check engine SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 760 of 1463

OM600 ENGINE CONTROLS 1F3-31

Tools Required

601 589 00 08 00Flange

601 589 05 21 00 Locking Screw

116 589 20 33 00 Sliding Hammer

116 589 02 34 00 Threaded Bolt

667 589 04 63 00 Retaining Plate

Removal & Installation Procedure

1. Remove the bolts (2) and then remove the cylinder head

cover (1) and gasket (3).

Installation Notice

Tightening Torque 10 Nm

Notice

Replace the gasket.

Rotate the engine 1 revolution by hand and check TDC

marking of the crankshaft and camshaft.

2. Loosen the camshaft sprocket bolt (14).

Notice

Do not remove the bolt.

Installation Notice

Notice

If max. length of bolt exceeds 53.6mm, replace it.

Tightening Torque 25Nm + 90°

3. Loosen the bolt (11) (left-hand thread).

Notice

Do not remove the bolt.

Page 763 of 1463

1F3-34 OM600 ENGINE CONTROLS

12. Push back the timing chain with retaining plate (26) and

remove the injection timing device (9).

Retaining Plate 667 589 04 63 00

13. Installation should follow the removal procedure in the

reverse order.

14. After assembling the engine, check start of delivery and

adjust if necessary.

Page 764 of 1463

OM600 ENGINE CONTROLS 1F3-35

INJECTION TIMING DEVICE

Preceding Work : Removal of injection timing device

1 Cam Sprocket........................................... Check

2 Bushing .................................................... Check

3 Governor Weights4 Segment Flange and Drive Hub

5 Compression Springs

Page 767 of 1463

1F3-38 OM600 ENGINE CONTROLS

Tools Required

617 589 08 21 00 Position Sensor

Test Procedure

1. Remove the screw plug (5) and seal (4) and collect oil in a

suitable vessel.

2. Install the position sensor (1) into the governor housing of

the injection pump to be the guide pin of the position sensor

facing up.

3. Connect the battery terminal of position sensor (1) to positive

terminal (+) of battery.

Position Sensor 617 589 08 21 00

4. Rotate the crankshaft by hand (in direction of engine rotation)

until the lamp ‘B’ lights up. Rotate the crankshaft carefully

further until both lamps ‘A and B’ come on. In this position,

check the Rl value on the crankshaft vibration damper.

Notice

If only lamp ‘A’ lights up, repeat the test and if out of

specification, adjust start of delivery.

Specification ATDC 14° - 16°

Page 770 of 1463

OM600 ENGINE CONTROLS 1F3-41

With Pulse Generator Tools Required

617 589 09 21 00 Rl Sensor

617 589 10 21 00 Timing Tester

667 589 00 21 00 TDC Pulse Generator

Commercial Tools

Item

Digital Tester

Without Pulse GeneratorTools

Bosch, MOT 001.03

Hartmann & Braun, EOMT3

Bosch, ETD 019.00

Sun, DIT 9000

ALV, Diesel - Tester 875

Test Procedure

1. Remove the screw plug (7) and seal (8) collect oil in a suitable

vessel.

2. Install the Rl sensor into the governor housing of injection

pump (1).

Rl Sensor 617 589 10 21 00

3. Connect the digital tester and TDC pulse sender unit

according to connection diagram.

4. Run the engine at idle speed and check the Rl value on the

digital tester

Notice

If out of standard, adjust the start of delivery.

5. Stop the engine.

6. Remove the Rl sensor, digital tester and TDC pulse sender

unit.

