SSANGYONG MUSSO 1998 Workshop Repair Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Repair Manual

Page 797 of 1463

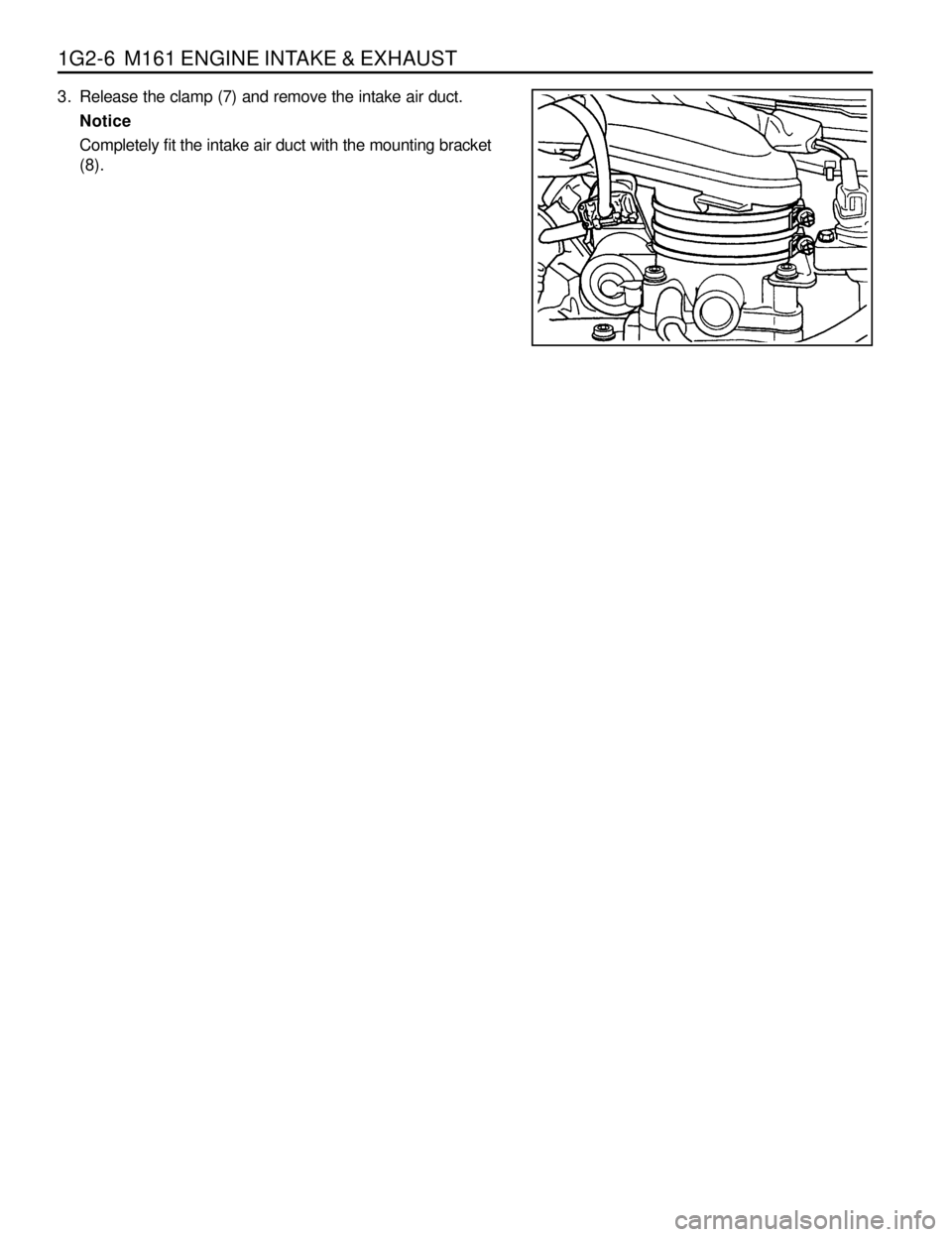

1G2-6 M161 ENGINE INTAKE & EXHAUST

3. Release the clamp (7) and remove the intake air duct.

Notice

Completely fit the intake air duct with the mounting bracket

(8).

