oil SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 1016 of 1463

AUTOMATIC TRANSMISSION 5A-39

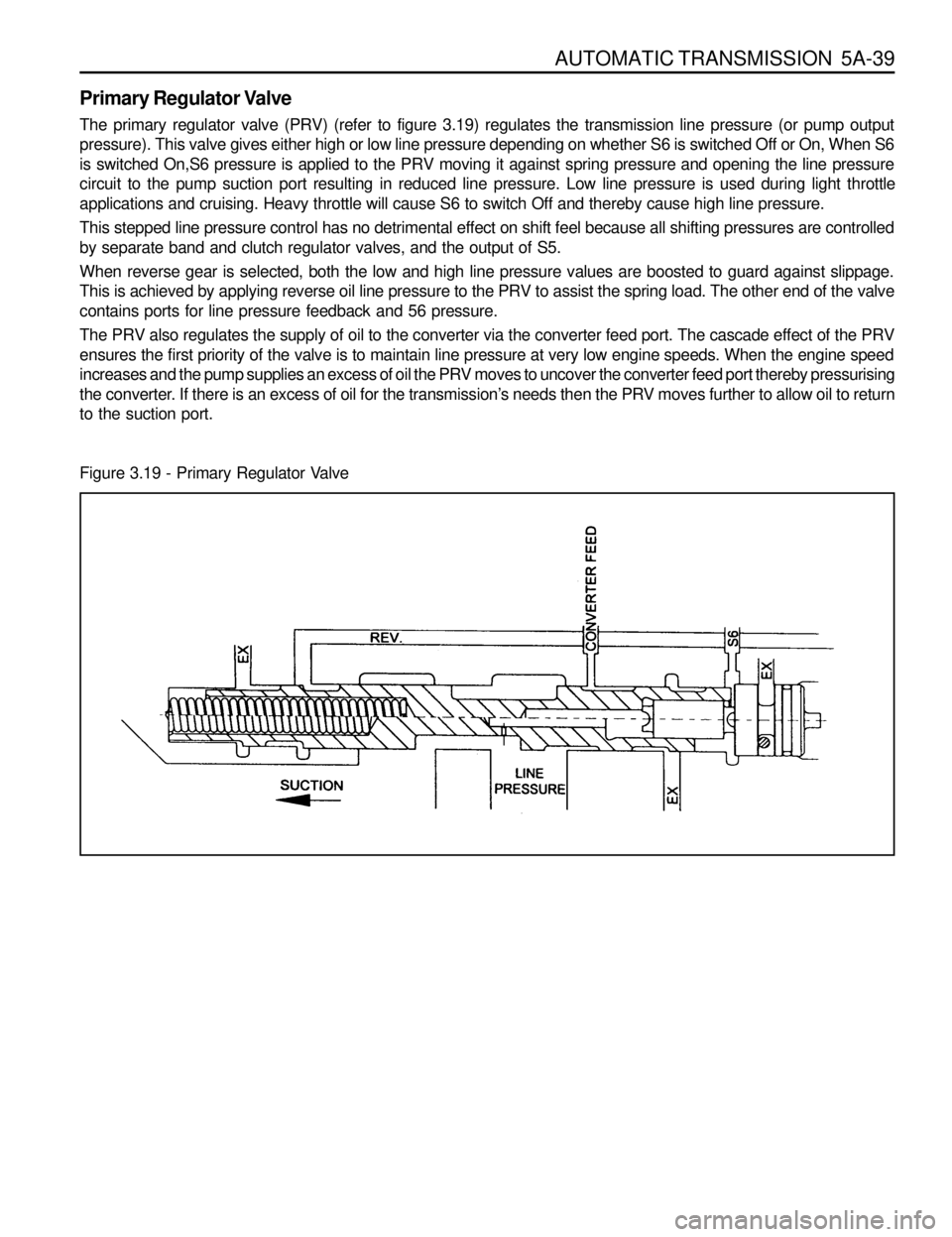

Primary Regulator Valve

The primary regulator valve (PRV) (refer to figure 3.19) regulates the transmission line pressure (or pump output

pressure). This valve gives either high or low line pressure depending on whether S6 is switched Off or On, When S6

is switched On,S6 pressure is applied to the PRV moving it against spring pressure and opening the line pressure

circuit to the pump suction port resulting in reduced line pressure. Low line pressure is used during light throttle

applications and cruising. Heavy throttle will cause S6 to switch Off and thereby cause high line pressure.

This stepped line pressure control has no detrimental effect on shift feel because all shifting pressures are controlled

by separate band and clutch regulator valves, and the output of S5.

When reverse gear is selected, both the low and high line pressure values are boosted to guard against slippage.

This is achieved by applying reverse oil line pressure to the PRV to assist the spring load. The other end of the valve

contains ports for line pressure feedback and 56 pressure.

The PRV also regulates the supply of oil to the converter via the converter feed port. The cascade effect of the PRV

ensures the first priority of the valve is to maintain line pressure at very low engine speeds. When the engine speed

increases and the pump supplies an excess of oil the PRV moves to uncover the converter feed port thereby pressurising

the converter. If there is an excess of oil for the transmission’s needs then the PRV moves further to allow oil to return

to the suction port.

