steering SSANGYONG MUSSO 1998 Workshop Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 1267 of 1463

POWER STEERING SYSTEM 6A-7

STEERING GEAR BOX

1 Bolt.......................................................30-40Nm

2 Spring Washer

3 Lower Shaft

4 Pressure Hose......................................12-18Nm

5 Return Pipe..........................................12-18Nm

6 Cotter Pin7 Slotted Nut............................................35-45Nm

8 Nut

9 Spring Washer

1 0 Bolt.......................................................35-45Nm

11 Washer

12 Steering Gearbox Assembly

Page 1268 of 1463

6A-8 POWER STEERING SYSTEM

Tightening Torque 35 - 45 Nm

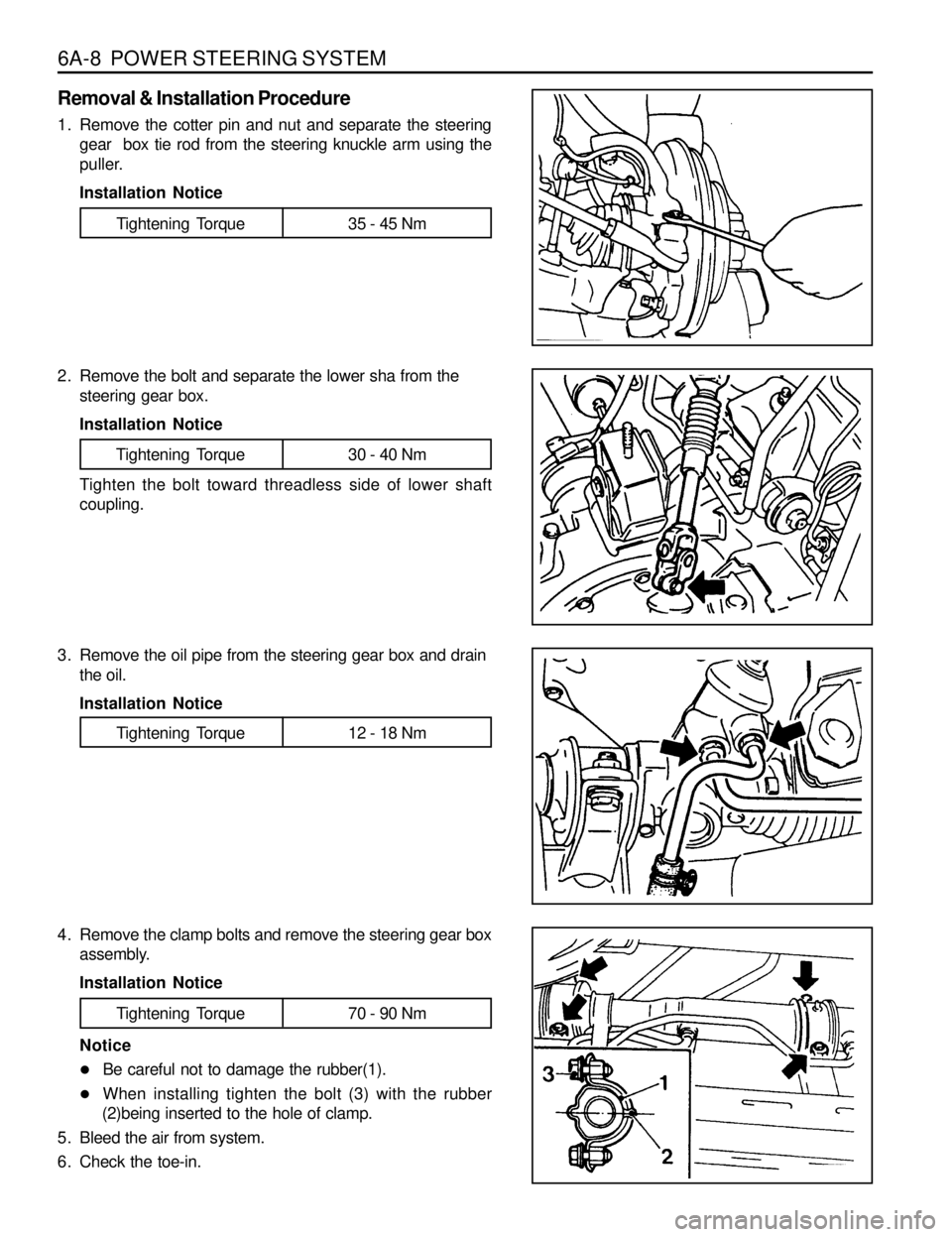

Removal & Installation Procedure

1. Remove the cotter pin and nut and separate the steering

gear box tie rod from the steering knuckle arm using the

puller.

