SSANGYONG MUSSO 2003 Service Manual

MUSSO 2003

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57511/w960_57511-0.png

SSANGYONG MUSSO 2003 Service Manual

Page 308 of 1574

OM600 ENGINE MECHANICAL 1B3-43

18. Disconnect the booster hose connected to intake manifold.

19. Remove the intake manifold and gasket.

20. Remove the cylinder head cover and gasket with the blow-by gas hose.

21. Disconnect the glow plug cables.

Page 309 of 1574

1B3-44 OM600 ENGINE MECHANICAL

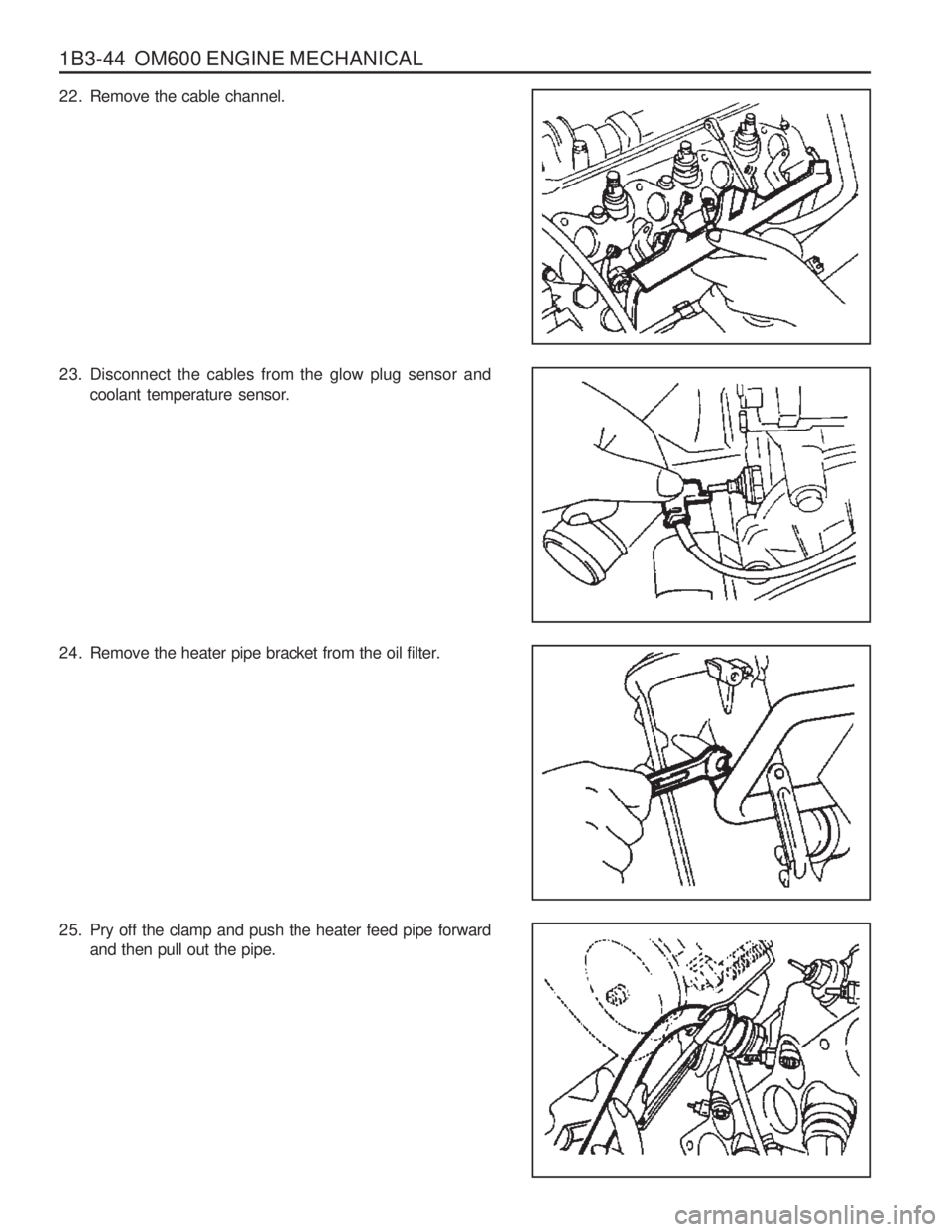

22. Remove the cable channel.

23. Disconnect the cables from the glow plug sensor andcoolant temperature sensor.

24. Remove the heater pipe bracket from the oil filter.

25. Pry off the clamp and push the heater feed pipe forward and then pull out the pipe.

Page 310 of 1574

OM600 ENGINE MECHANICAL 1B3-45

26. Disconnect the fuel lines from the fuel filter.

27. Disconnect the fuel lines from the injection pump.

28. Remove the fuel filter(35).

29. Remove the fuel injection nozzle(12) and nozzlewasher(11).

Socket Wrench Insert 001 589 65 09 00

Page 311 of 1574

1B3-46 OM600 ENGINE MECHANICAL

30. Rotate the crankshaft and set the no.1 cylinder at TDC.Notice Do not rotate the crankshaft to the opposite direction of engine revolution.

31. Place alignment marks on the camshaft gear and timing chain.

32. Ensure that the camshaft and the bearing cap marking are aligned.

33. Remove the starter motor and install the engine lock onto the flywheel ring gear.

Engine Lock 602 589 00 40 00

Page 312 of 1574

OM600 ENGINE MECHANICAL 1B3-47

34. Remove the turbocharger.

35. Remove the exhaust manifold and gasket.

36. Remove the chain tensioner and seal.

37. Remove the bolt and separate the drive sprocket(21).Notice During removal, be careful not to drop the sprocket and chain into the timing case. Carefully pull off the chain and then pull out the sprocket.

Page 313 of 1574

1B3-48 OM600 ENGINE MECHANICAL

