lock SSANGYONG KORANDO 2013 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 440 of 1336

1116-01

Engine and accessories

Engine has a lot of precise components. The specified tightening torque and correct procedures should

be kept during service works. And, the working area is always clean and well prepared.

When disassembling the engine, related parts (bolts, gaskets, etc.) should be stored as a set.

Carefully read the disassembly and reassembly procedures in this manual before starting the

works.

Clean the components completely with engine oil before assembling if needed.

Fully drain the engine oil, coolant and fuel from the vehicle and seal the inlets with the plugs before

removing the engine.

All the interference should be eliminated before removing the engine. -

-

-

-

Tightening the fastener

When reassembling the parts to G20DF, use the angle tightening as a final step.

1. Clean the mating surfaces before tightening.

2. Place the marks with paint to tighten by angle if the angle wrench is not available. Exhaust system

Wear the protective gloves before removing the exhaust pipe.

The exhaust pipe is very hot immediately after stopping th engine. Check if the exhaust pipe is fully

cooled down before servicing the exhaust system. -

-

Cooling system

Scalding hot coolant and steam could be blown out under pressure, which could cause serious

injury. Never remove the coolant reservoir cap when the engine and the radiator are hot. -

The position and direction of the componets is based on the rear view.

Do not tighten the fasteners with excessive force. Especially, the threads of cylinder block could be

damaged.

The self screw bolt makes the thread itself when tightening it. Do not apply excessive force.

Do not reuse the bolt that has been tightened with angle tightening method.

Page 445 of 1336

Location

Front mounting assembly

Location: Front side of transaxle housing and

front side of sub frame

Location Front mountingRight mounting assembly

Location: Engine block side and body side

member

Location Right mounting

Left mounting assembly

Location: Upper side of transaxle housing and

body side member

Location Left mountingRear mounting assembly

Location: Rear side of transaxle housing and front

side of sub frame

Location Rear mounting

Page 447 of 1336

1) Cylinder Head

Overview

The cylinder head assembly is located on the cylinder block.

This contains the combustion chamber, intake and exhaust ports, valve running housing, and oil gallery.

And, this also contains the water jacket to dissipate the heat from the combustion chamber

