cooling SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 16 of 1463

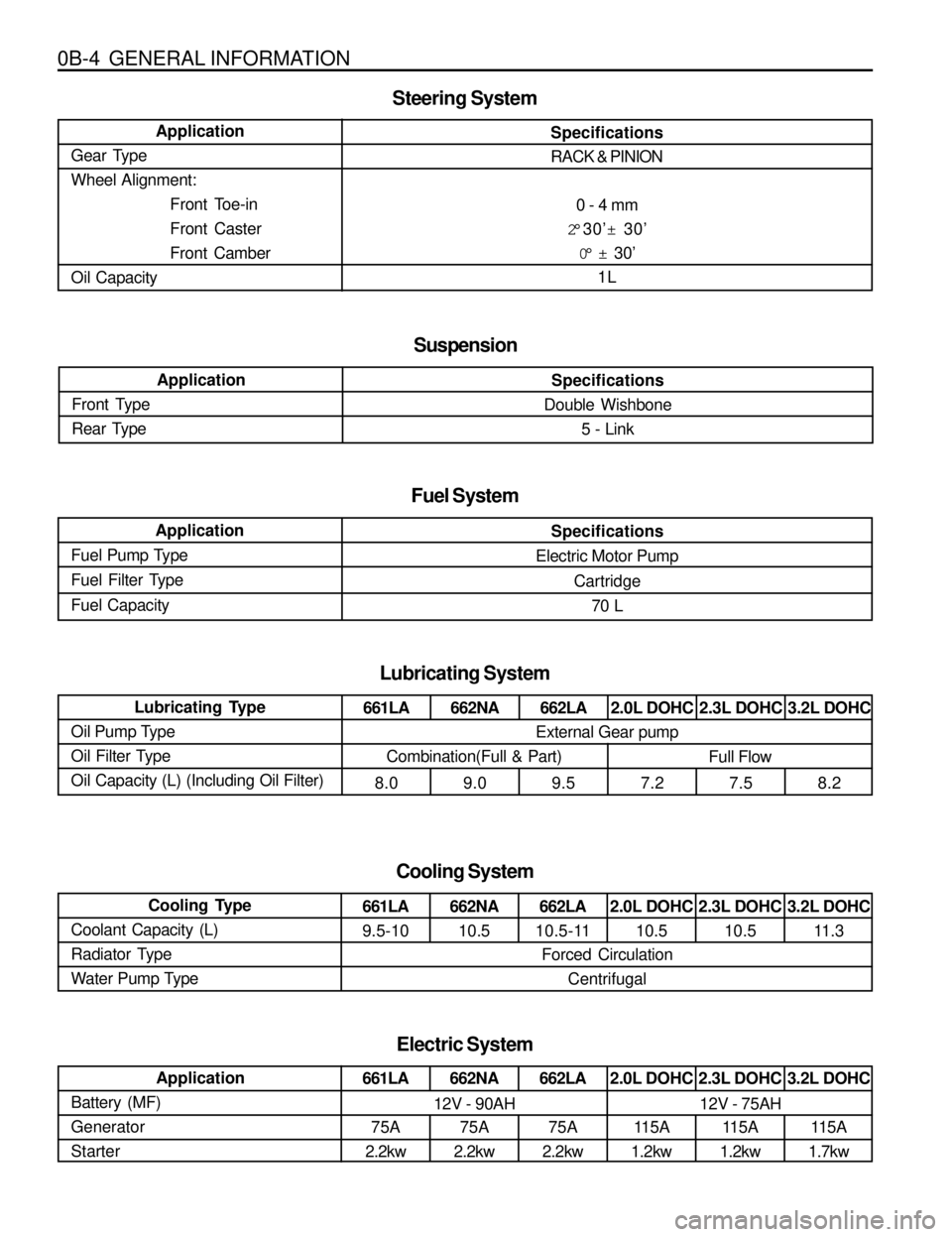

0B-4 GENERAL INFORMATION

Specifications

RACK & PINION

0 - 4 mm

2°30’± 30’

0° ± 30’

1L Application

Gear Type

Wheel Alignment:

