SSANGYONG MUSSO 1998 Workshop Manual Online

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Manual Online

Trending: level switch, spare tire location, fuel cap release, height adjustment, jacking, service indicator, mileage

Page 81 of 1463

1B1-8 M162 ENGINE MECHANICAL

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

ENGINE ASSEMBLY

Tools Required

000 589 10 99 01 Torque Wrench

000 589 40 37 00 Hose Clamp

112 589 00 72 00 Oil Extractor

Page 82 of 1463

M162 ENGINE MECHANICAL 1B1-9

4. Disconnect the coupling of HFM sensor and remove the air

cleaner cross pipe.

6. Loosen the radiator drain cock and drain the coolant.

Notice

Open the coolant reservoir cap. 5. Remove the air cleaner cover. Remove the mounting bolts

and air cleaner housing and element assembly.

Removal & Installation Procedure

1. Disconnect the negative terminal of battery.

2. Remove the hood.

3. Remove the under cover.

Installation Notice

Tightening Torque 28 - 47 Nm

Page 83 of 1463

1B1-10 M162 ENGINE MECHANICAL

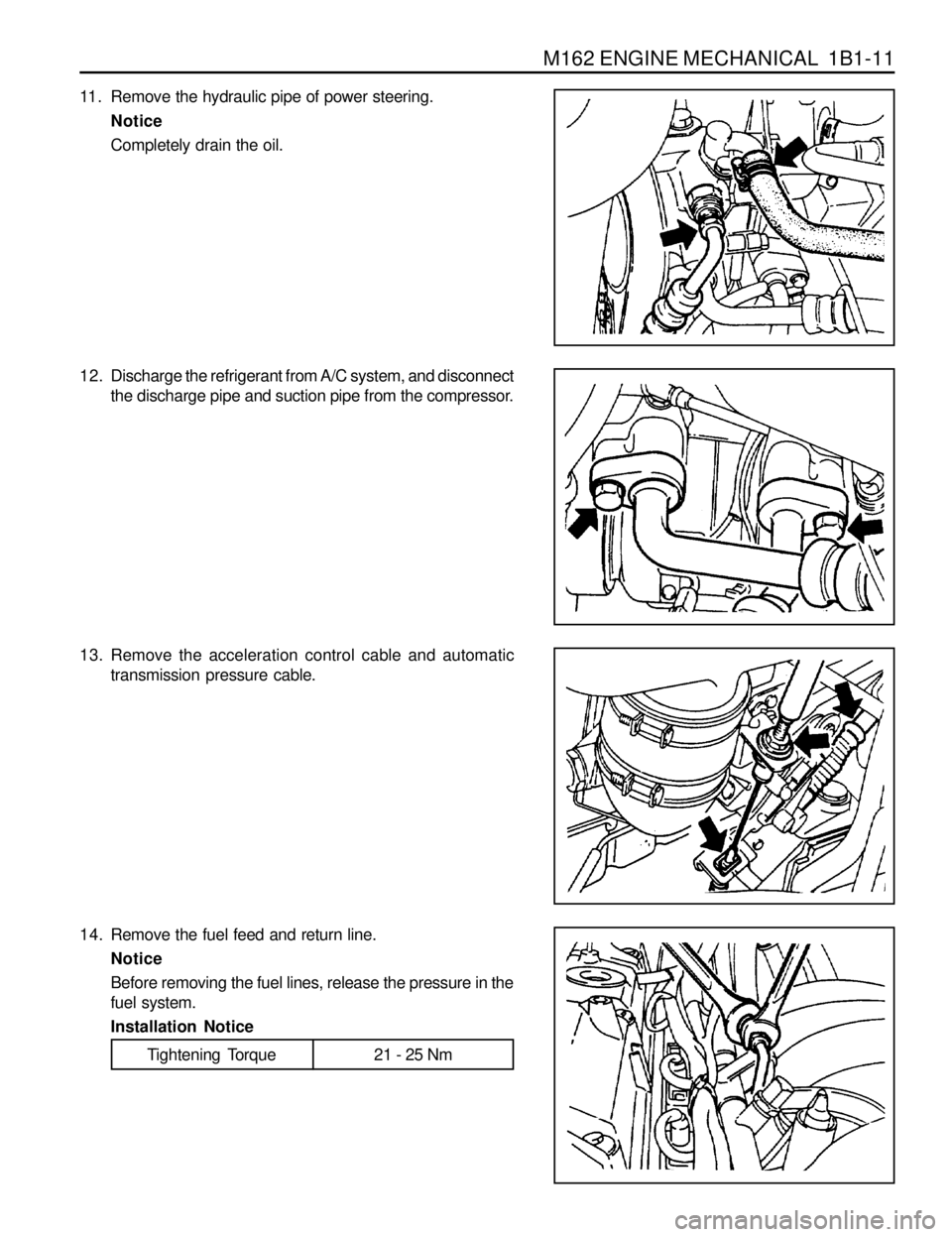

10. Remove the upper mounting bolts of radiator and then

remove the radiator.

