SSANGYONG MUSSO 1998 Workshop Repair Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Repair Manual

Trending: fuse box diagram, maintenance schedule, timing belt, bolt pattern, stop start, engine, octane

Page 131 of 1463

1B1-58 M162 ENGINE MECHANICAL

CAMSHAFT SPROCKET BOLT

Intake Flange Shaft Bolt

Notice

The sprocket bolts are designed to be used only once, so

always replace with new one.

Exhaust Camshaft Sprocket Bolt

Notice

The sprocket bolts are designed to be used only once, so

always replace with new one.

C. M7 x 13 Collar Bolt Torx-T30

e. 6.8 mm

16. Flange Shaft

18. Control Piston

22. Intake Camshaft

E. M7 x 13 Collar Bolt Torx-T30

e. 6.8 mm

13a. Camshaft Sprocket

22a. Exhaust Camshaft

Tightening Torque1st step 18 - 22 Nm

2nd step 90° ± 5°

Tightening Torque1st step 18 - 22 Nm

2nd step 90° ± 5°

Page 132 of 1463

M162 ENGINE MECHANICAL 1B1-59

CAMSHAFT

Preceding Work : Removal of cylinder head cover, removal of coolant connection fitting

1 Chain Tensioner Assembly..................72-88 Nm

2 Exhaust Camshaft Sprocket

3 Upper Guide Rail

4 Cylinder Head Front Cover5 Intake Camshaft Sprocket

6 Chain

7 Wrench (Special Tool)

Page 133 of 1463

1B1-60 M162 ENGINE MECHANICAL

Tools Required

000 589 01 10 00 Box Wrench Insert

104 589 01 01 00Spanner

Removal Procedure

1. Turn the crankshaft and position the No. 1 cylinder piston

at BTDC 30°.

2. Remove the alternator.

3. Remove the chain tensioner.

4. Remove the cylinder head front cover and the upper guide

rail.

6. Unscrew the exhaust camshaft sprocket bolt and remove

the sprocket.

7. Separate the chain from the intake camshaft sprocket and

put the chain not to be dropped into timing case. 5. Put the alignment marks (arrows) on the camshaft sprocket

(2, 5) and the timing chain (6).