Page 798 of 1463

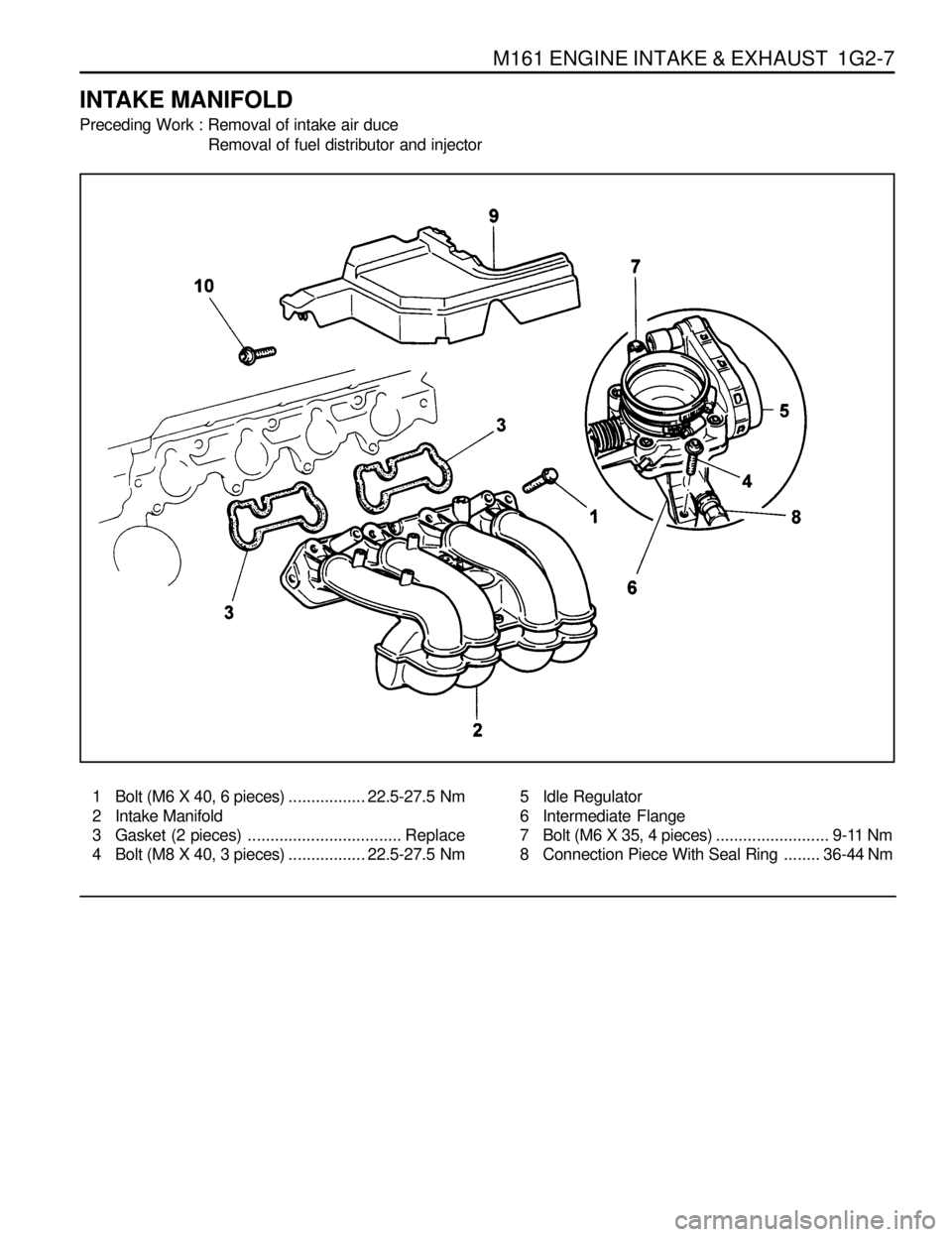

M161 ENGINE INTAKE & EXHAUST 1G2-7

INTAKE MANIFOLD

Preceding Work : Removal of intake air duce

Removal of fuel distributor and injector

1 Bolt (M6 X 40, 6 pieces).................22.5-27.5 Nm

2 Intake Manifold

3 Gasket (2 pieces).................................. Replace

4 Bolt (M8 X 40, 3 pieces).................22.5-27.5 Nm5 Idle Regulator

6 Intermediate Flange

7 Bolt (M6 X 35, 4 pieces)......................... 9-11 Nm

8 Connection Piece With Seal Ring........36-44 Nm

Page 799 of 1463

1G2-8 M161 ENGINE INTAKE & EXHAUST

Removal & Installation Procedure

1. Disconnect the battery ground cable.

2. Remove idle speed control plug connector (arrow).

3. Disconnect the brake booster vacuum line and other

vacuum lines.