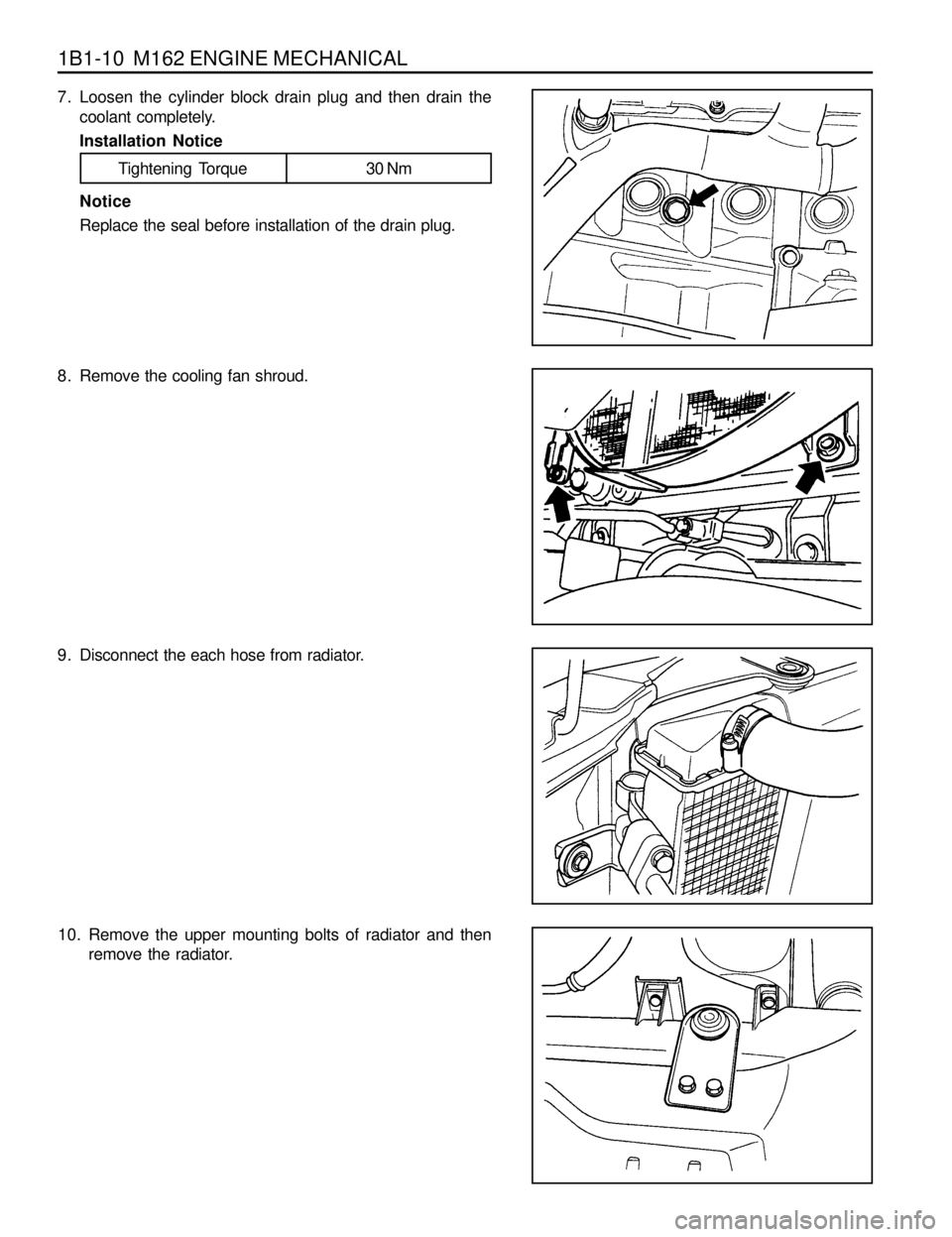

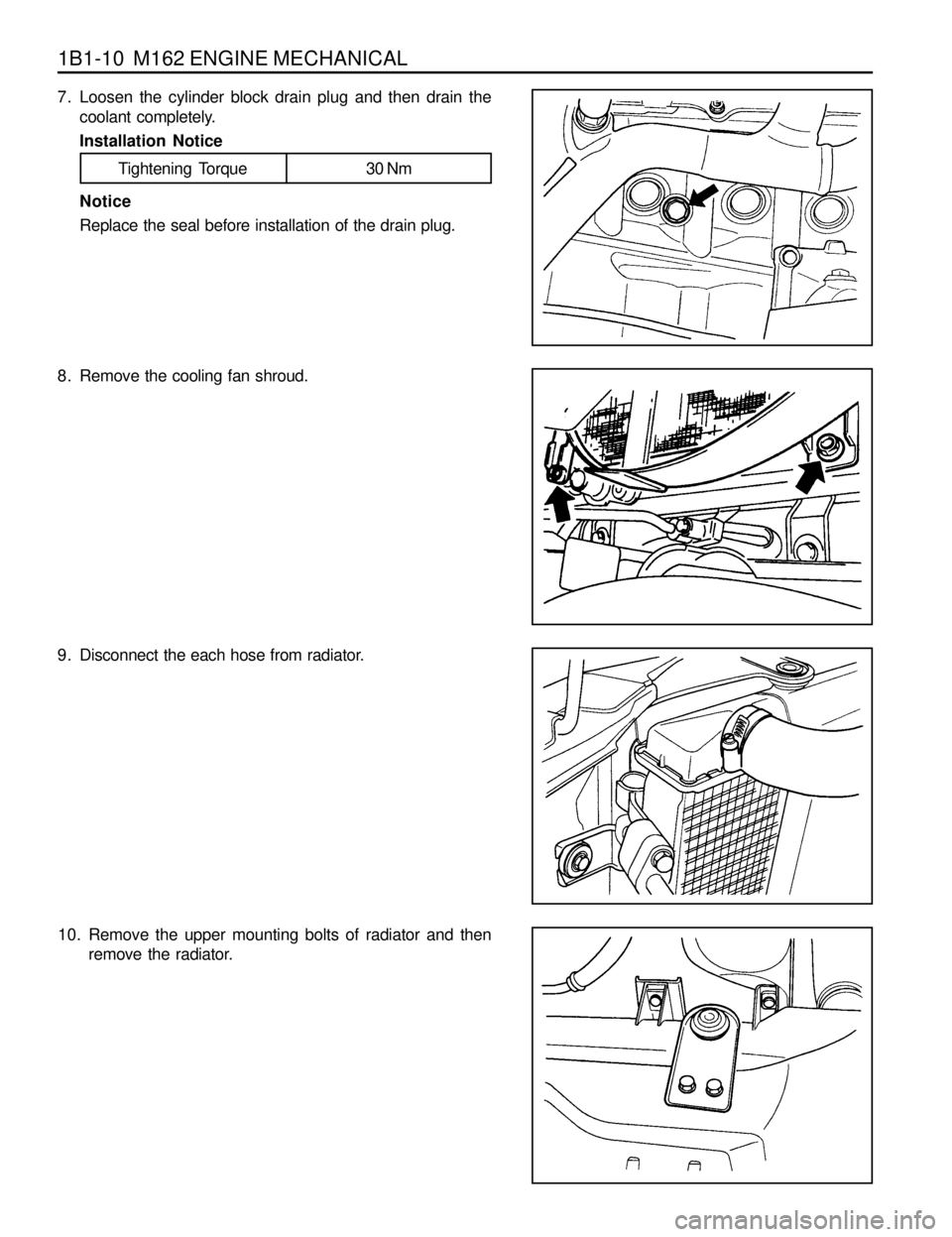

7. Loosen the cylinder block drain plug and then drain the

coolant completely.

Installation Notice

Tightening Torque 30 Nm

Notice

Replace the seal before installation of the drain plug.

