SSANGYONG MUSSO 1998 Workshop Repair Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Repair Manual

Trending: tire pressure, fuel cap, height adjustment, instrument panel, dimensions, brake rotor, brakes

Page 141 of 1463

1B1-68 M162 ENGINE MECHANICAL

Tools Required

111 589 01 59 00 Supporting Bar

111 589 18 61 00 Lever Pusher

111 589 25 63 00 Thrust Piece

116 589 06 63 00 Magnetic Finger

Removal & Installation Procedure

1. Place the supporting bar (12) and the slide (9) at the

camshaft bearing cap (Nos 1 & 7/8&14) and tighten them

with the bearing cap bolt.

Installation Notice

2. Turn the crankshaft to position the each cylinder piston at

TDC.

5. Install the engine lock to the ring gear to prevent the

crankshaft from rotating.

6. Blow up with compressed air.Notice

lRemove the valve spring only at TDC.

lAlways rotate the crankshaft by holding the chain to

prevent from timing chain damage and tangling, and for

smooth rotation.

3. Remove the valve tappet (1) using the magnetic finger.

4. Install the leakage tester connecting hose to the spark plug

hole.

Supporting Bar 111 589 01 59 00

Tightening Torque 22.5 - 27.5 Nm

Mark on The Vibration Damper

OT

120°

240°Cylinder

1, 6

2, 5

3, 4

Page 142 of 1463

M162 ENGINE MECHANICAL 1B1-69

8. Install the lever pusher (11) and the thrust piece (8) to the

slide (9).

13. Remove the valve cotter (2) using either the pincette (13)

or magnetic finger.

Lever Pusher 111 589 18 61 00

Magnetic Finger 116 589 06 63 00

9. Mount the thrust piece (8) vertically to the valve spring

retainer (3).

10. Make the thrust piece (8) and the slide (9) perpendicular

to each other.

11. Secure the slide (9) by turning the adjust bolt (10).

12. Press the valve spring (4) by using the lever pusher (11).

14. Remove the upper retainer (3) and the valve spring (4).

15. Remove the valve stem seal and replace if necessary.

Notice

Check the valve stem seal and replace if necessary.

16. Remove the lower retainer (6).

Notice

Check the retainer for damages and replace with a new

one if necessary.

17. Installation should follow the removal procedure in the

reverse order.

Page 143 of 1463

1B1-70 M162 ENGINE MECHANICAL

Test (Upper and Lower Valve Tappet and Valve

Cotter)

lUpper Valve Spring Retainer

lLower Valve Spring Retainer

lValve Cotter

12.3 (D)(d) 8.5

Size (mm)

Thickness (mm)

(a) 0.8 - 1.0

9.2 - 9.8 (H)(B) 9.0

Size (mm)

Page 144 of 1463

M162 ENGINE MECHANICAL 1B1-71

VALVE STEM SEAL

Preceding Work : Removal of valve spring

1 Drift (Special Tool)

2 Valve Stem Seal

3 Protective Sleeve

Drift 119 589 00 43 00 Pliers 104 589 00 37 00

Tools Required

104 589 00 37 00 Pliers

119 589 00 43 00 Drift

Replacement Procedure

1. Remove the valve stem seal (2) using the pliers.

Notice

Check the valve stem seal for damage and replace if

necessary.

2. Coat the valve stem seal with oil and assemble it with the

protective sleeve.

3. Insert the valve stem seal by pressing it with the drift.

Page 145 of 1463

1B1-72 M162 ENGINE MECHANICAL

CHAIN TENSIONER

1 Screw Plug................................................ 40 Nm

2 Seal

3 Filler Pin

4 Compression Spring5 Snap Ring

6 Thrust Pin

7 Chain Tensioner Housing.....................72-88 Nm

8 Seal

Removal Procedure

1. Position the No.1 cylinder to TDC (OT).

Notice

Remove the oil filler cap at adjustment position, and check

whether the intake camshaft cam’s lobe (arrow) stays in the

upper side.