Front Toe-in

Front Caster

Front Camber

Oil Capacity

Steering System

Application

Front Type

Rear Type

Suspension

Specifications

Double Wishbone

5 - Link

Application

Fuel Pump Type

Fuel Filter Type

Fuel Capacity

Specifications

Electric Motor Pump

Cartridge

70 L

Fuel System

Lubricating Type

Oil Pump Type

Oil Filter Type

Oil Capacity (L) (Including Oil Filter)

Lubricating System

661LA

8.0662NA

9.0662LA

9.52.0L DOHC

7.22.3L DOHC

7.53.2L DOHC

8.2

External Gear pump

Combination(Full & Part)

Full Flow

Cooling Type

Coolant Capacity (L)

Radiator Type

Water Pump Type

Cooling System

661LA

9.5-10662NA

10.5662LA

10.5-112.0L DOHC

10.52.3L DOHC

10.53.2L DOHC

11.3

Forced Circulation

Centrifugal

Application

Battery (MF)

Generator

Starter

Electric System

661LA

75A

2.2kw662NA

75A

2.2kw662LA

75A

2.2kw2.0L DOHC

115A

1.2kw2.3L DOHC

115A

1.2kw3.2L DOHC

115A

1.7kw

12V - 90AH12V - 75AH

Page 19 of 1463

GENERAL INFORMATION 0B-7

MAINTENANCE AND REPAIR

MAINTENANCE AND LUBRICATION

Fuel Filter Replacement

Replace the engine fuel filter every.

lGasoline Engine : 60,000km (36,000 miles)

lDiesel Engine : 45,000km (24,000 miles)

Spark Plug Replacement

Replace spark plugs with same type.

lType : BOSCH : F8DC4

BERU : 14F-8DU4

Champion : C11YCC

lGap : 0.8 ± 0.1 mm

Spark Plug Wire Replacement

Clean wires and inspect them for burns, cracks or other

damage. Check the wire boot fit at the Distributor and at

the spark plugs. Replace the wires as needed.

Brake System Service

Check the disc brake pads or the drum brake linings.

Check the pad and the lining thickness carefully.

