.

4. Connect the terminal No. 33 and No. 5 of ECM with a service wire.

5. Measure the fuel delivery from the fuel pump

Specified Value

1 Liter/max. 35 sec.

Notice:Check the fuel filter and fuel line when the fuel delivery is not within specified value.

Measure the Current Consumption of Fuel Pump

1. Remove the fuel pump relay from fuse and relay box in trunk, and turn the ignition switch to “ON” position.

2. Using a multimeter, measure the current consumption by connecting the terminal No. 30 and No. 87 of the fuel

pump relay connector.

Specified Value

5~9A

Notice:Replace the fuel pump relay if the measured value is over 9 A.

Page 1575 of 2053

FATC-HAVC 7D-21

SSANGYONG MY2002

KAA7D310

Fault : intake (recirculation/fresh air) door inoperative

Remove the glove box.

Check No. 24 fuse (15A) in the box.

YesNo

Check that it operates toward each direction after

connecting the battery to the 6C terminal of intake

actuator and ground 6A & 6B to the body.

Wiring side connector

Intake actuator is normal.

YesRepair and replace the intake actuator. No

Check intake actuator linkage and door for

proper operation and repair if necessary.Disconnect 20-pin connector from the airconditioner

control unit.

Check current between the intake actuator (6A, 6B)

and the airconditioner control unit (6,7).

Is there current?

YesRepair open wire between the intake actuator

and the control unit. No

Replace the good control unit and re-check. If no

fault, replace the control panel.

Measure voltage between 6c terminal positive pole

(+) and body (-).

Measured voltage is 12V.

Turn the ignitin switch OFF and disconnect harness

of the intake actuator.

Disconnect 3-pin connector of the intake mode

actuator and turn the ignition switch to ON position.

Page 1576 of 2053

SSANGYONG MY2002

7D-22 FATC-HAVC

Fault : air flow does not change toward panel side.

Remove the center panel of the instrument panel.

Measure voltage between 8I terminal positive pole

(+) and body (-).

Measured voltage is 12V.Check No. 24 fuse (15A) in the fuse box.

Turn the ignition switch OFF and disconnect harness

of the mode actuator.YesNo

Disconnect 8-pin connector of the mode actuator and

turn the ignition switch to ON position.

Check that it operates toward each directions when

ground is connected to terminal (8J, 8H, 8F, 8D, 8B)

of the mode actuator alternatively.

Mode actuator is normal.

YesRepair and replace the mode actuator. No

Check the intake actuator linkage and door

for proper operation and repair if necessary.Disconnect 20-pin connector from the airconditioner

control unit.

Check current between the mode actuator (8J, 8H,

8F, 8D, 8B) and the airconditioner control unit (11,

12, 13, 14, 15).

Is there current?

YesRepair open wire between the mode actuator

and the control unit. No

Replace the good control unit and re-check. If no

fault, replace the control panel.

KAA7D350

Page 1644 of 2053

SSANGYONG MY2002

8B-62 SUPPLEMENTAL RESTRAINTS SYSTEM

KAA8B160

PASSENGER AIRBAG MODULE

Removal and installation Procedure

Caution: The SDM can maintain sufficient voltage

to deploy the airbags for 0.15 seconds after the

Ignition is OFF and the airbag fuse has been

removed. If the airbags are not disconnected, service

cannot begin until one minute has passed after

disconnecting power to the SDM. If the airbags are

disconnected, service can begin immediately

without waiting for one-minute time period to

expire. Failure to temporarily disable the SRS

during service result in unexpected deployment,

personal injury, and otherwise unneeded SRS repair.

1. Disconnect the negative battery cable.

2. Remove the glove box. Refer to Section 9E,

Instrumentation/Driver Information.

3. Disconnect the passenger airbag yellow electrical

connector.

4. Remove two nuts form the airbag bracket.

Installation Notice

5. Remove the passenger airbag module from the

instrument panel by pushing back side of

passenger airbag.

6. Installation should follow the removal procedure

in the reverse order.

Tightening Torque 16 Nm (12 lb-ft)

FRONT SEAT BELT PRETENSIONER

For removal and installation refer to Section 8A, Seat

Belts.

KAA8B210

Page 1652 of 2053

SECTION 9A

BODY WIRING SYSTEM

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless

otherwise noted.

TABLE OF CONTENTS

General Description.............................................9A-2

Wire Color Chart..................................................9A-2

Engine Room Fuse & Relay Box......................... 9A-3

Usage of Fuse in Engine Room Fuse Box.............9A-5

Passenger Room Fuse Box..................................9A-6

Usage of Fuse in Engine Room Fuse Box.............9A-7

Schematic and Routing Diagrams.......................9A-8

Engine Room Fuse & Relay Circuit.......................9A-8

Wiring Harness & Connector &

Ground Location................................................. 9A-11

W/H Engine Room.............................................9A-11W/H Main..........................................................9A-12

W/H Main (Floor)............................................... 9A-14

W/H Roof..........................................................9A-15

W/H Seat Heater................................................9A-16

W/H Door..........................................................9A-17

W/H Tail Gate....................................................9A-18

W/H Air-Conditioner...........................................9A-19

W/H Engine Control (Gasoline)...........................9A-20

W/H Pre-Heating (Diesel)...................................9A-21

W/H Transmission..............................................9A-22

Page 1654 of 2053

BODY WIRING SYSTEM 9A-3

SSANGYONG MY2002

ENGINE ROOM FUSE & RELAY BOX

Position Of Relay And Fuse (Front View)

