SSANGYONG MUSSO 1998 Workshop Owners Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Owners Manual

Trending: alternator belt, glow, bonnet, oil, spark plugs replace, engine oil capacity, charging

Page 91 of 1463

1B1-18 M162 ENGINE MECHANICAL

ALTERNATOR

1 Nut (M8).........................................22.5-27.5 Nm

2 Bolt (M8 x 30, 3 pieces).................22.5-27.5 Nm

3 Bolt (M8 x 40, 1 piece)...................22.5-27.5 Nm

Removal & Installation Procedure

1. Remove the drive belt.

2. Remove the alternator.

3. Unscrew the alternator carrier bolts and remove the carrier.

Installation Notice4 Bolt (M8 x 70, 1 piece)...................22.5-27.5 Nm

5 Bolt (M8 x 75, 1 piece)...................22.5-27.5 Nm

Tightening Torque 10 - 15 Nm

4. Installation should follow the removal procedure in the

reverse order.

Page 92 of 1463

M162 ENGINE MECHANICAL 1B1-19

POWER STEERING PUMP AND A/C BRACKET

Preceding Work : Removal of cooling fan and shroud

1 Vent Hose

2 Bolt (M8 x 91, 2 pieces).................22.5-27.5 Nm

3 Power Steering Pump

4 Bolt (M8 x 105, 4 pieces)...............22.5-27.5 Nm

5 Washer

6 A/C Compressor

7 Bolt (M8 x 40, 3 pieces,

M8 x 95, 2 pieces)..........................22.5-27.5 Nm8 A/C Bracket