7. Replace the seal and tighten the plug.

8. Check engine oil level and adjust if necessary.

Rl value ATDC 14° - 16°

Tightening Torque 30 Nm

Page 780 of 1463

OM600 ENGINE CONTROLS 1F3-51

12. Connect the vacuum line (13, 14).

13. Connect the connecting rod (9).

14. Connect the accelerator control damper (10).

(Manual transmission vehicle)

15. Install the chain tensioner.

16. Install the vacuum pump.

17. Check the start of delivery.

18. Adjust the idle speed.

11. Assemble the plastic clip (8).

Page 786 of 1463

1G1-6 M162 ENGINE INTAKE & EXHAUST

Removal & Installation Procedure

lUpper Intake Manifold

1. Disconnect the vacuum hose (8,9).

2. Loosen the clip (22).

3. Remove the upper intake manifold (5) after unscrewing the

bolt (6).

Installation Notice

Notice

Check the gasket and replace it if necessary.

4. Installation should follow the removal procedure in the

reverse order.

lLower Intake Manifold

Preceding work : removal of upper intake manifold

1. Remove the hose of brake booster vacuum line and idle

speed connector.

2. Disconnect the hot water inlet pipe from the bottom of lower

intake manifold.

3. Unscrew the bolt (17) and remove the lower intake manifold

(16).

Installation Notice

4. Start the engine and check for leaks at each connection

part.

Tightening Torque 22.5 - 27.5 Nm

Tightening Torque 22.5 - 27.5 Nm

Page 787 of 1463

M162 ENGINE INTAKE & EXHAUST 1G1-7

RESONANCE FLAP

1 Soft Cap (2)

2 Bolt (M6 x 25, 4 pieces)......................... 9-11 Nm

3 O-ring

Removal & Installation Procedure

1. Remove the 2 soft caps (1).

2. Remove the upper resonance flap coupling after removing

4 bolts (2).

Notice

Connect carefully the vacuum hose (4) for installation.