Figure 3.19 - Primary Regulator Valve

Page 1017 of 1463

5A-40 AUTOMATIC TRANSMISSION

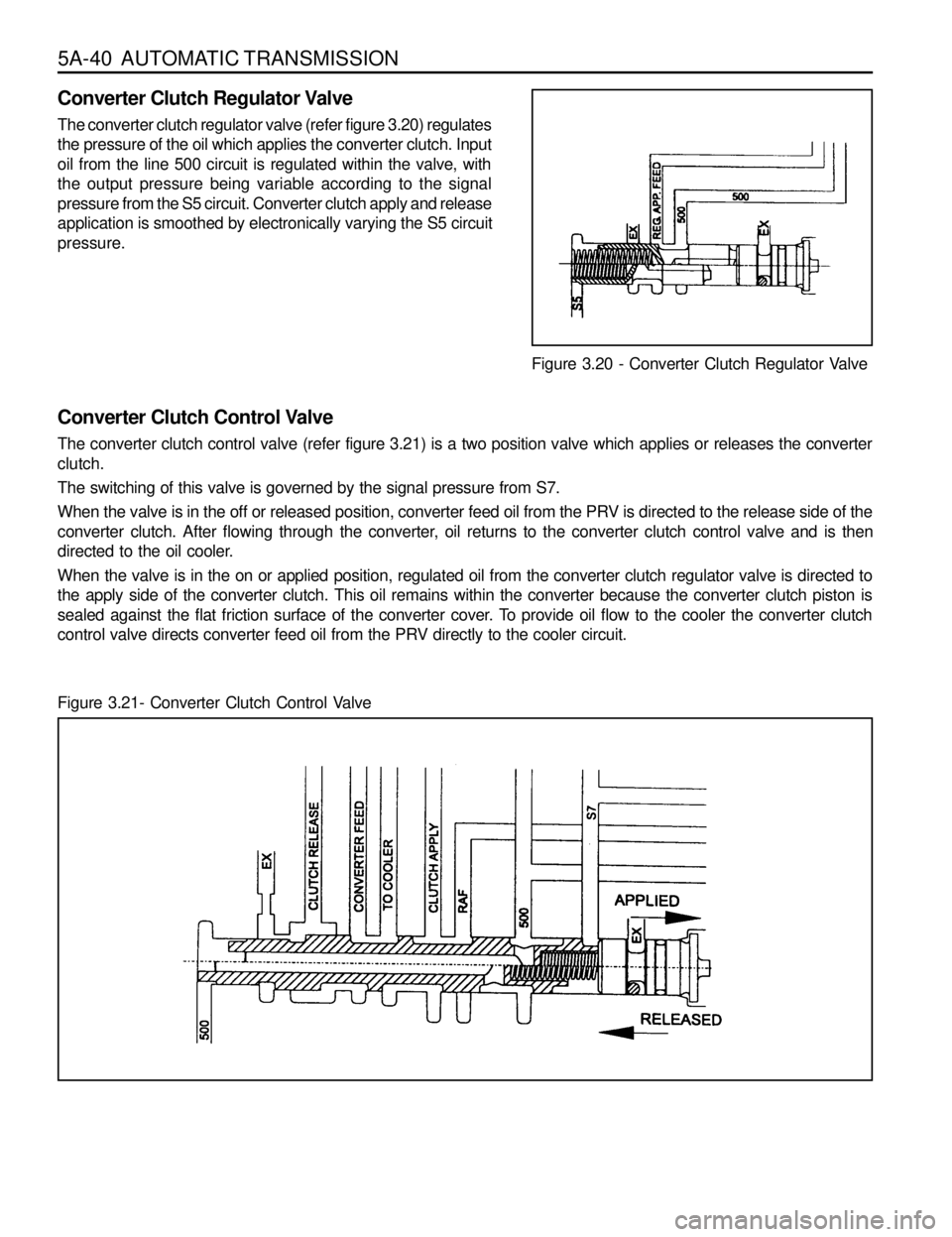

Converter Clutch Regulator Valve

The converter clutch regulator valve (refer figure 3.20) regulates

the pressure of the oil which applies the converter clutch. Input

oil from the line 500 circuit is regulated within the valve, with

the output pressure being variable according to the signal

pressure from the S5 circuit. Converter clutch apply and release

application is smoothed by electronically varying the S5 circuit

pressure.

Converter Clutch Control Valve

The converter clutch control valve (refer figure 3.21) is a two position valve which applies or releases the converter

clutch.

The switching of this valve is governed by the signal pressure from S7.

When the valve is in the off or released position, converter feed oil from the PRV is directed to the release side of the

converter clutch. After flowing through the converter, oil returns to the converter clutch control valve and is then

directed to the oil cooler.

When the valve is in the on or applied position, regulated oil from the converter clutch regulator valve is directed to

the apply side of the converter clutch. This oil remains within the converter because the converter clutch piston is

sealed against the flat friction surface of the converter cover. To provide oil flow to the cooler the converter clutch

control valve directs converter feed oil from the PRV directly to the cooler circuit.

Figure 3.21- Converter Clutch Control ValveFigure 3.20 - Converter Clutch Regulator Valve

Page 1018 of 1463

AUTOMATIC TRANSMISSION 5A-41

C1 Bias Valve

The C1 bias valve (refer figure 3.22) ensures that the converter lock-up clutch is only applied in third and fourth

gears. It uses C1 clutch oil pressure as the switching signal since C1 is only applied in third and fourth gears.

Line to 500 oil is routed through the C1 bias valve to S7. The C1 bias valve therefore acts as a safety feature to

ensure drivability in the event of S7 failure.

Figure 3.22- C1 Bias Valve

B1R Exhaust Valve

The B1R exhaust valve (refer figure 3.23) is a two position

spring loaded valve located in the transmission case directly

adjacent to the front servo. It permits the servo release oil to

be rapidly exhausted into the transmission case during

application of the front band (B1). This prevents the need to

force the oil back from the front servo through the valve body

and through the 3-4 shift valve. The spring positions the valve

to prevent oil entering the release area of the servo until the

B1R circuit oil pressure reaches approximately 100 kPa.