Installation Notice

2. Remove the bolt and separate the lower sha from the

steering gear box.

Installation Notice

Tightening Torque 30 - 40 Nm

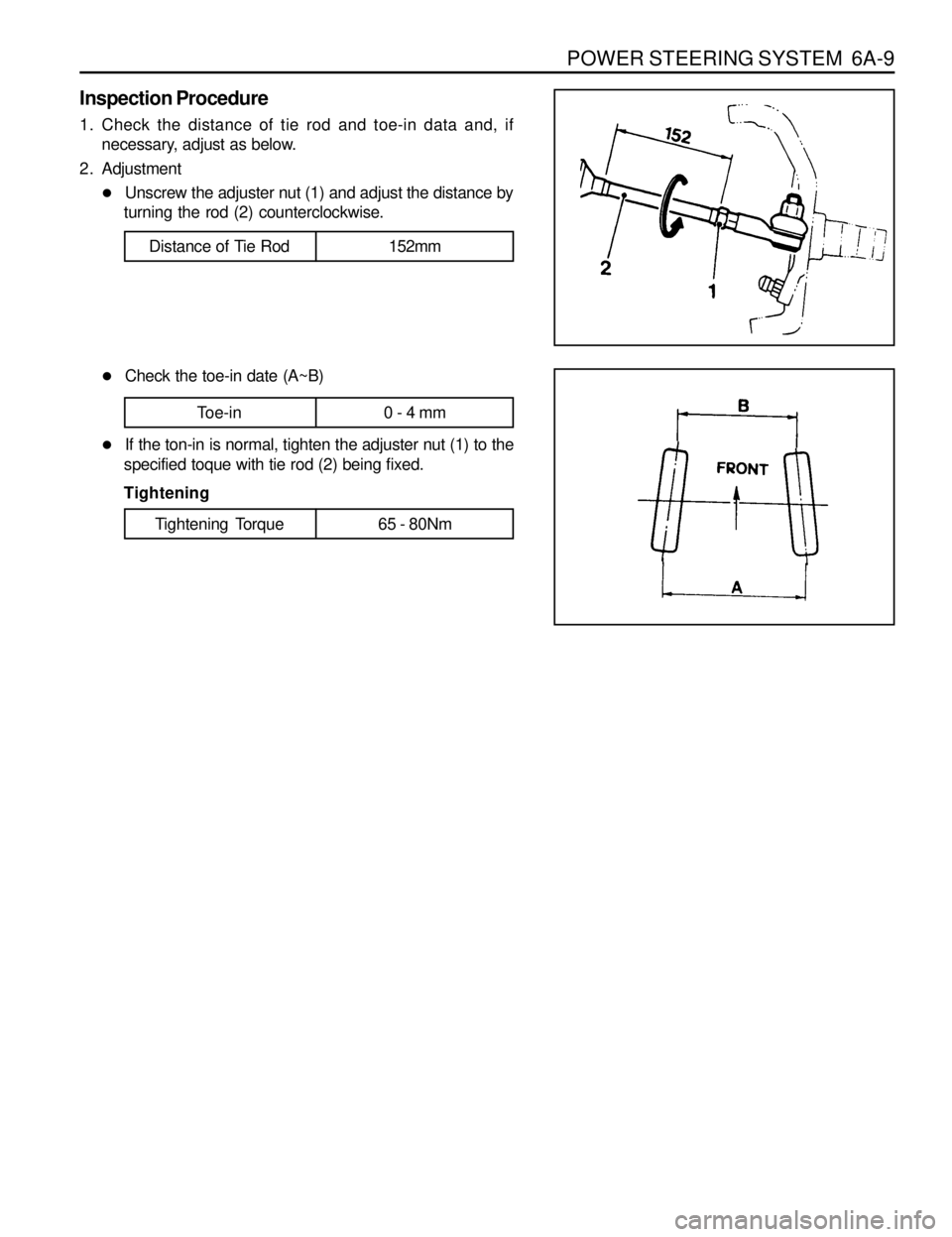

3. Remove the oil pipe from the steering gear box and drain

the oil.

Installation Notice

4. Remove the clamp bolts and remove the steering gear box

assembly.

Installation Notice

Tightening Torque 12 - 18 Nm

Notice

lBe careful not to damage the rubber(1).

lWhen installing tighten the bolt (3) with the rubber

(2)being inserted to the hole of clamp.