4. Disconnector the rod from bearing bracket assembly and

remove the connection piece (8).

Installation Notice

Tightening Torque 36 - 44 Nm

5. Unscrew the three bolts (4) and remove the idle regulator

and intermediate flange (6).

Installation Notice

Tightening Torque 22.5 - 27.5 Nm

6. Unscrew the two bolts (M8 X 16) and remove the support

assembly (arrow).

Installation Notice

7. Unscrew the intake manifold assembly mounting bolts (1)

and remove the intake manifold and gasket.

Installation Notice

Notice

Replace the gasket with new one.

8. Installation should follow the removal procedure in the

reverse order.

9. Start the engine and check for leaks in each connection.

Tightening Torque 22.5 - 27.5 Nm

Tightening Torque 22.5 - 27.5 Nm

Page 800 of 1463

M161 ENGINE INTAKE & EXHAUST 1G2-9

EXHAUST MANIFOLD

1 Oxygen Sensor..............................49.5-60.5 Nm

2 Bolt (4 pieces)........................................ 9-11 Nm

3 Upper Cover

4 Nut (11 pieces)...............................31.5-38.5 Nm5 Exhaust Manifold

6 Flange Bolt & Exhaust Pipe

Mounting Nut............................................ 30 Nm

7 Gasket ................................................... Replace

Removal & Installation Procedure

1. Remove the oxygen sensor if necessary.

Installation Notice

Tightening Torque 49.5 - 60.5 Nm

2. Unscrew the bolt (2) and remove the exhaust manifold upper

cover (3).

3. Unscrew the flange bolt (6) of front exhaust pipe and

separate the front exhaust pipe.

Installation Notice

Tightening Torque 30 Nm

Notice

Check the exhaust pipe mounting nut, and replace it with

new one if necessary.

Page 801 of 1463

1G2-10 M161 ENGINE INTAKE & EXHAUST

4. Unscrew the eleven nuts (4) and remove the exhaust

manifold (5) and gasket (7).

Installation Notice

Tightening Torque 31.5 - 38.5 Nm

5. Replace the gasket (7) with new one.

6. Installation should follow the removal procedure in the

reverse order.

