check engine SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 699 of 1463

1F2-50 M161 ENGINE CONTROLS

Tightening Torque

22.5 - 27.5 Nm

Tightening Torque22.5 - 27.5 Nm

Removal & Installation Procedure

1. Discharge the fuel pressure from the fuel pressure test

connector by pushing service valve (arrow).

2. Disconnect the battery ground cable.

3. Disconnect the vacuum hose from the fuel pressure

regulator.

4. Disconnect the cable from ignition coil.

5. Remove the fuel return and supply line.

Installation Notice

Notice

lFor removal, cover around parts with cloths not to

bestained by fuel.

lIn case of checking the injector only, do not remove the

fuel return and supply line.

6. Remove the four injector connectors (arrows).

7. Unscrew the two combination bolts (8).

Installation Notice

Page 700 of 1463

M161 ENGINE CONTROLS 1F2-51

9. Installation should follow the removal procedure in the

reverse order.

10. Check for fuel pressure and internal leakage by operating

the engine. 8. Pull out the injector from intake manifold and remove the

fuel distributor.

Notice

Replace the injector O-ring with new one.

Ignition Coil & Cable

lIgnition coil T1/1 No.1 cylinder + No.4 cylinder

lInition coil T1/2 No.1 cylinder + No.4 cylinder

Page 702 of 1463

M161 ENGINE CONTROLS 1F2-53

3. If there is no change in fuel pressure and maintain the

following pressure over 30 minutes, it is normal.

Internal Leakage Test

1. Connect the fuel pressure gauge to the fuel pressure test

connector.

2. Stop the engine for approx. 30 minutes and then check the

fuel pressure changes.

Fuel pressure

drops slowly

·Fuel leakage at the

injector

• Faulty fuel pressure

regulator's

diaphragm and O-

ring.

Fuel pressure

drops rapidly• Faulty check valve

in the fuel pump.

Possible Cause Pressure Change

Fuel Pressure(bar) 2.5

Discharging the pressure in fuel system

1. Remove the fuel pressure test connector.

Installation Notice

2. Remove the fuel pressure in fuel system by pressing the

service valve with a clean, pointy tool.

Notice

Place a cloth so that the fuel doesn't stain around.

Tightening Torque

22.5 - 27.5 Nm

Page 704 of 1463

M161 ENGINE CONTROLS 1F2-55

Removal & Installation Procedure

1. Remove the O-ring.

Check for damage and replace it if necessary.

2. Remove the injector bracket from the injector.

Installation Notice

Exactly seat the anti-twist lock into the square groove in

injector.

3. Separate the injector from the fuel distributor.

Inspection & Maintenance

Inspection of the Injector operation and spray pattern

1. Connect the contact box to the ECU.

2. Connect the shop made test plug to the injector and place

it into the tank.

3. Position the ignition switch to ON.

4. Connect the pin 63(+) and 69(-) of the contact box with a

test cable.

5. Check the injector spray pattern.

Notice

Replace the injector if the injector spray pattern is abnormal

or the fuel doesn't inject.

Injector Resistance Inspection

1. Remove the injector connector.

2. Measure the injector coil resistance using a resistance

tester.

Notice

Replace the injector if the measured values is out of the

specified values. Check the connector and wire connection

between the ECU and the injector if the measured values

are normal.

Specified Value

14 - 17 W

Page 705 of 1463

1F2-56 M161 ENGINE CONTROLS

The Injector Spray Pattern Check

1. Connect the test box (129 589 00 21 00) to the ECU.

2. Disconnect the connector from connector.

3. Disconnect the fuel distributor and injector with a unit from

engine without removing the fuel supply and return line.

Notice

Prepare the beaker for taking the poping fuel.

4. Connect either end of shop made cable to the injector.

5. Connect the other end of shop made cable to the (+:63)

and (-:69) terminal of the test box.

6. Turn the ignition switch to "ON" position.

7. Check the injector for normal spray pattern as shown in the

figure. Check injector for leaks or later drops.