5. Bleed the air from system.

6. Check the toe-in.

Tightening Torque 70 - 90 Nm Tighten the bolt toward threadless side of lower shaft

coupling.

Page 1269 of 1463

POWER STEERING SYSTEM 6A-9

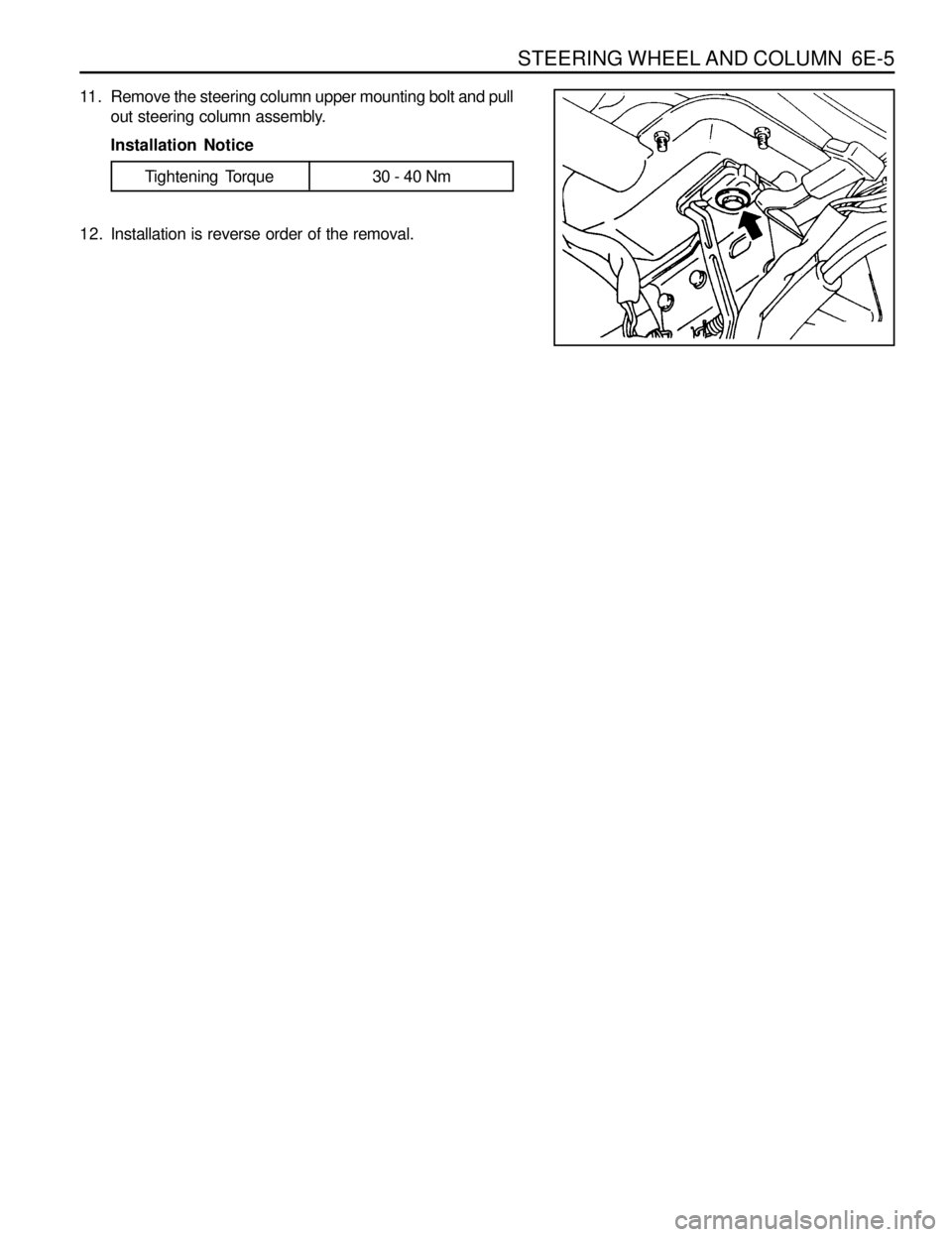

Inspection Procedure

1. Check the distance of tie rod and toe-in data and, if

necessary, adjust as below.

2. Adjustment

lUnscrew the adjuster nut (1) and adjust the distance by

turning the rod (2) counterclockwise.

Distance of Tie Rod152mm

Toe-in 0 - 4 mm

Tightening Torque 65 - 80Nm

lCheck the toe-in date (A~B)

lIf the ton-in is normal, tighten the adjuster nut (1) to the

specified toque with tie rod (2) being fixed.

