SSANGYONG MUSSO 1998 Workshop Owners Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Owners Manual

Page 207 of 1463

1B2-18 M161 ENGINE MECHANICAL

Operation at Idling and Mid-Load

lThe throttle valve(6) is closed or very partially opened, and

the vacuum pressure in intake manifold is high.

The blow-by gas and the fresh air that is additionally supplied

through the vent connection(D) in the crankcase in partial

load gets supplied to the combustion chamber from the crank

chamber(12) through the oil separation chamber(11), air-

conditioner bracket(10), vent line(9), and restrictor(7)

mounted to the cylinder head.

The circulated engine oil returns to the oil pan through the

oil return pipe(13) at the bottom of oil separation

chamber(11).

The fresh air gets supplied to the crank chamber(12) through

the HFM sensor(1), intake air duct(4), vent line(5), oil

separation chamber(3), chain housing(17), and the timing

gear case cover(15).

The additional supply of the fresh air is needed to prevent

from forming the residues of the engine oil.

Page 208 of 1463

M161 ENGINE MECHANICAL 1B2-19

Operation When Full-Load at Partial Load

1 HFM Sensor

2 Cylinder Head Cover

3 Oil Spearation Chamber (Full-Load or Over

Mid-Load)

4 Intake Air Duct (Cross Pipe)

5 Vent Line (Full-Load or Over Mid-Load)

6 Throttle Valve

7 Restrictor, Diameter 1.1mm (Mid-Load at Idling)

8 Intake Manifold

9 Vent Line (Mid-Load at Idling)

10 Air Conditioner Bracket11 Oil Separation Chamber (Mid-Load at Idling)

12 Crank Chamber

13 Oil Return Pipe

14 Oil Pan

15 Timing Gear Case Cover

16 Crankcase

17 Chain Housing

A Fresh Air

C Blow-by Gas

D Vent Connection

Page 209 of 1463

1B2-20 M161 ENGINE MECHANICAL

Operation When Full-Load at Partial Load

lThe throttle valve (6) is partially opened or fully opened.

The air flows very rapidly through the vent line(5)s

connection(D) and the intake air duct when full-load at partial

load.

Consequently, most of the low-by gases are supplied to the

combustion chamber through the timing gear case

cover(15), chain housing(17), oil separation chamber(3),

vent line(5), throttle valve(6), and intake manifold(8).

Page 212 of 1463

M161 ENGINE MECHANICAL 1B2-23

Removal & Installation Procedure

1. Remove the belt pulley after removal of poly v-belt.

Installation Notice

2. Disconnect the hydraulic pipe of the power steering pump

and drain the oil.

3. Unscrew the bolts (arrows) and remove the steering pump.

Installation Notice Notice

Pull the tensioning pulley counterclockwise as shown in the

figure.

4. Remove the compressor after disconnecting the wiring

connector and refrigerant pipe of A/C compressor.

Notice

Discharge all the refrigerant before removing the pipes.

Tightening Torque 40.5 - 49.5 Nm

Tightening Torque 22.5 - 27.5 Nm

Page 213 of 1463

1B2-24 M161 ENGINE MECHANICAL

5. Disconnect the vent hose from the A/C bracket.

6. Unscrew all the mounting bolts (arrows) and remove the

A/C bracket and the gasket.

Installation Notice

7. Clean the sealing surface.

8. Replace the gasket with new one.

9. Installation should follow the removal procedure in the

reverse order.

10. Check the oil leakage by operating the engine after

installation.

Tightening Torque 22.5 - 27.5 Nm

Page 216 of 1463

M161 ENGINE MECHANICAL 1B2-27

1 Upper Nut

2 Hydraulic Installer.................62~93 Nm

3 Lower Nut.............................28~47 Nm

Removal and Installation Procedure

1. Unscrew the upper nut(1) on engine mounting and remove

the engine.

Installation Notice

3. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 62 - 93 Nm

2. Unscrew the lower nut(3) and remove the hydraulic engine

mounting insulator.

Installation Notice

Tightening Torque 28 - 47 Nm

Notice

If the insulator is spotted with oil, replace the hydraulic

insulator assembly.

Page 224 of 1463

M161 ENGINE MECHANICAL 1B2-35

CYLINDER HEAD COVER

1 Ignition Coil Cover

2 Spark Plug Connector

3 Bolt (M6 X 45 : 4 pieces, M6 X 60 :

6 pieces)............................................. 10 ± 1 Nm4 Cylinder Head Cover

5 Gasket ................................................... Replace

Page 225 of 1463

1B2-36 M161 ENGINE MECHANICAL

Removal & Installation Procedure

1. Remove the intake air duct.

Installation Notice

2. Remove the ignition coil cover.

Installation Notice

3. Remove the spark plug connector and ignition cable.Notice

Release 3 screws from the ignition cover and remove the

cover for M161 Engine coil.