8. Remove the cooling fan shroud.

9. Disconnect the each hose from radiator.

Page 84 of 1463

M162 ENGINE MECHANICAL 1B1-11

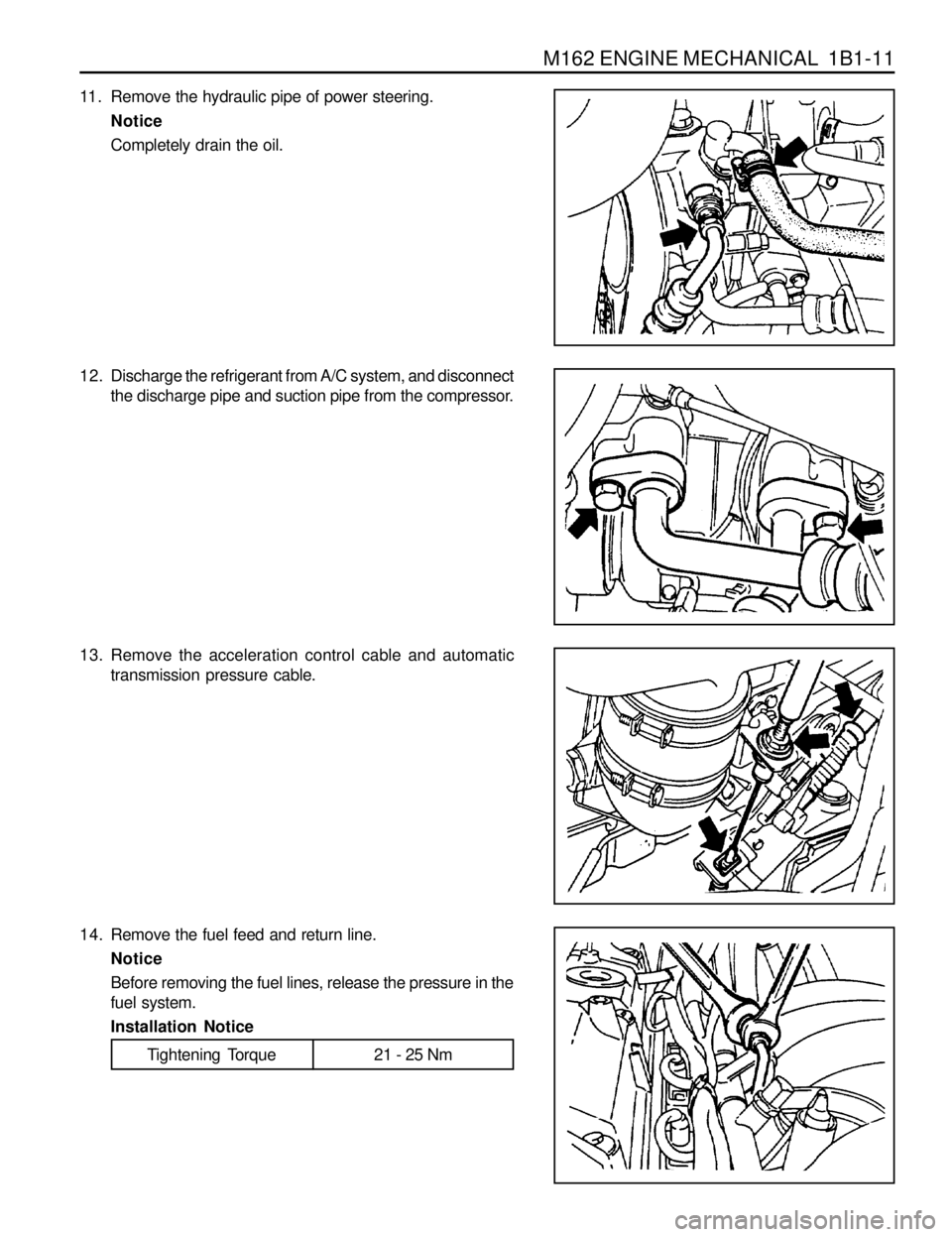

12. Discharge the refrigerant from A/C system, and disconnect

the discharge pipe and suction pipe from the compressor.

14. Remove the fuel feed and return line.

Notice

Before removing the fuel lines, release the pressure in the

fuel system.

Installation Notice 13. Remove the acceleration control cable and automatic

transmission pressure cable. 11. Remove the hydraulic pipe of power steering.

Notice

Completely drain the oil.

