SSANGYONG MUSSO 1998 Workshop Repair Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Repair Manual

Trending: air bleeding, clock setting, horn, oil viscosity, door lock, fog light bulb, tow

Page 451 of 1463

OM600 ENGINE MECHANICAL 1B3-149

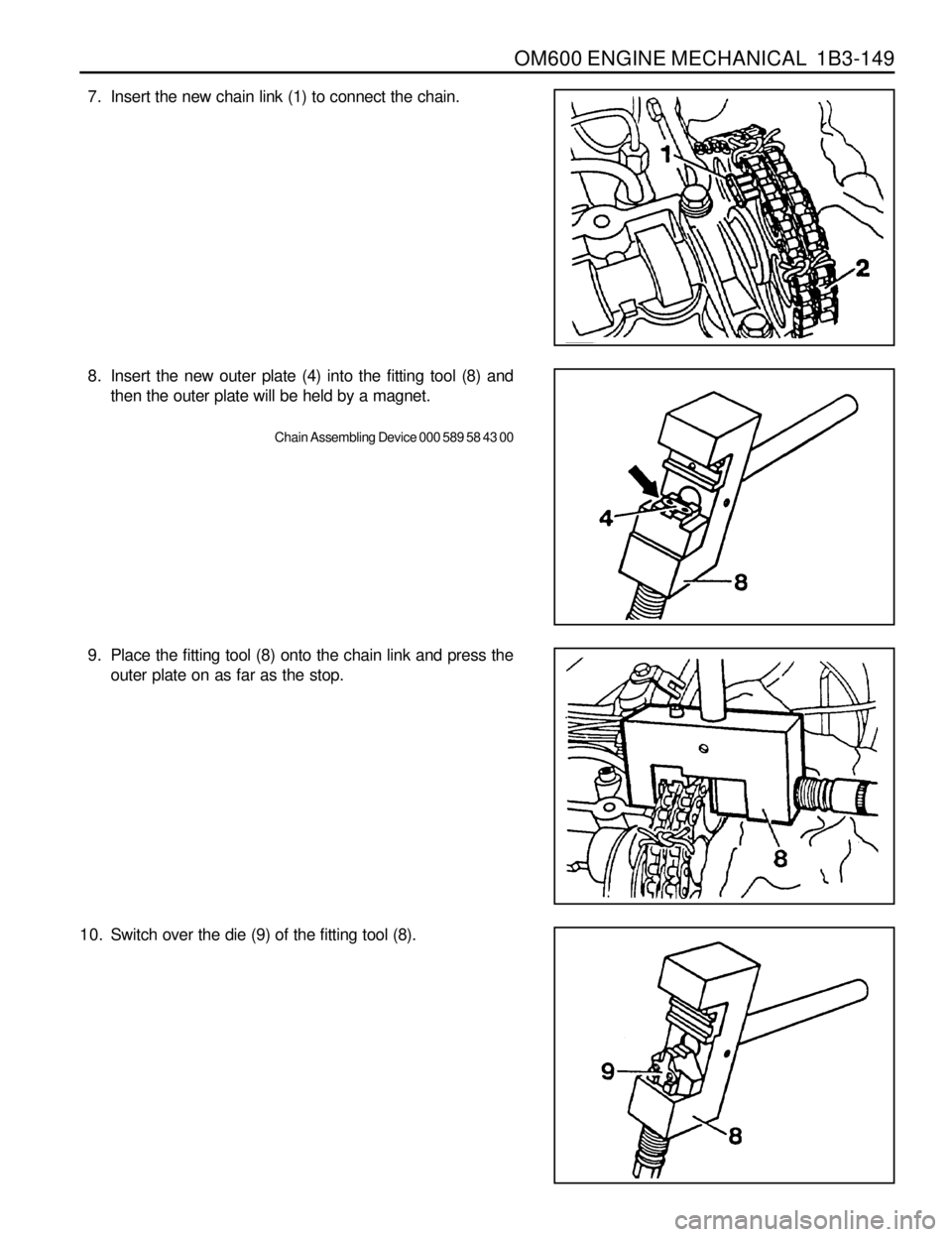

7. Insert the new chain link (1) to connect the chain.

8. Insert the new outer plate (4) into the fitting tool (8) and

then the outer plate will be held by a magnet.