KAA9A010

Page 1656 of 2053

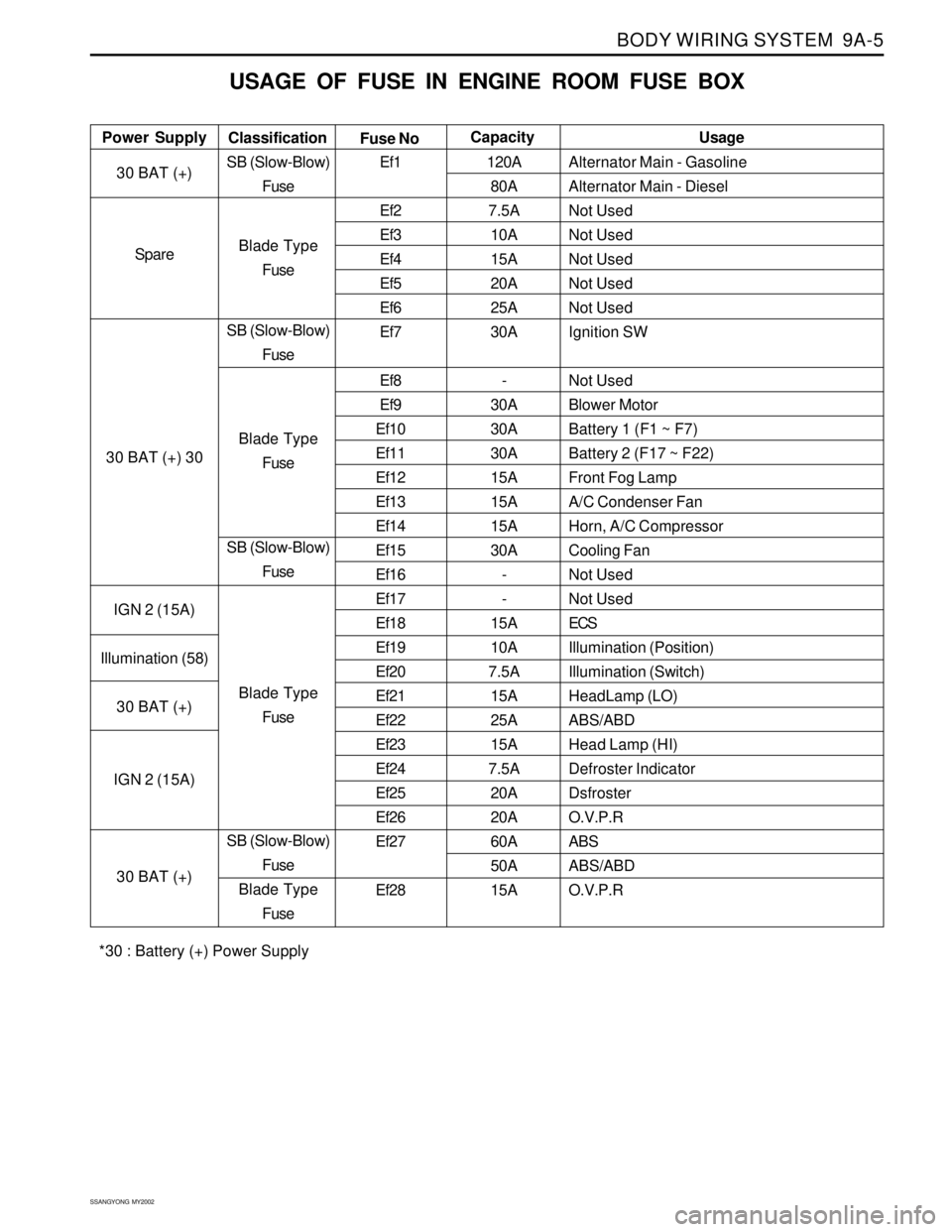

BODY WIRING SYSTEM 9A-5

SSANGYONG MY2002

USAGE OF FUSE IN ENGINE ROOM FUSE BOX

Alternator Main - Gasoline

Alternator Main - Diesel

Not Used

Not Used

Not Used

Not Used

Not Used

Ignition SW

Not Used

Blower Motor

Battery 1 (F1 ~ F7)

Battery 2 (F17 ~ F22)

Front Fog Lamp

A/C Condenser Fan

Horn, A/C Compressor

Cooling Fan

Not Used

Not Used

ECS

Illumination (Position)

Illumination (Switch)

HeadLamp (LO)

ABS/ABD

Head Lamp (HI)

Defroster Indicator

Dsfroster

O.V.P.R

ABS

ABS/ABD

O.V.P.R Power SupplyUsage

Classification

Fuse NoCapacity

30 BAT (+)

Spare

30 BAT (+) 30

IGN 2 (15A)

Illumination (58)

30 BAT (+)

IGN 2 (15A)

30 BAT (+)SB (Slow-Blow)

Fuse

Blade Type

Fuse

SB (Slow-Blow)

Fuse

Blade Type

Fuse

SB (Slow-Blow)

Fuse

Blade Type

Fuse

SB (Slow-Blow)

Fuse

Blade Type

FuseEf1

Ef2

Ef3

Ef4

Ef5

Ef6

Ef7

Ef8

Ef9

Ef10

Ef11

Ef12

Ef13

Ef14

Ef15

Ef16

Ef17

Ef18

Ef19

Ef20

Ef21

Ef22

Ef23

Ef24

Ef25

Ef26

Ef27

Ef28120A

80A

7.5A

10A

15A

20A

25A

30A

-

30A

30A

30A

15A

15A

15A

30A

-

-

15A

10A

7.5A

15A

25A

15A

7.5A

20A

20A

60A

50A

15A

*30 : Battery (+) Power Supply