Tightening Torque 21 - 25 Nm

Page 85 of 1463

1B1-12 M162 ENGINE MECHANICAL

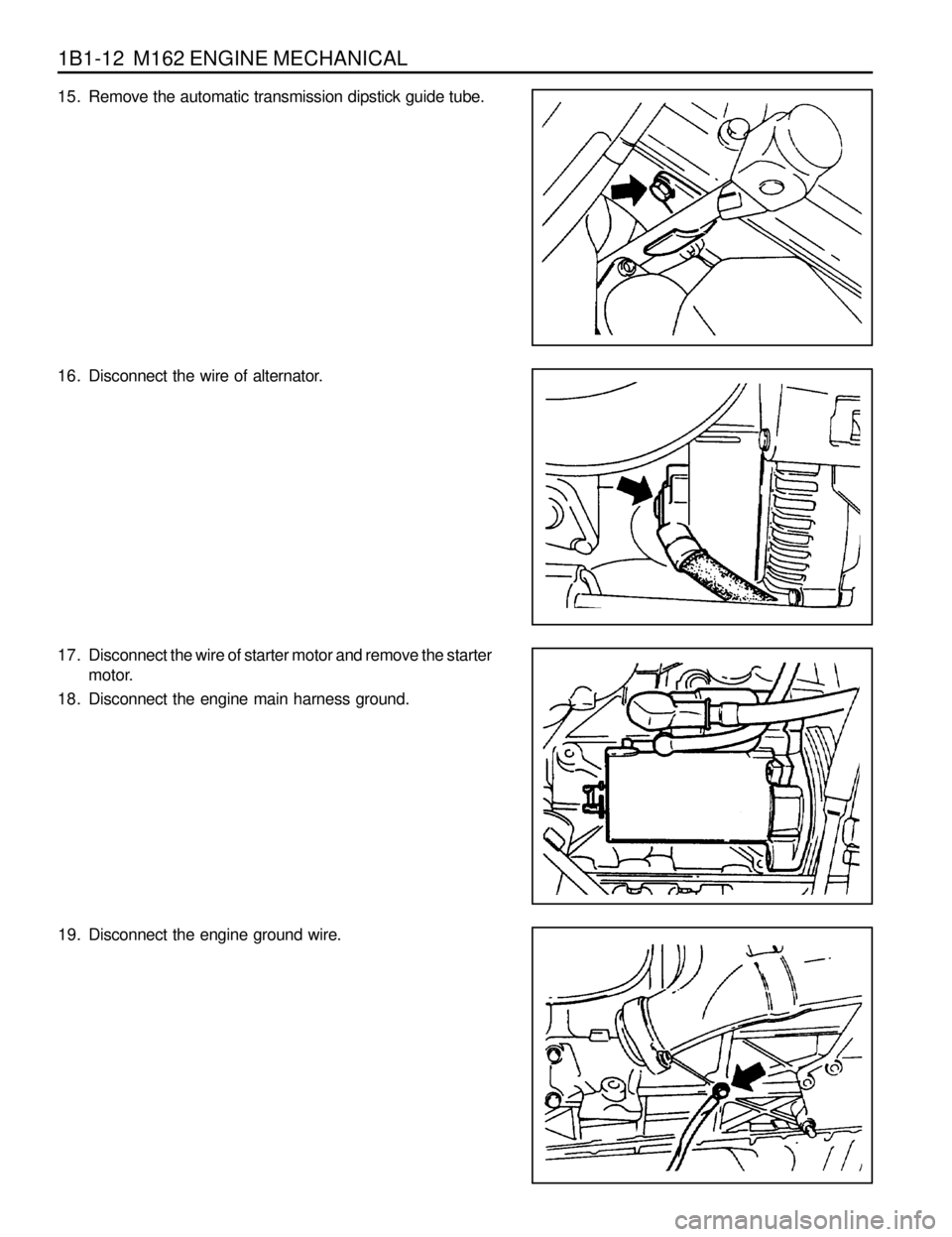

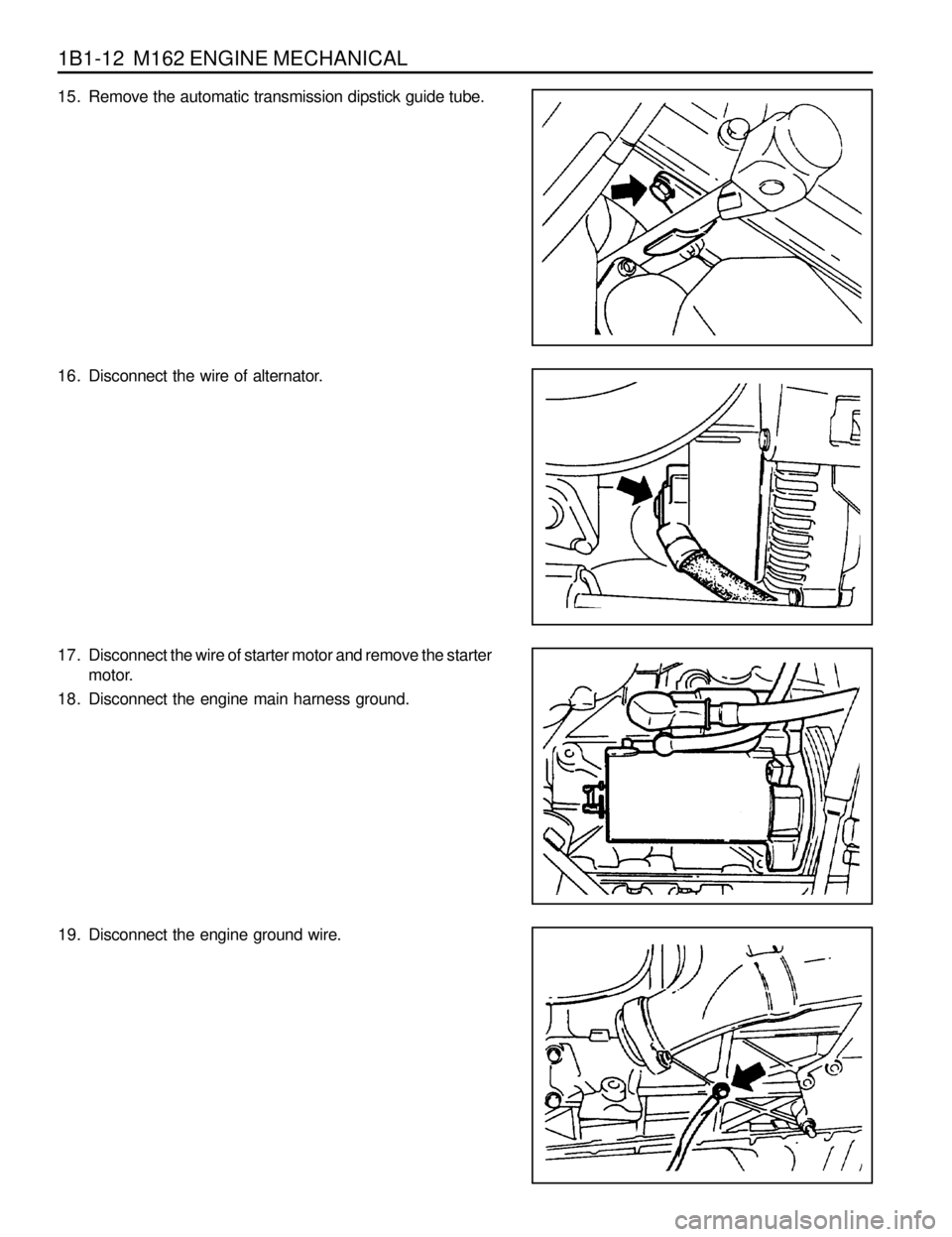

19. Disconnect the engine ground wire. 15. Remove the automatic transmission dipstick guide tube.

16. Disconnect the wire of alternator.

17. Disconnect the wire of starter motor and remove the starter

motor.