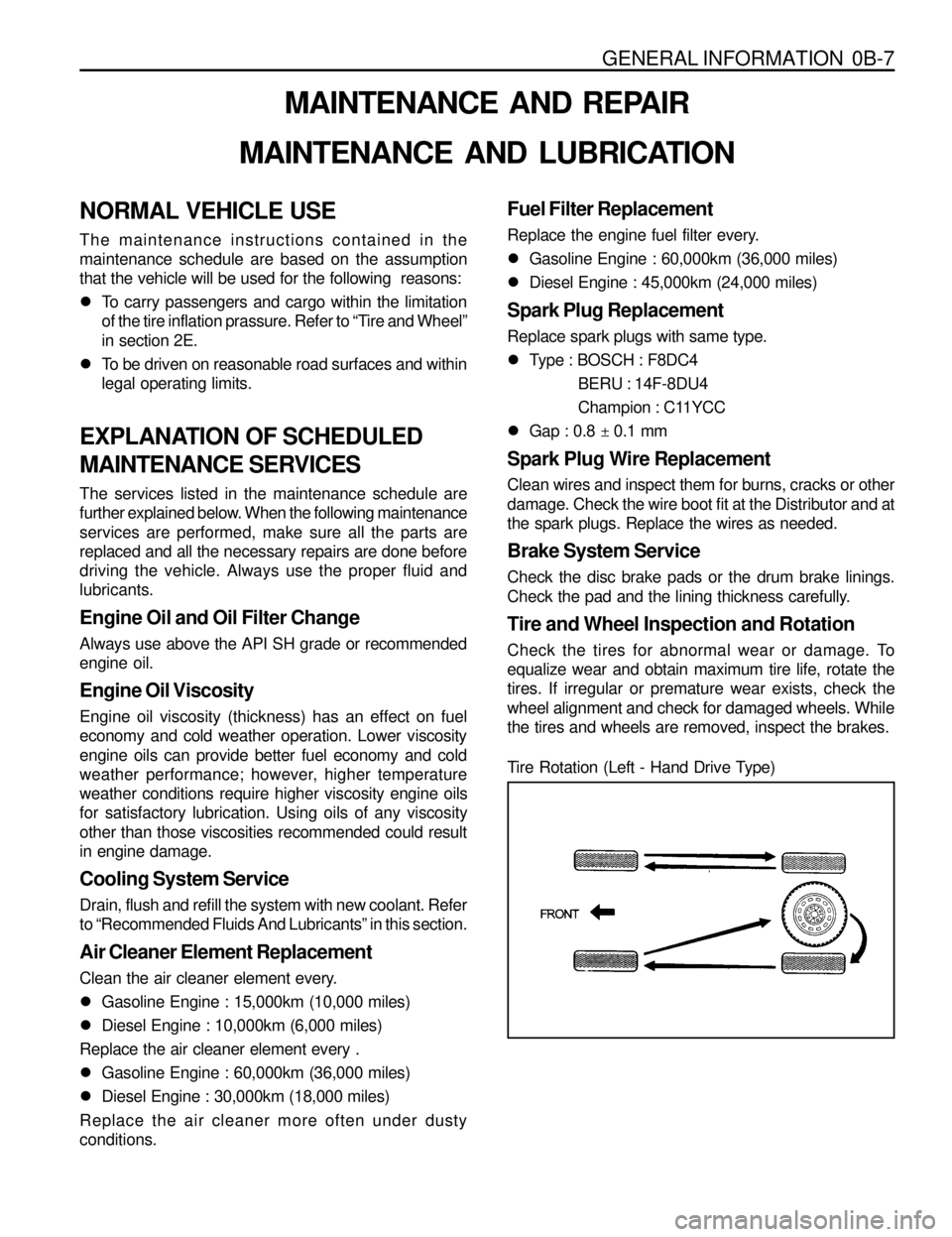

Tire and Wheel Inspection and Rotation

Check the tires for abnormal wear or damage. To

equalize wear and obtain maximum tire life, rotate the

tires. If irregular or premature wear exists, check the

wheel alignment and check for damaged wheels. While

the tires and wheels are removed, inspect the brakes.

NORMAL VEHICLE USE

The maintenance instructions contained in the

maintenance schedule are based on the assumption

that the vehicle will be used for the following reasons:

lTo carry passengers and cargo within the limitation

of the tire inflation prassure. Refer to “Tire and Wheel”

in section 2E.

lTo be driven on reasonable road surfaces and within

legal operating limits.

EXPLANATION OF SCHEDULED

MAINTENANCE SERVICES

The services listed in the maintenance schedule are

further explained below. When the following maintenance

services are performed, make sure all the parts are

replaced and all the necessary repairs are done before

driving the vehicle. Always use the proper fluid and

lubricants.

Engine Oil and Oil Filter Change

Always use above the API SH grade or recommended

engine oil.

Engine Oil Viscosity

Engine oil viscosity (thickness) has an effect on fuel

economy and cold weather operation. Lower viscosity

engine oils can provide better fuel economy and cold

weather performance; however, higher temperature

weather conditions require higher viscosity engine oils

for satisfactory lubrication. Using oils of any viscosity

other than those viscosities recommended could result

in engine damage.

Cooling System Service

Drain, flush and refill the system with new coolant. Refer

to “Recommended Fluids And Lubricants” in this section.

Air Cleaner Element Replacement

Clean the air cleaner element every.

lGasoline Engine : 15,000km (10,000 miles)

lDiesel Engine : 10,000km (6,000 miles)

Replace the air cleaner element every .

lGasoline Engine : 60,000km (36,000 miles)

lDiesel Engine : 30,000km (18,000 miles)

Replace the air cleaner more often under dusty

conditions.

Tire Rotation (Left - Hand Drive Type)