Location

Top of cylinder headBottom of cylinder head

Intake sideExhaust side

Page 453 of 1336

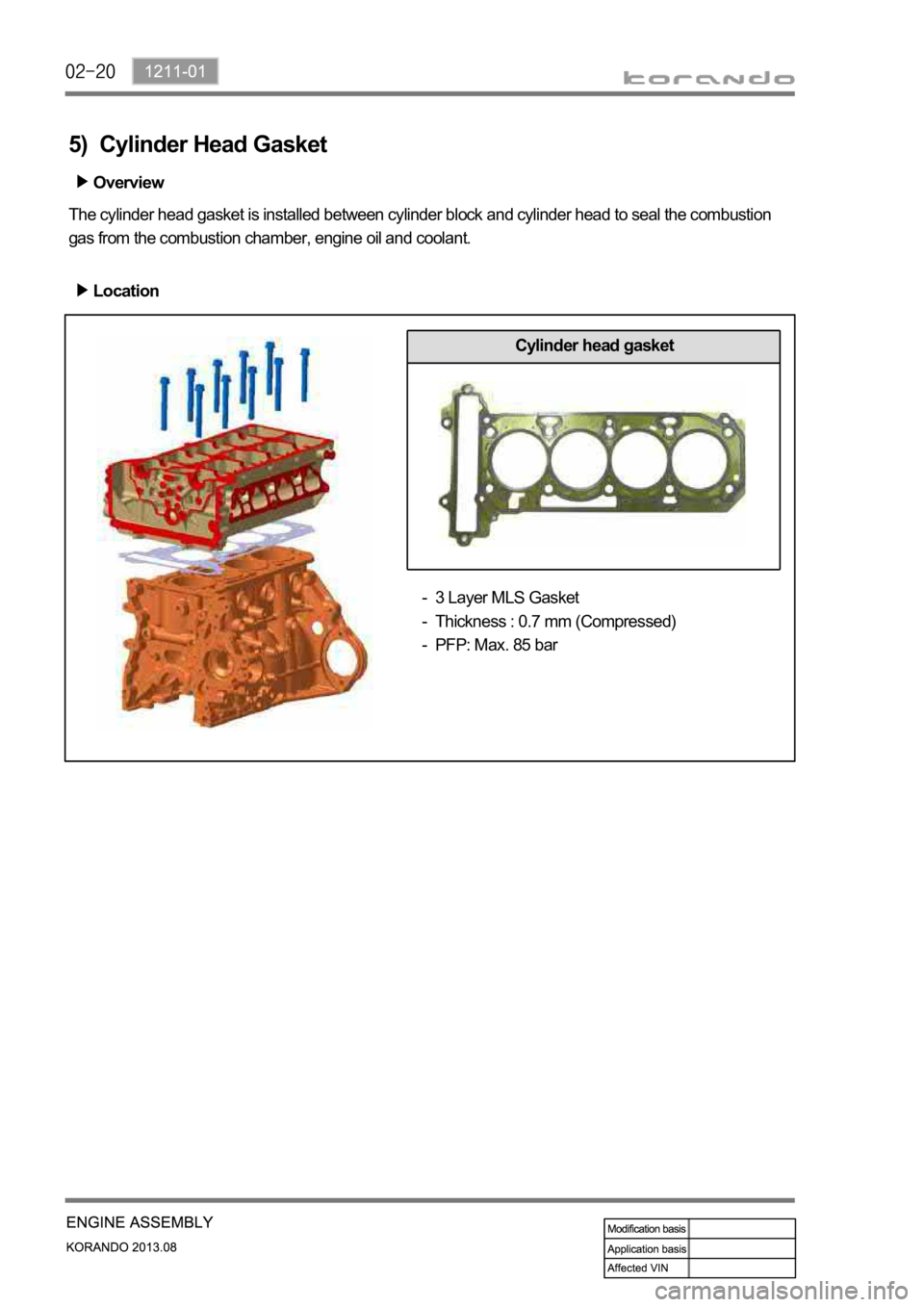

5) Cylinder Head Gasket

The cylinder head gasket is installed between cylinder block and cylinder head to seal the combustion

gas from the combustion chamber, engine oil and coolant.Overview

Location

Cylinder head gasket

3 Layer MLS Gasket

Thickness : 0.7 mm (Compressed)

PFP: Max. 85 bar -

-

-

Page 462 of 1336

1130-13

3) Features of DMF

Reduced vibration noise from the powertrain by blocking the torsional vibrations

Enhanced vehicle silence and riding comforts: reduced engine torque fluctuation

Reduced shifting shocks

Smooth acceleration and deceleration -

-

-

-

4) Advantages of DMF

Improved torque response by using 2-stage type spring: Strengthens the torque response in all

ranges (low, medium, and high speed) by applying respective spring constant at each

range.

Stable revolution of the primary and secondary wheel by using planetary gear: Works as auxiliary

damper against spring changes

Less heat generation due to no direct friction against spring surface: Plastic material is covered on the