18. Disconnect the engine main harness ground.

Page 86 of 1463

M162 ENGINE MECHANICAL 1B1-13

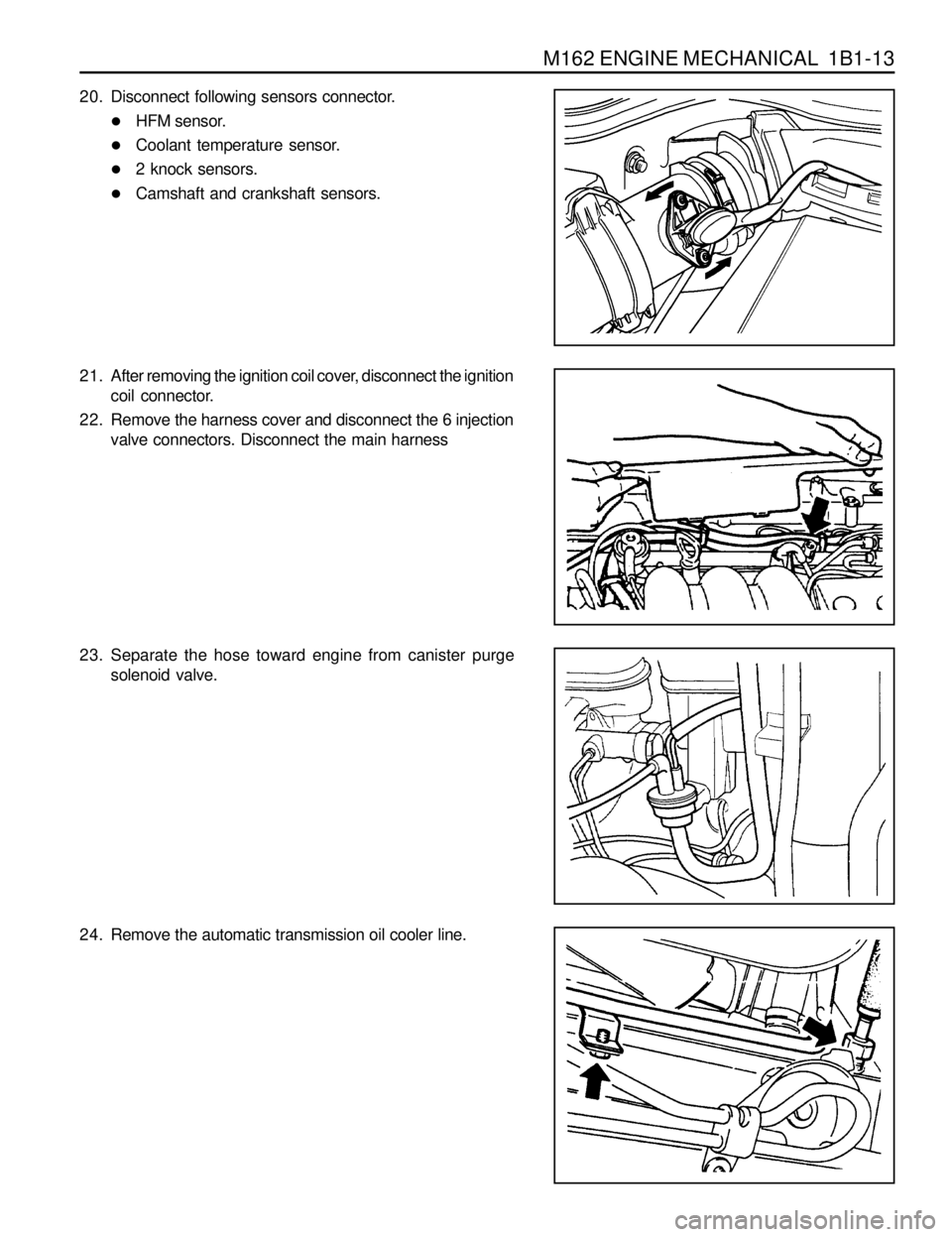

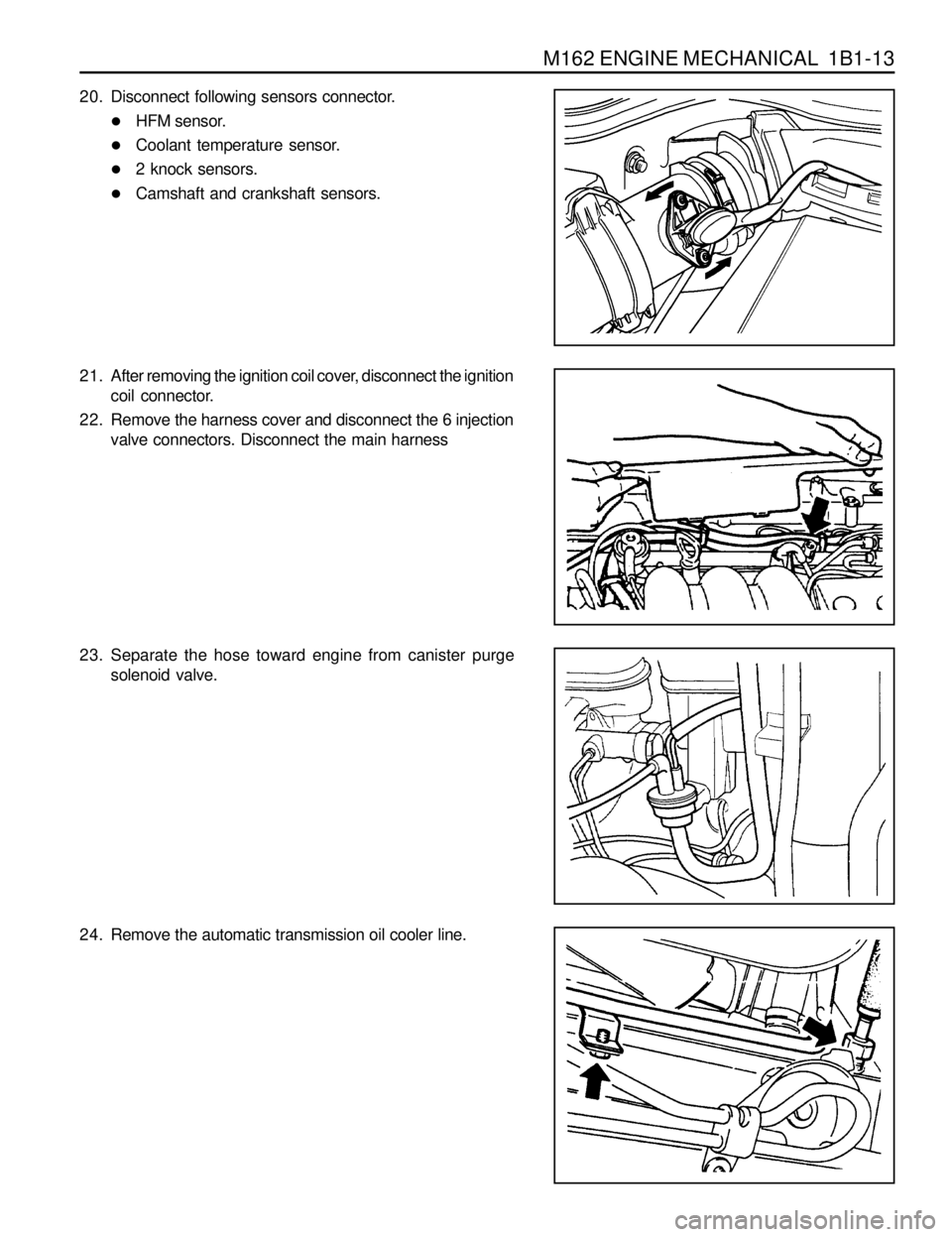

20. Disconnect following sensors connector.

lHFM sensor.

lCoolant temperature sensor.

l2 knock sensors.

lCamshaft and crankshaft sensors.

21. After removing the ignition coil cover, disconnect the ignition

coil connector.

22. Remove the harness cover and disconnect the 6 injection

valve connectors. Disconnect the main harness

23. Separate the hose toward engine from canister purge

solenoid valve.

24. Remove the automatic transmission oil cooler line.

Page 87 of 1463

1B1-14 M162 ENGINE MECHANICAL

Tightening Torque 30 Nm 29. Remove the exhaust manifold and exhaust pipe.

Installation Notice

25. Separate the vacuum hose for brake booster.

26. Separate the other vacuum hoses.

27. Remove the propeller shaft from the front axle.

Installation Notice

28. By rotating the crankshaft from the front of engine, remove

the 6 torque converter mounting bolts from the engine

ring gear plate.

Tightening Torque 81 - 89 Nm

Page 88 of 1463

M162 ENGINE MECHANICAL 1B1-15

30. Remove the transmission mounting bolts and separate

the transmission from the engine.

Installation Notice

Tightening Torque 65 Nm

31. Remove the bolts for engine mounting bracket.

Installation Notice

Tightening Torque 50 - 75 Nm

32. Hook the chain to the bracket of engine and by using a

hoist or crane, carefully separate the engine assembly

from the vehicle.

33. Installation should follow the removal procedure in the

reverse order.

Page 89 of 1463

1B1-16 M162 ENGINE MECHANICAL

CRANKCASE VENTILATION SYSTEM

1 Crankcase

2 Air Admission Port in Crankcase

3 Oil Drain Port

4 Filter

5 Gasket

6 A/C Bracket