Chain Assembling Device 000 589 58 43 00

9. Place the fitting tool (8) onto the chain link and press the

outer plate on as far as the stop.

10. Switch over the die (9) of the fitting tool (8).

Page 452 of 1463

1B3-150 OM600 ENGINE MECHANICAL

In this position, the marking on camshaft / camshaft bearing

cap (arrow) must also be aligned. If the markings are not

aligned, the timing chain must be re-set and the injection

pump timing has to be set.

14. Position the no.1 cylinder at TDC.

11. Place the fitting tool (8) onto the chain link and rivet the

chain pins one by one.

12. Check the riveting of chain pins and re-rivet if necessary.

13. Remove the wire.

Tightening Torque 35 - 40 Nm

Page 453 of 1463

OM600 ENGINE MECHANICAL 1B3-151

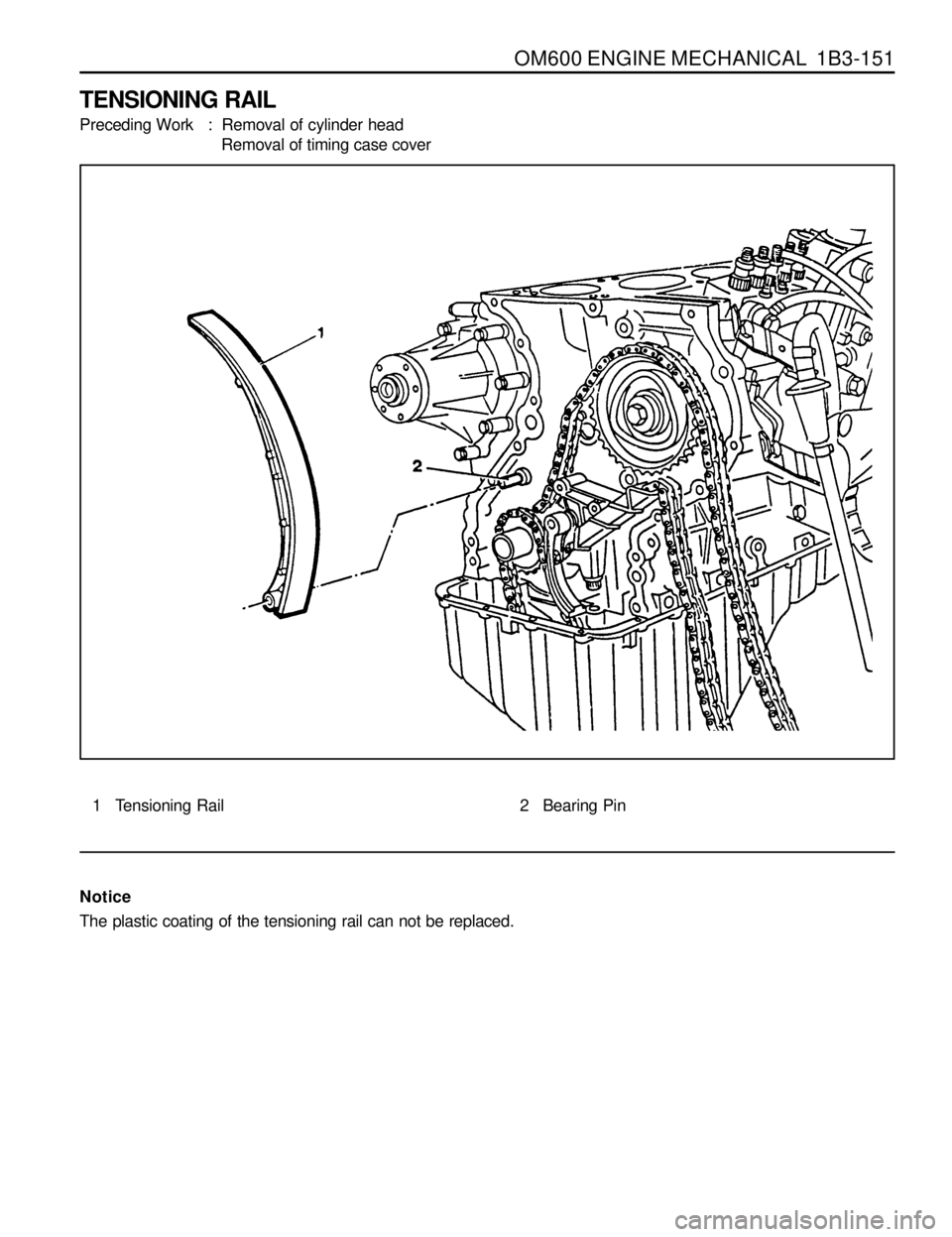

TENSIONING RAIL

Preceding Work : Removal of cylinder head

Removal of timing case cover

1 Tensioning Rail 2 Bearing Pin

Notice

The plastic coating of the tensioning rail can not be replaced.

