engine oil SSANGYONG MUSSO 1998 Workshop Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 122 of 1463

M162 ENGINE MECHANICAL 1B1-49

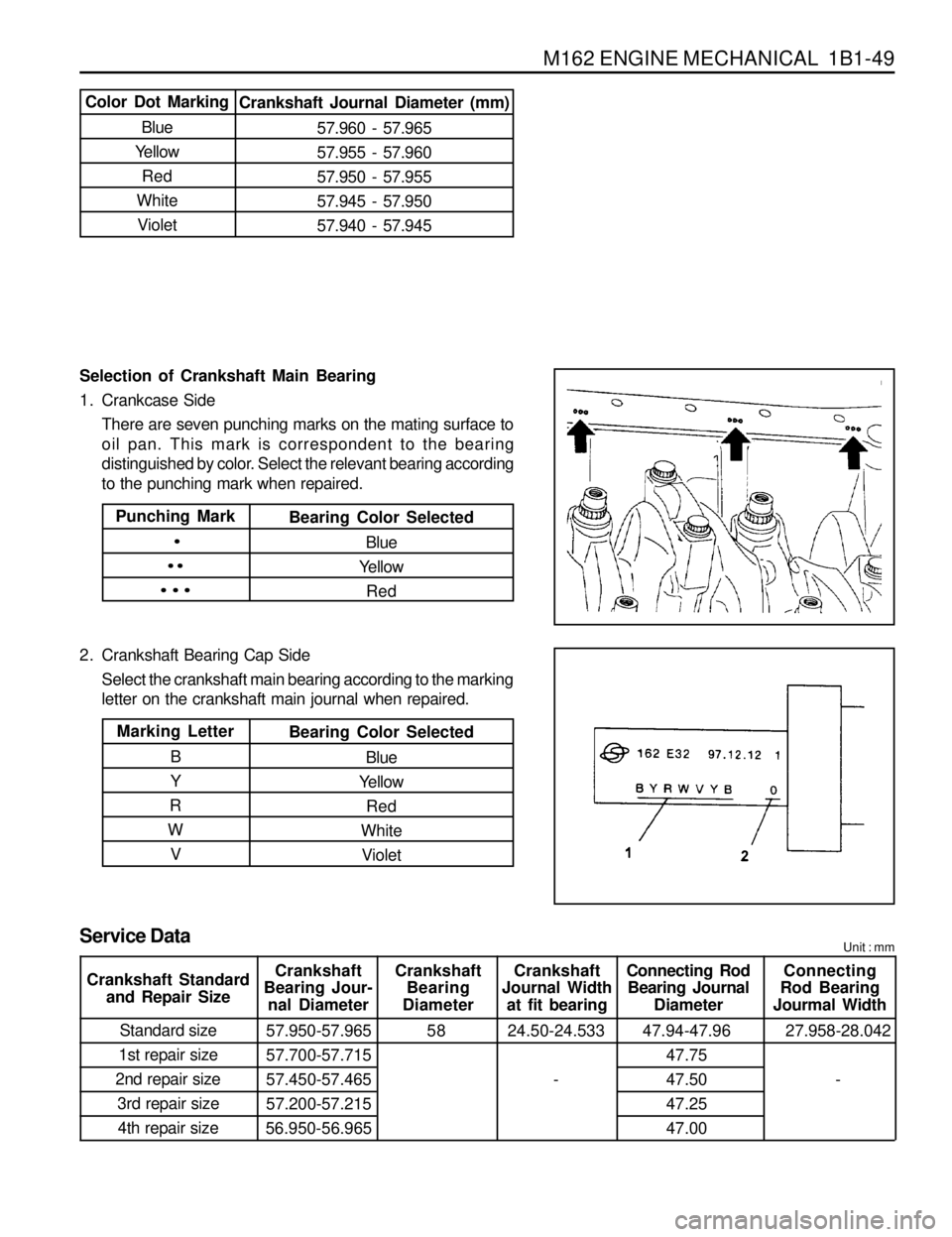

Selection of Crankshaft Main Bearing

1. Crankcase Side

There are seven punching marks on the mating surface to

oil pan. This mark is correspondent to the bearing

distinguished by color. Select the relevant bearing according

to the punching mark when repaired.

2. Crankshaft Bearing Cap Side

Select the crankshaft main bearing according to the marking

letter on the crankshaft main journal when repaired.