spring outer surface

Increased durability by using plastic bushing (extends the lifetime of grease) -

-

-

-

Page 464 of 1336

1130-33

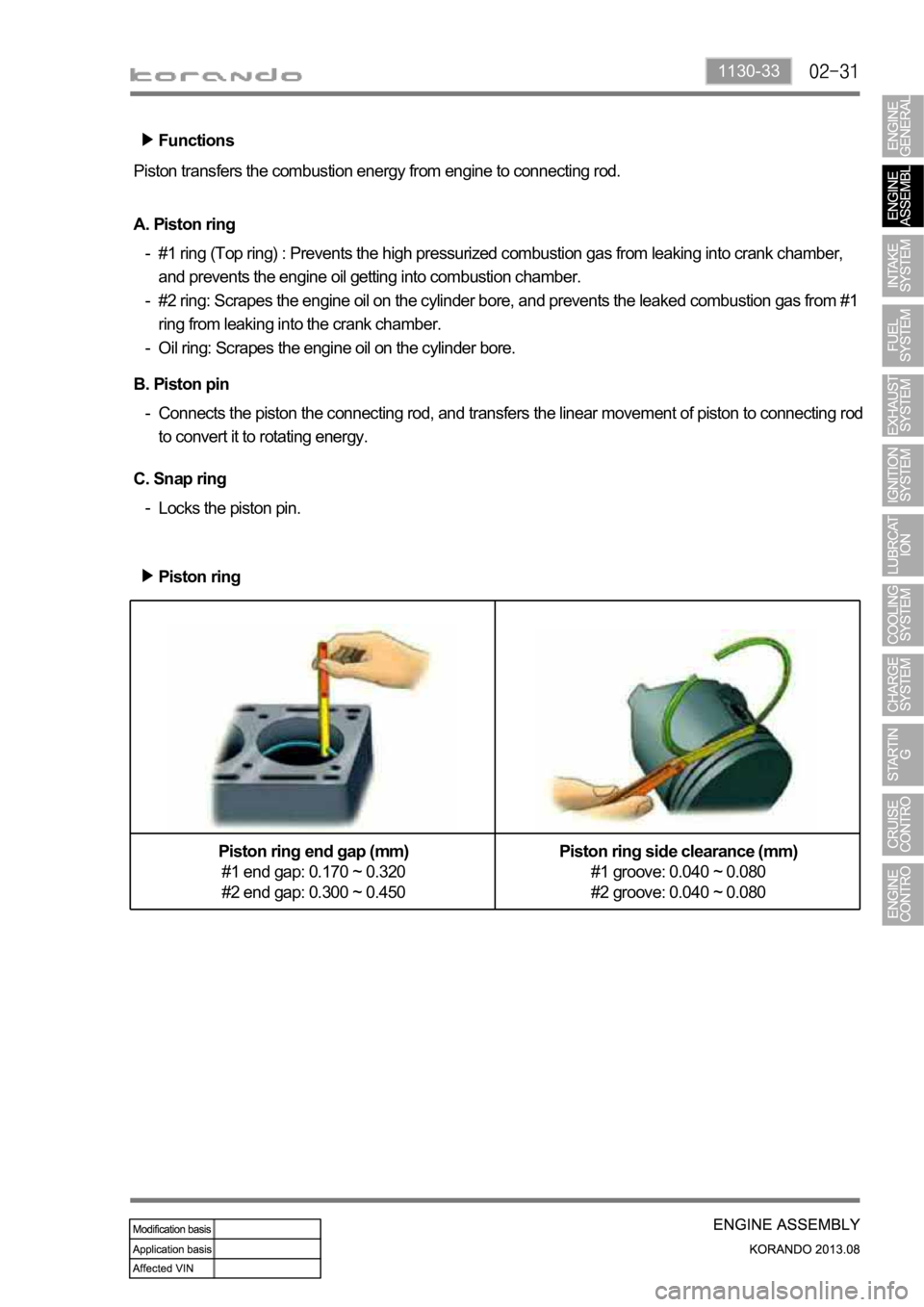

Functions

Piston transfers the combustion energy from engine to connecting rod.

C. Snap ring

Locks the piston pin. - A. Piston ring

#1 ring (Top ring) : Prevents the high pressurized combustion gas from leaking into crank chamber,

and prevents the engine oil getting into combustion chamber.

#2 ring: Scrapes the engine oil on the cylinder bore, and prevents the leaked combustion gas from #1

ring from leaking into the crank chamber.

Oil ring: Scrapes the engine oil on the cylinder bore. -

-

-

B. Piston pin

Connects the piston the connecting rod, and transfers the linear movement of piston to connecting rod

to convert it to rotating energy. -

Piston ring

Piston ring end gap (mm)

#1 end gap: 0.170 ~ 0.320

#2 end gap: 0.300 ~ 0.450Piston ring side clearance (mm)

#1 groove: 0.040 ~ 0.080

#2 groove: 0.040 ~ 0.080

Page 465 of 1336

Assembly mark

Top surface of piston Top surface of cylinder block

Assembling the piston

Install the piston rings with the "X" mark on the ring facing upwards.-

-

-

#1 cylinder

Page 468 of 1336

1130-01

Overview

Crankshaft is installed on the cylinder block. The crankshaft converts the reciprocative movement of

piston to the rotatinal movement.

Layout and Components

Crankshaft

Page 469 of 1336

Bottom of cylinder block Crankshaft sprocket installing surface

Crankshaft lower bearing Crankshaft lower bearing

Selection of crankshaft main bearing

Pin

punch

markColorDiameter of crankshaft

main journal in cylinder

block (mm)

* Blue 62.500 ~ 62.506

** Yellow 62.506 ~ 62.513

*** Red 62.513 ~ 62.519Mark ColorDiameter of

crankshaft main

journal (mm)

