SSANGYONG MUSSO 1998 Workshop Repair Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Repair Manual

Trending: technical specifications, 4WD, inflation pressure, brake rotor, run flat, oil pressure, steering

Page 551 of 1463

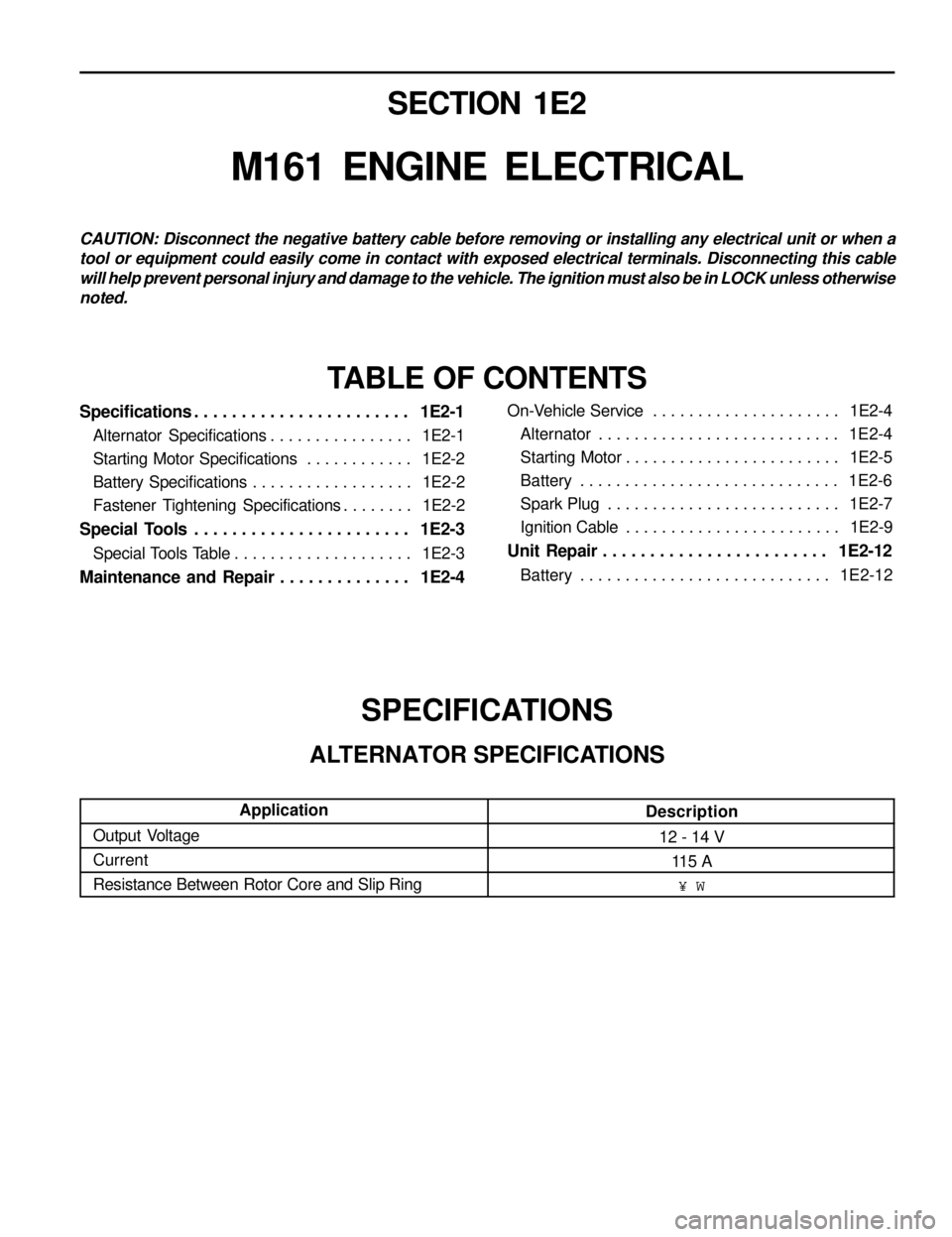

SECTION 1E2

M161 ENGINE ELECTRICAL

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1E2-1

Alternator Specifications . . . . . . . . . . . . . . . . 1E2-1

Starting Motor Specifications . . . . . . . . . . . . 1E2-2

Battery Specifications . . . . . . . . . . . . . . . . . . 1E2-2

Fastener Tightening Specifications . . . . . . . . 1E2-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1E2-3