3. Check the O-ring (3) and replace it if necessary.

4. Remove the lower resonance flap (5).

5. Replace the gasket (6).

6. Installation should follow the removal procedure in the

reverse order.4 Vacuum Hose

5 Resonance Flap

6 Gasket ................................................... Replace

Page 790 of 1463

1G1-10 M162 ENGINE INTAKE & EXHAUST

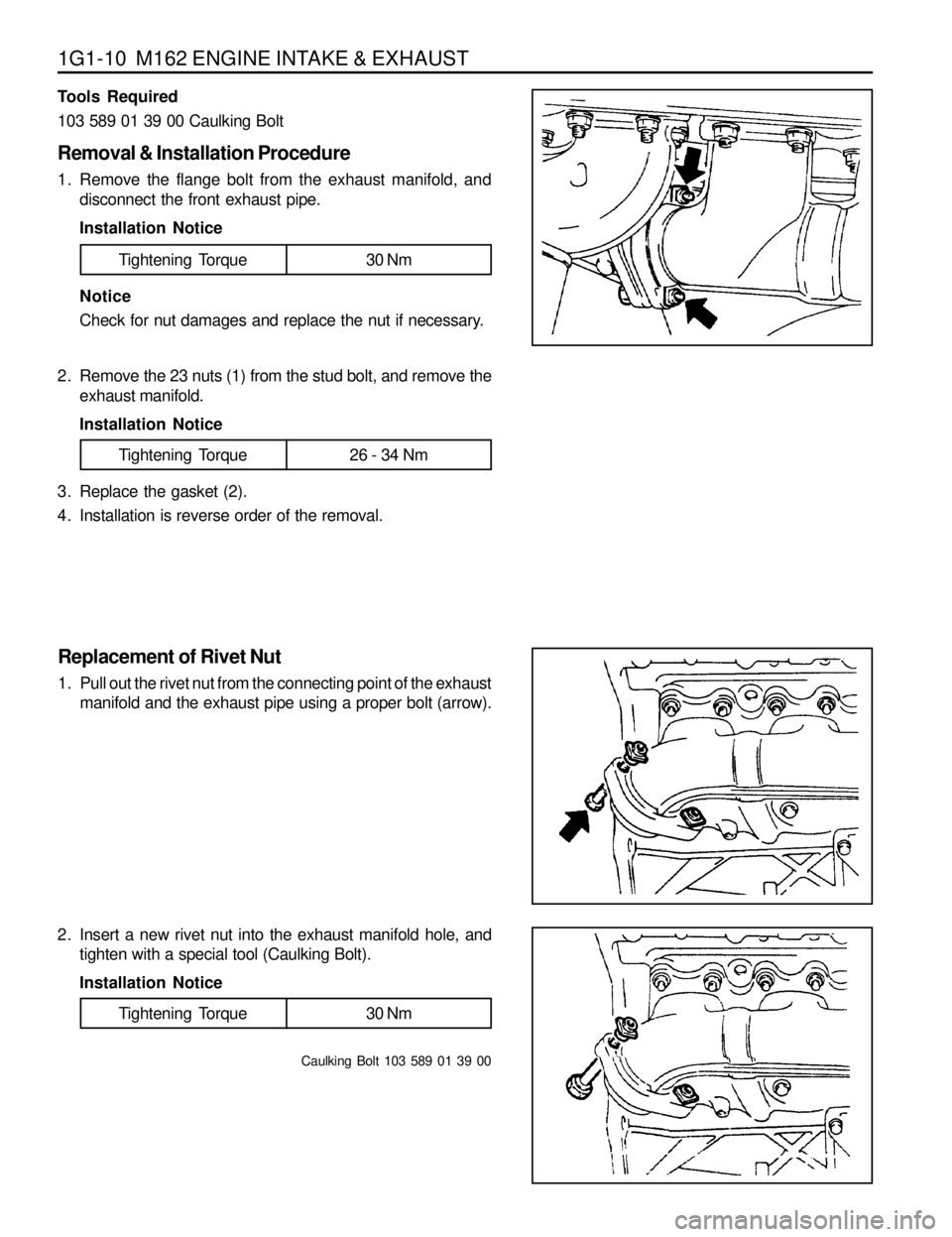

Tools Required

103 589 01 39 00 Caulking Bolt

Removal & Installation Procedure

1. Remove the flange bolt from the exhaust manifold, and

disconnect the front exhaust pipe.

Installation Notice

Notice

Check for nut damages and replace the nut if necessary.

2. Remove the 23 nuts (1) from the stud bolt, and remove the

exhaust manifold.

Installation Notice

3. Replace the gasket (2).

4. Installation is reverse order of the removal.

Replacement of Rivet Nut

1. Pull out the rivet nut from the connecting point of the exhaust

manifold and the exhaust pipe using a proper bolt (arrow).

2. Insert a new rivet nut into the exhaust manifold hole, and

tighten with a special tool (Caulking Bolt).

Installation Notice

Caulking Bolt 103 589 01 39 00

Tightening Torque 30 Nm

Tightening Torque 26 - 34 Nm

Tightening Torque 30 Nm

Page 799 of 1463

1G2-8 M161 ENGINE INTAKE & EXHAUST

Removal & Installation Procedure

1. Disconnect the battery ground cable.

2. Remove idle speed control plug connector (arrow).

3. Disconnect the brake booster vacuum line and other

vacuum lines.

4. Disconnector the rod from bearing bracket assembly and

remove the connection piece (8).

Installation Notice

Tightening Torque 36 - 44 Nm

5. Unscrew the three bolts (4) and remove the idle regulator

and intermediate flange (6).

Installation Notice

Tightening Torque 22.5 - 27.5 Nm

6. Unscrew the two bolts (M8 X 16) and remove the support

assembly (arrow).

Installation Notice

7. Unscrew the intake manifold assembly mounting bolts (1)

and remove the intake manifold and gasket.

Installation Notice

Notice

Replace the gasket with new one.

8. Installation should follow the removal procedure in the

reverse order.

9. Start the engine and check for leaks in each connection.

Tightening Torque 22.5 - 27.5 Nm

Tightening Torque 22.5 - 27.5 Nm