SSANGYONG MUSSO 1998 Workshop Repair Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Repair Manual

Trending: parking brake, coolant, glow, traction control, fuse, rear view mirror, technical specifications

Page 491 of 1463

1D1-2 M162 ENGINE COOLING

FASTENER TIGHTENING SPECIFICATIONS

N

· ·· ·

·m

30

22.5 - 27.5

9 - 11

9 - 11

9 - 11

40.5 - 49.5

3 - 7

3 - 7 Application

Coolant Drain Plug

Engine Hanger Bracket and Coolant Outlet

Port Bolt

Thermostat Cover Bracket Bolt

Oil Cooler Pipe Line Bolt

Cooling Fan Bolt

Viscous Clutch Bolt

Automatic Transmission Oil Cooling Hose Bolt

Cooling Fan Shroud Bolt

Page 492 of 1463

M162 ENGINE COOLING 1D1-3

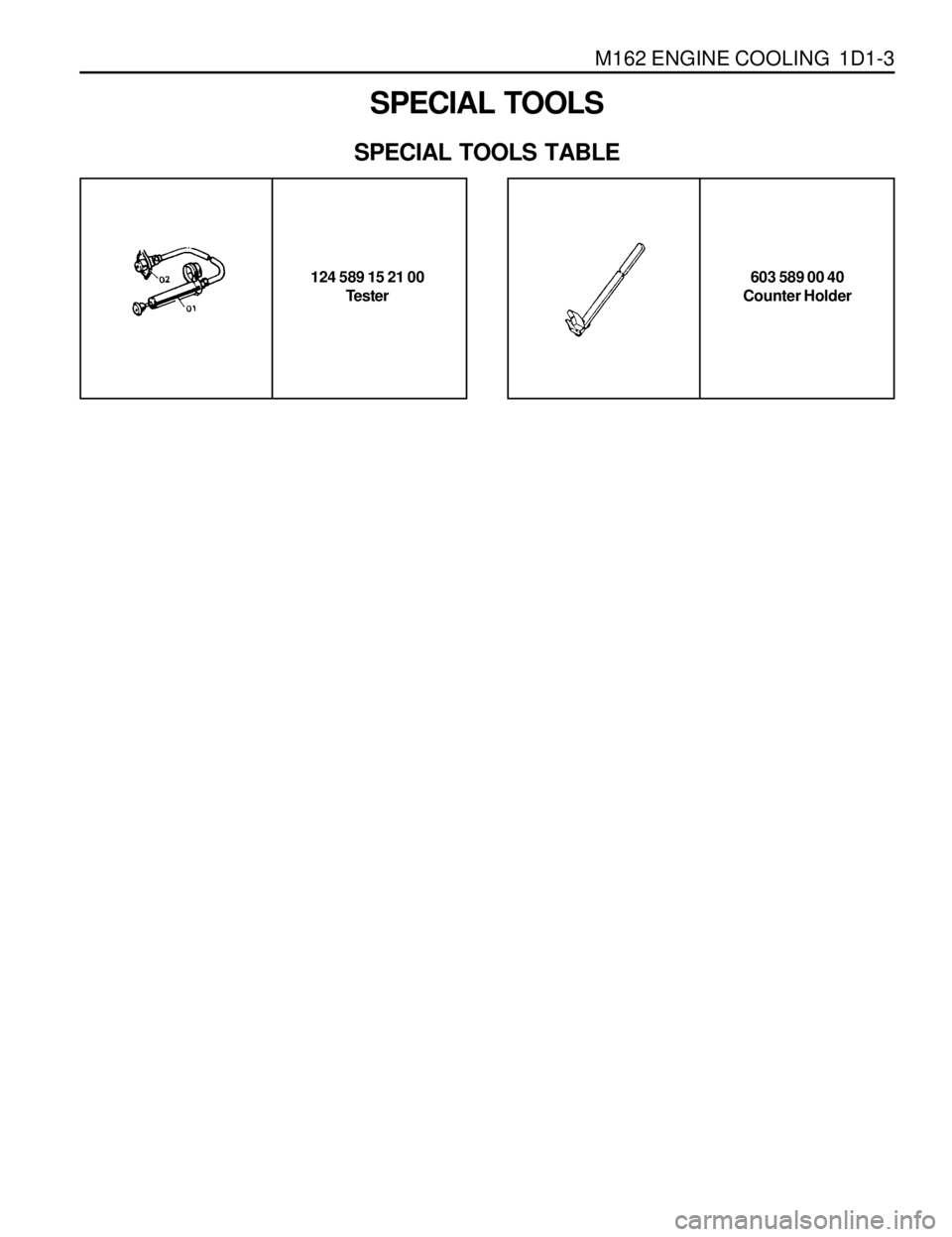

SPECIAL TOOLS

SPECIAL TOOLS TABLE

124 589 15 21 00

Tester603 589 00 40

Counter Holder

Page 493 of 1463

1D1-4 M162 ENGINE COOLING

DIAGNOSIS

3. Connect the special tool to the reservoir filler cap and apply

1.4 bar of pressure.

SYSTEM LEAKAGE TEST

Tools Required

124 589 15 21 00 Tester

Test Procedure

1. Loosen the cap a little and release pressure and remove

the cap.

Notice

For the risk of scalding, cap must not be opened unless the

coolant temperature is below 90°C.

2. Fill coolant up to upper edge (arrow) of reservoir.

Tester 124 589 15 21 00

4. If the pressure on the tester drops, check leakage at the all

coolant hoses and pipes and each connections. Replace

or retighten if necessary.