Page 802 of 1463

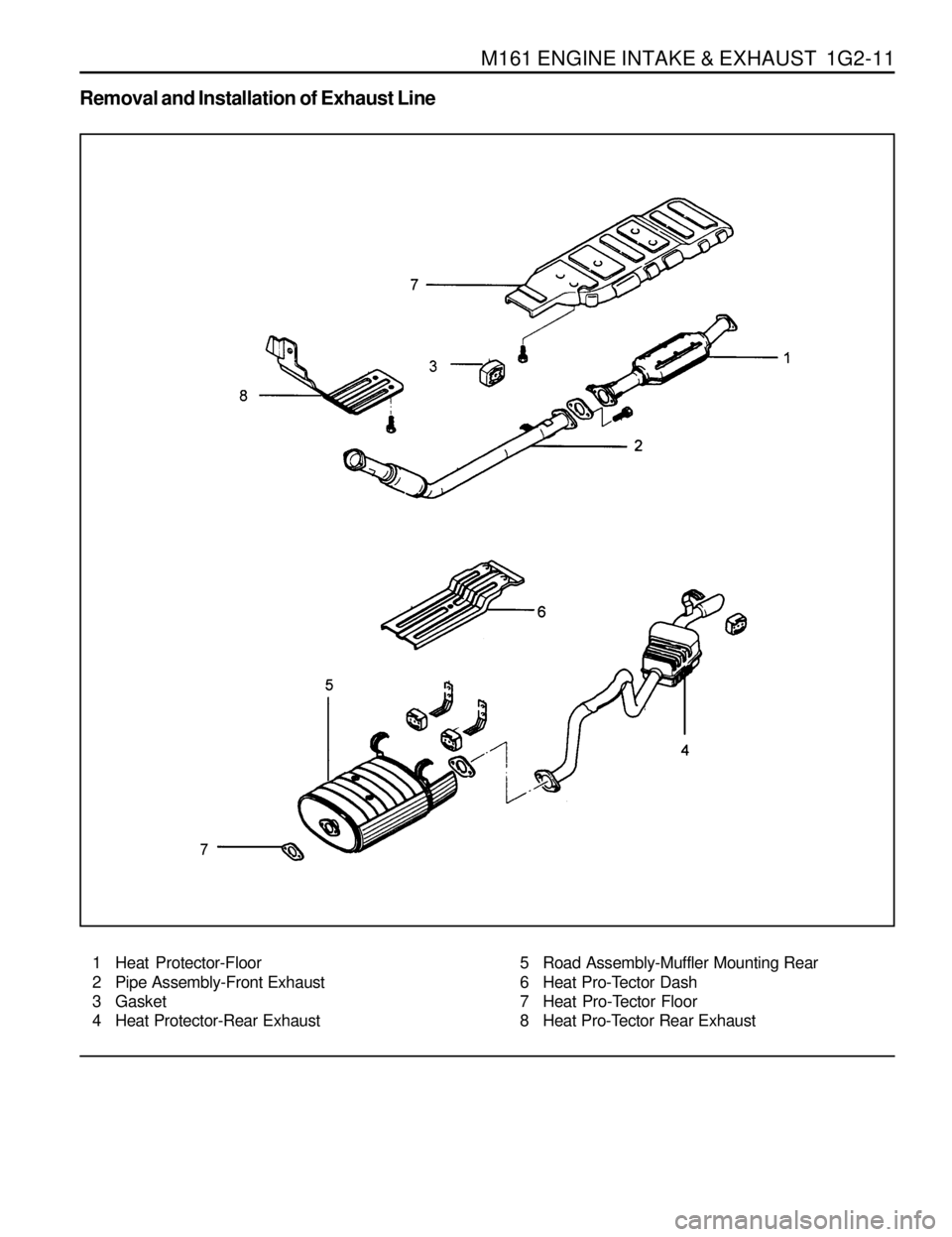

M161 ENGINE INTAKE & EXHAUST 1G2-11

Removal and Installation of Exhaust Line

1 Heat Protector-Floor

2 Pipe Assembly-Front Exhaust

3 Gasket

4 Heat Protector-Rear Exhaust5 Road Assembly-Muffler Mounting Rear

6 Heat Pro-Tector Dash

7 Heat Pro-Tector Floor

8 Heat Pro-Tector Rear Exhaust

Page 803 of 1463

SECTION 1G3

OM600 ENGINE INTAKE & EXHAUST

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1G3-1

Fastener Tightening Specifications . . . . . . . . 1G3-1

Schematic and Routing Diagrams . . . . . . . 1G3-2

EGR Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . 1G3-2

Maintenance and Repair . . . . . . . . . . . . . . 1G3-3

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1G3-3

TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Application

Air Cleaner Housing Cover Nut

Intake Manifold Bolt (M8 x 20)

Intake Manifold Bolt (M8)

Exhaust Mainfold Stud Bolt

Exhaust Pipe Nut (Engine)