Page 454 of 1463

1B3-152 OM600 ENGINE MECHANICAL

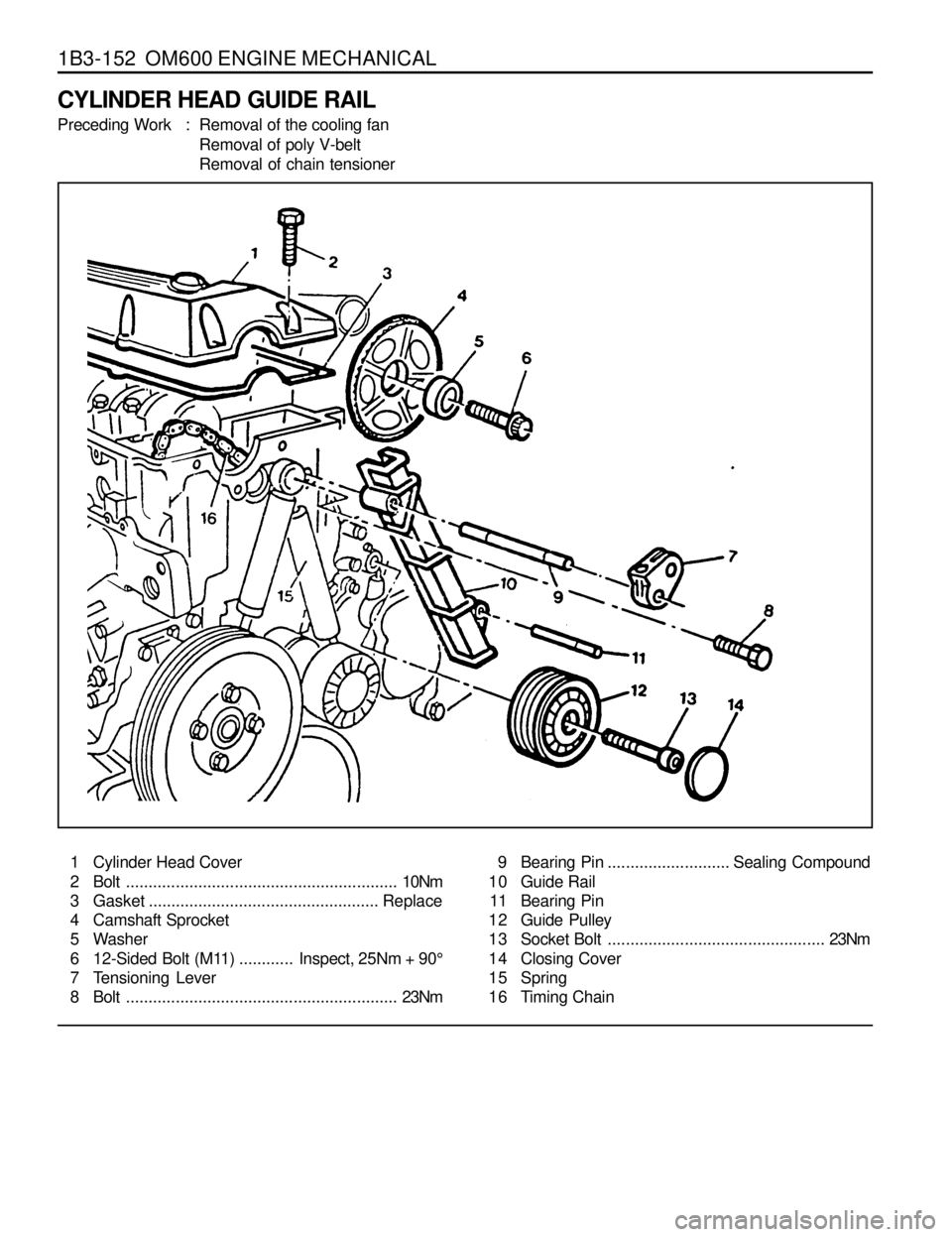

CYLINDER HEAD GUIDE RAIL

Preceding Work : Removal of the cooling fan

Removal of poly V-belt

Removal of chain tensioner

1 Cylinder Head Cover

2 Bolt............................................................10Nm

3 Gasket ................................................... Replace

4 Camshaft Sprocket

5 Washer

6 12-Sided Bolt (M11)............Inspect, 25Nm + 90°

7 Tensioning Lever

8 Bolt............................................................23Nm9 Bearing Pin...........................Sealing Compound