Figure 3.23 - B1R Exhaust Valve

Page 1025 of 1463

5A-48 AUTOMATIC TRANSMISSION

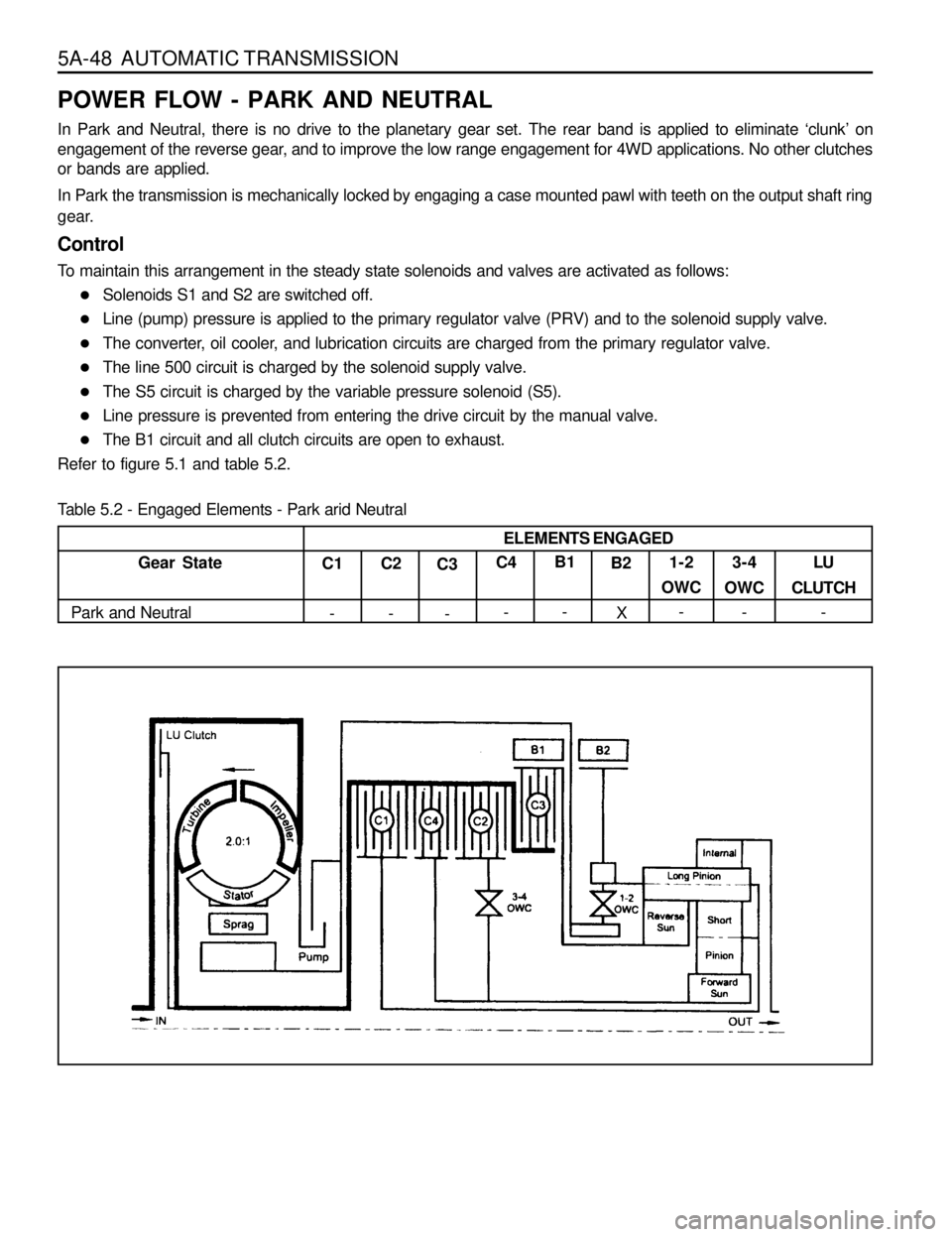

POWER FLOW - PARK AND NEUTRAL

In Park and Neutral, there is no drive to the planetary gear set. The rear band is applied to eliminate ‘clunk’ on

engagement of the reverse gear, and to improve the low range engagement for 4WD applications. No other clutches

or bands are applied.

In Park the transmission is mechanically locked by engaging a case mounted pawl with teeth on the output shaft ring

gear.

Control

To maintain this arrangement in the steady state solenoids and valves are activated as follows:

lSolenoids S1 and S2 are switched off.

lLine (pump) pressure is applied to the primary regulator valve (PRV) and to the solenoid supply valve.

lThe converter, oil cooler, and lubrication circuits are charged from the primary regulator valve.

lThe line 500 circuit is charged by the solenoid supply valve.

lThe S5 circuit is charged by the variable pressure solenoid (S5).

lLine pressure is prevented from entering the drive circuit by the manual valve.

lThe B1 circuit and all clutch circuits are open to exhaust.

Refer to figure 5.1 and table 5.2.