Exhaust Pipe BoltN

· ·· ·

·m

9 - 11

22.5 - 27.5

22.5 - 27.5

9.5 - 12.5

15 - 28

28 - 47

Air Cleaner and Inlet Duct & Hose . . . . . . . . 1G3-3

Intake and Exhaust Manifold . . . . . . . . . . . . . 1G3-5

Turbocharger . . . . . . . . . . . . . . . . . . . . . . . 1G3-8

Charge Air System Diagram . . . . . . . . . . . . . 1G3-8

Intercooler . . . . . . . . . . . . . . . . . . . . . . . . . . 1G3-9

Turbocharger Assembly . . . . . . . . . . . . . . . 1G3-11

Page 804 of 1463

1G3-2 OM600 ENGINE INTAKE & EXHAUST

SCHEMATIC AND ROUTING DIAGRAMS

EGR CIRCUIT

Page 805 of 1463

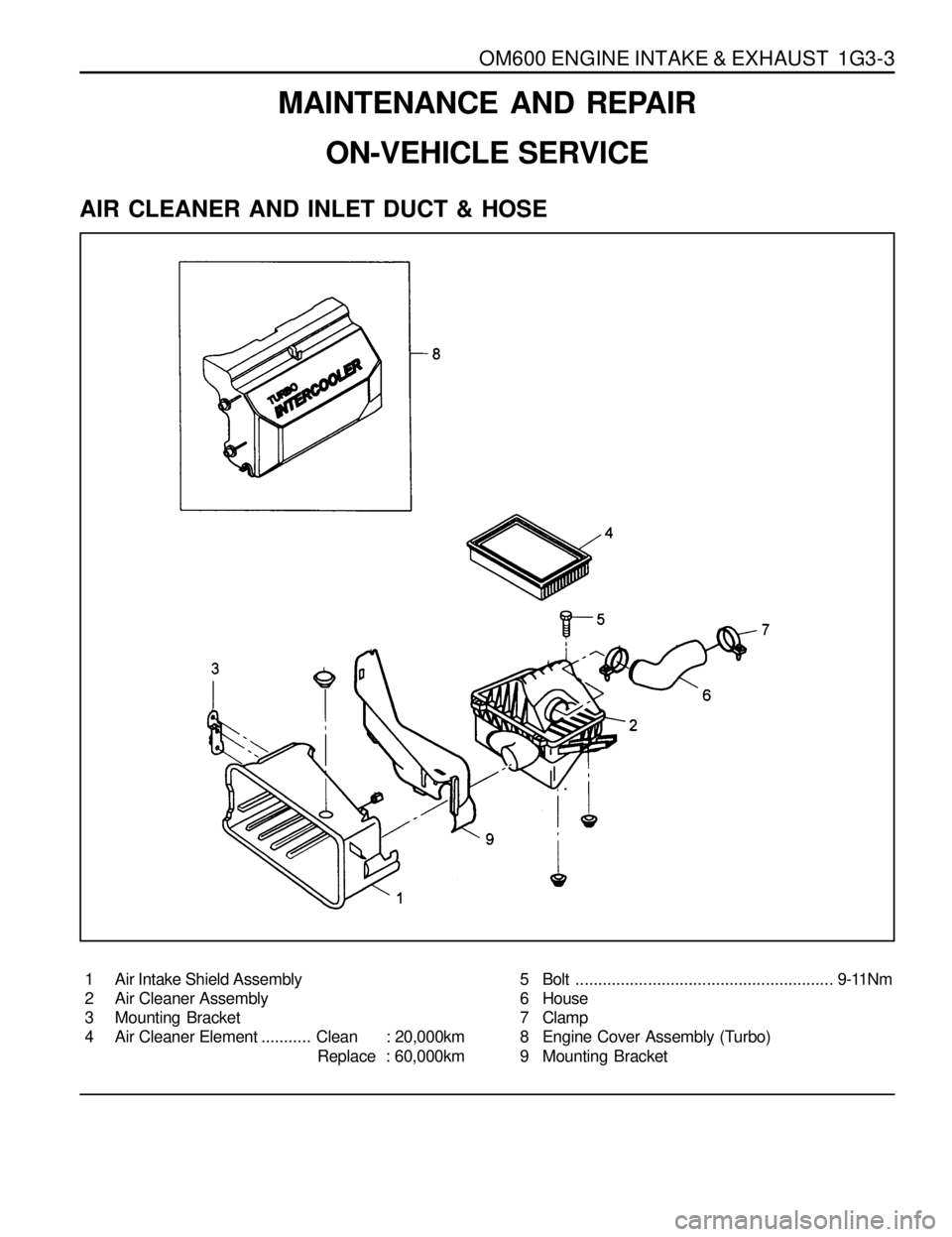

OM600 ENGINE INTAKE & EXHAUST 1G3-3

AIR CLEANER AND INLET DUCT & HOSE

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

1 Air Intake Shield Assembly

2 Air Cleaner Assembly

3 Mounting Bracket

4 Air Cleaner Element...........Clean : 20,000km

Replace : 60,000km5 Bolt......................................................... 9-11Nm