10 Guide Rail

11 Bearing Pin

12 Guide Pulley

13 Socket Bolt................................................23Nm

14 Closing Cover

15 Spring

16 Timing Chain

Page 455 of 1463

OM600 ENGINE MECHANICAL 1B3-153

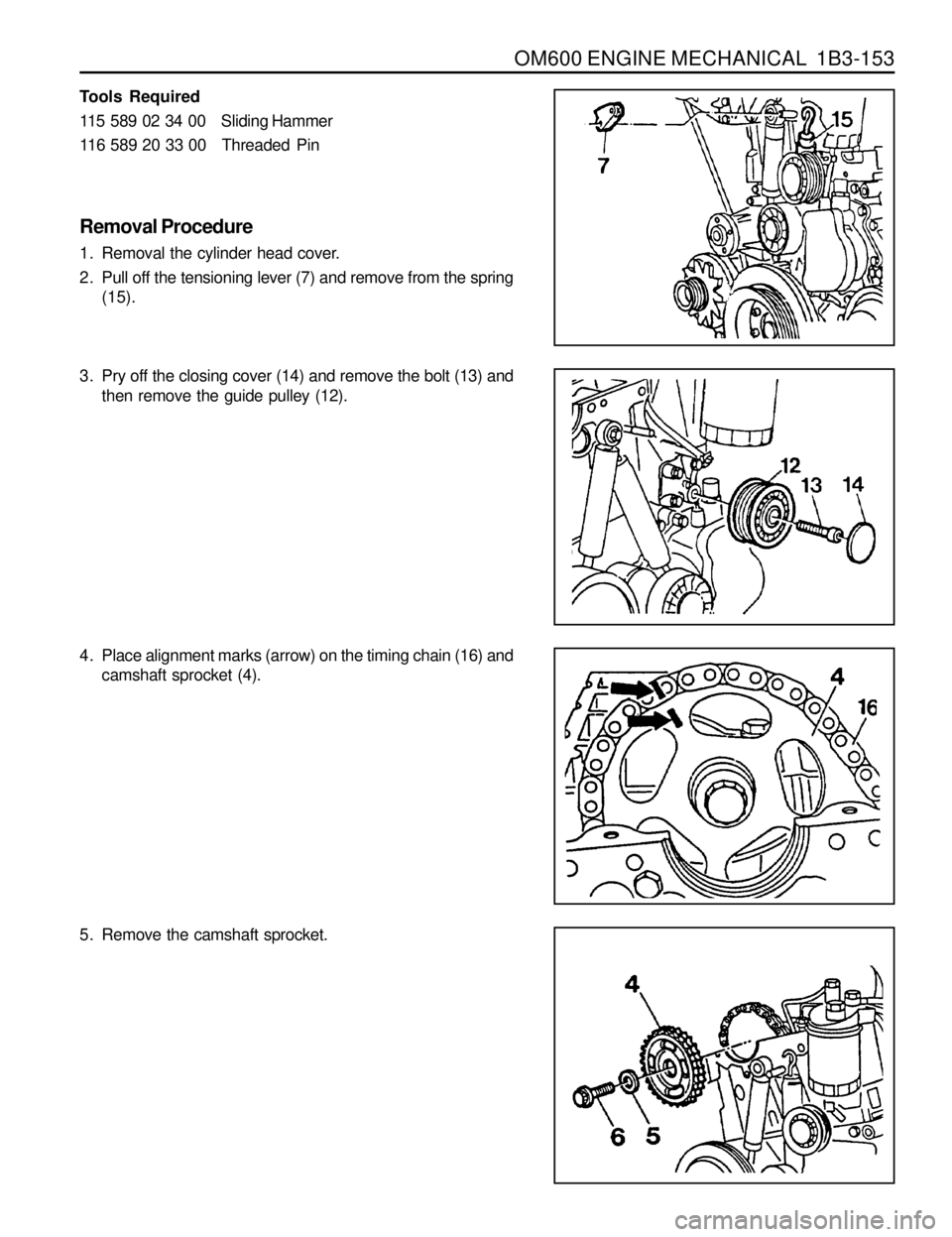

Tools Required

115 589 02 34 00 Sliding Hammer

116 589 20 33 00 Threaded Pin

Removal Procedure

1. Removal the cylinder head cover.

2. Pull off the tensioning lever (7) and remove from the spring

(15).

3. Pry off the closing cover (14) and remove the bolt (13) and

then remove the guide pulley (12).

4. Place alignment marks (arrow) on the timing chain (16) and

camshaft sprocket (4).

5. Remove the camshaft sprocket.

Page 456 of 1463

1B3-154 OM600 ENGINE MECHANICAL

4. Position the no. 1 cylinder at the TDC of OT.

6. Pull out the bearing pins (9, 11) with sliding hammer and

remove the guide rail 10.

Sliding Hammer 116 589 20 33 00

Threaded Pin 116 589 02 34 00

Installation Procedure

1. Apply collar of both bearing pins with sealing compound.

2. Position the guide rail and insert the bearing pins.

3. Install the camshaft sprocket.

Tightening Torque 10 Nm

Notice

If the max. length ‘L’ of the 12-sided bolt exceeds 53.6mm,

replace it.

Page 457 of 1463

OM600 ENGINE MECHANICAL 1B3-155

In this position, the marking on the camshaft / camshaft

bearing cap (arrow) must also be aligned.