Page 20 of 1463

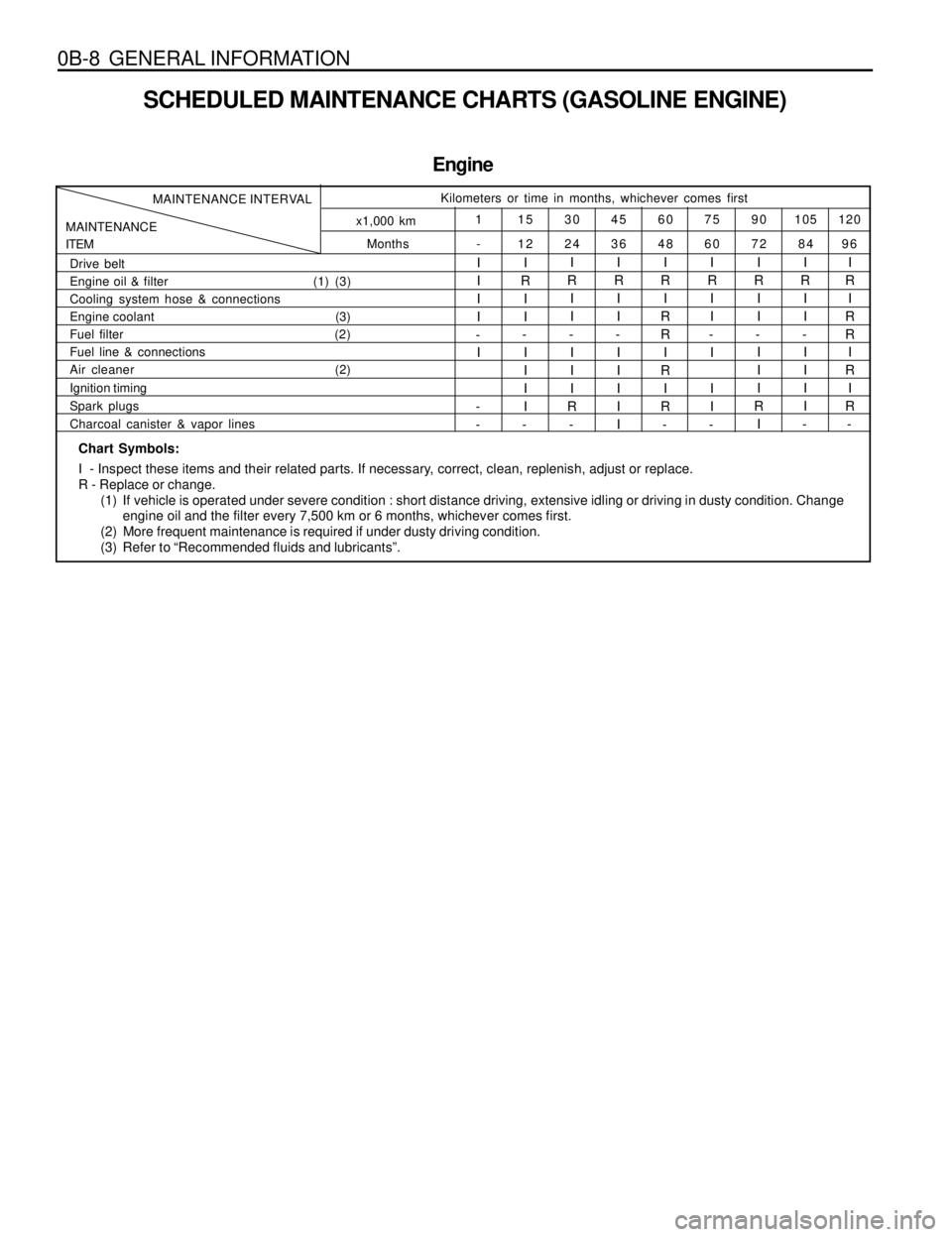

0B-8 GENERAL INFORMATION

SCHEDULED MAINTENANCE CHARTS (GASOLINE ENGINE)

Engine

Months

MAINTENANCE

ITEMMAINTENANCE INTERVALKilometers or time in months, whichever comes first

120 105 90 75 60 45 30 15 1

96 84 72 60 48 36 24 12 - x1,000 km

Chart Symbols:

I - Inspect these items and their related parts. If necessary, correct, clean, replenish, adjust or replace.

R - Replace or change.

(1) If vehicle is operated under severe condition : short distance driving, extensive idling or driving in dusty condition. Change

engine oil and the filter every 7,500 km or 6 months, whichever comes first.

(2) More frequent maintenance is required if under dusty driving condition.

(3) Refer to “Recommended fluids and lubricants”.