Tightening

Page 1270 of 1463

SECTION 6E

STEERING WHEEL AND COLUMN

TABLE OF CONTENTS

Specification . . . . . . . . . . . . . . . . . . . . . . . . 6E-1

Fastener Tightening Specifications . . . . . . . . . 6E-1

Maintenance and Repair . . . . . . . . . . . . . . . 6E-2

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Application

Steering Wheel Mounting Nut

Steering Lower Shaft Bolt

Steering Column Shaft Bolt

Steering Column Mounting BoltNlm

50 - 80

30 - 40

9 - 14

15 - 20

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . . 6E-2

Steering Column . . . . . . . . . . . . . . . . . . . . . . . 6E-2

Page 1271 of 1463

6E-2 STEERING WHEEL AND COLUMN

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

STEERING COLUMN

1 Horn Pad

2 Nut .......................................................50-80 Nm

3 Washer

4 Steering Wheel

5 Combination Switch Assembly

6 Combination Switch Lower Cover

7 Combination Switch Upper Cover

8 Bolt

9 Bolt1 0 Bolt

11 Crash Pad Panel

1 2 Bolt......................................................30-40 Nm

13 Spring Washer

14 Steering Column Shaft

1 5 Bolt........................................................9-14 Nm

1 6 Bolt......................................................13-40 Nm

17 Column & Shaft Assembly

Page 1272 of 1463

STEERING WHEEL AND COLUMN 6E-3

Removal & Installation Procedure

1. Remove the horn pad from the steering wheel and

disconnect the connectors .

2. Place an alignment marks on the column shaft end and

fixing nut and then remove the fixing nut.

Installation Notice

3. Remove the steering wheel.

4. Remove the combination switch upper cover .

Tightening Torque 50 - 80 Nm

5. Release the crash pad panel.

Notice

Remove the hood release wire and the other switch

connectors.

Page 1273 of 1463

6E-4 STEERING WHEEL AND COLUMN

6. Disconnect each connectors.

7. Remove the vacuum hose from the ignition switch(Diesel

only) .

9. Remove the lower shaft by removing the bolt of the steering

column shaft.