Color Dot Marking

Blue

Yellow

Red

White

VioletCrankshaft Journal Diameter (mm)

57.960 - 57.965

57.955 - 57.960

57.950 - 57.955

57.945 - 57.950

57.940 - 57.945

Punching Mark

·

··

···

Bearing Color Selected

Blue

Yellow

Red

Marking Letter

B

Y

R

W

VBearing Color Selected

Blue

Yellow

Red

White

Violet

Service DataUnit : mm

Crankshaft

Bearing Jour-

nal DiameterCrankshaft

Bearing

DiameterCrankshaft

Journal Width

at fit bearingConnecting Rod

Bearing Journal

DiameterConnecting

Rod Bearing

Jourmal Width

Standard size

1st repair size

2nd repair size

3rd repair size

4th repair size57.950-57.965

57.700-57.715

57.450-57.465

57.200-57.215

56.950-56.96558 24.50-24.533

-47.94-47.96

47.75

47.50

47.25

47.0027.958-28.042

- Crankshaft Standard

and Repair Size

Page 123 of 1463

1B1-50 M162 ENGINE MECHANICAL

Installation Notice

lMake sure the crankshaft bearing cap properly seated

in place in the crankcase side. When perfectly installed,

the projected part (arrow) locates in the left side (intake

manifold side).

lAssemble so that the projected part of the cap and

crankcase face the same direction.

Removal & Installation Procedure

1. Unscrew the connecting rod bearing cap bolt and remove

the bearing cap.

Installation Notice

2. Unscrew the crankshaft bearing cap bolts and separate the

upper and lower bearing shells and thrust washers.

Installation Notice

lRemove the bearing cap from front (pulley side) to rear.

lMake sure that the upper and lower bearing shells do

not change each other and coat with engine oil.

lThe oil grooves (arrows) in the thrust washers must face

outward and insert the thrust bearing into the bearing

cap.

lThere are five kinds of thrust washers by thickness. Select

the proper washer when repaired.

3. Remove the crankshaft.

4. Installation should follow the removal procedure in the

reverse order.

5. After completion of the installation, check for the rotating

condition of the crankshaft.

lMake sure that the upper and lower bearing shells do

not change each other.

lCoat the bearing shell with engine oil.

lInstall the bearing cap according to the consecutive

number.

Part No. : 601 030 00 622.15 mm

Part No. : 601 030 01 622.20 mm

Part No. : 601 030 02 622.25 mm

Part No. : 601 030 03 622.30 mm

Part No. : 601 030 04 622.40 mm

Tightening Torque 40 Nm + 90°

Tightening Torque 55 Nm + 90°

Page 127 of 1463

1B1-54 M162 ENGINE MECHANICAL

Removal & Installation Procedure

1. Unscrew the stretch bolt.

Installation Notice

Sectional View

1 Oil Pan

2 Cover

3 Crankshaft Front Seal

4 Flywheel MTG Bolt

5 Crankshaft

6 Dowel Pin

7 Plate

8 TGCC

9 Bolt

10 Front Drive Plate

11 Rear Drive Plate

12 Rivet

13 Segment

14 Ring Gear

lReplace the bolt when the stretch side diameter (d) of

the flywheel mounting bolt is less than 8.0mm.

lFor the stretch bolt tightening, keep the socket wrench

and Tommy-bar to be 90° and tighten as specified.

2. Remove the flywheel for manual transmission vehicles, or

the driven plate (3), and plate (2) for Auto. transmission

vehicle.

