SSANGYONG MUSSO 1998 Workshop Repair Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Repair Manual

Trending: handbrake, turn signal bulb, trailer, mileage, open hood, brake light, ESP inoperative

Page 471 of 1463

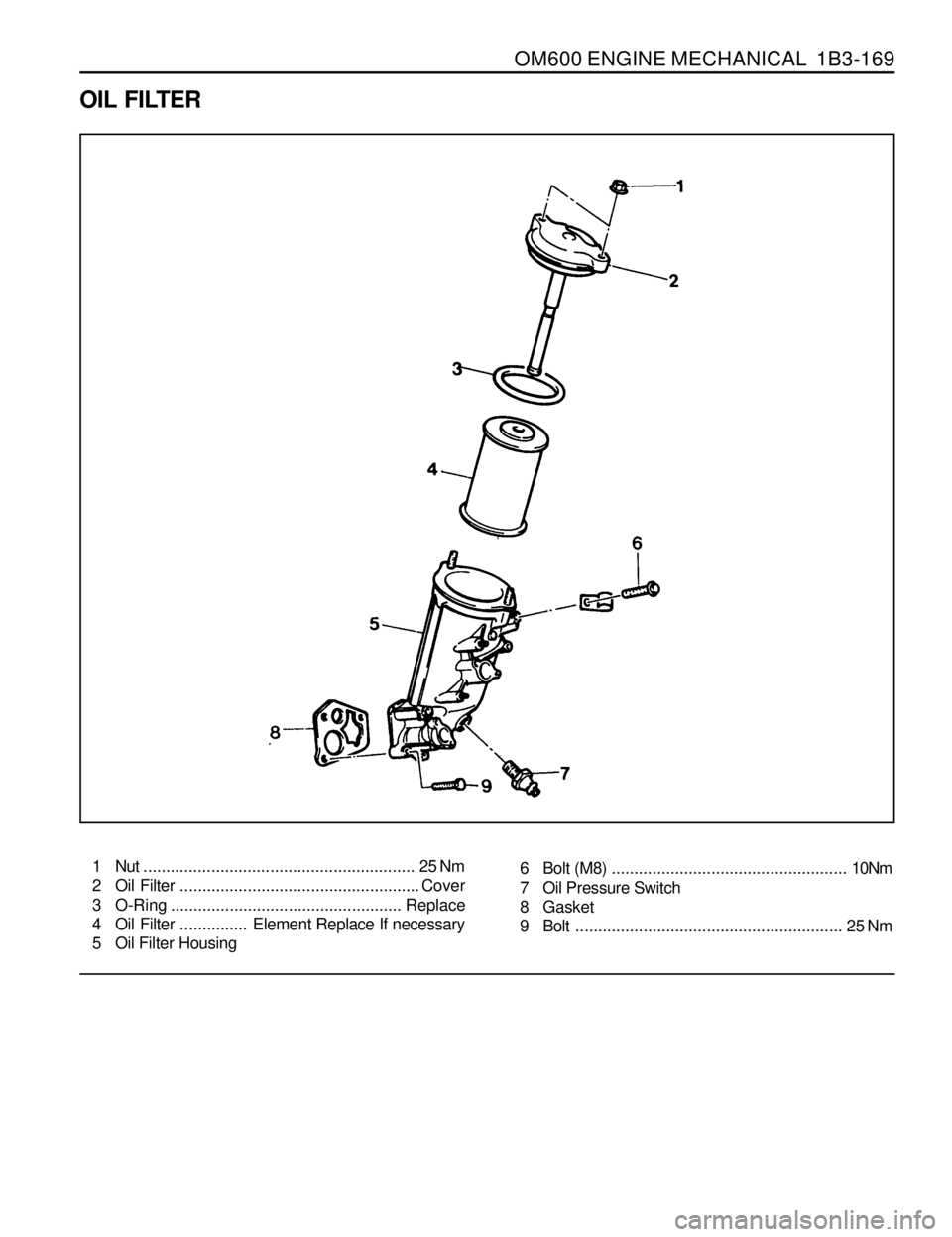

OM600 ENGINE MECHANICAL 1B3-169

OIL FILTER

1 Nut ............................................................ 25 Nm

2 Oil Filter..................................................... Cover

3 O-Ring ................................................... Replace

4 Oil Filter...............Element Replace If necessary

5 Oil Filter Housing6 Bolt (M8)....................................................10Nm

7 Oil Pressure Switch

8 Gasket

9 Bolt........................................................... 25 Nm

Page 472 of 1463

1B3-170 OM600 ENGINE MECHANICAL

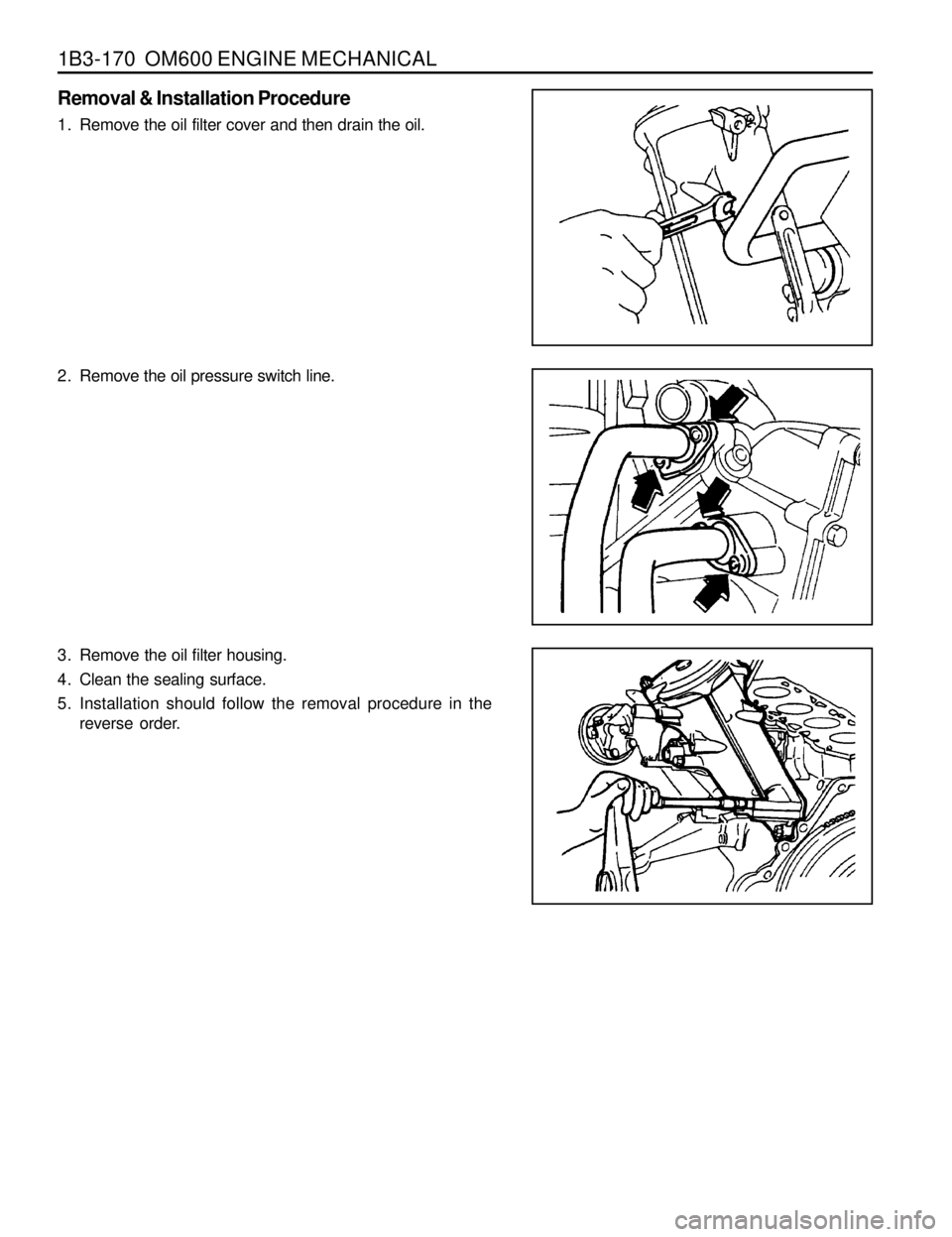

Removal & Installation Procedure

1. Remove the oil filter cover and then drain the oil.

2. Remove the oil pressure switch line.

3. Remove the oil filter housing.

4. Clean the sealing surface.

5. Installation should follow the removal procedure in the

reverse order.

Page 473 of 1463

OM600 ENGINE MECHANICAL 1B3-171

OIL PAN

1 Gasket ................................................... Replace

2 Upper Oil Pan

3 Combination Bolt...................................... 10 Nm

4 Combination Bolt...................................... 10 Nm

5 Gasket ................................................... Replace6 Lower Oil Pan

7 Combination Bolt...................................... 25 Nm

8 Drain Plug................................................. 25 Nm

9 Washer Seal.......................................... Replace

10 Oil Pan

*Remove and install as numerical sequence.

Notice

Replace the washer seal with new one.