Table 5.2 - Engaged Elements - Park arid Neutral

Gear State

Park and NeutralC1

-C2

-C3

-C4

-B1

-B2

X1-2

OWC

-3-4

OWC

-LU

CLUTCH

- ELEMENTS ENGAGED

Page 1026 of 1463

AUTOMATIC TRANSMISSION 5A-49

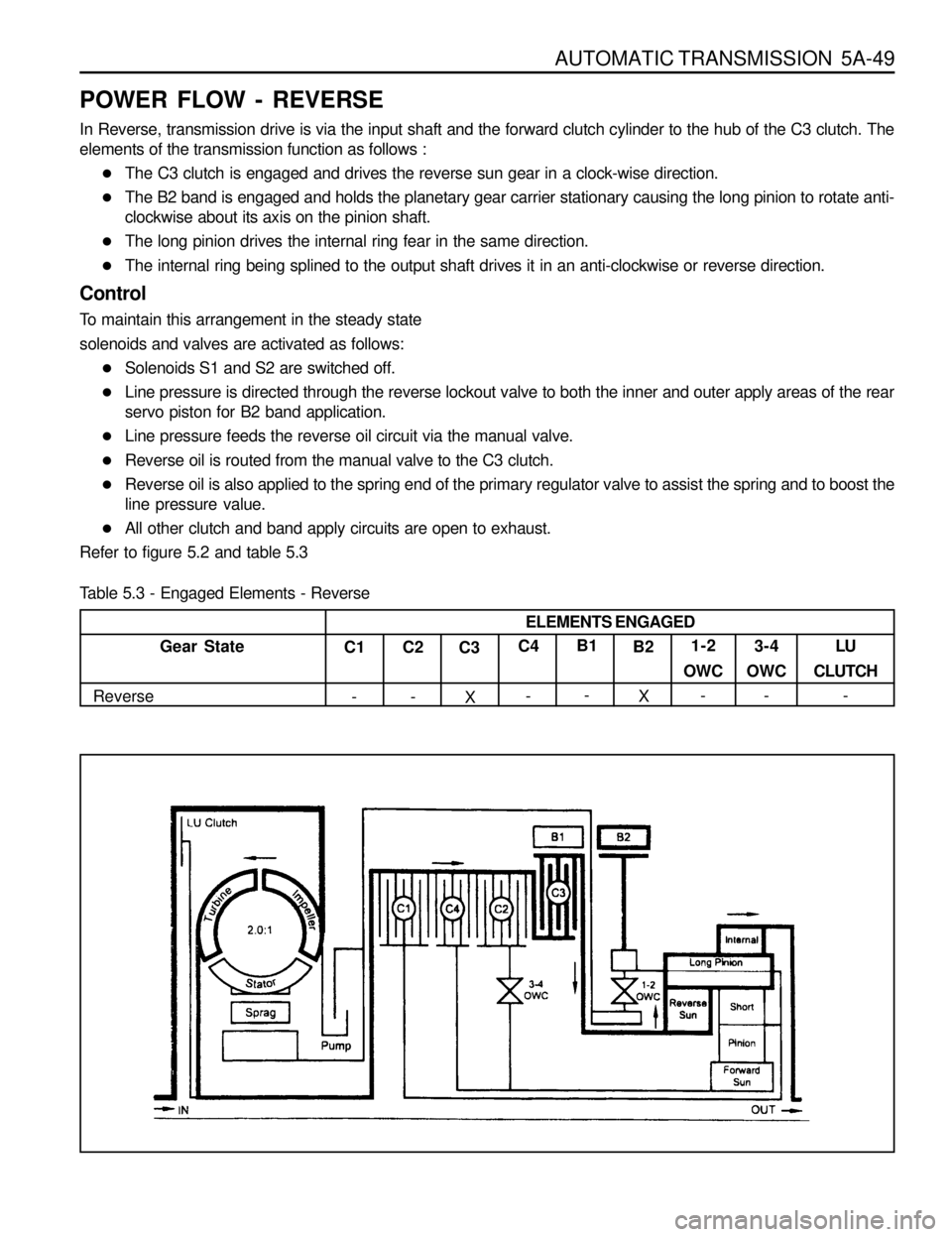

POWER FLOW - REVERSE

In Reverse, transmission drive is via the input shaft and the forward clutch cylinder to the hub of the C3 clutch. The

elements of the transmission function as follows :

lThe C3 clutch is engaged and drives the reverse sun gear in a clock-wise direction.

lThe B2 band is engaged and holds the planetary gear carrier stationary causing the long pinion to rotate anti-

clockwise about its axis on the pinion shaft.

lThe long pinion drives the internal ring fear in the same direction.

lThe internal ring being splined to the output shaft drives it in an anti-clockwise or reverse direction.

Control

To maintain this arrangement in the steady state

solenoids and valves are activated as follows:

lSolenoids S1 and S2 are switched off.

lLine pressure is directed through the reverse lockout valve to both the inner and outer apply areas of the rear

servo piston for B2 band application.

lLine pressure feeds the reverse oil circuit via the manual valve.

lReverse oil is routed from the manual valve to the C3 clutch.

lReverse oil is also applied to the spring end of the primary regulator valve to assist the spring and to boost the

line pressure value.

lAll other clutch and band apply circuits are open to exhaust.