Page 134 of 1463

M162 ENGINE MECHANICAL 1B1-61

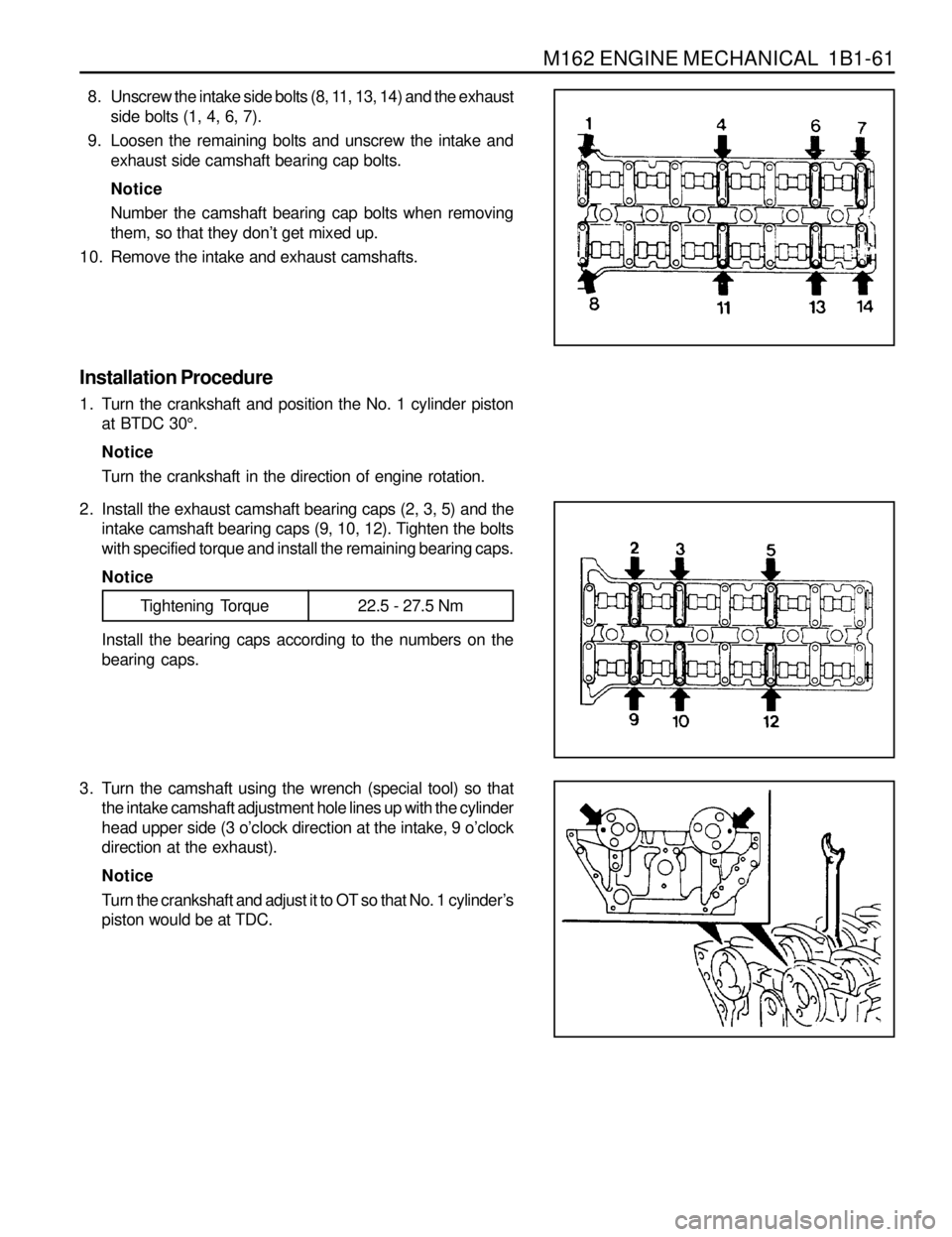

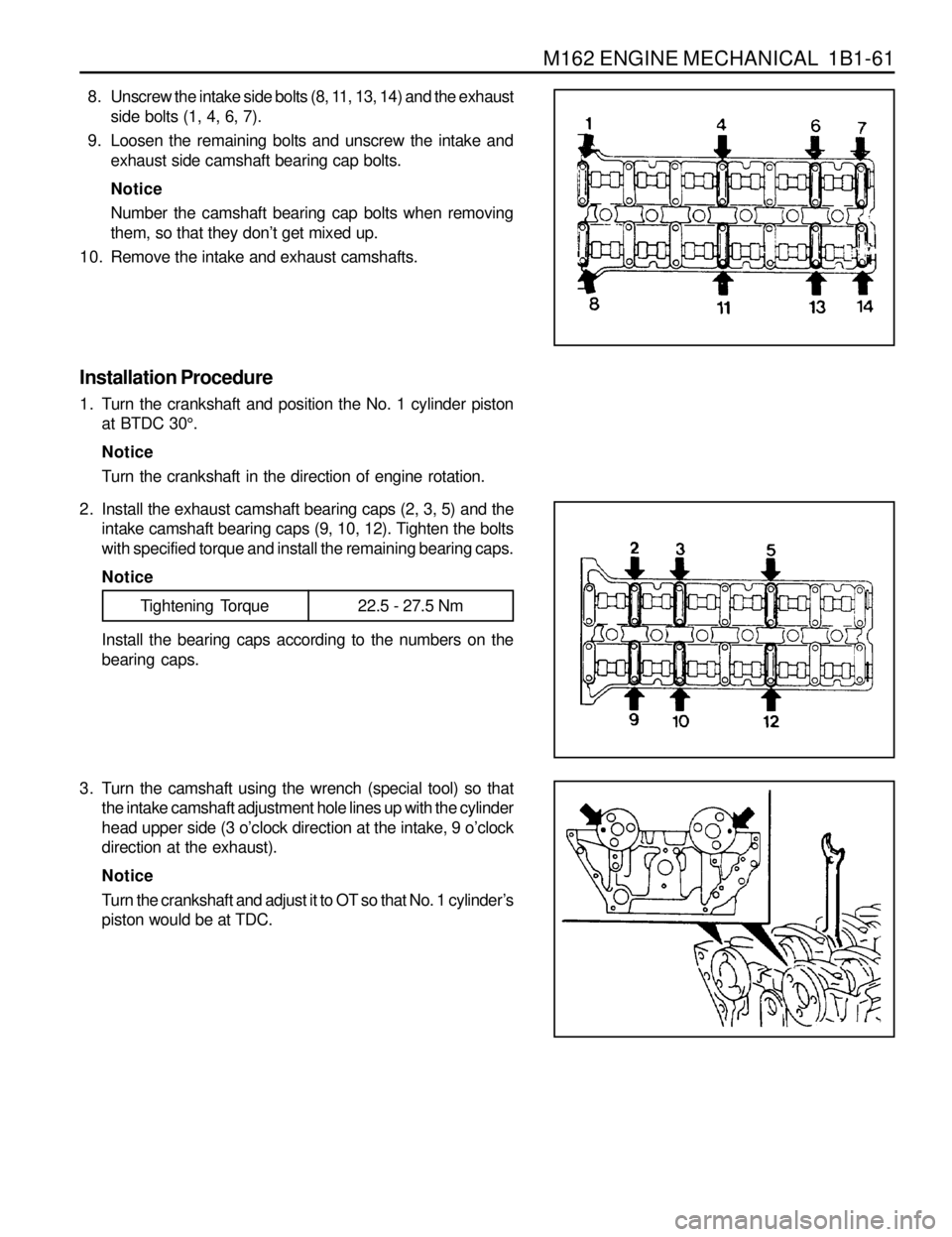

8 . Unscrew the intake side bolts (8, 11, 13, 14) and the exhaust

side bolts (1, 4, 6, 7).

9. Loosen the remaining bolts and unscrew the intake and

exhaust side camshaft bearing cap bolts.

Notice

Number the camshaft bearing cap bolts when removing

them, so that they don’t get mixed up.

10. Remove the intake and exhaust camshafts.

Installation Procedure

1. Turn the crankshaft and position the No. 1 cylinder piston

at BTDC 30°.

Notice

Turn the crankshaft in the direction of engine rotation.