OM662LAOM661LA

Page 474 of 1463

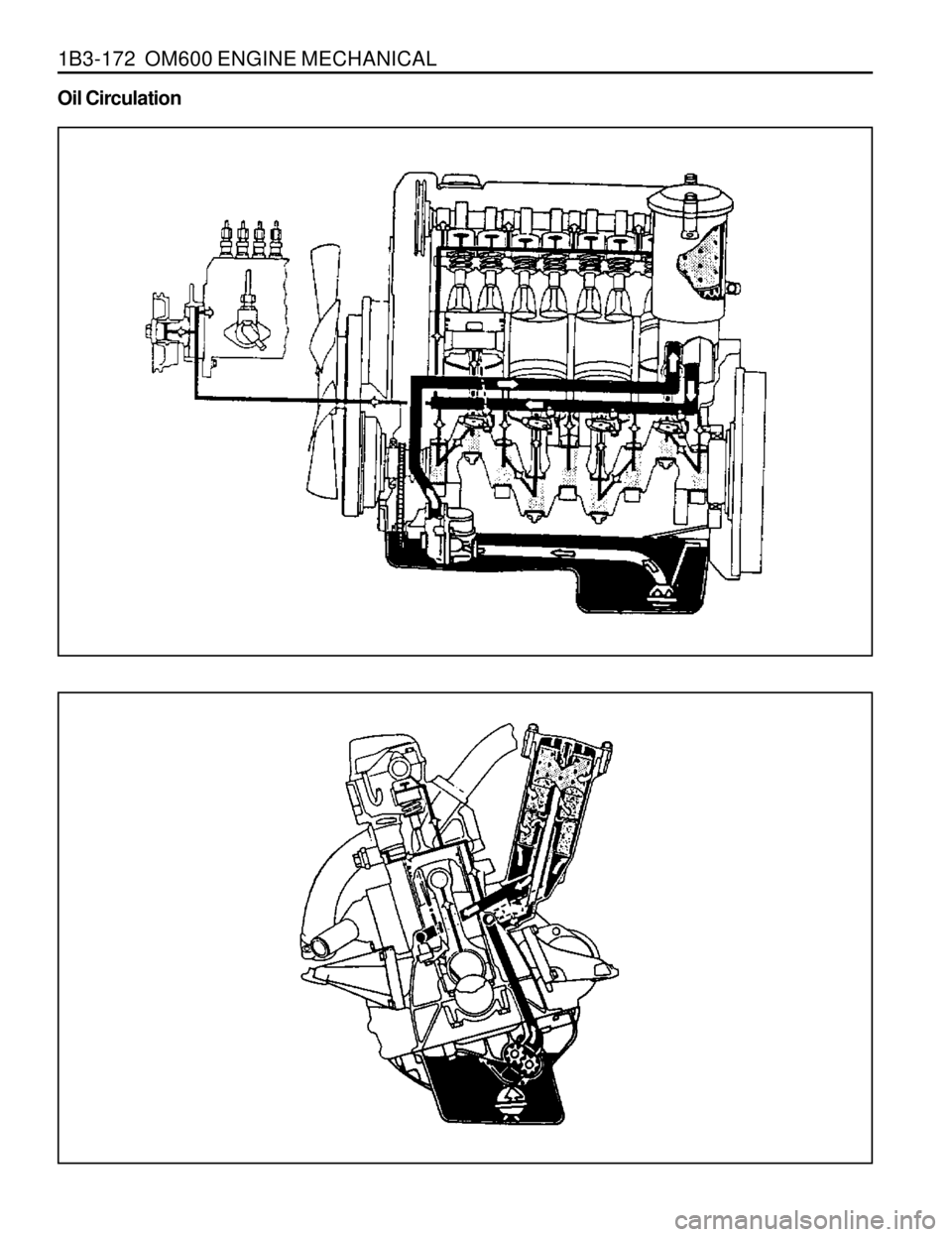

1B3-172 OM600 ENGINE MECHANICAL

Oil Circulation

Page 475 of 1463

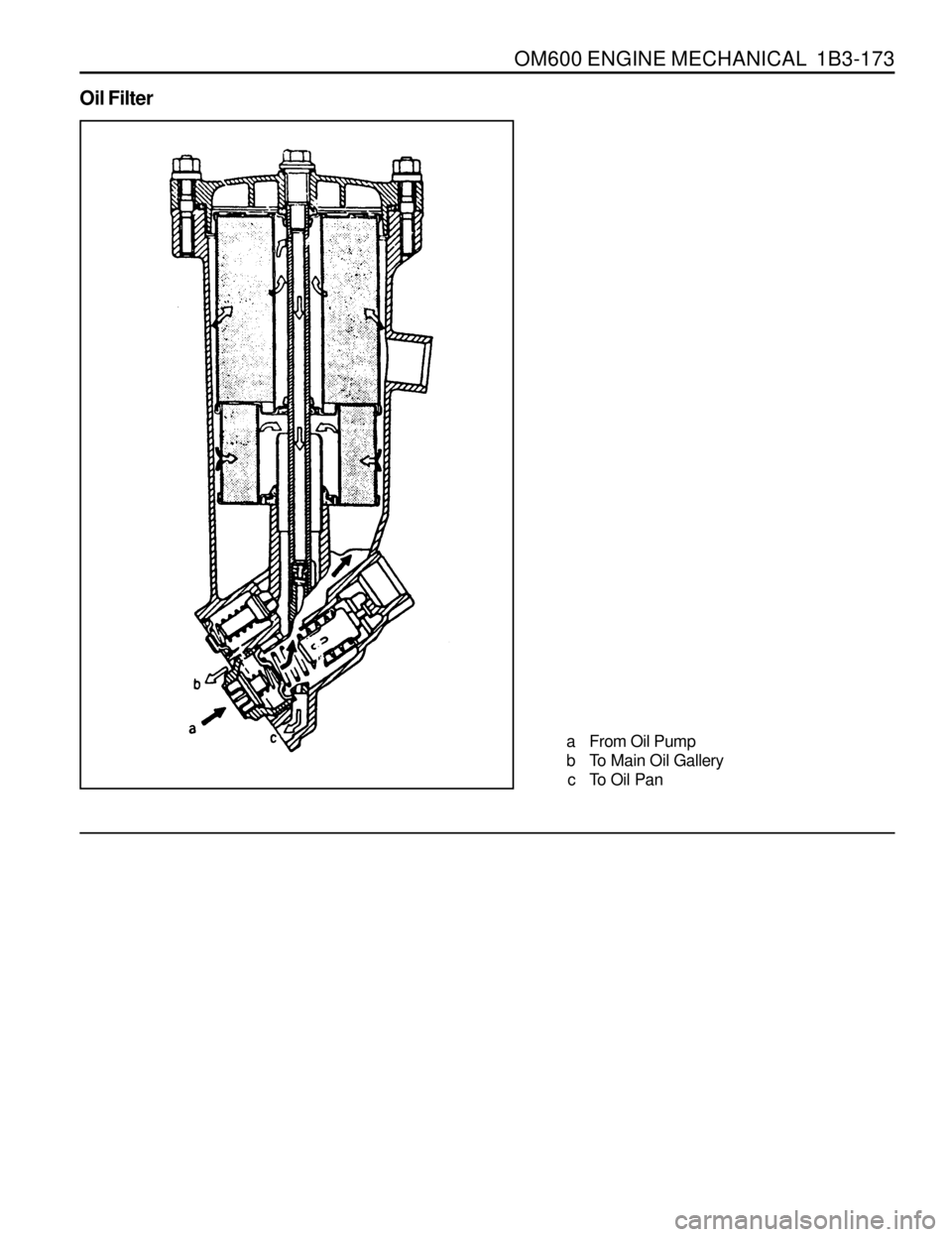

OM600 ENGINE MECHANICAL 1B3-173

Oil Filter

a From Oil Pump

b To Main Oil Gallery

c To Oil Pan

Page 476 of 1463

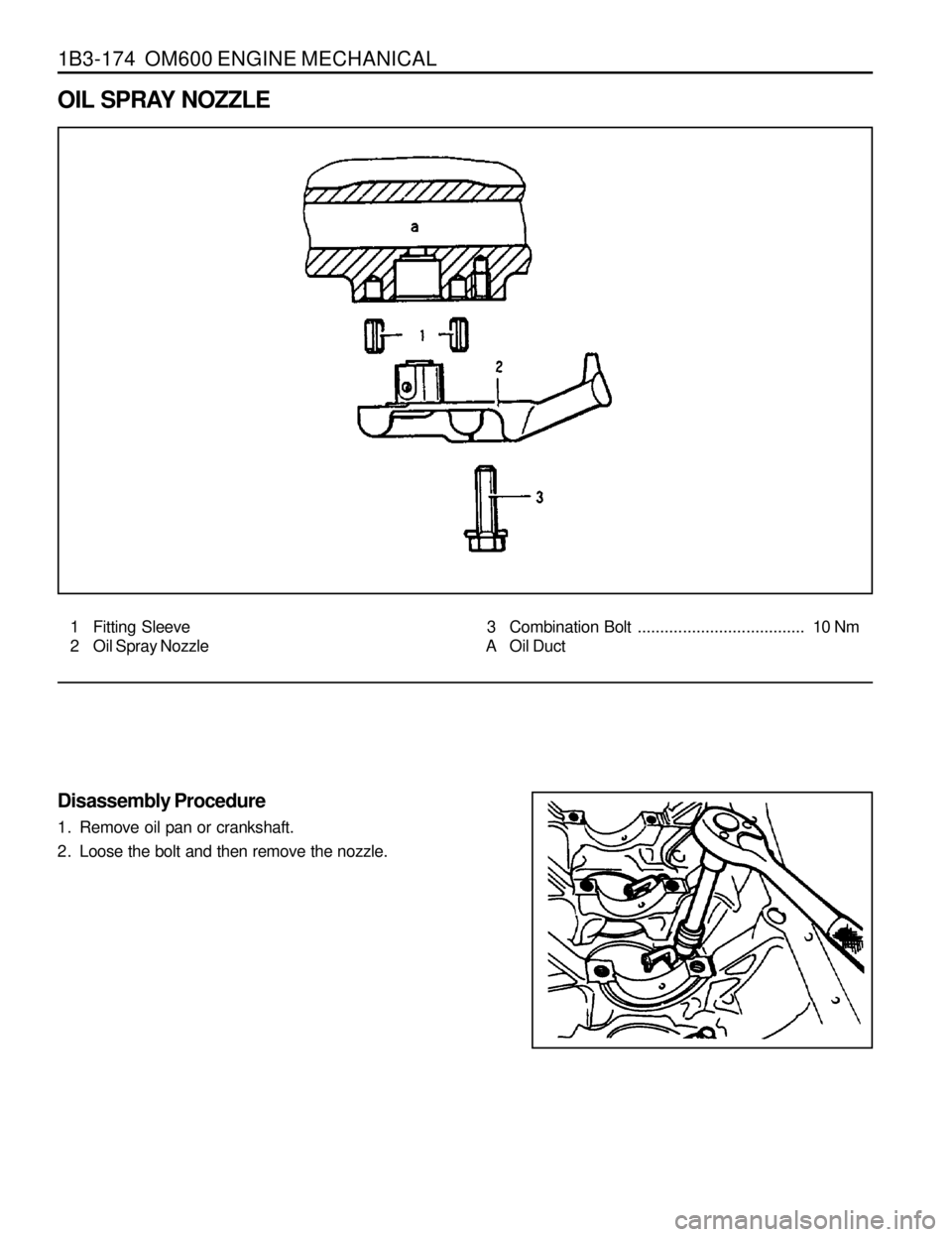

1B3-174 OM600 ENGINE MECHANICAL

OIL SPRAY NOZZLE

1 Fitting Sleeve