Installation Notice

Tightening Torque 9 - 14 Nm

8. Remove the combination switch assembly.

10. Remove the dash panel mounting bolts.

Installation Notice

Tightening Torque 30 - 40 Nm

Page 1274 of 1463

STEERING WHEEL AND COLUMN 6E-5

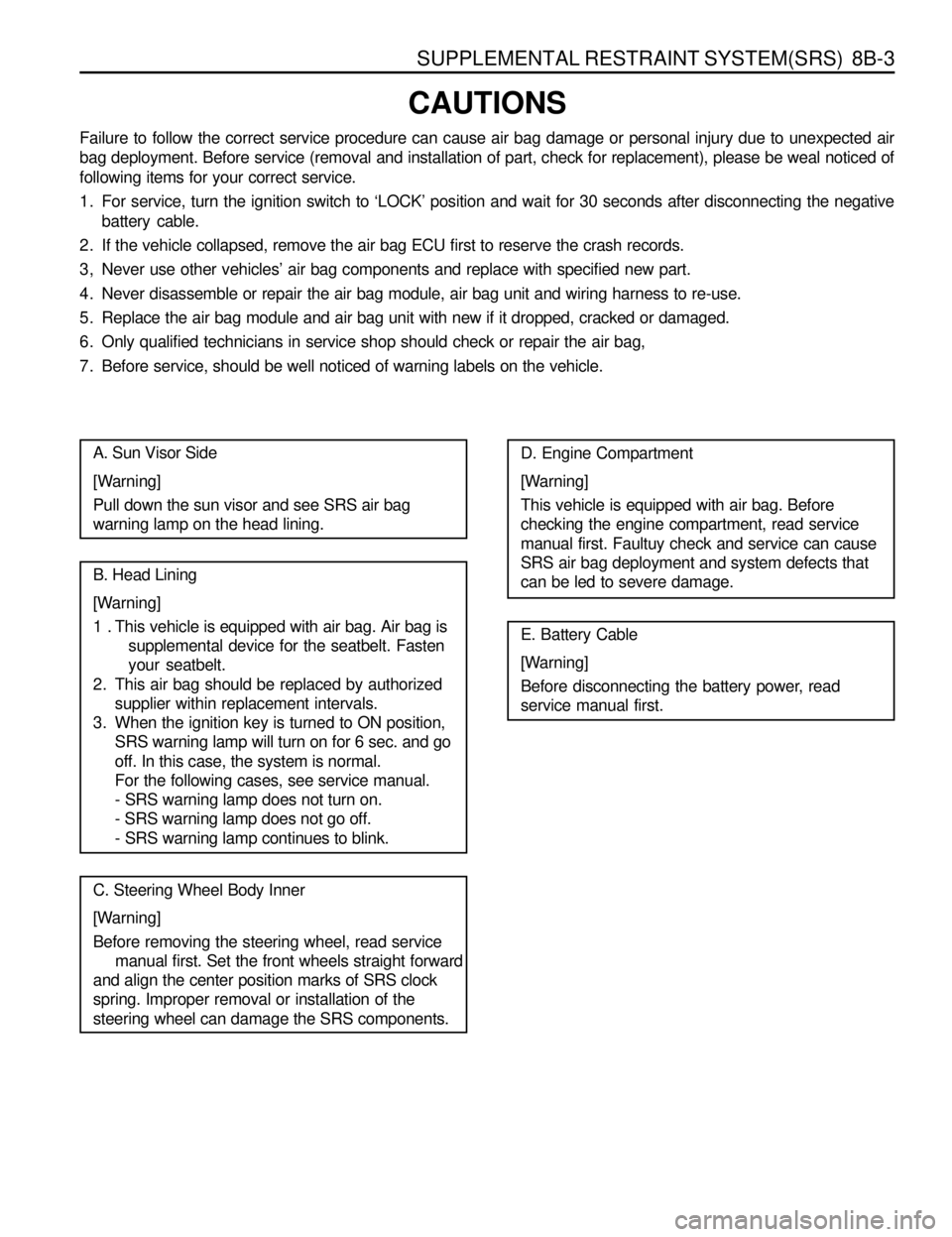

Tightening Torque 30 - 40 Nm 11. Remove the steering column upper mounting bolt and pull

out steering column assembly.

Installation Notice

12. Installation is reverse order of the removal.

Page 1307 of 1463

SUPPLEMENTAL RESTRAINT SYSTEM(SRS) 8B-3

CAUTIONS

Failure to follow the correct service procedure can cause air bag damage or personal injury due to unexpected air

bag deployment. Before service (removal and installation of part, check for replacement), please be weal noticed of

following items for your correct service.

1. For service, turn the ignition switch to ‘LOCK’ position and wait for 30 seconds after disconnecting the negative

battery cable.

2. If the vehicle collapsed, remove the air bag ECU first to reserve the crash records.

3, Never use other vehicles’ air bag components and replace with specified new part.

4. Never disassemble or repair the air bag module, air bag unit and wiring harness to re-use.

5. Replace the air bag module and air bag unit with new if it dropped, cracked or damaged.

6. Only qualified technicians in service shop should check or repair the air bag,

7. Before service, should be well noticed of warning labels on the vehicle.

A. Sun Visor Side

[Warning]

Pull down the sun visor and see SRS air bag

warning lamp on the head lining.

B. Head Lining

[Warning]

1 . This vehicle is equipped with air bag. Air bag is

supplemental device for the seatbelt. Fasten

your seatbelt.

2. This air bag should be replaced by authorized

supplier within replacement intervals.

3. When the ignition key is turned to ON position,

SRS warning lamp will turn on for 6 sec. and go

off. In this case, the system is normal.

For the following cases, see service manual.

- SRS warning lamp does not turn on.

- SRS warning lamp does not go off.

- SRS warning lamp continues to blink.

C. Steering Wheel Body Inner

[Warning]

Before removing the steering wheel, read service

manual first. Set the front wheels straight forward

and align the center position marks of SRS clock

spring. Improper removal or installation of the

steering wheel can damage the SRS components.D. Engine Compartment

[Warning]

This vehicle is equipped with air bag. Before

checking the engine compartment, read service

manual first. Faultuy check and service can cause

SRS air bag deployment and system defects that

can be led to severe damage.

E. Battery Cable

[Warning]

Before disconnecting the battery power, read

service manual first.

Page 1310 of 1463

8B-6 SUPPLEMENTAL RESTRAINT SYSTEM(SRS)

AIR BAG MODULE

Air bag module is installed in the pad of steering wheel center and inflator is consisted of igniter, explosives, gas

generating material and bag. When crashed, the air bag control unit sends current to the air bag module through

squib line and this current ignites as ignition energy (6mJ) momentarily igniting explosives and bag will be inflated

by nitrogen gas protecting driver at the same and then deflates.

1 Air bag Module

2 Module Housing

3 Bag

4 Module Bracket

5 Retainer Ring

6 Inflator

7 Horn Switch

8 Backing Plate