Drive belt

Engine oil & filter (1) (3)

Cooling system hose & connections

Engine coolant (3)

Fuel filter (2)

Fuel line & connections

Air cleaner (2)

Ignition timing

Spark plugs

Charcoal canister & vapor linesI

I

I

I

-

I

-

-I

R

I

I

-

I

I

I

I

-I

R

I

I

-

I

I

I

R

-I

R

I

I

-

I

I

I

I

II

R

I

R

R

I

R

I

R

-I

R

I

I

-

I

I

I

-I

R

I

I

-

I

I

I

R

II

R

I

I

-

I

I

I

I

-I

R

I

R

R

I

R

I

R

-

Page 22 of 1463

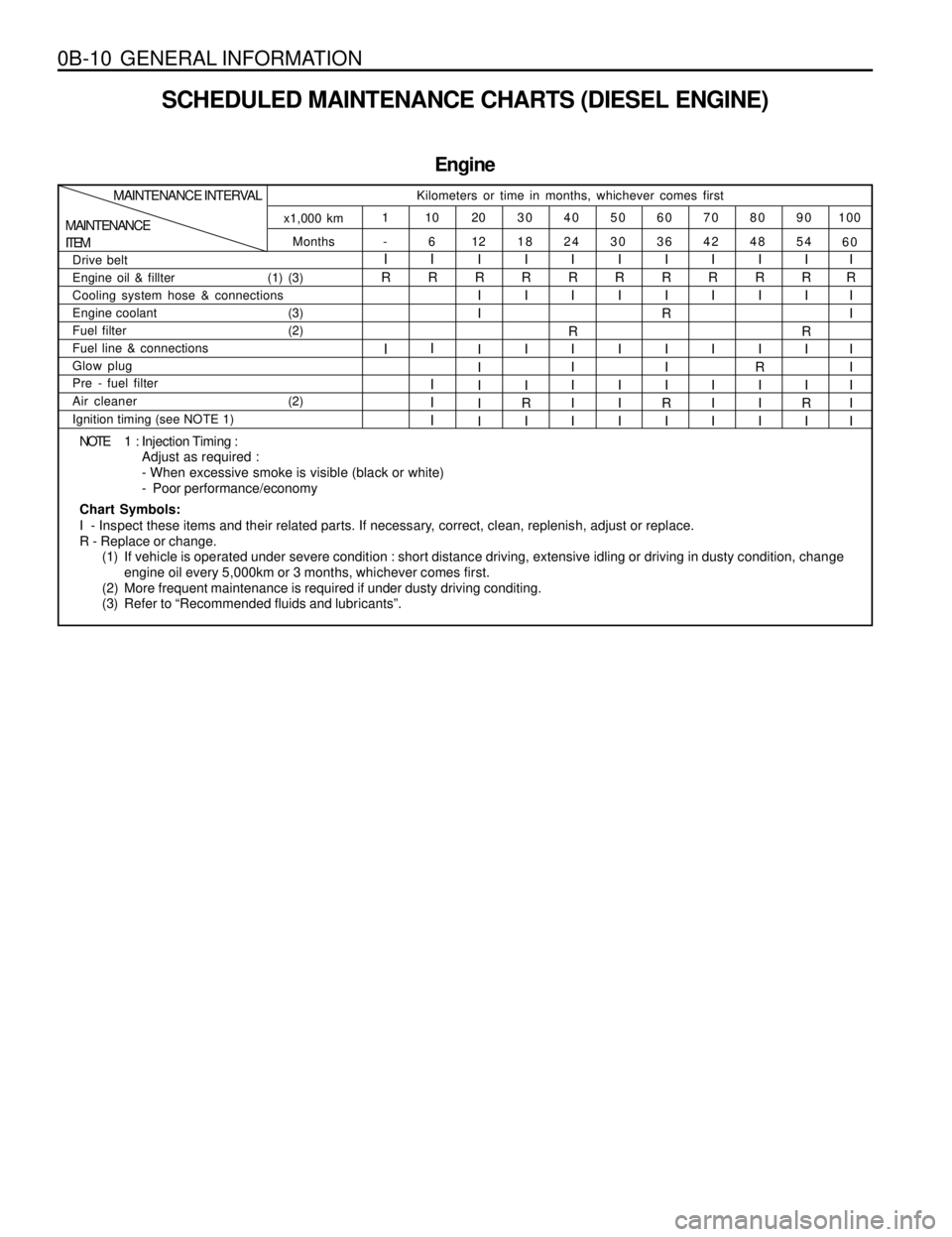

0B-10 GENERAL INFORMATION

SCHEDULED MAINTENANCE CHARTS (DIESEL ENGINE)

Engine

Months

-

MAINTENANCE

ITEMMAINTENANCE INTERVAL

Kilometers or time in months, whichever comes first

100 90 80 70 60 50 40 30 20 10 1

60 54 48 42 36 30 24 18 12 6 x1,000 km

NOTE 1 :Injection Timing :

Adjust as required :

- When excessive smoke is visible (black or white)

- Poor performance/economy

Chart Symbols:

I - Inspect these items and their related parts. If necessary, correct, clean, replenish, adjust or replace.