9 Gasket ................................................... Replace

10 Bracket

11 Bolt (M8 x 22, 2 pieces).................22.5-27.5 Nm

12 Tensioning Pulley

13 Nut .................................................40.5-49.5 Nm

Page 93 of 1463

1B1-20 M162 ENGINE MECHANICAL

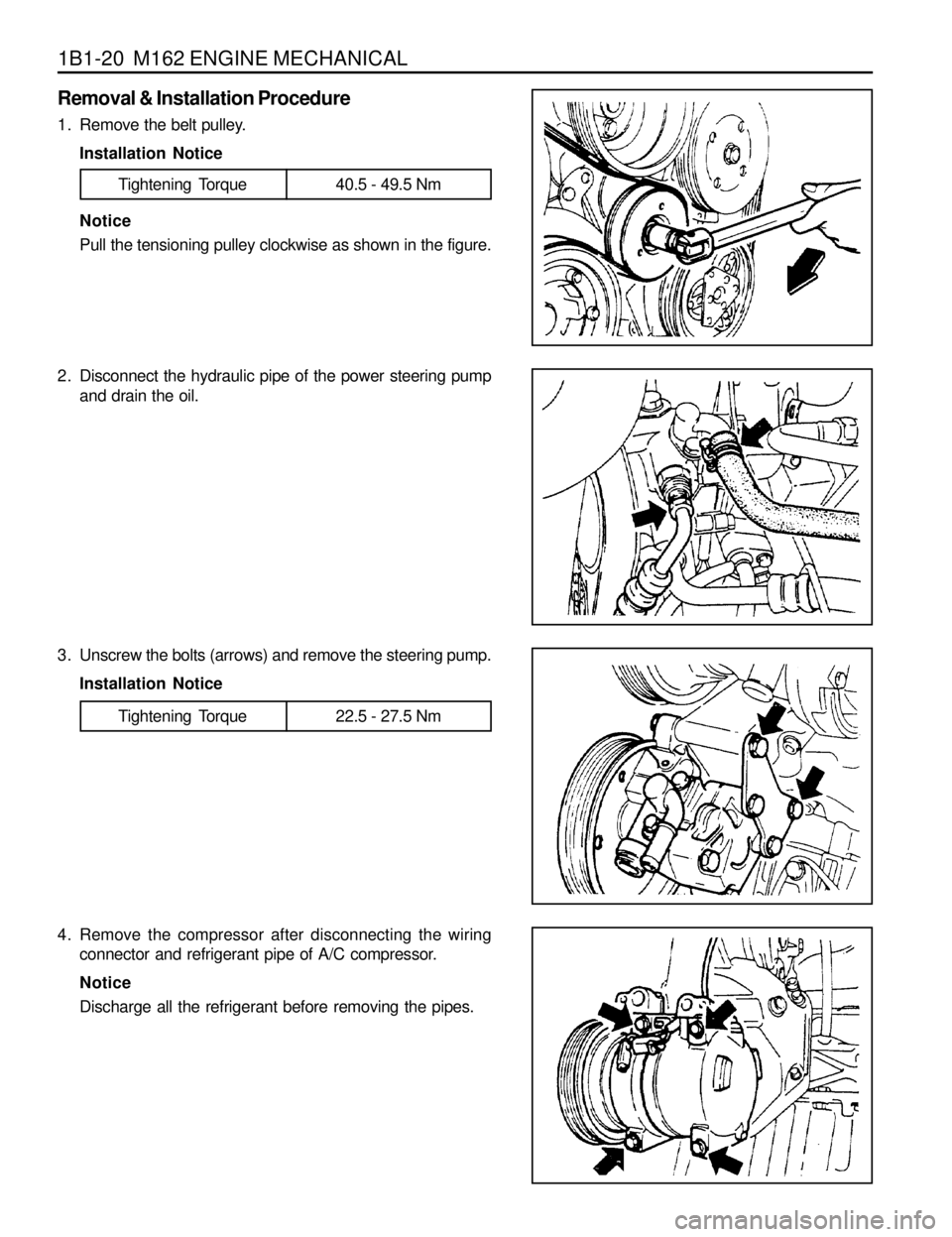

Removal & Installation Procedure

1. Remove the belt pulley.

Installation Notice

2. Disconnect the hydraulic pipe of the power steering pump

and drain the oil.

3. Unscrew the bolts (arrows) and remove the steering pump.

Installation Notice Notice

Pull the tensioning pulley clockwise as shown in the figure.

4. Remove the compressor after disconnecting the wiring

connector and refrigerant pipe of A/C compressor.

Notice

Discharge all the refrigerant before removing the pipes.

Tightening Torque 40.5 - 49.5 Nm

Tightening Torque 22.5 - 27.5 Nm

Page 94 of 1463

M162 ENGINE MECHANICAL 1B1-21

5. Disconnect the vent hose from the A/C bracket.

6. Unscrew all the mounting bolts (arrows) and remove the

A/C bracket and the gasket.

Installation Notice

7. Clean the sealing surface.

8. Replace the gasket with new one.

9. Installation should follow the removal procedure in the

reverse order.

10. Check the oil leakage by operating the engine after

installation.