Refer to figure 5.2 and table 5.3

Table 5.3 - Engaged Elements - Reverse

Gear State

ReverseC1

-C2

-C3

XC4

-B1

-B2

X1-2

OWC

-3-4

OWC

-LU

CLUTCH

- ELEMENTS ENGAGED

Page 1027 of 1463

5A-50 AUTOMATIC TRANSMISSION

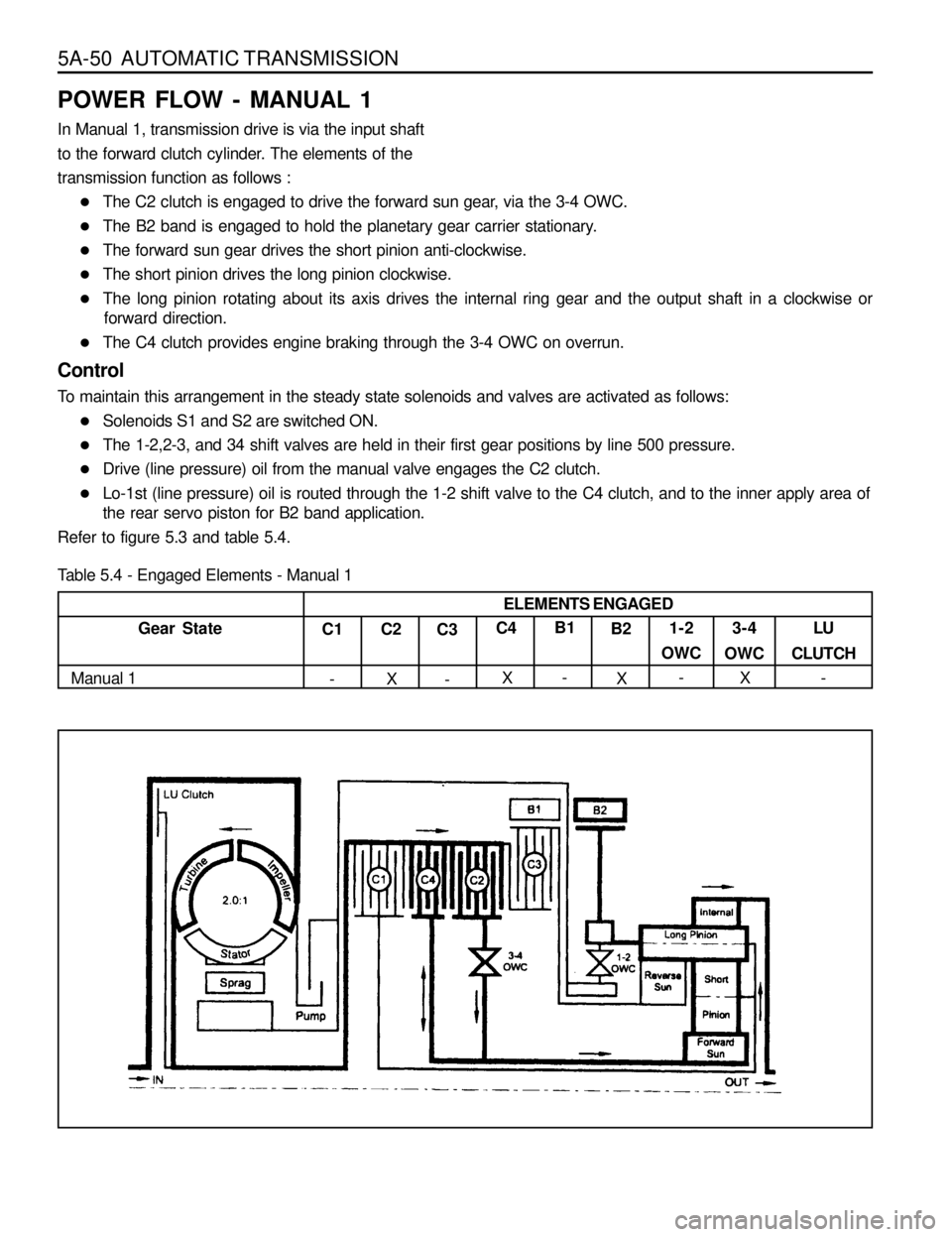

POWER FLOW - MANUAL 1

In Manual 1, transmission drive is via the input shaft

to the forward clutch cylinder. The elements of the

transmission function as follows :

lThe C2 clutch is engaged to drive the forward sun gear, via the 3-4 OWC.

lThe B2 band is engaged to hold the planetary gear carrier stationary.

lThe forward sun gear drives the short pinion anti-clockwise.

lThe short pinion drives the long pinion clockwise.

lThe long pinion rotating about its axis drives the internal ring gear and the output shaft in a clockwise or

forward direction.

lThe C4 clutch provides engine braking through the 3-4 OWC on overrun.

Control

To maintain this arrangement in the steady state solenoids and valves are activated as follows:

lSolenoids S1 and S2 are switched ON.

lThe 1-2,2-3, and 34 shift valves are held in their first gear positions by line 500 pressure.

lDrive (line pressure) oil from the manual valve engages the C2 clutch.

lLo-1st (line pressure) oil is routed through the 1-2 shift valve to the C4 clutch, and to the inner apply area of

the rear servo piston for B2 band application.

Refer to figure 5.3 and table 5.4.

Table 5.4 - Engaged Elements - Manual 1

Gear State

Manual 1C1

-C2

XC3

-C4

XB1

-B2

X1-2

OWC

-3-4

OWC

XLU

CLUTCH

- ELEMENTS ENGAGED

Page 1028 of 1463

AUTOMATIC TRANSMISSION 5A-51

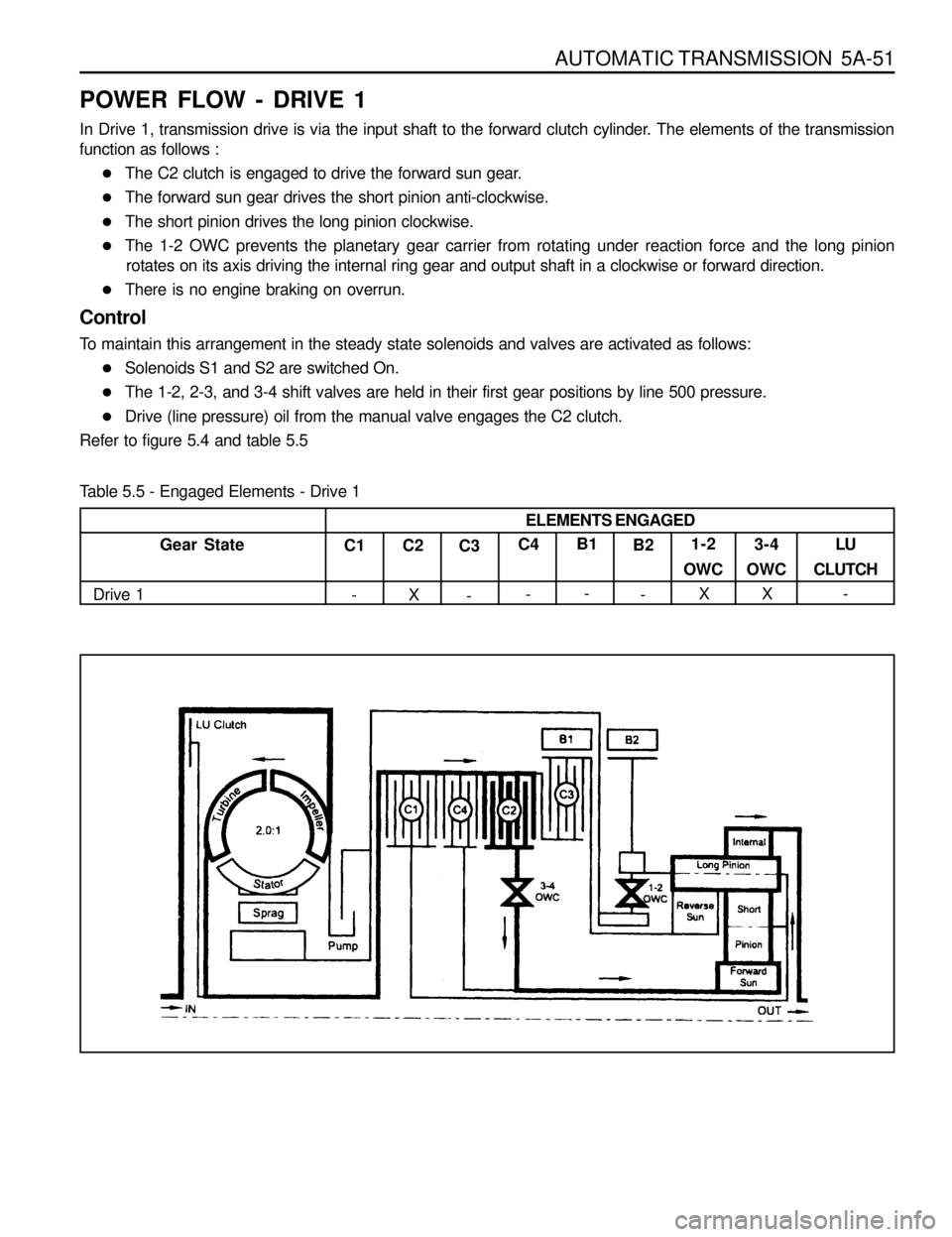

POWER FLOW - DRIVE 1

In Drive 1, transmission drive is via the input shaft to the forward clutch cylinder. The elements of the transmission

function as follows :

lThe C2 clutch is engaged to drive the forward sun gear.

lThe forward sun gear drives the short pinion anti-clockwise.

lThe short pinion drives the long pinion clockwise.

lThe 1-2 OWC prevents the planetary gear carrier from rotating under reaction force and the long pinion

rotates on its axis driving the internal ring gear and output shaft in a clockwise or forward direction.

lThere is no engine braking on overrun.