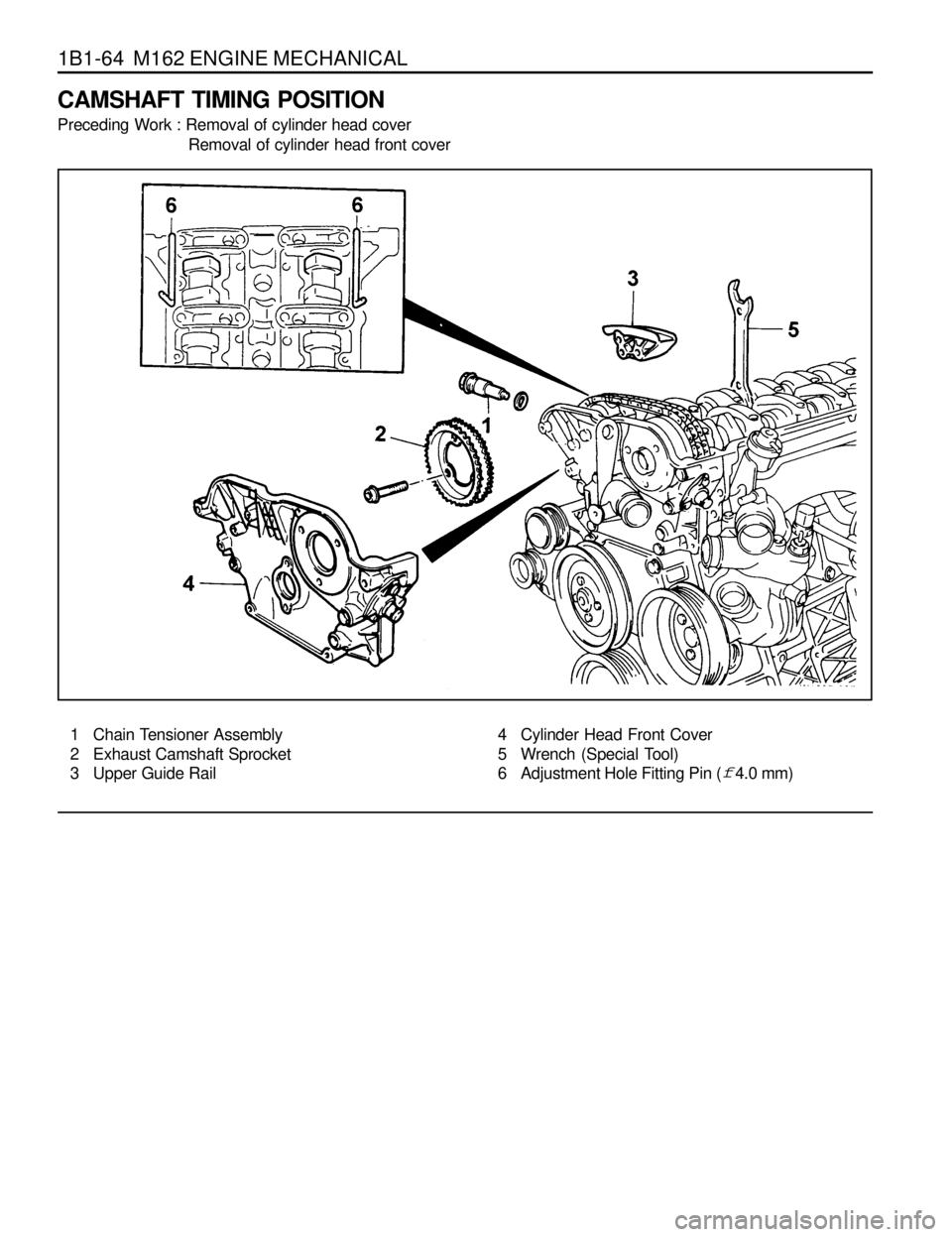

3. Turn the camshaft using the wrench (special tool) so that

the intake camshaft adjustment hole lines up with the cylinder

head upper side (3 o’clock direction at the intake, 9 o’clock

direction at the exhaust).

Notice

Turn the crankshaft and adjust it to OT so that No. 1 cylinder’s

piston would be at TDC. Install the bearing caps according to the numbers on the

bearing caps.

Tightening Torque 22.5 - 27.5 Nm 2. Install the exhaust camshaft bearing caps (2, 3, 5) and the

intake camshaft bearing caps (9, 10, 12). Tighten the bolts

with specified torque and install the remaining bearing caps.

Notice

Page 135 of 1463

1B1-62 M162 ENGINE MECHANICAL

4. Turn the intake camshaft adjuster to the direction of camshaft

rotation by hard until it stops and then install the chain.

Notice

lMake sure that the camshaft sprocket and timing chain

are aligned with marks.

lIntake camshaft adjuster should be in retarded position.

5. Install the chain on the exhaust sprocket and tighten the

sprocket bolts.