2 Oil Spray Nozzle

Disassembly Procedure

1. Remove oil pan or crankshaft.

2. Loose the bolt and then remove the nozzle.

3 Combination Bolt..................................... 10 Nm

A Oil Duct

Page 477 of 1463

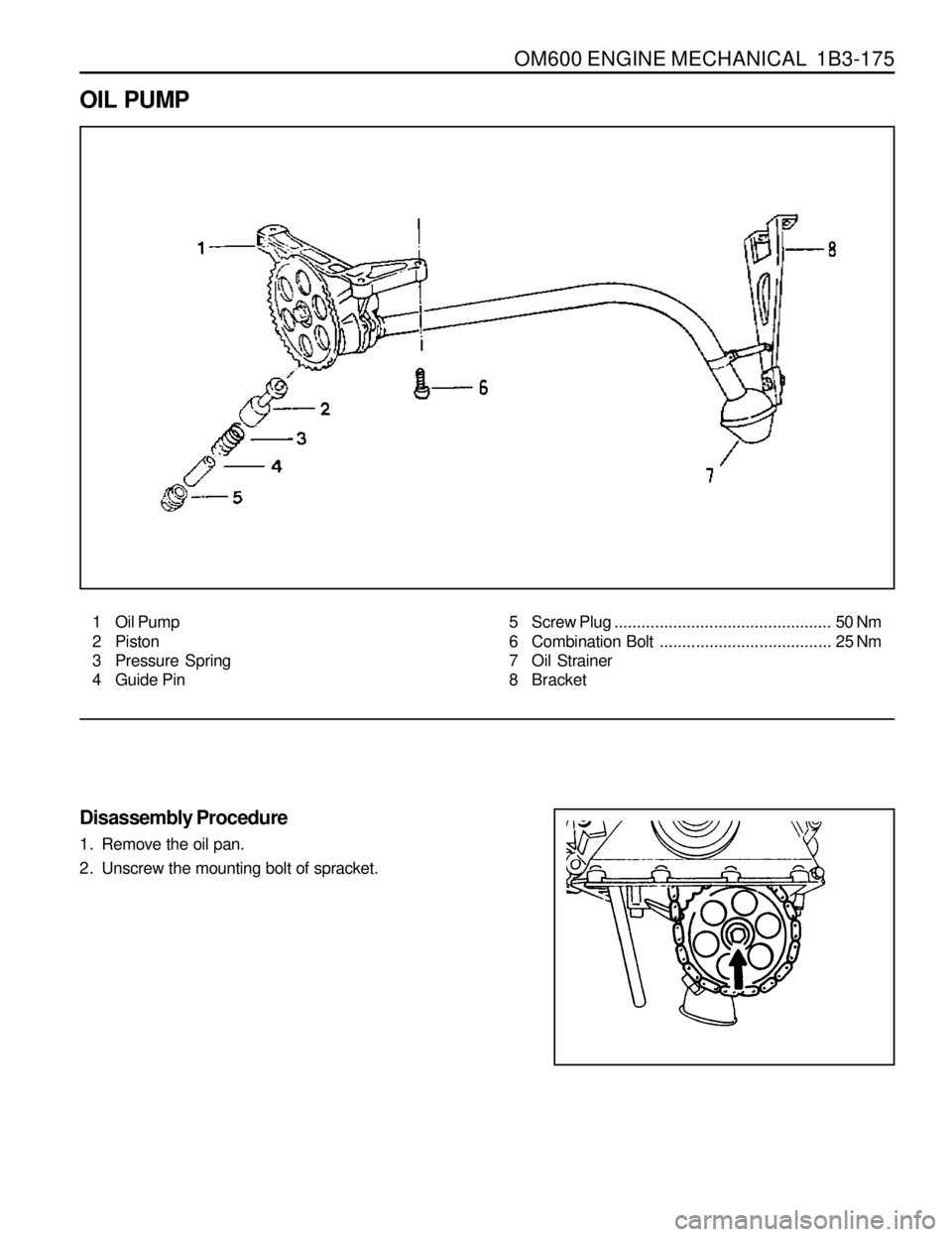

OM600 ENGINE MECHANICAL 1B3-175

OIL PUMP

1 Oil Pump

2 Piston

3 Pressure Spring

4 Guide Pin5 Screw Plug................................................ 50 Nm

6 Combination Bolt...................................... 25 Nm

7 Oil Strainer

8 Bracket

Disassembly Procedure

1. Remove the oil pan.

2. Unscrew the mounting bolt of spracket.

Page 478 of 1463

1B3-176 OM600 ENGINE MECHANICAL

Tightening Torque 10 Nm

3. Unscrew the oil strainer bracket bolt.

4. Remove the oil pump.

5. Unscrew the screw plug and remove the relief valve.

6. Installation should follow the removal procedure in the

reverse order.

Page 479 of 1463

OM600 ENGINE MECHANICAL 1B3-177

CYLINDER HEAD PRESSURE LEAKAGE TEST

Preceding Work : Removal of the cylinder head

Removal of the exhaust manifold

Removal of the valve

1 Feed Pipe

2 Bolt

3 Return Connection

4 Gasket ................................................................ Replace

5 Coolant Gallery................................................... Sealing

6 Pressure Measuring Plate..................................Completely tight to the cylinder head

7 Cylinder Head.....................................................

Immerse with pressure measuring plate into warm water of approx. 60°C and pressurize with compressed

airof 2 bar.

Notice

If air bubbles are seen, replace the cylinderhead.