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1E2-3

Maintenance and Repair . . . . . . . . . . . . . . 1E2-4

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 1E2-4

Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E2-4

Starting Motor . . . . . . . . . . . . . . . . . . . . . . . . 1E2-5

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E2-6

Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . 1E2-7

Ignition Cable . . . . . . . . . . . . . . . . . . . . . . . . 1E2-9

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . . 1E2-12

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E2-12

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

TABLE OF CONTENTS

SPECIFICATIONS

ALTERNATOR SPECIFICATIONS

Application

Output Voltage

Current

Resistance Between Rotor Core and Slip RingDescription

12 - 14 V

115 A

¥ W

Page 552 of 1463

1E2-2 M161 ENGINE ELECTRICAL

N·m

14 - 18

4 - 5

45 - 50

12 - 15

6 - 7

35 - 48

12 - 18

12 - 18

12 - 18

9 - 11

9 - 11

25 - 30

STARTING MOTOR SPECIFICATIONS

Application

Voltage

Output PowerDescription

12 V

1.2 KW

BATTERY SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Application

Capacity

Specific Gravity

Max. Tolerance Between CellsDescription

90 Ah

³ 1.24

³ 0.04

Application

Alternator Terminal B+Nut

Alternator Terminal D+Nut

Alternator Combinction Bolt

Battery Cable Nut on Starting Motor

Electric Wire Nut on Starting Motor

Starting Motor Mounting Nut

Battery Mounting Bracket Nut

Battery Negative Cable

Battery Positive Cable

Ignition Cable Cover Bolt

Ignition Cable Bolt

Spark plug

Page 553 of 1463

M161 ENGINE ELECTRICAL 1E2-3

SPECIAL TOOLS

SPECIAL TOOLS TABLE

120 589 02 09 00

Spark Plug Wrench

Page 554 of 1463

1E2-4 M161 ENGINE ELECTRICAL

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

ALTERNATOR

Preceding Work : Removal of the drivebelt

Removal & Installation Procedure

1. Disconnect the negative battery terminal.

2. Unscrew the nut and disconnect the terminal (1).

Installation Notice

1 Terminal (B+)

2 Terminal (D+)

3 Combination Bolt

4 Alternator

3. Unscrew the nut and disconnect the terminal (2).

Installation Notice

Tightening Torque 14 - 18 Nm

4. Unscrew the combination bolt (3).

Installation Notice

Tightening Torque 4 - 5 Nm

5. Remove the alternator.

6. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 42 - 50 Nm

Page 555 of 1463

M161 ENGINE ELECTRICAL 1E2-5

3 Fixing Bolt

4 Starting Motor

4. Unscrew the mounting bolts (3) of starting motor.

Installation Notice

5. Remove the starting motor.

6. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 35 - 48 Nm

STARTING MOTOR

Removal & Installation Procedure

1. Disconnect the ground cable.

2. Unscrew the nut and disconnect the battery cable(1).

Installation Notice

1 Battery Cable

2 Engine Electric Wire

3. Unscrew the nut and disconnect the engine electric wire

(2).

Installation Notice

Tightening Torque 12 - 15 Nm

Tightening Torque 6 - 7 Nm

Page 556 of 1463

1E2-6 M161 ENGINE ELECTRICAL

BATTERY

1 Cable Terminal (-)

2 Cable Terminal Cap (-)

3 Cable Terminal Cap (+)

4 Nut

5 Fuseblink Box

6 Terminal (+)7 Battery holddown Bracket

8 Battery Clamp Bolt

9 Battery

10 Sub Tray

11 Battery Tray

Removal & Installation Procedure

Notice

lDisconnect the battery negative cable first.

lInsert the clamp bolt (8) into the battery tray hole (11)

from inside when installing.