Notice

Refer to fuel injector test of engine diagnosis in this section

for detailed information.

Page 706 of 1463

M161 ENGINE CONTROLS 1F2-57

FUEL FILTER

1 Fuel Filter

2 Outlet

Removal & Installation Procedure

1. Open the fuel tank cap and remove the fuel tank pressure.

2. Remove the fuel out (2) and in (3).

Installation Notice

Notice

Place the fuel pump pad. There may be a corrosion due to

the contact between the fuel filter and the bracket.

4. Check for leaks by operating the engine.

Notice

Installation should follow the removal procedure in the

reverse order. 3. Remove the mounting bracket bolt (4) and remove the fuel

filter (1).

Installation Notice3 Inlet

Tightening Torque

25 - 30 Nm

Tightening Torque

4 - 8 Nm

Page 709 of 1463

1F2-60 M161 ENGINE CONTROLS

Tools Required

661 589 00 46 00 Cap Remover

Removal & Installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the harness connector (1).

3. Disconnect the fuel supply (6) and return (5) pipes.

4. Using a special tool, Unscrew the eight fuel retaining bolts

and remove the pump from fuel tank.

Notice

Check the condition of the seal and replace if necessary.

Drain the fuel before removing the pump.

Page 710 of 1463

M161 ENGINE CONTROLS 1F2-61

Notice

Replace the fuel pump relay if the measured value is over

9A. Notice

Check the fuel filter and fuel line when the fuel delivery is

not within specified value.

Measure the Current Consumption of Fuel Pump

1. Remove the fuel pump relay from fuse and relay box in

trunk, and turn the ignition switch to "ON" position.

2. Using a multi-tester, measure the current consumption by

connecting the terminal No.1 and No.3 of pump.

Measure the Fuel Delivery From the Fuel Pump

1. Disconnect the return pipe from fuel distributor and insert

the appropriate hose into it.

2 . Place the hose end into the beaker with the minimum capacity

of 1Liter.

3. Turn the ignition switch to "ON" position.

4. Connect the terminal No.33 and No.5 of ECU with a service

wire.

5. Measure the fuel delivery from the fuel pump.

1Liter/max.35sec. Specifed Value

5 - 9A Specifed Value

Page 712 of 1463

M161 ENGINE CONTROLS 1F2-63

4. Remove the line to canister and measure the pressure with

the vacuum pressure gauge.

Test

1. Maintain the normal temperature and idling state by

operating the engine.

2. Connect the ECU terminal No.11 and No.34 and check for

normal operation through the output waves using the

scanner.

Notice

Test during purge control switchover valve operation after

the minimum of 1 minute after the engine turned on.

3. Connect the ECU terminal No.34 and No.10 and check for

current consumption during the ignition switch ON.

Purge switchover valve output wave Specified Value

0.3 - 0.5

Specified Value

> 50mbar

(after approx. 1min.)

purge switchover valve

operates at this time

Notice

Test while at normal temperature and at idling state by

operating the engine.

Page 716 of 1463

M161 ENGINE CONTROLS 1F2-67

Crankshaft Position Sensor Resistance

Inspection

1. Disconnect the coupling "E" of ECU while the ignition switch

is in "OFF" position.

2. Measure the resistance between the coupling terminal pin

No.99 and No.100 using a multimeter.

Notice

Measure the insulator resistance of the crankshaft position

sensor if out of the specified value.