Tightening Torque 22.5 - 27.5 Nm

Page 95 of 1463

1B1-22 M162 ENGINE MECHANICAL

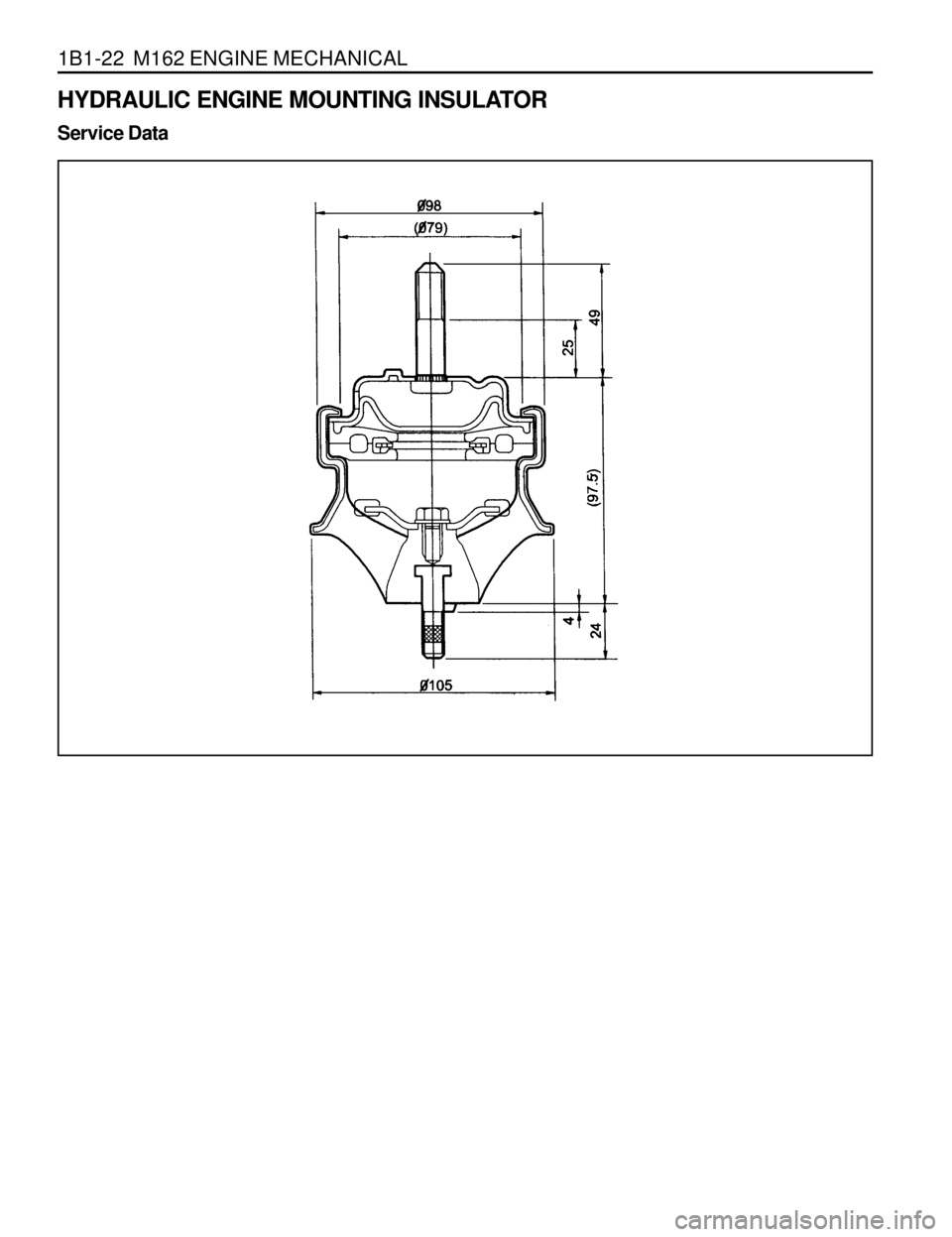

HYDRAULIC ENGINE MOUNTING INSULATOR

Service Data

Page 96 of 1463

M162 ENGINE MECHANICAL 1B1-23

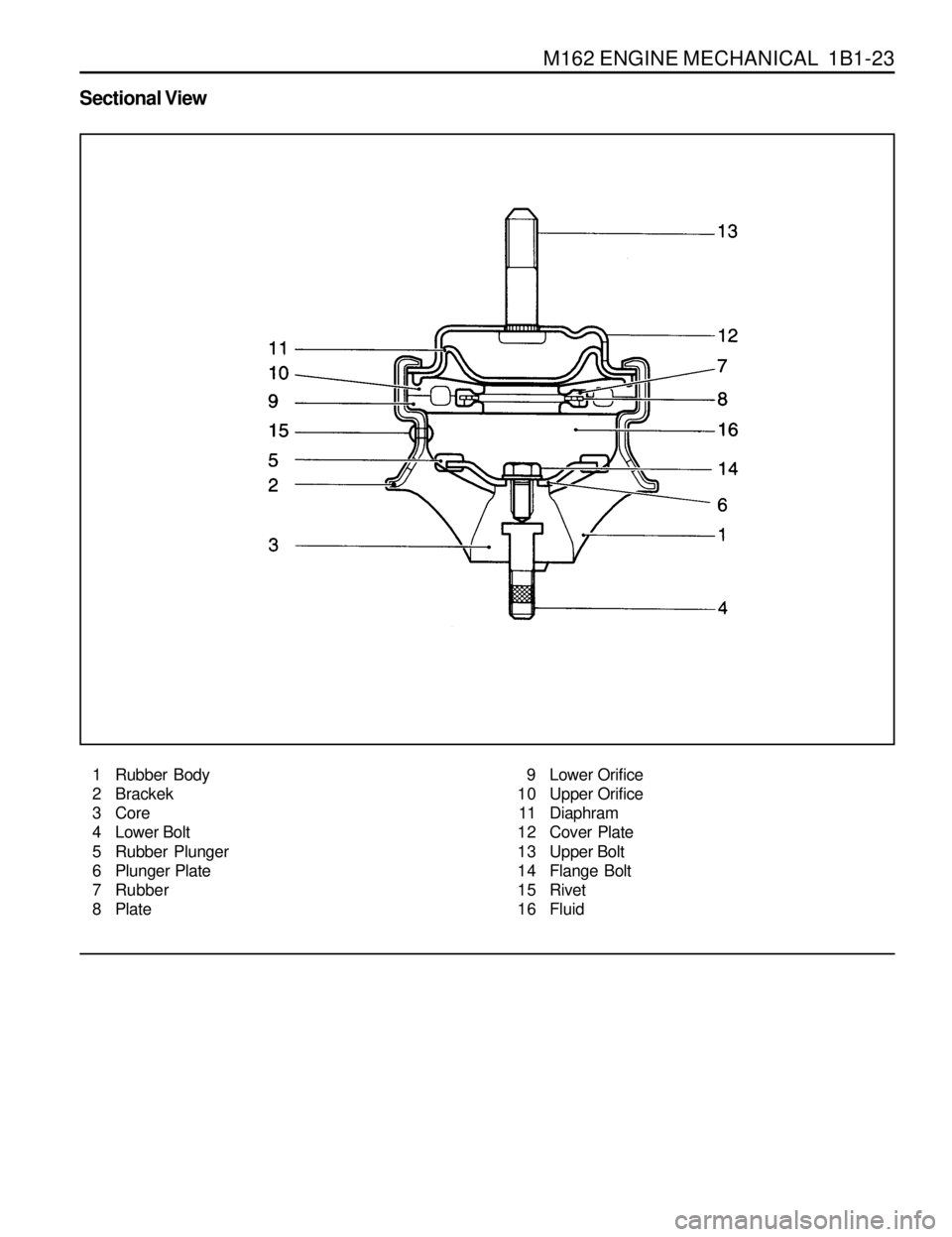

Sectional View

1 Rubber Body

2 Brackek

3 Core

4 Lower Bolt

5 Rubber Plunger

6 Plunger Plate

7 Rubber

8 Plate9 Lower Orifice

10 Upper Orifice

11 Diaphram

12 Cover Plate

13 Upper Bolt

14 Flange Bolt

15 Rivet

16 Fluid

Page 97 of 1463

1B1-24 M162 ENGINE MECHANICAL

1 Upper Nut

2 Hydraulic Installor.................62-93 Nm

3 Lower Nut.............................28-47 Nm

Removal and Installation Procedure

1. Unscrew the upper nut(1) on engine mounting and remove

the engine.

Installation Notice

3. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 62 - 93 Nm

2. Unscrew the lower nut(3) and remove the hydraulic engine

mounting insulator.

Installation Notice

Tightening Torque 28 - 47 Nm

Notice

If the insulator is spotted with oil, replace the hydraulic

insulator assembly.