Page 557 of 1463

M161 ENGINE ELECTRICAL 1E2-7

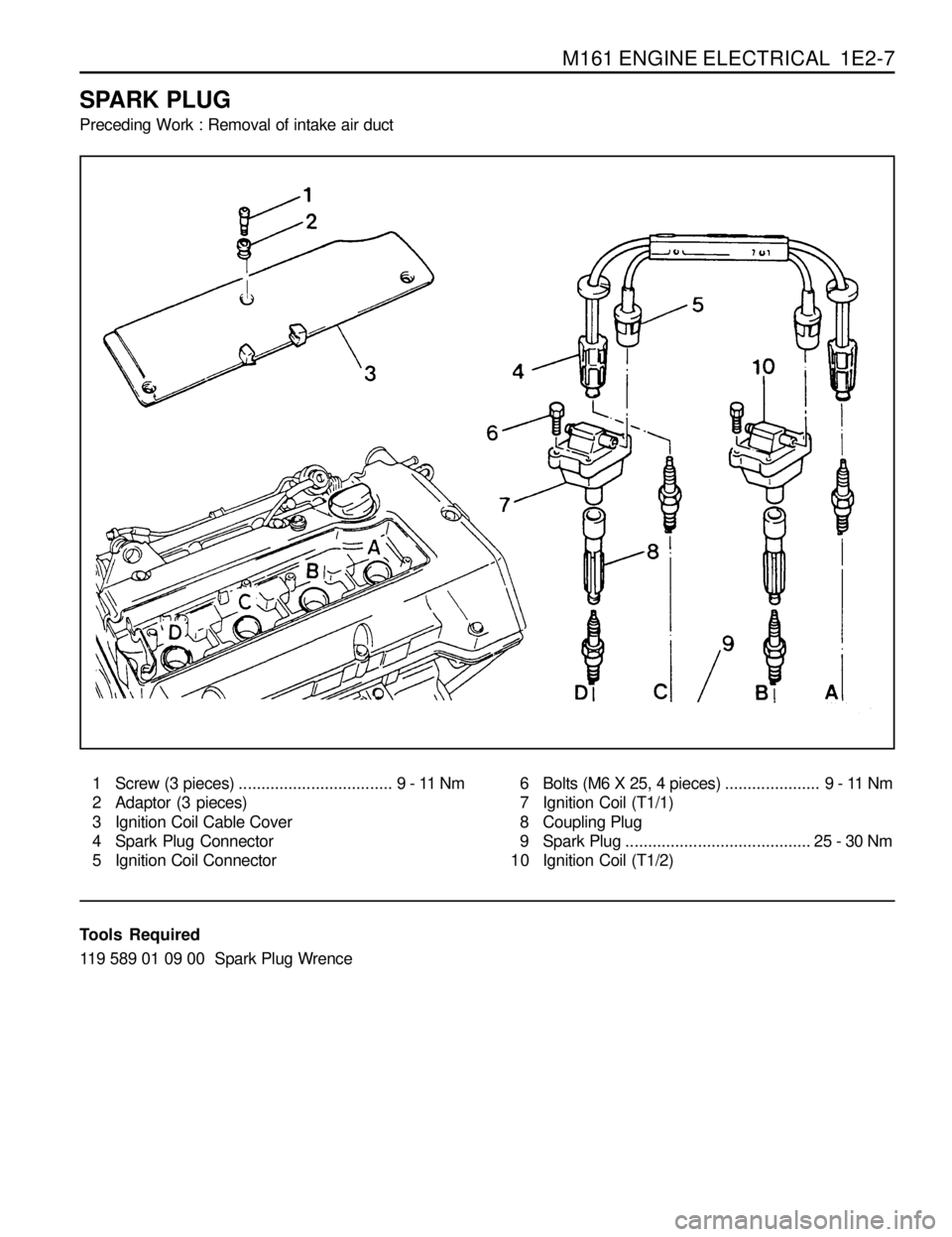

SPARK PLUG

Preceding Work : Removal of intake air duct

Tools Required

119 589 01 09 00 Spark Plug Wrence1 Screw (3 pieces).................................. 9 - 11 Nm

2 Adaptor (3 pieces)

3 Ignition Coil Cable Cover

4 Spark Plug Connector

5 Ignition Coil Connector6 Bolts (M6 X 25, 4 pieces)..................... 9 - 11 Nm

7 Ignition Coil (T1/1)

8 Coupling Plug

9 Spark Plug......................................... 25 - 30 Nm

10 Ignition Coil (T1/2)

Page 558 of 1463

1E2-8 M161 ENGINE ELECTRICAL

Tightening Torque 9 - 11Nm

Replacement Procedure

1. Unscrew the three screws(1) and remove the ignition coil

cable cover

Installation Notice

Tightening Torque

Clearance25 - 30 Nm

0.8 + 0.1 mm

2. Disconnect the cable from ignition coil and spark plug.

4. Using the special tool, remove the spark plug .

Installation Notice

Spark Plug Wrench 119 589 01 09 00

Notice

lTighten the spark plug with specified torque.

lInstall the ignition coil to number 2 and 4 cylinder, and

connect the cable to number 1, 4 and 2, 3 cylinder

- T1/1 : cylinder 1 and 4

- T1/2 : cylinder 2 and 3

3. Unscrew two bolts(M6 X 25) from each ignition coil and

remove the ignition coil(arrow) .