Notice

7. Rotate the crankshaft 2 revolutions and check followings:

- TDC of no. 1 cylinder : OT

- Alignment between camshaft adjustment hole and

cylinder head surface.

- Alignments between timing chain and sprocket marks.

Notice

lTurn the crankshaft in the direction of engine rotation.

lRead just if not aligned. 6. Install the chain tensioner and tighten it as specified.

Notice lMake sure that the camshaft sprocket and timing chain

are aligned with marks.

lReplace the sprocket bolt with new one.

Tightening Torque1st step 18 - 22 Nm

2nd step 90° ± 5°

Tightening Torque( 1 ) 40 Nm

(2) 72 - 88 Nm

Page 136 of 1463

M162 ENGINE MECHANICAL 1B1-63

8. Install the upper guide rail and cylinder head front cover.

9. Install the alternator.

Page 137 of 1463

1B1-64 M162 ENGINE MECHANICAL

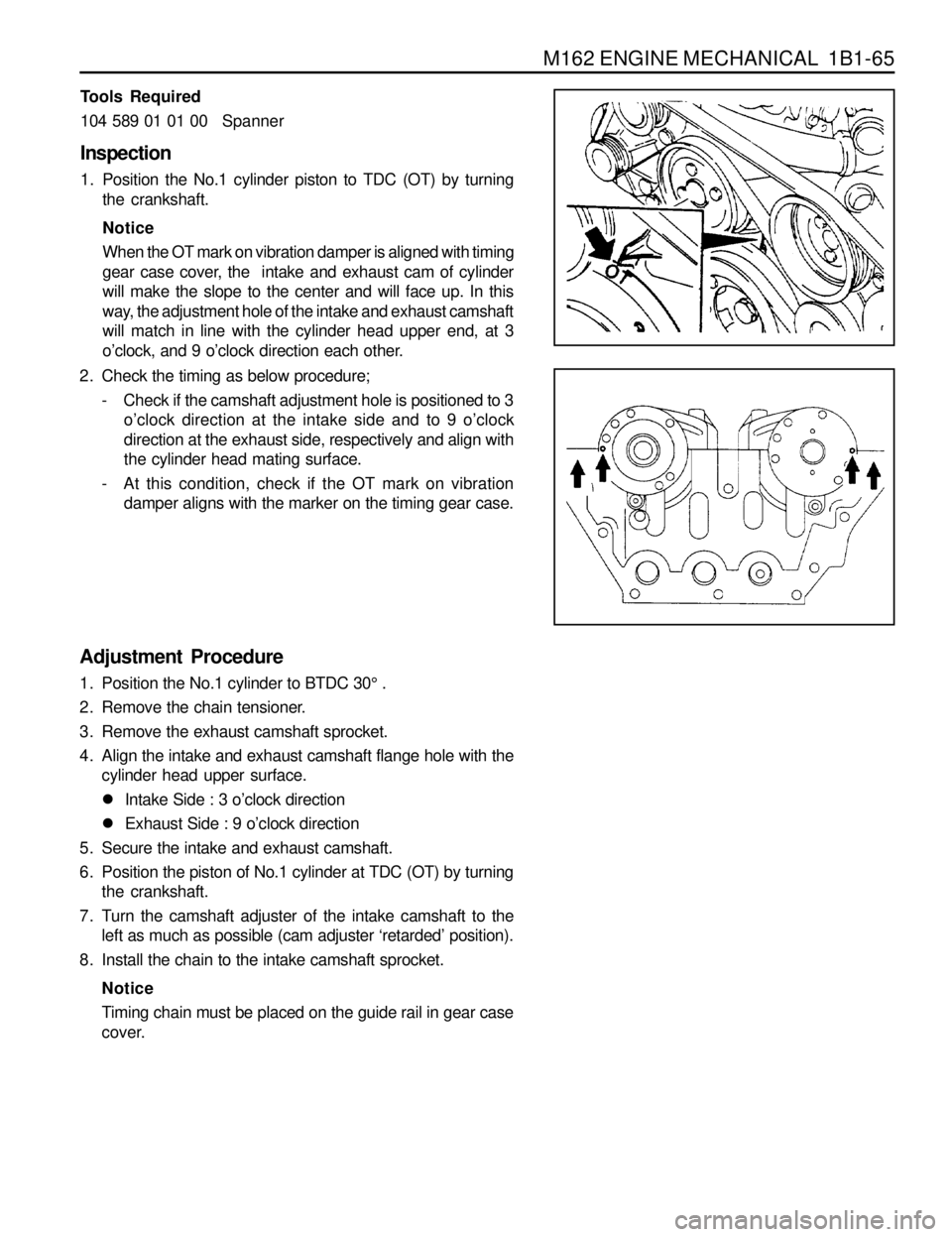

CAMSHAFT TIMING POSITION

Preceding Work : Removal of cylinder head cover

Removal of cylinder head front cover

1 Chain Tensioner Assembly

2 Exhaust Camshaft Sprocket

3 Upper Guide Rail4 Cylinder Head Front Cover

5 Wrench (Special Tool)

6 Adjustment Hole Fitting Pin (

f4.0 mm)

Page 138 of 1463

M162 ENGINE MECHANICAL 1B1-65

Adjustment Procedure

1. Position the No.1 cylinder to BTDC 30° .

2. Remove the chain tensioner.

3. Remove the exhaust camshaft sprocket.

4. Align the intake and exhaust camshaft flange hole with the

cylinder head upper surface.

lIntake Side : 3 o’clock direction

lExhaust Side : 9 o’clock direction

5. Secure the intake and exhaust camshaft.

6. Position the piston of No.1 cylinder at TDC (OT) by turning

the crankshaft.

7. Turn the camshaft adjuster of the intake camshaft to the

left as much as possible (cam adjuster ‘retarded’ position).