Control

To maintain this arrangement in the steady state solenoids and valves are activated as follows:

lSolenoids S1 and S2 are switched On.

lThe 1-2, 2-3, and 3-4 shift valves are held in their first gear positions by line 500 pressure.

lDrive (line pressure) oil from the manual valve engages the C2 clutch.

Refer to figure 5.4 and table 5.5

Table 5.5 - Engaged Elements - Drive 1

Gear State

Drive 1C1

-C2

XC3

-C4

-B1

-B2

-1-2

OWC

X3-4

OWC

XLU

CLUTCH

- ELEMENTS ENGAGED

Page 1029 of 1463

5A-52 AUTOMATIC TRANSMISSION

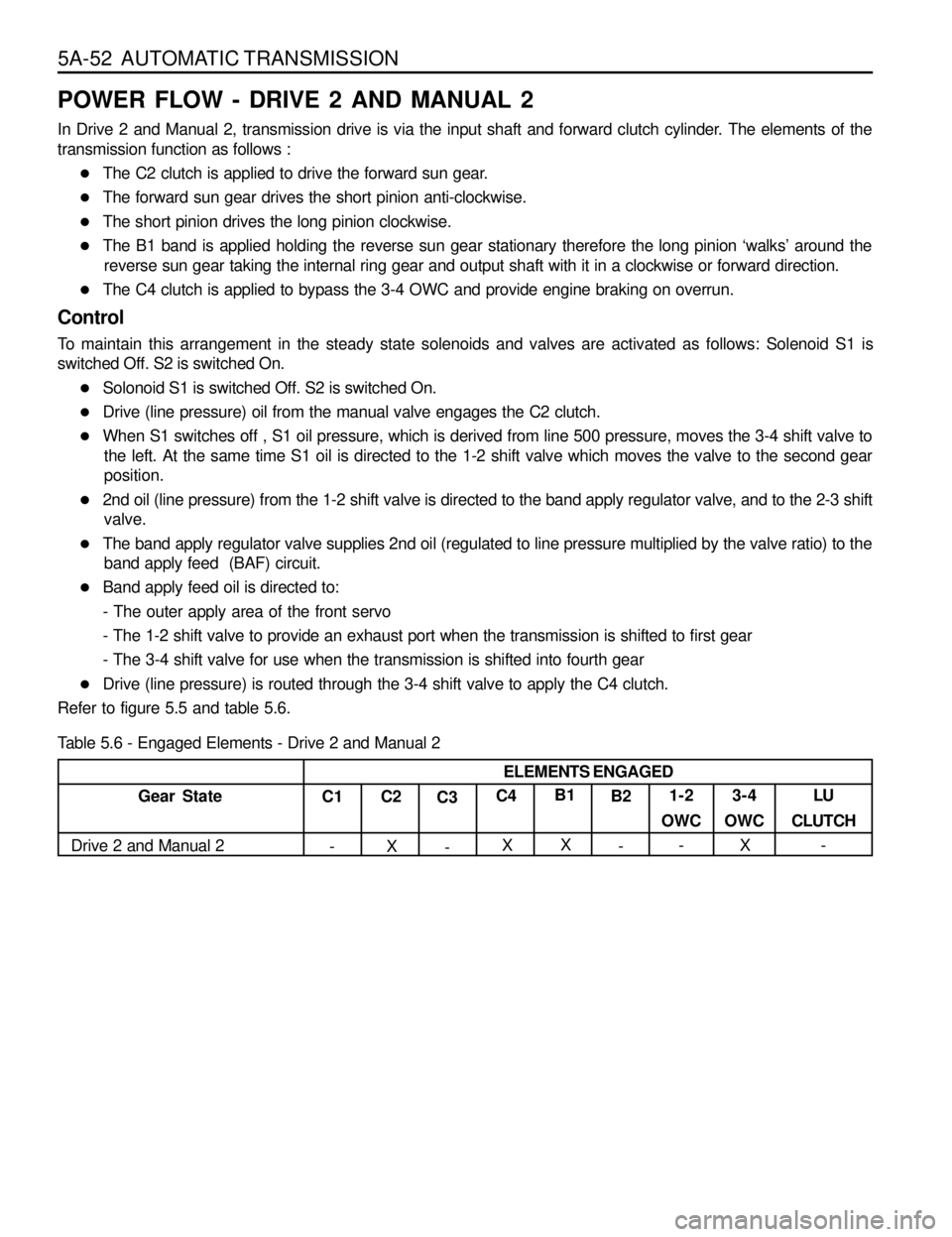

POWER FLOW - DRIVE 2 AND MANUAL 2

In Drive 2 and Manual 2, transmission drive is via the input shaft and forward clutch cylinder. The elements of the

transmission function as follows :

lThe C2 clutch is applied to drive the forward sun gear.

lThe forward sun gear drives the short pinion anti-clockwise.

lThe short pinion drives the long pinion clockwise.

lThe B1 band is applied holding the reverse sun gear stationary therefore the long pinion ‘walks’ around the

reverse sun gear taking the internal ring gear and output shaft with it in a clockwise or forward direction.

lThe C4 clutch is applied to bypass the 3-4 OWC and provide engine braking on overrun.

Control

To maintain this arrangement in the steady state solenoids and valves are activated as follows: Solenoid S1 is

switched Off. S2 is switched On.

lSolonoid S1 is switched Off. S2 is switched On.

lDrive (line pressure) oil from the manual valve engages the C2 clutch.

lWhen S1 switches off , S1 oil pressure, which is derived from line 500 pressure, moves the 3-4 shift valve to

the left. At the same time S1 oil is directed to the 1-2 shift valve which moves the valve to the second gear

position.

l2nd oil (line pressure) from the 1-2 shift valve is directed to the band apply regulator valve, and to the 2-3 shift

valve.

lThe band apply regulator valve supplies 2nd oil (regulated to line pressure multiplied by the valve ratio) to the

band apply feed (BAF) circuit.

lBand apply feed oil is directed to:

- The outer apply area of the front servo

- The 1-2 shift valve to provide an exhaust port when the transmission is shifted to first gear

- The 3-4 shift valve for use when the transmission is shifted into fourth gear

lDrive (line pressure) is routed through the 3-4 shift valve to apply the C4 clutch.