6 House

7 Clamp

8 Engine Cover Assembly (Turbo)

9 Mounting Bracket

Page 806 of 1463

1G3-4 OM600 ENGINE INTAKE & EXHAUST

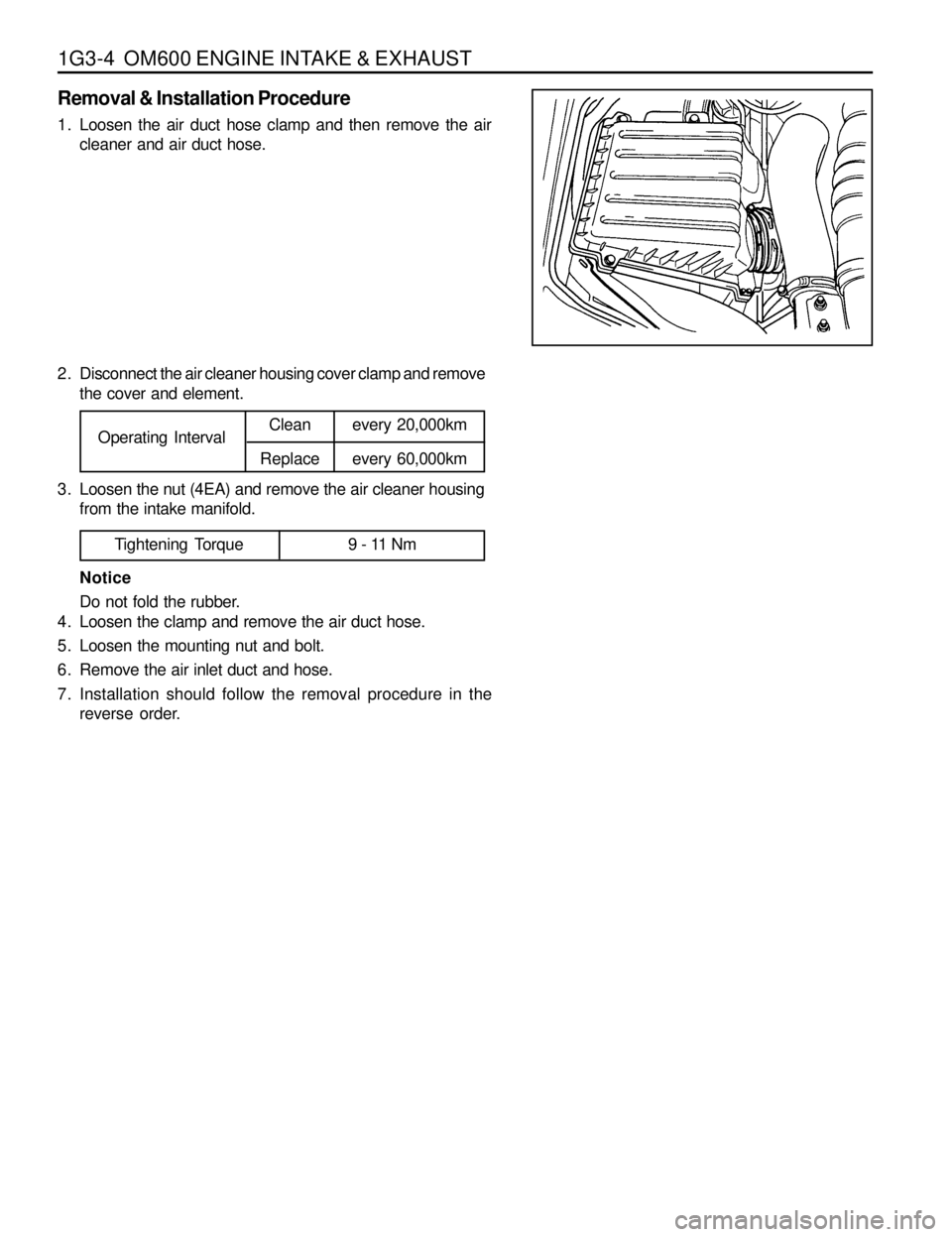

Removal & Installation Procedure

1. Loosen the air duct hose clamp and then remove the air

cleaner and air duct hose.

2. Disconnect the air cleaner housing cover clamp and remove

the cover and element.

Tightening Torque 9 - 11 Nm 3. Loosen the nut (4EA) and remove the air cleaner housing

from the intake manifold.

Notice

Do not fold the rubber.

Operating IntervalClean

Replaceevery 20,000km

every 60,000km

4. Loosen the clamp and remove the air duct hose.

5. Loosen the mounting nut and bolt.

6. Remove the air inlet duct and hose.

7. Installation should follow the removal procedure in the

reverse order.