8. Install the chain to the intake camshaft sprocket.

Notice

Timing chain must be placed on the guide rail in gear case

cover. Tools Required

104 589 01 01 00Spanner

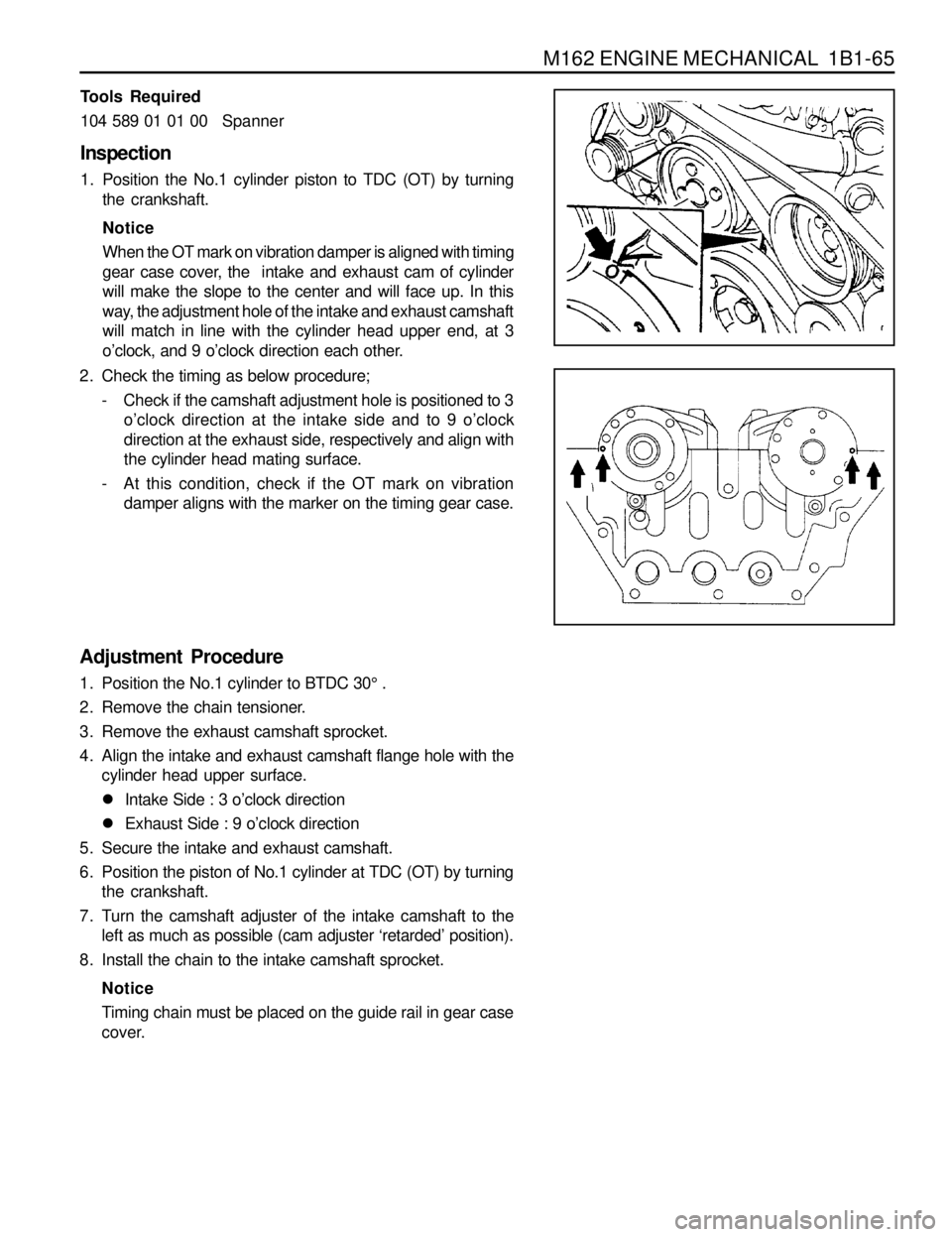

Inspection

1. Position the No.1 cylinder piston to TDC (OT) by turning

the crankshaft.

Notice

When the OT mark on vibration damper is aligned with timing

gear case cover, the intake and exhaust cam of cylinder

will make the slope to the center and will face up. In this

way, the adjustment hole of the intake and exhaust camshaft

will match in line with the cylinder head upper end, at 3

o’clock, and 9 o’clock direction each other.

2. Check the timing as below procedure;

- Check if the camshaft adjustment hole is positioned to 3

o’clock direction at the intake side and to 9 o’clock

direction at the exhaust side, respectively and align with

the cylinder head mating surface.

- At this condition, check if the OT mark on vibration

damper aligns with the marker on the timing gear case.

Page 139 of 1463

1B1-66 M162 ENGINE MECHANICAL

11. Check the camshaft timing.The sprocket bolt is designed to be used only once, so

replace with new one.

10. Install the chain tensioner.

Installation NoticeTightening Torque1st step 18 - 22 Nm

2nd step 90° ± 5°

9. Install the chain to the exhaust camshaft sprocket and

install it to the camshaft.

Installation Notice (Sprocket Bolt)

Tightening

TorqueScrew Plug

40 Nm

Tensioner Assembly

72 - 88 Nm

Page 140 of 1463

M162 ENGINE MECHANICAL 1B1-67

VALVE SPRING

Preceding Work : Removal of camshaft

Removal of spark plug

1 Valve Tappet Assembly

2 Valve Cotter

3 Upper Retainer

4 Valve Spring..........Check, Replace if necessary

5 Valve Stem Seal

6 Lower Retainer7 Connecting Hose

8 Thrust Piece

9 Slide

10 Adjust Bolt

11 Lever Pusher

12 Supporting Bar

Trending: fog light, center console, rid height, brake fluid, set clock, brakes, compression ratio