7 Oil Drain Pipe

8 Oil Pan

9 Air Admission Line

10 Vent Line

11 Restriction Hole (Diameter = 2 mm)

12 Intake Manifold13 Intake Air Duct (Cross Pipe)

14 Cylinder Head Cover

15 Oil Separator

16 Oil Separator

17 Air Admission and Vent Connection

18 Air Admission and Vent Connection

19 Throttle Valve

20 Vent Line

A Fresh Air

B Blowby Gas in Partial Load

C Blowby Gas in Full Load

Page 90 of 1463

M162 ENGINE MECHANICAL 1B1-17

Operation at Idling and Mid-Load

lIt show that the throttle valve (19) is closed or very partially

opened and the vacuum pressure in intake manifold is high.

The blowby gas in the crankcase in partial load flows into

the intake manifold through the vent line (20) after passing

the air conditioner bracket (6) and the filter (4). The air

reentered into the intake manifold will be dilluted on the flow

through the restriction hole (11) in the vent line (10).

The circulated engine oil is separated at the air conditioner

bracket (6) and then returns into the oil pan through the

drain pipe (7).

The vacuum pressure generated at the crankcase sucks

fresh air from intake air line(13) through the air admission

and vent connection (17,18).

The fresh air prevents engine oil from being contami-nated

and the air admission and vent connection (17,18) is

designed to control the rapid pressure changes in intake

air line (13).

Operation at Full-Load

lThe throttle valve (19) is fully opened.

All the blowby gases flow into the intake air duct (13) after

passing through the oil separator (15,16) of the cylinder

head cover (14) when fully loaded. This dilluted air will be

supplied to the combustion chamber through the intake

manifold (12).

Trending: seat adjustment, lights, lug pattern, fuel tank removal, handbrake, glove box, cruise control