Page 494 of 1463

M162 ENGINE COOLING 1D1-5

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

COOLANT DRAIN AND FILL UP

Draning & Filling up Procedure

1. Loosen the cap a little and release pressure and remove

the cap.

Notice

For the risk of scalding, the cap must not be opened unless

the coolant temperature is below 90

oC.

2. Loosen the radiator lower drain cock and drain the coolant.

Notice

Collect coolant by using a proper container.

3. Drain the coolant from the crankcase by inserting a hose

(dia. 14mm) onto the drain bolt on the side of crankcase

(exhaust manifold) and by loosening the plug.

Notice

lJust loosen the drain plug to drain the coolant and do

not remove the plug completely.

lCollect coolant by using proper container.

4. After complete draining of the coolant, remove the hose

connector to drain plug and reinstall the drain plug.

Installation Notice

5. Tighten the radiator lower drain cock.

Tightening Torque 30 Nm

Page 495 of 1463

1D1-6 M162 ENGINE COOLING

6. Remove the de-aeration hose clamp in the coolant pump

and remove the de-aeration hose.

7. Fill up the coolant through the coolant reservoir tank.

Notice

lMatch the anti-freeze and the water ratio to 50 : 50.

lSupplement the coolant until the coolant overflows to

the deaeration hose.

8. Insert the de-aeration hose and completely tighten the

clamp.

9. Check the coolant level in the coolant reservoir tank.

10. Warm up(until thermostat is opened) the engine and

recheck the coolant level in the reservoir tank and fill up

the coolant if necessary.

Page 496 of 1463

M162 ENGINE COOLING 1D1-7

COOLANT CONNECTION FITTING

Preceding Work : Removal of cooling fan shroud

1 Bolt (M8 X 100, 2 pieces)...............22.5-27.5 Nm

2 Engine Hanger Bracket

3 Coolant Outlet Port

Removal & Installation Procedure

1. Drain coolant from the radiator.

2. Remove the hose mounting clamp (5) and disconnect the

coolant hose (6).

3. Remove the two bolts (1), the engine hanger bracket (2)

and coolant outlet port (3).

Installation Notice4 O-ring

5 Hose Mounting Clamp

6 Hose

Replace the O-ring with new one.

4. Installation should follow the removal procedure in the

reverse order.

5. Fill up the coolant as specified.

6. Check the leaks in the cooling system.

Tightening Torque22.5 - 27.5 Nm

Page 497 of 1463

1D1-8 M162 ENGINE COOLING

WATER PUMP

Preceding Work : Removal of V-belt

Removal of air admission housing

1 Air Admission Housing

2 Oil Cooler Pipe Line

3 Seal....................................................... Replace

4 Bolt........................................................9-11 Nm

5 Coolant Hose

6 Coolant Hose

7 Outlet Coolant Hose8 Coolant Hose

9 Inlet Coolant Hose

10 Coolant Pump

1 1 Bolt........................................................... 21 Nm

12 Dowel Sleeve

1 3 Seal....................................................... Replace

Page 498 of 1463

M162 ENGINE COOLING 1D1-9

Removal & Installation Procedure

1. Drain the coolant.

2. Disconnect the coolant pump wire connector.

3. Loosen the hose clip and dsconnect all hoses from the

coolant pump

4. Remove the coolant line bolts (4) and then remove the

coolant line (2).

Installation Notice

Notice

Replace the seal (3).

5. Remove the mounting bolts (11) and carefully pull out

coolant pump (10).

Installation Notice

Tightening Torque 9 - 11 Nm

Notice

Replace the seal (13).

Tightening Torque 21 Nm

6. Installation should follow the removal procedure in the

reverse order.

7. Fill up coolant.

8. Do coolaing system leakage test

Page 499 of 1463

1D1-10 M162 ENGINE COOLING

THERMOSTAT

Removal & Installation Procedure

1. Drain the coolant from the radiator.

2. Loosen the hose mounting clamp (6) and remove the heater

hose (7).

3. Unscrew the three bolts (5) and remove the thermostat cover

bracket, thermostat cover and the thermostat in order.

Installation Notice 1 Thermostat Cover

2 Thermostat

3 O-ring

4 Thermostat Cover Bracket5 Bolt (M6 X 25, 3 pieces).........................9-11 Nm

6 Hose Mounting Clamp

7 Heater Hose

Do not separate the thermostat cover and thermostat.

4. Replace the O-ring if necessary.

5. Check the leakage in the cooling system.

Tightening Torque 9 - 11 Nm

Page 500 of 1463

M162 ENGINE COOLING 1D1-11

OIL COOLER PIPE LINE

Preceding Work : Removal of upper intake manifold

Tightening Torque 9 - 11 Nm 1 Upper Intake Manifold

2 Bolt (M6 X 35, 1 piece)...........................9-11 Nm

3 Bolt (M6 X 16, 2 pieces).........................9-11 Nm4 Oil Cooler Pipe Line

5 O-ring .................................................... Replace

Removal & Installation Procedure

1. Drain the coolant.

2. Unscrew the bolts (2, 3) and remove the oil cooler pipe line (4).

Replace the O-ring with new one.

Installation Notice

3. Installation should follow the removal procedure in the

reverse order.

4. Fill up the coolant as specified.

5. Check the leaks in the cooling system.

Trending: overheating, air filter, jack points, jump start, reset, tires, coolant temperature