Refer to figure 5.5 and table 5.6.

Table 5.6 - Engaged Elements - Drive 2 and Manual 2

Gear State

Drive 2 and Manual 2C1

-C2

XC3

-C4

XB1

XB2

-1-2

OWC

-3-4

OWC

XLU

CLUTCH

- ELEMENTS ENGAGED

Page 1031 of 1463

5A-54 AUTOMATIC TRANSMISSION

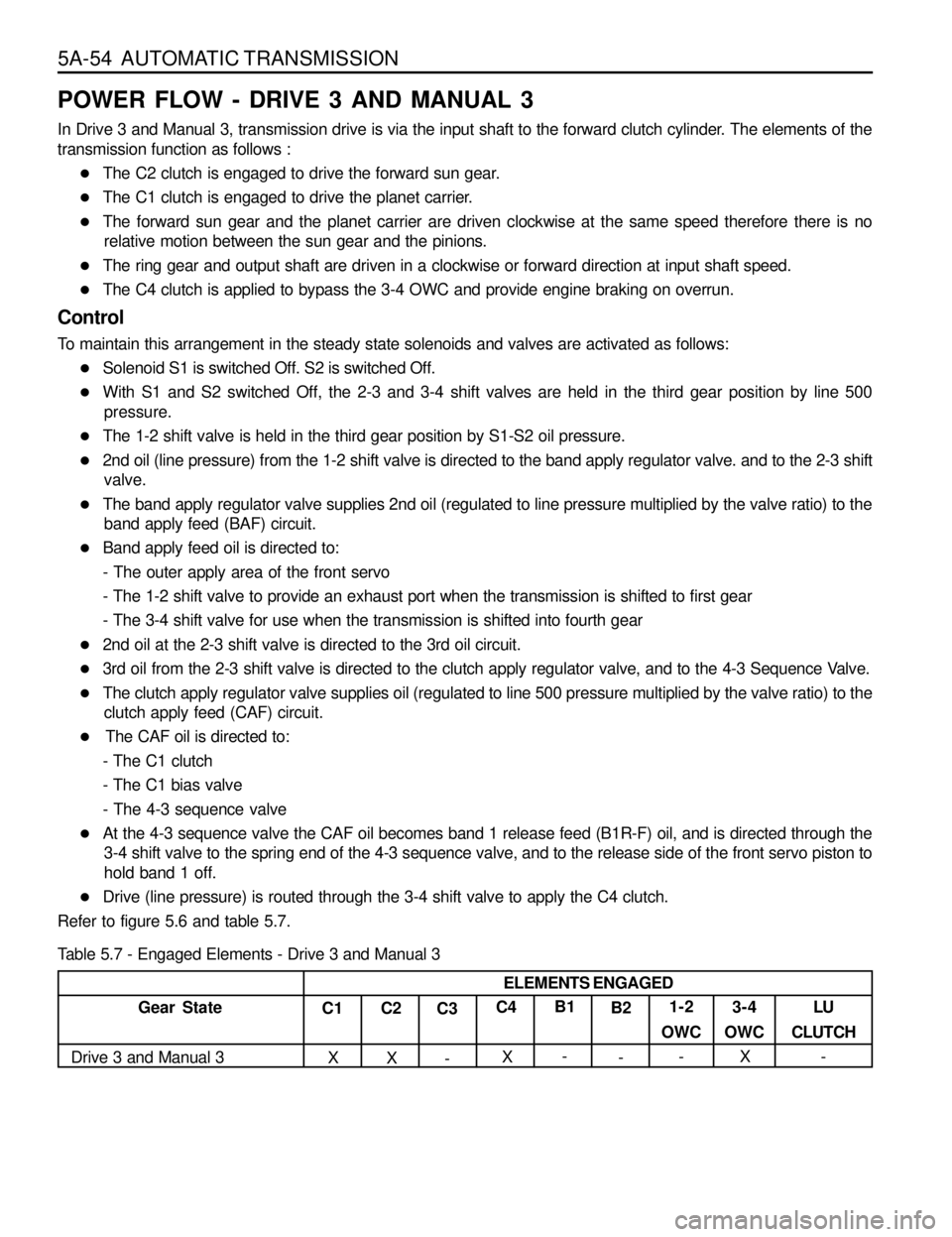

POWER FLOW - DRIVE 3 AND MANUAL 3

In Drive 3 and Manual 3, transmission drive is via the input shaft to the forward clutch cylinder. The elements of the

transmission function as follows :

lThe C2 clutch is engaged to drive the forward sun gear.

lThe C1 clutch is engaged to drive the planet carrier.

lThe forward sun gear and the planet carrier are driven clockwise at the same speed therefore there is no

relative motion between the sun gear and the pinions.

lThe ring gear and output shaft are driven in a clockwise or forward direction at input shaft speed.

lThe C4 clutch is applied to bypass the 3-4 OWC and provide engine braking on overrun.

Control

To maintain this arrangement in the steady state solenoids and valves are activated as follows:

lSolenoid S1 is switched Off. S2 is switched Off.

lWith S1 and S2 switched Off, the 2-3 and 3-4 shift valves are held in the third gear position by line 500

pressure.

lThe 1-2 shift valve is held in the third gear position by S1-S2 oil pressure.

l2nd oil (line pressure) from the 1-2 shift valve is directed to the band apply regulator valve. and to the 2-3 shift

valve.

lThe band apply regulator valve supplies 2nd oil (regulated to line pressure multiplied by the valve ratio) to the

band apply feed (BAF) circuit.

lBand apply feed oil is directed to:

- The outer apply area of the front servo

- The 1-2 shift valve to provide an exhaust port when the transmission is shifted to first gear

- The 3-4 shift valve for use when the transmission is shifted into fourth gear

l2nd oil at the 2-3 shift valve is directed to the 3rd oil circuit.

l3rd oil from the 2-3 shift valve is directed to the clutch apply regulator valve, and to the 4-3 Sequence Valve.

lThe clutch apply regulator valve supplies oil (regulated to line 500 pressure multiplied by the valve ratio) to the

clutch apply feed (CAF) circuit.

l The CAF oil is directed to:

- The C1 clutch

- The C1 bias valve

- The 4-3 sequence valve

lAt the 4-3 sequence valve the CAF oil becomes band 1 release feed (B1R-F) oil, and is directed through the

3-4 shift valve to the spring end of the 4-3 sequence valve, and to the release side of the front servo piston to

hold band 1 off.

lDrive (line pressure) is routed through the 3-4 shift valve to apply the C4 clutch.