Tightening Torque 9 - 11 Nm

Tightening Torque 9 - 10 Nm

Page 233 of 1463

1B2-44 M161 ENGINE MECHANICAL

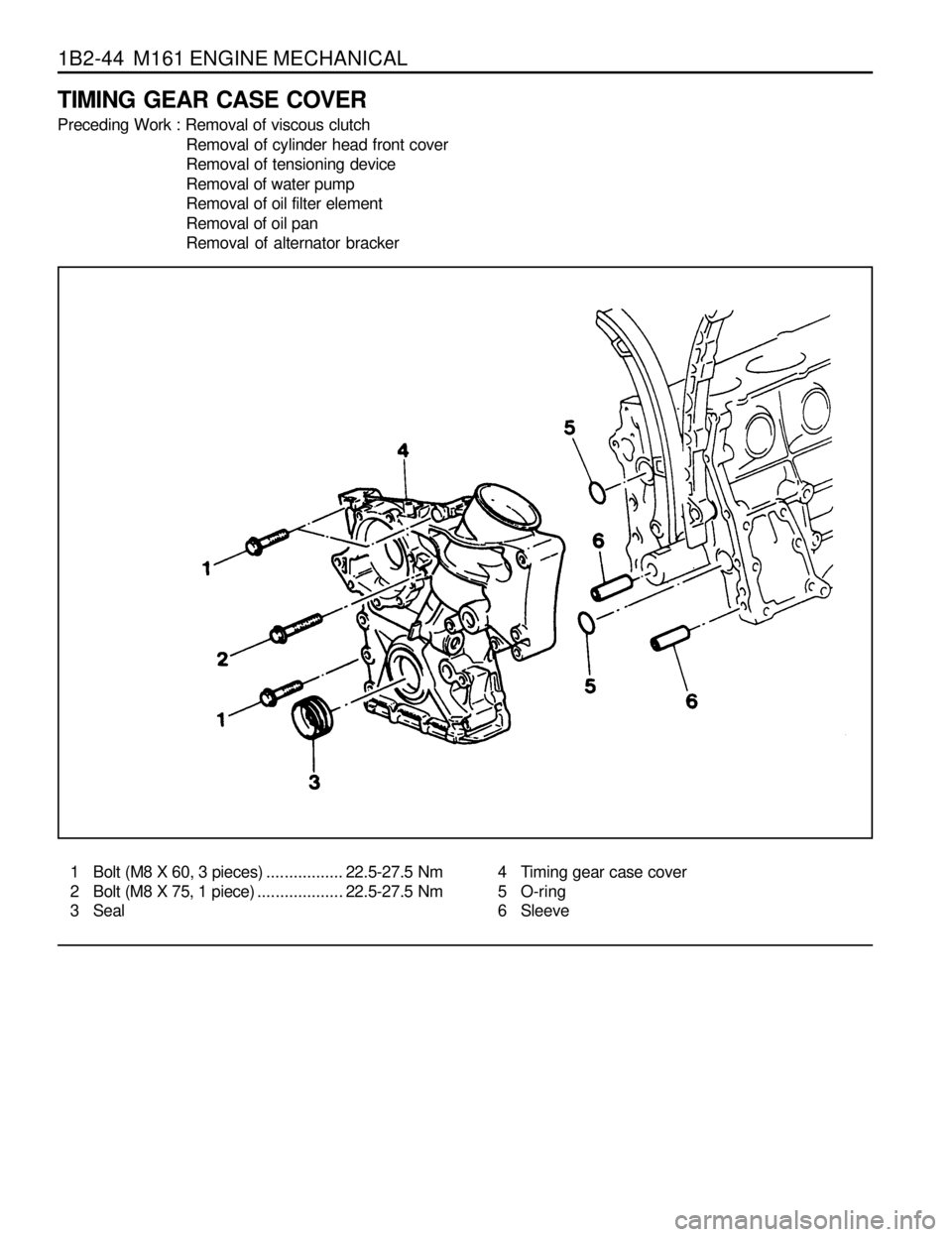

TIMING GEAR CASE COVER

Preceding Work : Removal of viscous clutch

Removal of cylinder head front cover

Removal of tensioning device

Removal of water pump

Removal of oil filter element

Removal of oil pan

Removal of alternator bracker

1 Bolt (M8 X 60, 3 pieces).................22.5-27.5 Nm

2 Bolt (M8 X 75, 1 piece)...................22.5-27.5 Nm

3 Seal4 Timing gear case cover

5 O-ring

6 Sleeve

Page 234 of 1463

M161 ENGINE MECHANICAL 1B2-45

Tools Required

001 589 72 21 00 Torque Wrench

116 589 2 0 33 00 Sliding Hammer

116 589 01 34 00 Threaded Bolt

Removal & Installation Procedure

1. Remove the power steering belt pulley and A/C compressor

bracket.

2. Remove the oil line from power steering pump.

3. Rotate the crankshaft so that the piston of number, cylinder

is at ATDC20°

Sliding Hammer 116 589 20 33 00

Threaded Pin 116 589 02 34 00

4. Put the alignment marks (arrows) on the timing chain and

camshaft sprocket.

5. Remove the chain tensioner.

Installation Notice

Tightening Torque 78 - 88 Nm

6. Remove the intake and exhaust camshaft sprocket

(remove the camshaft adjuster assembly in E23 engine).

Installation Notice

Tightening Torque1st step 18 - 22 Nm

2nd step 85° - 95°

Notice

The flange bolt is designed to be used only once, so always

replace with new one.

7. Remove the guide rail pin using the sliding hammer (02)

and the threaded pin (03).

Notice

Apply the sealant on guide rail pin when installation.