Tools Required

115 589 34 63 00 Pressure Measuring Plate

601 589 00 25 00 Suspension Device

UNIT REPAIR

Page 480 of 1463

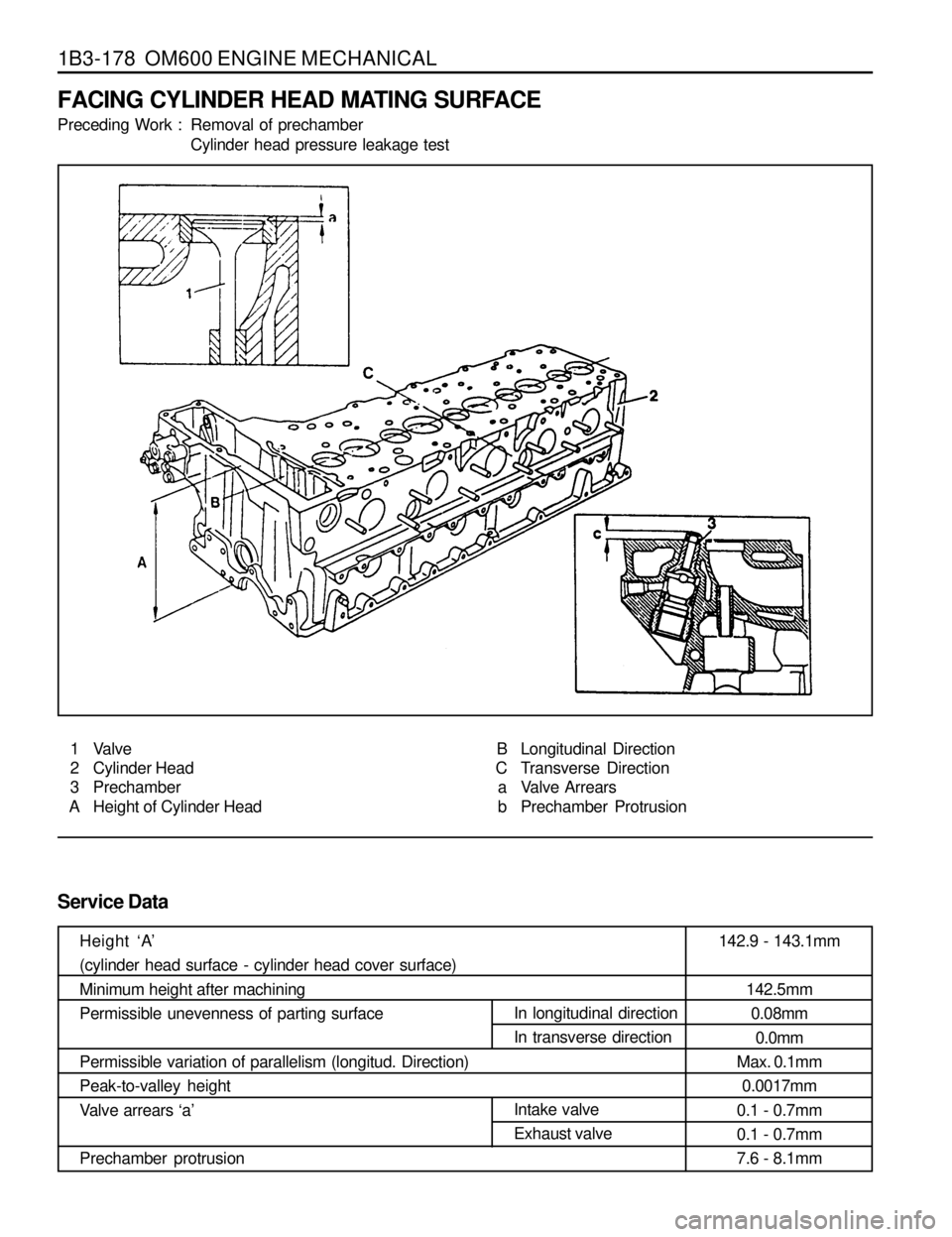

1B3-178 OM600 ENGINE MECHANICAL

Height ‘A’

(cylinder head surface - cylinder head cover surface)

Minimum height after machining

Permissible unevenness of parting surface

Permissible variation of parallelism (longitud. Direction)

Peak-to-valley height

Valve arrears ‘a’

Prechamber protrusion

Service Data

In longitudinal direction

In transverse direction

Intake valve

Exhaust valve142.9 - 143.1mm

142.5mm

0.08mm

0.0mm

Max. 0.1mm

0.0017mm

0.1 - 0.7mm

0.1 - 0.7mm

7.6 - 8.1mm

FACING CYLINDER HEAD MATING SURFACE

Preceding Work : Removal of prechamber

Cylinder head pressure leakage test

1 Valve

2 Cylinder Head

3 Prechamber

A Height of Cylinder HeadB Longitudinal Direction

C Transverse Direction

a Valve Arrears

b Prechamber Protrusion

Trending: weight, compression ratio, turn signal bulb, tailgate, rid height, technical data, wheel alignment