Refer to figure 5.6 and table 5.7.

Table 5.7 - Engaged Elements - Drive 3 and Manual 3

Gear State

Drive 3 and Manual 3C1

XC2

XC3

-C4

XB1

-B2

-1-2

OWC

-3-4

OWC

XLU

CLUTCH

- ELEMENTS ENGAGED

Page 1033 of 1463

5A-56 AUTOMATIC TRANSMISSION

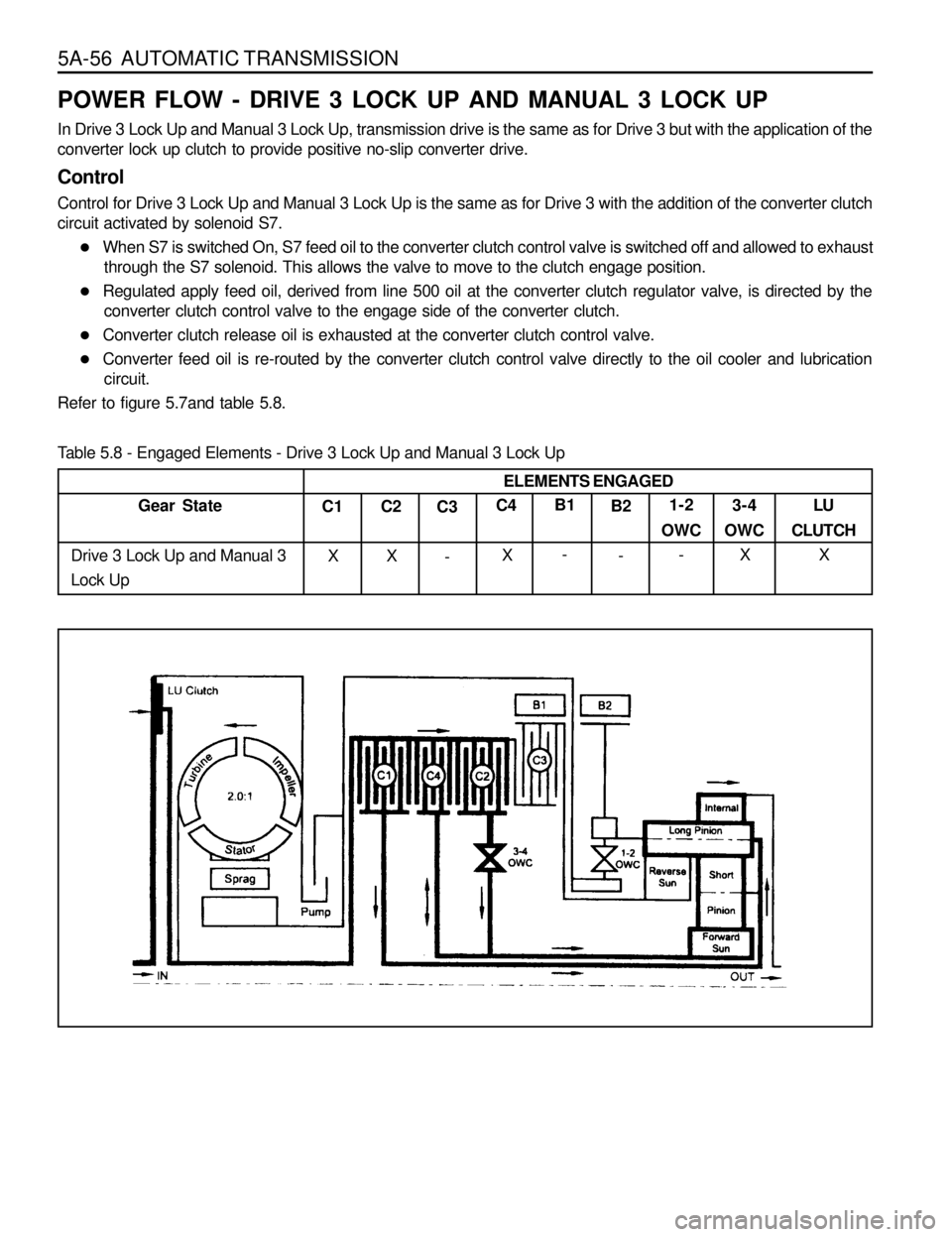

POWER FLOW - DRIVE 3 LOCK UP AND MANUAL 3 LOCK UP

In Drive 3 Lock Up and Manual 3 Lock Up, transmission drive is the same as for Drive 3 but with the application of the

converter lock up clutch to provide positive no-slip converter drive.

Control

Control for Drive 3 Lock Up and Manual 3 Lock Up is the same as for Drive 3 with the addition of the converter clutch

circuit activated by solenoid S7.

lWhen S7 is switched On, S7 feed oil to the converter clutch control valve is switched off and allowed to exhaust

through the S7 solenoid. This allows the valve to move to the clutch engage position.

lRegulated apply feed oil, derived from line 500 oil at the converter clutch regulator valve, is directed by the

converter clutch control valve to the engage side of the converter clutch.

lConverter clutch release oil is exhausted at the converter clutch control valve.

lConverter feed oil is re-routed by the converter clutch control valve directly to the oil cooler and lubrication

circuit.

Refer to figure 5.7and table 5.8.

Table 5.8 - Engaged Elements - Drive 3 Lock Up and Manual 3 Lock Up

Gear State

Drive 3 Lock Up and Manual 3

Lock UpC1

XC2

XC3

-C4

XB1

-B2

-1-2

OWC

-3-4

OWC

XLU

CLUTCH

X ELEMENTS ENGAGED