5. Install the guide pulley (12).

Tightening Torque 23 Nm

6. Attach the tensioning lever (7) to the spring (15) and install.

7. Replace the gasket and install the cylinder head cover.

Tightening Torque 10 Nm

Page 458 of 1463

1B3-156 OM600 ENGINE MECHANICAL

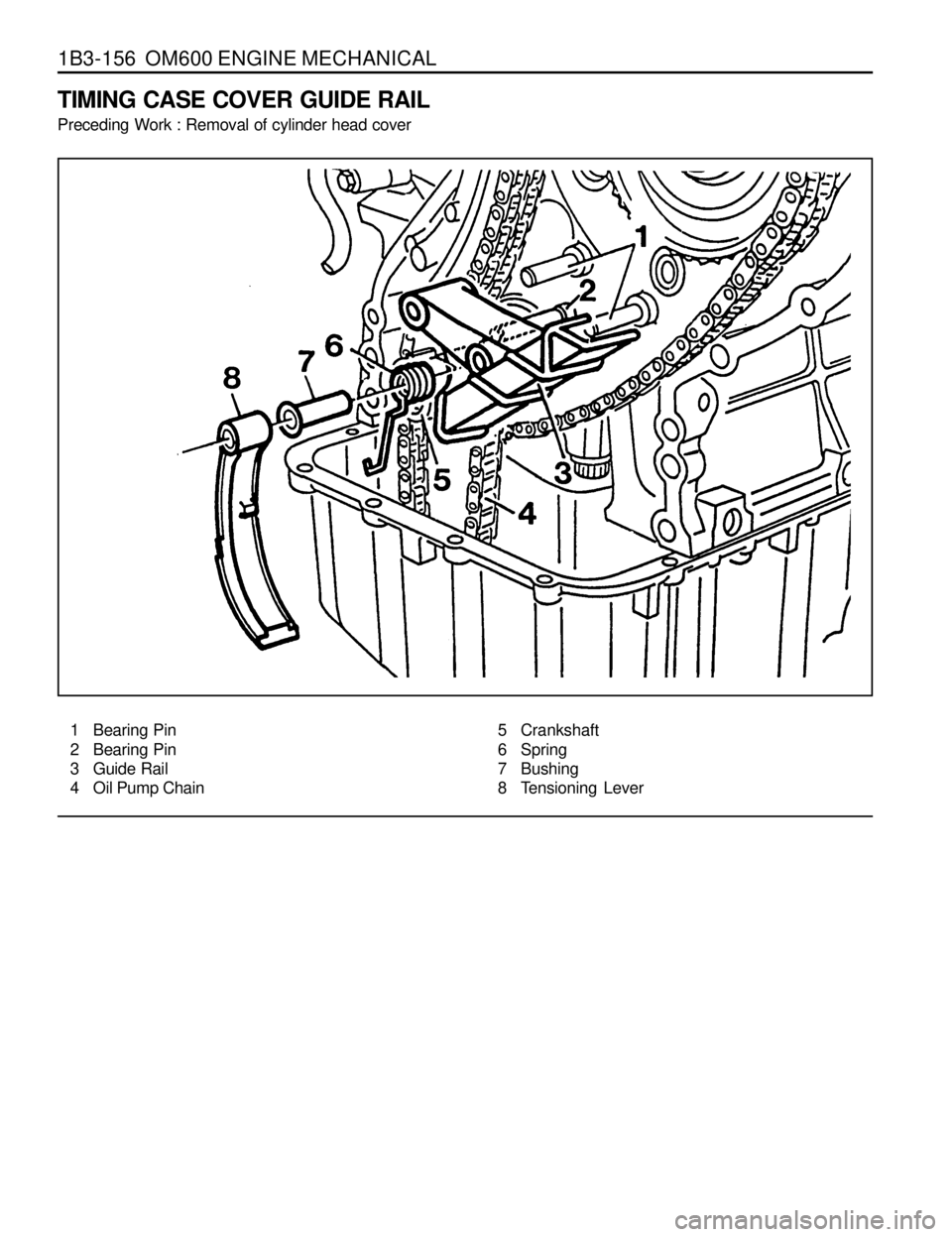

TIMING CASE COVER GUIDE RAIL

Preceding Work : Removal of cylinder head cover

1 Bearing Pin

2 Bearing Pin

3 Guide Rail

4 Oil Pump Chain5 Crankshaft

6 Spring

7 Bushing

8 Tensioning Lever

Page 459 of 1463

OM600 ENGINE MECHANICAL 1B3-157

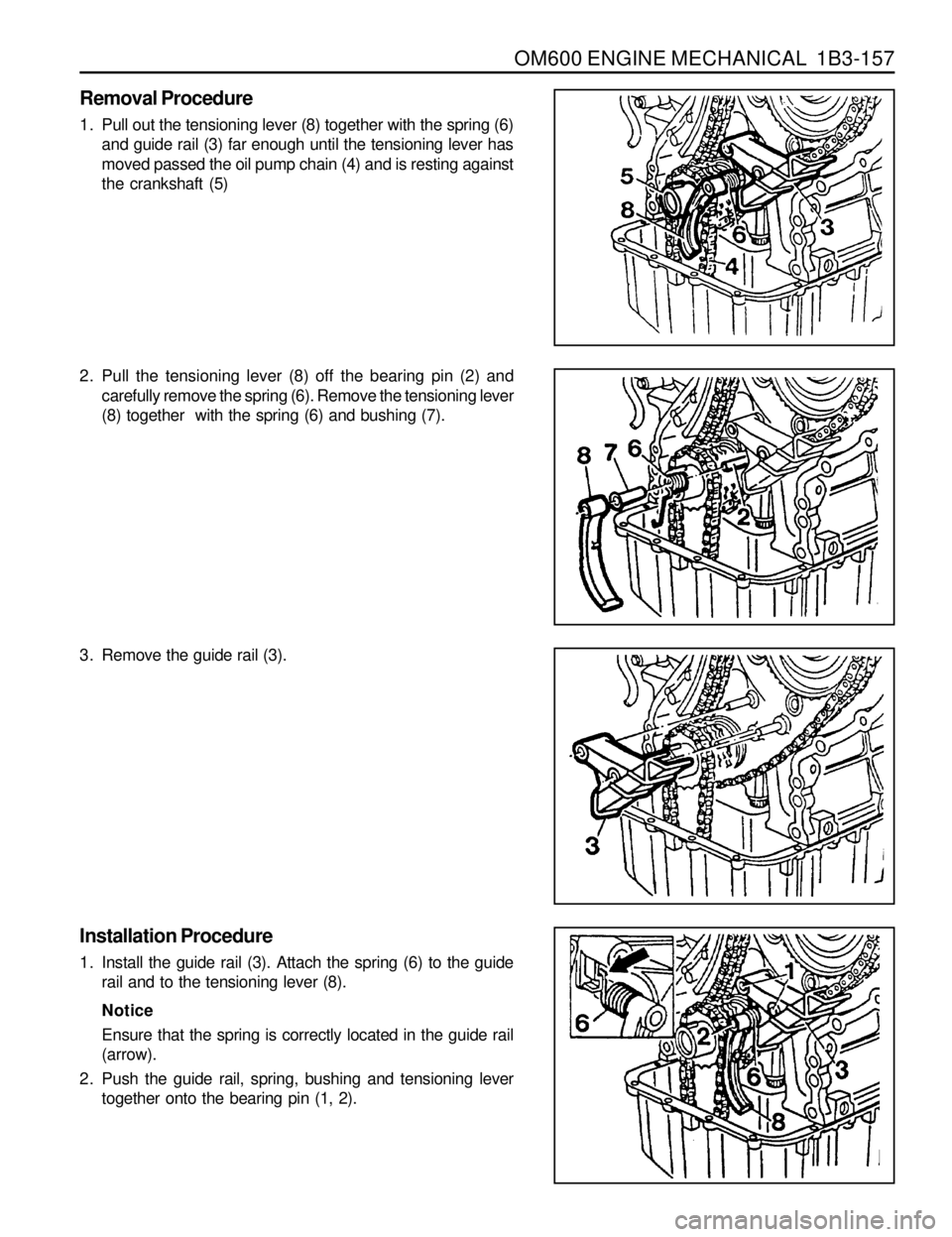

Removal Procedure

1. Pull out the tensioning lever (8) together with the spring (6)