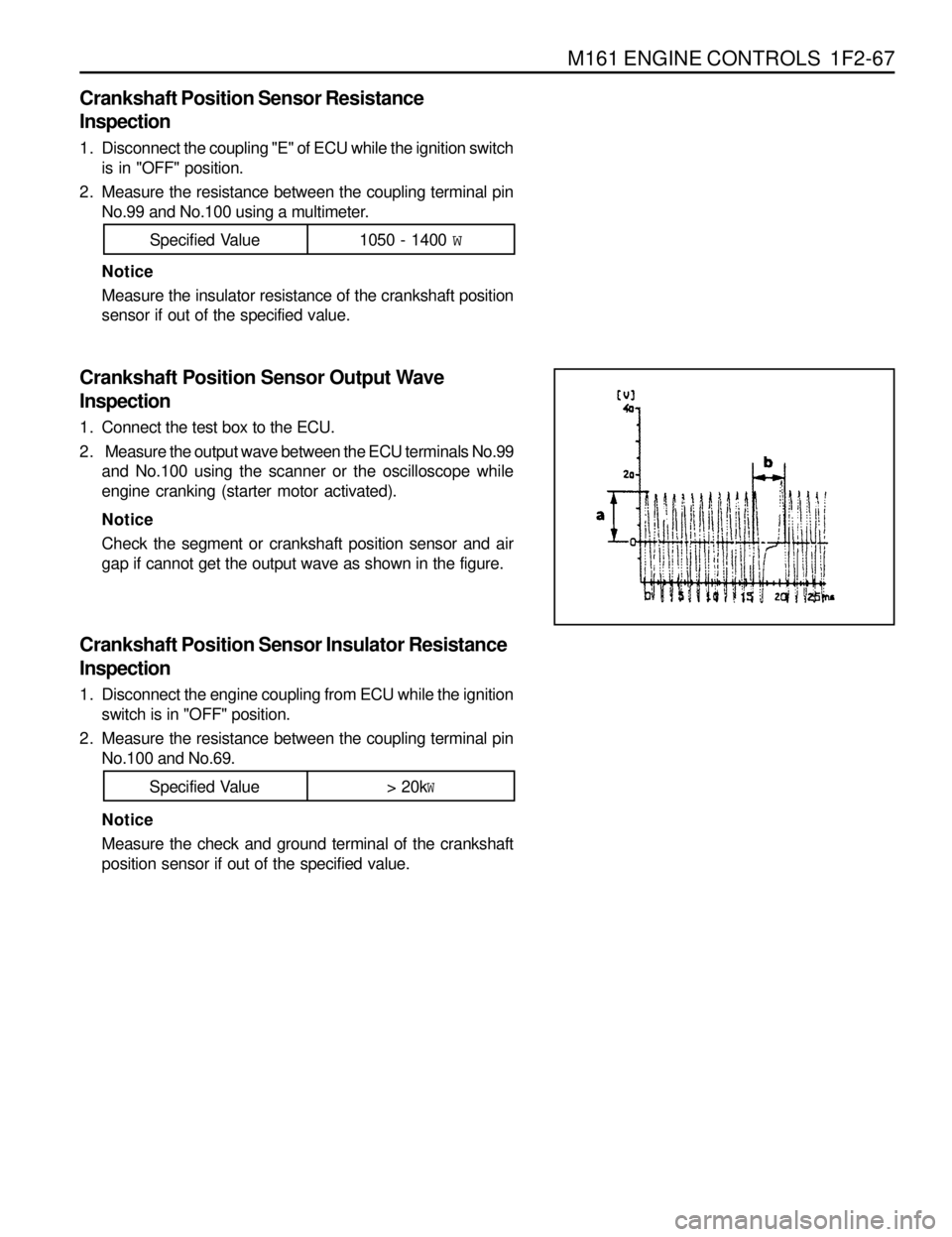

Crankshaft Position Sensor Output Wave

Inspection

1. Connect the test box to the ECU.

2. Measure the output wave between the ECU terminals No.99

and No.100 using the scanner or the oscilloscope while

engine cranking (starter motor activated).

Notice

Check the segment or crankshaft position sensor and air

gap if cannot get the output wave as shown in the figure.

Specified Value 1050 - 1400 W

Specified Value > 20kW

Crankshaft Position Sensor Insulator Resistance

Inspection

1. Disconnect the engine coupling from ECU while the ignition

switch is in "OFF" position.

2. Measure the resistance between the coupling terminal pin

No.100 and No.69.

Notice

Measure the check and ground terminal of the crankshaft

position sensor if out of the specified value.