3. Installation should follow the removal procedure in the

reverse order.Tightening Torque1st step 45+5 Nm

2nd step 90° + 10°

Page 128 of 1463

M162 ENGINE MECHANICAL 1B1-55

CAMSHAFT ADJUSTER

1 Bolt (M6 x 16, 3 pieces)........................ 9-11 Nm

2 Electromagnetic Actuator (2 Pin Connector)

3 Bolt........................................................... 35 Nm

4 Armature

5 Roll Pin

6 Nut (M20 x 1.5)....................................60-70 Nm

7 Front Cover

8 Seal

9 Camshaft Position Sensor

10 Bolt (M6 x 16, 2 pieces)......................... 9-11 Nm

11 Seal

12 Seal Cover13 Camshaft Sprocket and Position Indicator (b)

14 Adjuster piston

15 Flange bolt (M7 x 13, 3 pieces)

..............................................1st step 18-22 Nm

2nd step 90° ± 5°

16 Flange Shaft

17 Compression Spring

18 Control Piston

19 Circlip

20 Oil Gallery

21 Pin

22 Intake Camshaft

Page 144 of 1463

M162 ENGINE MECHANICAL 1B1-71

VALVE STEM SEAL

Preceding Work : Removal of valve spring

1 Drift (Special Tool)

2 Valve Stem Seal

3 Protective Sleeve

Drift 119 589 00 43 00 Pliers 104 589 00 37 00

Tools Required

104 589 00 37 00 Pliers

119 589 00 43 00 Drift

Replacement Procedure

1. Remove the valve stem seal (2) using the pliers.

Notice

Check the valve stem seal for damage and replace if

necessary.

2. Coat the valve stem seal with oil and assemble it with the

protective sleeve.

3. Insert the valve stem seal by pressing it with the drift.

Page 145 of 1463

1B1-72 M162 ENGINE MECHANICAL

CHAIN TENSIONER

1 Screw Plug................................................ 40 Nm

2 Seal

3 Filler Pin

4 Compression Spring5 Snap Ring

6 Thrust Pin

7 Chain Tensioner Housing.....................72-88 Nm

8 Seal

Removal Procedure

1. Position the No.1 cylinder to TDC (OT).

Notice

Remove the oil filler cap at adjustment position, and check

whether the intake camshaft cam’s lobe (arrow) stays in the

upper side.

2. Cover the alternator with a clean cloth.

3. Release the tension by unscrewing the screw plug once.

Notice

In case that the tension is reduced by unscrewing the screw

plug, reinstall after completely removing the chain tensioner.

If the chain tensioner is tightened again without completely

reducing its tension, then the detent spring doesn’t return

to the original position and the tension gets excedded.

Page 147 of 1463

1B1-74 M162 ENGINE MECHANICAL

4. Lightly apply the grease to the seal (2) and install the screw

plug (1).

Installation Notice

Sectional View

1 Screw Plug

2 Ball (Nonreturn Valve)

3 Compression Spring

4 Ball Guide

5 Seal (Aluminum)

6 Filler Pin

7 Compression Spring

8 Snap Ring

9 Thrust Pin

10 Ball (Nonreturn Valve)

11 Compression Spring

12 Thrust Piece13 Chain Tensioner Housing

1 4 Seal

15 Timing Gear Case Cover

16 Cylinder Head

17 Bolt / Washer

18 Tensioning Rail

19 Cylinder Head Gasket

20 Timing Chain

21 Tensioning Rail Base (Sliding Surface)

A Oil Supply Hole

B Chain Tensioner Oil Storage Hole 5. Check for leaks by operating the engine.

Tightening Torque 40 Nm

Page 156 of 1463

M162 ENGINE MECHANICAL 1B1-83

CRANKSHAFT SPROCKET

Preceding Work : Removal of oil pan

Removal of tensioning rail

Removal of crank case guide rail

6 Bolt (M8 x 20, 1 piece) / Washer..........29-35 Nm

7 Oil Pump Sprocket

8 Oil Pump

9 Oil Pump Roller Chain

10 Timing Chain 1 Oil Pump Chain Tensioner

2 Oil Pump Chain Bushing

3 Oil Pump Chain Spring

4 Crankshaft Sprocket

5 Key

Page 157 of 1463

1B1-84 M162 ENGINE MECHANICAL

Tools Required

615 589 01 33 00 Puller

Removal & Installation Procedure

1. Put the assembly mark at the crankshaft sprocket (4) and

the timing chain (10) with the paint (arrow).

Installation Notice

Align the assembly marks on cranshaft sprocket and timing

chain. Also, align the assembly marks on camshaft sprocket

and timing chain when installing.

2. Unscrew the bolt (6) and remove the oil pump sprocket (7)

from the oil pump.

Installation Notice

Puller (04) 615 589 01 33 00

3. Remove the oil pump roller chain (9).

4. Remove the oil pump chain tensioner (1), oil pump chain

bushing (2), and the oil pump chain spring (3).

5. Remove the crankshaft sprocket (4) using the puller (04,

special tool).

Notice

lMake sure not to lose the crankshaft pulley key(5) when

removing.

lInstall the crankshaft sprocket(4) after warming it up.

6. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 29 - 35 Nm

Page 158 of 1463

M162 ENGINE MECHANICAL 1B1-85

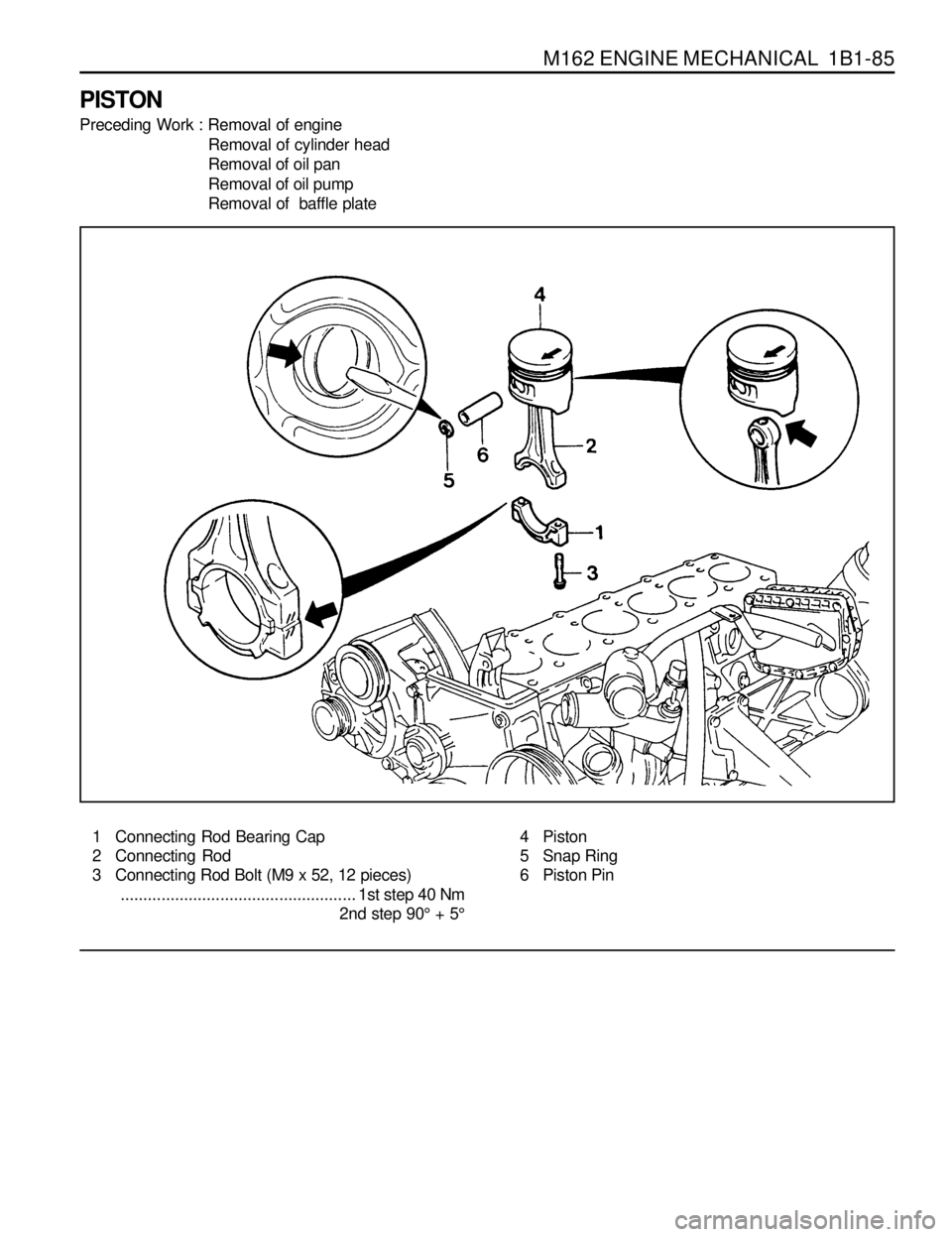

PISTON

Preceding Work : Removal of engine

Removal of cylinder head

Removal of oil pan

Removal of oil pump

Removal of baffle plate

1 Connecting Rod Bearing Cap

2 Connecting Rod

3 Connecting Rod Bolt (M9 x 52, 12 pieces)

....................................................1st step 40 Nm

2nd step 90° + 5°4 Piston

5 Snap Ring

6 Piston Pin