and guide rail (3) far enough until the tensioning lever has

moved passed the oil pump chain (4) and is resting against

the crankshaft (5)

2. Pull the tensioning lever (8) off the bearing pin (2) and

carefully remove the spring (6). Remove the tensioning lever

(8) together with the spring (6) and bushing (7).

3. Remove the guide rail (3).

Installation Procedure

1. Install the guide rail (3). Attach the spring (6) to the guide

rail and to the tensioning lever (8).

Notice

Ensure that the spring is correctly located in the guide rail

(arrow).

2. Push the guide rail, spring, bushing and tensioning lever

together onto the bearing pin (1, 2).

Page 460 of 1463

1B3-158 OM600 ENGINE MECHANICAL

CRANKSHAFT SPROCKET

Preceding Work : Removal of oil pan

Removal of timing case cover

1 12-Sided Stretch Bolt (M11) .. Check, 25Nm + 90°

2 Washer

3 Camshaft Sprocket

4 Timing Chain

5 Bearing Pin

6 Bearing Pin

7 Oil Pump

8 Oil Pump Sprocket

9 Oil Pump Chain

10 Washer11 Bolt............................................................25Nm

12 Crankshaft Sprocket

13 Crankshaft

15 Key

16 Guide Rail

17 Spring

18 Bushing

19 Tensioning Lever

Trending: clock setting, spark plugs, stop start, bulb, Vacuum, battery replacement, brake pads