Page 98 of 1463

M162 ENGINE MECHANICAL 1B1-25

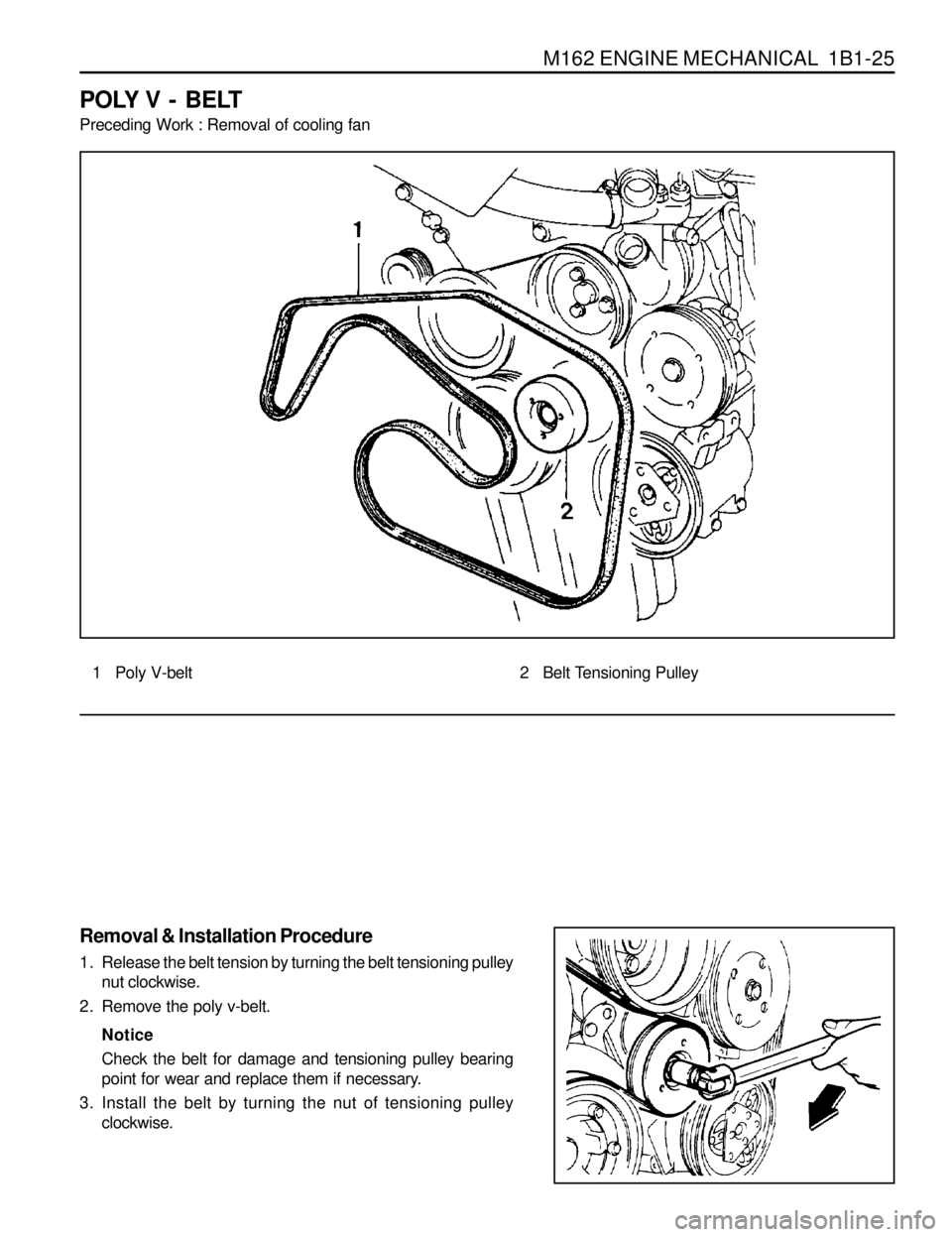

POLY V - BELT

Preceding Work : Removal of cooling fan

1 Poly V-belt

Removal & Installation Procedure

1. Release the belt tension by turning the belt tensioning pulley

nut clockwise.

2. Remove the poly v-belt.

Notice

Check the belt for damage and tensioning pulley bearing

point for wear and replace them if necessary.

3. Install the belt by turning the nut of tensioning pulley

clockwise.