2. Cover the alternator with a clean cloth.

3. Release the tension by unscrewing the screw plug once.

Notice

In case that the tension is reduced by unscrewing the screw

plug, reinstall after completely removing the chain tensioner.

If the chain tensioner is tightened again without completely

reducing its tension, then the detent spring doesn’t return

to the original position and the tension gets excedded.

Page 146 of 1463

M162 ENGINE MECHANICAL 1B1-73

Installation Procedure

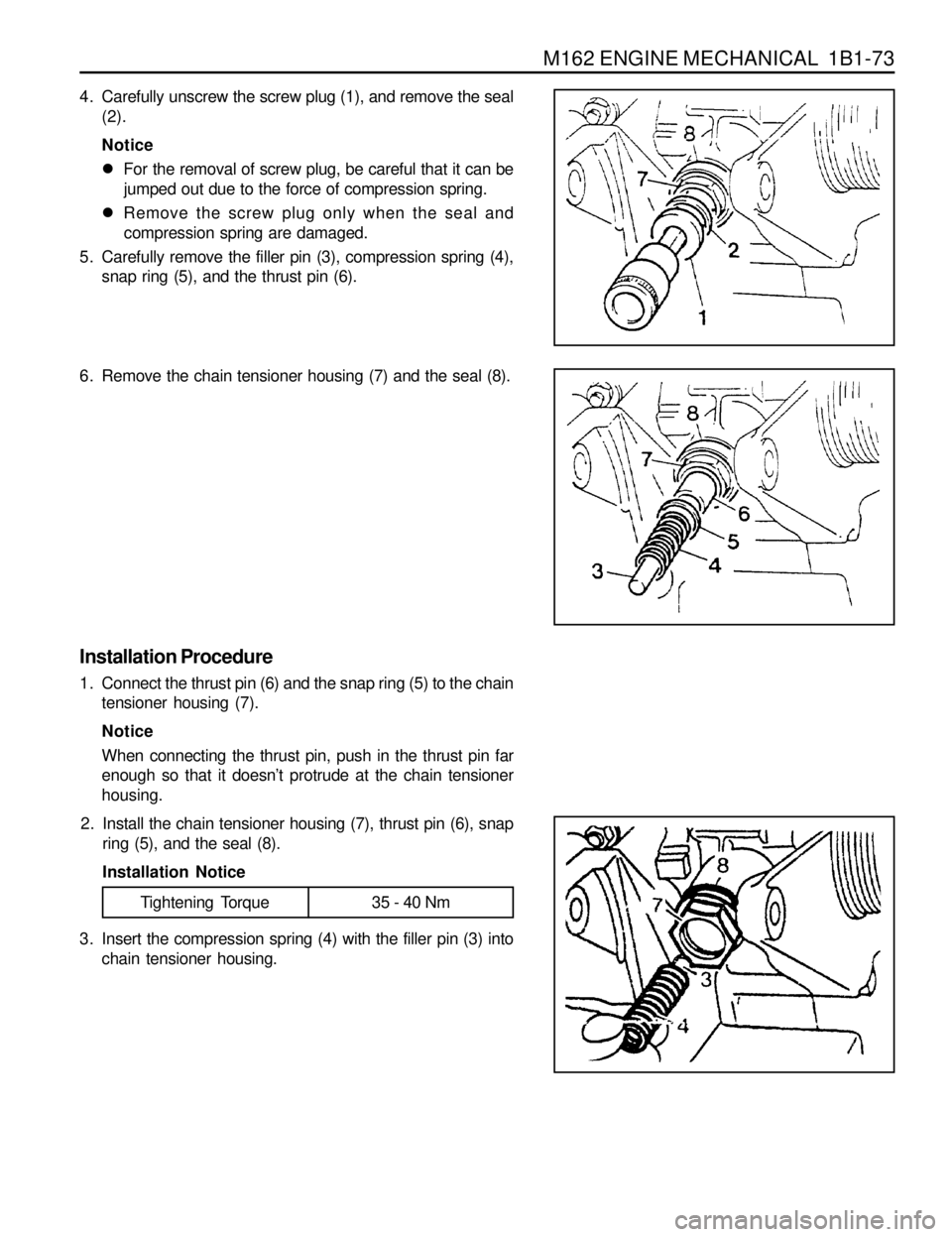

1. Connect the thrust pin (6) and the snap ring (5) to the chain

tensioner housing (7).