Installation Notice

Tightening Torque 9 - 11Nm

Page 559 of 1463

M161 ENGINE ELECTRICAL 1E2-9

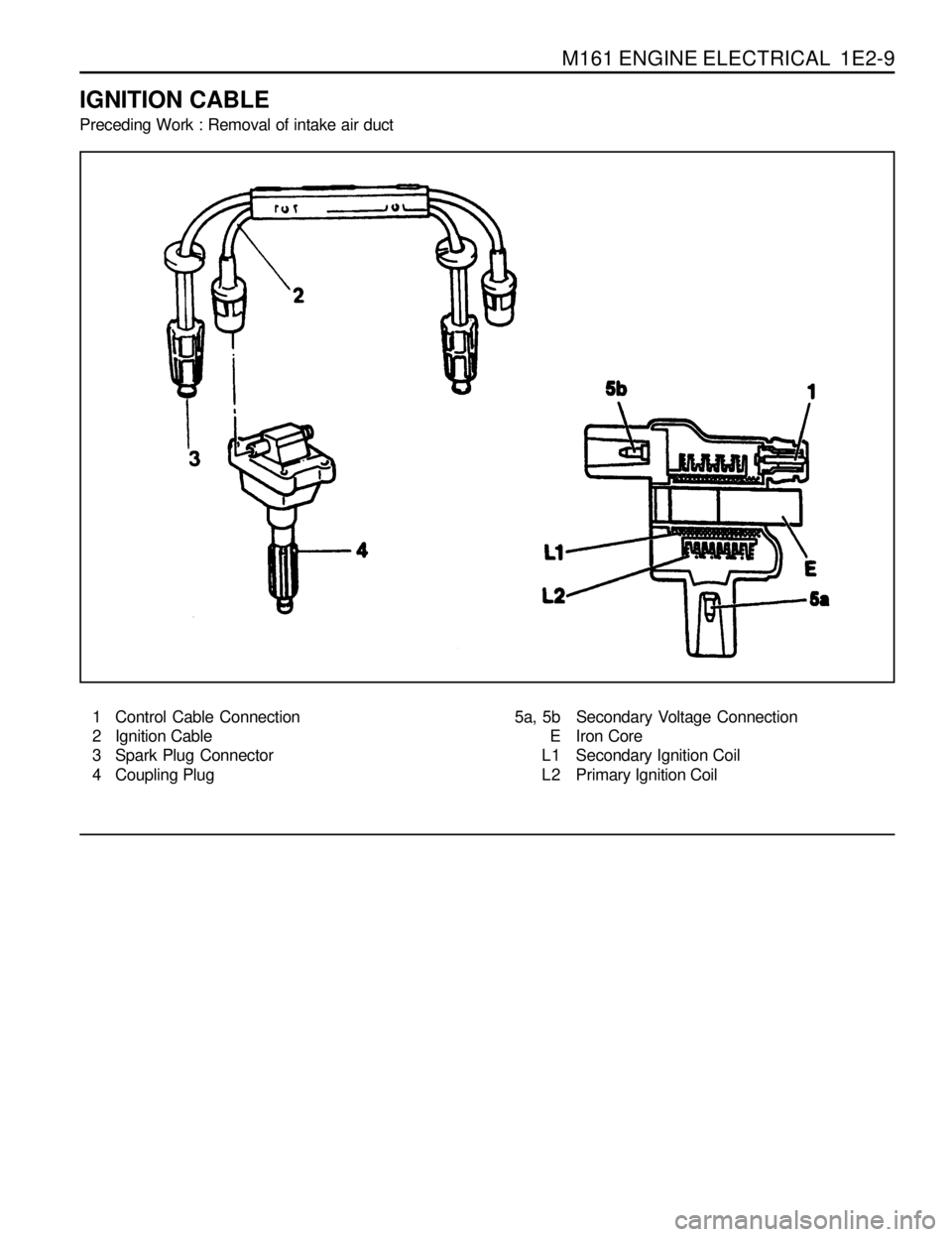

IGNITION CABLE

Preceding Work : Removal of intake air duct

1 Control Cable Connection

2 Ignition Cable

3 Spark Plug Connector

4 Coupling Plug5a, 5b Secondary Voltage Connection

E Iron Core

L1 Secondary Ignition Coil

L2 Primary Ignition Coil

Page 560 of 1463

1E2-10 M161 ENGINE ELECTRICAL

Ignition Cable and Cable Lay-out

1. Firing Order : 1-3-4-2

2. T1/1 : Connect the cylinder 1 + 4

3. T1/2 : Connect the cylinder 2 + 3

Removal & Installation Procedure

1. Disconnect the battery negative cable.

2. Unscrew the 3 screws and remove the ignition cable duct

cover.

Installation Notice

3. Seperate the cable from the ignition cable and the spark

plug.

4. Remove the 2 bolts from each ignition cable and remove

the ignition cables.

Installation Notice

Install the ignition cable to the cylinder 2 and 4 and connect

the cable from 1 to 4, and from 2 to 3.

- T1/1 : Cylinder 1 and 4

- T1/2 : Cylinder 2 and 3

5. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 9 - 11 Nm

Tightening Torque 9 - 11 Nm

Trending: fog light, recommended oil, drain bolt, weight, keyless, coolant reservoir, gearbox