2 Belt Tensioning Pulley

Page 99 of 1463

1B1-26 M162 ENGINE MECHANICAL

Poly V-Belt Arrangement

1 Belt Tensioning Pulley

2 Crankshaft Belt Pulley

3 A/C Compressor Pulley

4 Cooling Fan Pulley5 Alternator Pulley

6 Idler

7 Power Steering Pump Pulley

8 Cooling Fan and Water Pump Pulley

Page 100 of 1463

M162 ENGINE MECHANICAL 1B1-27

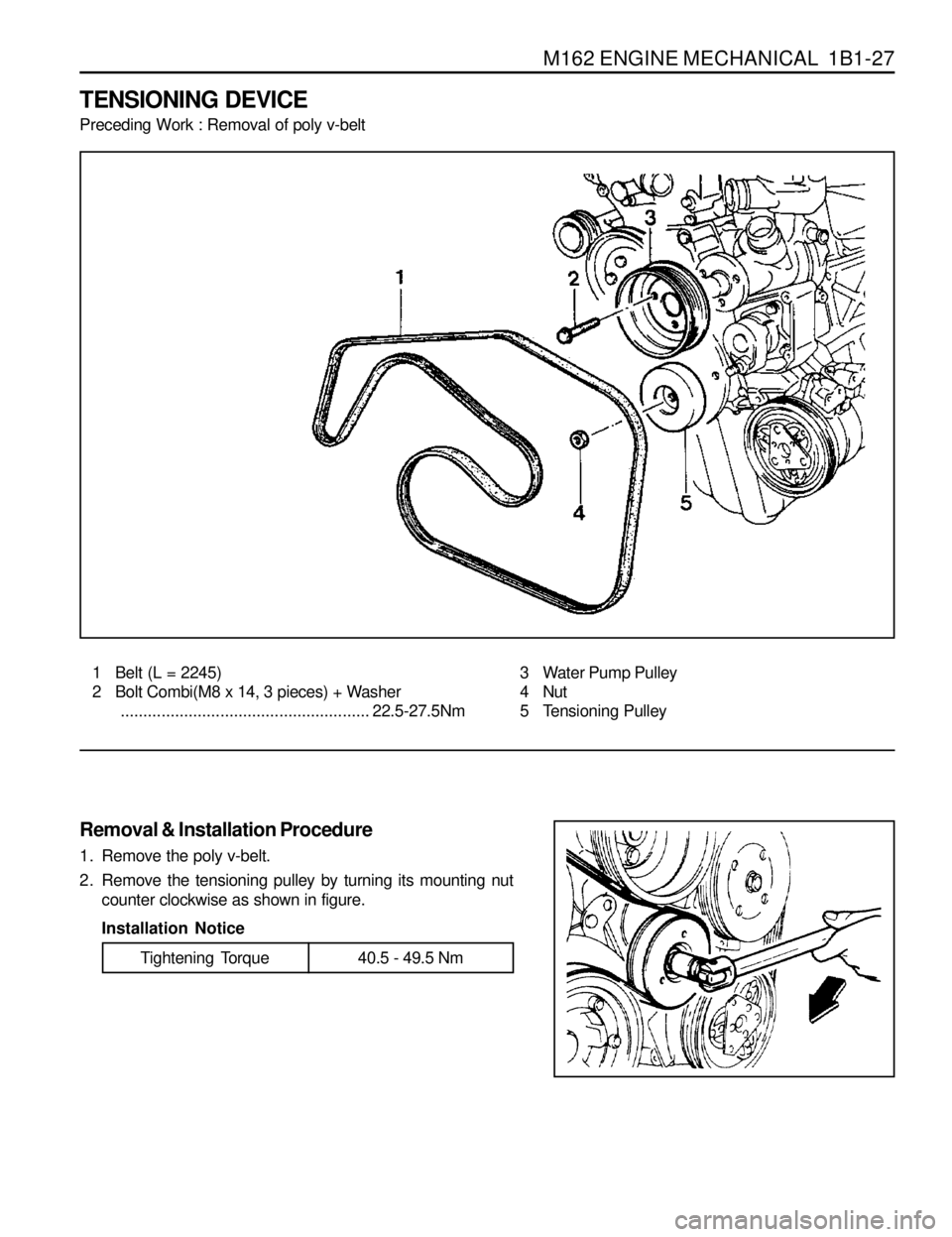

TENSIONING DEVICE

Preceding Work : Removal of poly v-belt

1 Belt (L = 2245)

2 Bolt Combi(M8 x 14, 3 pieces) + Washer

.......................................................22.5-27.5Nm

Removal & Installation Procedure

1. Remove the poly v-belt.

2. Remove the tensioning pulley by turning its mounting nut

counter clockwise as shown in figure.

Installation Notice3 Water Pump Pulley

4 Nut

5 Tensioning Pulley

Tightening Torque 40.5 - 49.5 Nm

Trending: run flat, compression ratio, clutch, service indicator, fuses, airbag, parking brake