R - Replace or change.

(1) If vehicle is operated under severe condition : short distance driving, extensive idling or driving in dusty condition, change

engine oil every 5,000km or 3 months, whichever comes first.

(2) More frequent maintenance is required if under dusty driving conditing.

(3) Refer to “Recommended fluids and lubricants”.

Drive belt

Engine oil & fillter (1) (3)

Cooling system hose & connections

Engine coolant (3)

Fuel filter (2)

Fuel line & connections

Glow plug

Pre - fuel filter

Air cleaner (2)

Ignition timing (see NOTE 1)I

R

II

R

I

I

I

I

I

R

I

I

I

I

I

I

II

R

I

I

I

R

II

R

I

R

I

I

I

I

II

R

I

I

I

I

II

R

I

R

I

I

I

R

II

R

I

I

I

I

II

R

I

I

R

I

I

II

R

I

R

I

I

R

II

R

I

I

I

I

I

I

I

Page 25 of 1463

GENERAL INFORMATION 0B-13

Weather-Strip Lubrication

Apply a thin film silicone grease using a clean cloth.

EACH TIME THE OIL IS CHANGED

Brake System Inspection

This inspection should be done when the wheels are

removed for rotation. Inspect the lines and the hoses

for proper hookup, binding, leaks, cracks, chafing, etc.

Inspect the disc brake pads for wear. Inspect the rotors

for surface condition. Inspect other brake parts, the

parking brake, etc., at the same time. Inspect the brakes

more often if habit or conditions result in frequent braking.

Steering, Suspension and Front Drive Axle

Boot And Seal Inspection

Inspect the front and rear suspension and the steering

system for damaged, loose or missing parts, signs of

wear or lack of lubrication. Inspect the power steering

line and the hoses for proper hookup, binding, leaks,

cracks, chafing, etc. Clean and inspect the drive axle

boot and seals for damage, tears or leakage. Replace

the seals if necessary.

Exhaust System Inspection

Inspect the complete system (including the catalytic

converter if equipped). Inspect the body near the exhaust

system. Look for broken, damaged, missing, or out-of-

position parts as well as open seams, holes, loose

connections, or other conditions which could cause heat

buildup in the floor pan or could let exhaust fumes seep

into the trunk or passenger compartment.

Throttle Linkage Inspection

Inspect the throttle linkage for interference or binding,

damaged, or missing parts. Lubricate all linkage joints

and throttle cable joints, the intermediate throttle shaft

bearing, the return spring at throttle valve assembly, and

the accelerator pedal sliding face with suitable grease.

Check the throttle cable for free movements.

Engine Drive Belts

Inspect all belts for cracks, fraying, wear and proper

tension. Adjust or replace the belts as needed.

Hood Latch Operation

When opening the hood, note the operation of the

secondary latch. It should keep the hood from opening

all the way when the primary latch is released. The hood

must close firmly.

AT LEAST ANNUALLY

Lap and Shoulder Belts Condition and

Operation

Inspect the belt system including: the webbing, the

buckles, the latch plates, the retractor, the guide loops

and the anchors.

Movable Head Restraint Operation

On vehicles with movable head restraints, the restraints

must stay in the desired position.

Spare Tire and Jack Storage

Be alert to rattles in the rear of the vehicle. The spare

tire, all the jacking equipment, and the tools must be

securely stowed at all times. Oil the jack ratchet or the

screw mechanism after each use.

Key Lock Service

Lubricate the key lock cylinder.

Body Lubrication Service

Lubricate all the body door hinges including the hood,

the fuel door, the rear compartment hinges and the

latches, the glove box and the console doors, and any

folding seat hardware.

Underbody Flushing

Flushing the underbody will remove any corrosive

materials used for ice and snow removal and dust control.

At least every spring clean the underbody. First, loosen

the sediment packed in closed areas of the vehicle. Then

flush the underbody with plain water.

Engine Cooling System

Inspect the coolant and freeze protection fluid. If the fluid

is dirty or rusty, drain, flush and refill the engine cooling

system with new coolant. Keep the coolant at the proper

mixture in order to ensure proper freeze protection,

corrosion protection and engine operating temperature.