B Blue 57.960 ~ 57.965

Y Yellow 57.955 ~ 57.960

R Red 57.950 ~ 57.955

W White 57.945 ~ 57.950

V Violet 57.940 ~ 57.945

Engine

name

Main

journal

bearing

#1 #2 #3 #4 #5

G2 0DF

RRWWR

Page 470 of 1336

1128-01

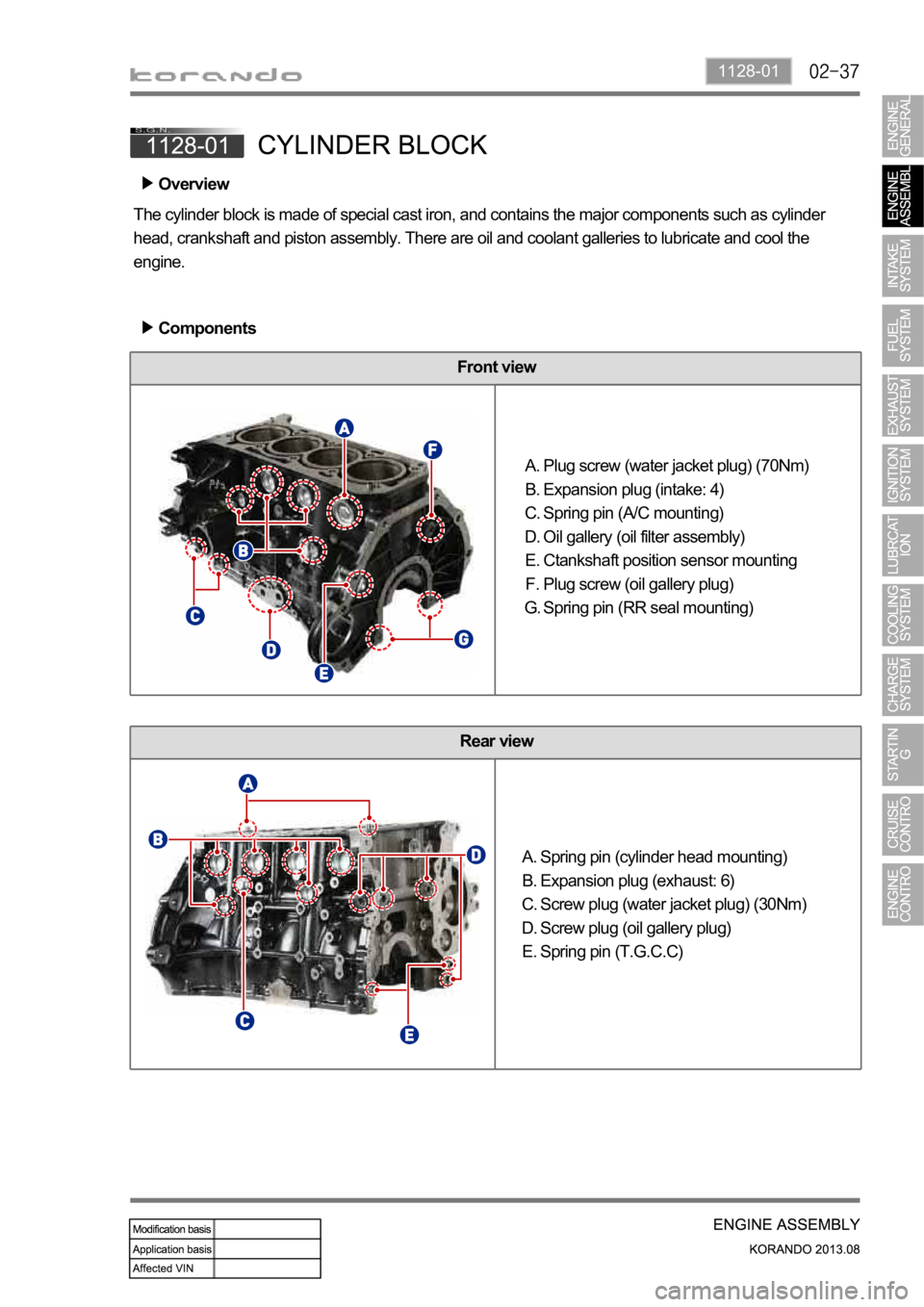

Front view

Rear view

Spring pin (cylinder head mounting)

Expansion plug (exhaust: 6)

Screw plug (water jacket plug) (30Nm)

Screw plug (oil gallery plug)

Spring pin (T.G.C.C) A.

B.

C.

D.

E.

Overview

The cylinder block is made of special cast iron, and contains the major components such as cylinder

head, crankshaft and piston assembly. There are oil and coolant galleries to lubricate and cool the

engine.

Components

Plug screw (water jacket plug) (70Nm)

Expansion plug (intake: 4)

Spring pin (A/C mounting)

Oil gallery (oil filter assembly)

Ctankshaft position sensor mounting

Plug screw (oil gallery plug)

Spring pin (RR seal mounting) A.

B.

C.

D.

E.

F.

G.