Notice

When connecting the thrust pin, push in the thrust pin far

enough so that it doesn’t protrude at the chain tensioner

housing. 4. Carefully unscrew the screw plug (1), and remove the seal

(2).

Notice

lFor the removal of screw plug, be careful that it can be

jumped out due to the force of compression spring.

lRemove the screw plug only when the seal and

compression spring are damaged.

5. Carefully remove the filler pin (3), compression spring (4),

snap ring (5), and the thrust pin (6).

6. Remove the chain tensioner housing (7) and the seal (8).

3. Insert the compression spring (4) with the filler pin (3) into

chain tensioner housing. 2. Install the chain tensioner housing (7), thrust pin (6), snap

ring (5), and the seal (8).

Installation Notice

Tightening Torque 35 - 40 Nm

Page 147 of 1463

1B1-74 M162 ENGINE MECHANICAL

4. Lightly apply the grease to the seal (2) and install the screw

plug (1).

Installation Notice

Sectional View

1 Screw Plug

2 Ball (Nonreturn Valve)

3 Compression Spring

4 Ball Guide

5 Seal (Aluminum)

6 Filler Pin

7 Compression Spring

8 Snap Ring

9 Thrust Pin

10 Ball (Nonreturn Valve)

11 Compression Spring

12 Thrust Piece13 Chain Tensioner Housing

1 4 Seal

15 Timing Gear Case Cover

16 Cylinder Head

17 Bolt / Washer

18 Tensioning Rail

19 Cylinder Head Gasket

20 Timing Chain

21 Tensioning Rail Base (Sliding Surface)

A Oil Supply Hole

B Chain Tensioner Oil Storage Hole 5. Check for leaks by operating the engine.

Tightening Torque 40 Nm

Page 148 of 1463

M162 ENGINE MECHANICAL 1B1-75

TIMING CHAIN

Preceding Work : Removal of cylinder head cover

Removal of spark plug

1 Pin

2 New Timing Chain

3 Timing Chain (Used)

4 Wedge5 Link

6 Center Plate

7 Outer Plate

Page 149 of 1463

1B1-76 M162 ENGINE MECHANICAL

Tools Required

000 589 58 43 00 Chain Assembly

103 589 01 63 00 Rivet Set

001 589 72 21 00 Torque Wrench

Replacement Procedure

1. Position the No.1 cylinder to TDC (OT).

4. Mount the wedges to both sides of the camshaft sprocket

as shown in the figure. 2. Insert the

f4mm pin to the intake and exhaust camshaft

flange not to rotate camshaft.

3. Remove the chain tensioner.

5. Cover the chain housing with a clean cloth, and grind off

the timing chain pin from the intake camshaft sprocket with

the grinder.

Page 150 of 1463

M162 ENGINE MECHANICAL 1B1-77

7. Connect the new timing chain (2) to the used timing chain

(3) with the link (5), center plate (6, thickness 1.6mm),

and the outer plate (7).

8. Rotate the crankshaft in the direction if engine revolution

by pressing the new timing chain against the exhaust

camshaft sprocket to prevent it to be tangled.

Notice

Be sure to remove the wedge before cranking the engine.

9. Take out the used timing chain out from the chain housing.

10. Connect both separators of the new timing chain with the

link (5) and the center plate (6). 6. Remove the outer plate (7) with the screw driver and

remove the link (5).

11. Install the jaw (a) and the thrust piece (b) to the assembly

tool as shown in the figures.

Trending: coolant temperature, instrument cluster, radiator cap, sensor, tailgate, change wheel, brake rotor