Inspect the hoses. Replace the cracked, swollen, or

deteriorated hoses. Tighten the clamps. Clean the

outside of the radiator and the air conditioning

condenser. Wash the filler cap and the neck. Pressure

test the cooling system and the cap in order to help

ensure proper operation.

Page 35 of 1463

1A1-4 GENERAL ENGINE INFORMATION

23 Camshaft Adjuster

24 Cooling Fan and Viscous Clutch

25 Piston

26 Flywheel of Drive Plate27 Oil Pump Drive Chain

28 Oil Return Pipe

29 Timing Chain

30 Oil Pump

SIDE VIEW

Page 39 of 1463

1A1-8 GENERAL ENGINE INFORMATION

ENGINE CRANKING AT THE FRONT OF CRANKSHAFT

Preceding Work : Removal of cooling fan

1 Vibration Damper Assembly

2 Crankshaft Pulley

Notice

lRemove the negative ground cable before proceeding the work.

lRotate the pulley in normal engine rotating direction when cranking.3 Bolt.................................................8.6 ± 0.9 Nm

Tools Required

000 589 10 99 01 Torque wrench

001 589 65 09 00 Socket

Page 48 of 1463

1A2-4 GENERAL ENGINE INFORMATION

23 Camshaft Adjuster

24 Oil Filler Cap

25 Engine Hanger Bracket

26 Cooling Fan and Viscous Clutch

27 Oil Filter

28 Timing Chain29 Oil Pump Drive Chain

30 Oil Strainer

31 Oil Pump

32 Ring Gear and Flywheel of Drive Plate

33 Piston

SIDE VIEW

Page 53 of 1463

GENERAL ENGINE INFORMATION 1A2-9

ENGINE CRANKING AT THE FRONT OF CRANKSHAFT

Preceding Work : Removal of cooling fan

1 Torque Wrench

2 Socket

3 Vibration Damper Ass'y

Notice

lRemove the negative ground cable before proceeding the work.

lRotate the pulley in normal engine rotating direction when cranking.

Tools Required

000 589 10 99 01 Torque Wrench

001 589 65 09 00 Socket4 Center Bolt (M18 ´ 55, 1piece)

.....................................1st Step 200Nm + 20Nm

2nd Step 90° + 10°

Page 75 of 1463

1B1-2 M162 ENGINE MECHANICAL

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

N

· ·· ·

·m

35 - 40

10 - 15

5 - 10

21 - 25

30

56 - 66

50 - 60

10 - 15

41.5 - 49.5

22.5 - 27.5

22.5 - 27.5

9 - 11

9 - 11

22.5 - 27.5

9 - 11

22.5 - 27.5

10

+90°

55

+90°

+90°

22.5 - 27.5

22.5 - 27.5

9 - 10

9 - 10

200

+90°

40

+90°

45

+90°

35

9 - 11

20

+90°

20

+90°

20 / + 90°

20 / + 90°

22.5 - 27.5Application

Power Steering Hydraulic Lines

A/C High Pressure and Liquid Hose

Radiator Support Menber Bolt

Fuel Supply and Return Hose to Fuel Distributor

Exhaust Manifold and Pipe

Propeller Shaft to Transmission

Engine Mounting Nut

Alternator Carrier Bolt

Belt Pulley Bolt

Steering Pump Bolt

A/C Bracket Bolt

Intake Air Duct Bolt

Ignition Cable Cover Bolt

Cylinder Head Cover Bolt

Camshaft Adjuster Bolt

Cylinder Head Front Cover Bolt

Flange Bolt in Exhaust Camshaft Sprocket

Cylinder Head Bolt

Cooling Fan Bracket Bolt

Timing Gear Case Cover Bolt M8

M6

Crankshaft Rear Cover Bolt

Vibration Damper Center Bolt

Connecting Rod Bearing Cap Bolt

Flywheel Stretch Bolt

Amarture Bolt in Flywheel

Ring and Seal Cover Nut in Flywheel

Sprocket Bolt to Exhaust Camshaft

Camshaft Adjuster Flange Bolt

Intake Flange Shaft Bolt

Exhaust Camshaft Sprocket Bolt

Camshaft Bearing Cap Bolt