38. Remove the camshaft bearing cap bolts according to thenumerical sequence. Notice Remove the No.1 bolts first and then remove the No. 2 bolts. Do not remove the bolts at a time completely butremove them step by step evenly or camshaft can beseriously damaged.

OM662LA

39. Remove the bearing caps and then pull out the camshaft(20) upward. Notice

Be careful not to miss the locking washer.

40. Remove the locking washer. Notice

Check the locking washer and replace if necessary.

OM661LA

Page 314 of 1574

OM600 ENGINE MECHANICAL 1B3-49

41. Remove the bolt(32).

42. Separate the spring and pull out the tensioning lever(31).

43. Pry off the closing cover. Remove the bolt and then removethe idle pulley.

44. Using the sliding hammer(36) and the threaded pin(37), pull out the sliding rail pins(25, 26) and remove the sliding rail(24).

Sliding Hammer 116 589 20 33 00Threaded Pin 116 589 02 34 00

Page 315 of 1574

1B3-50 OM600 ENGINE MECHANICALOM 662LA

46. Disconnect the vacuum pipe from thermo valve.

47. Remove the socket bolts(13) of the chain box.

T Type Socket Wrench 116 589 03 07 00Magnetic Bar 102 589 03 40 00

48. Remove the cylinder head bolts in numerical se-quence. Cylinder Head Bolt Wrench 601 589 00 10 00

45. Remove the vacuum line from the vacuum pump.

Page 316 of 1574

OM600 ENGINE MECHANICAL 1B3-51

49. Remove the cylinder head(2) and gasket(3).

OM 661LA

Page 317 of 1574

1B3-52 OM600 ENGINE MECHANICALLength(L)

Assembly Procedure

1. Replace the cylinder head gasket.

2. Install the cylinder head onto the crankcase.

Notice Align the cylinder head holes with the guide pins.

3. Measure the length(L) of cylinder head bolts. Notice If the max. length is exceeded, replace the bolts.

Thread Dia. Max. Limit(L)

M10 M10 M1080mm

102mm 115mm 82mm

104mm 117mm

when new

4. Coat the head contact surface of bolts and thread with oil

and insert them as shown. - Cylinder head bolts arrangement

Bore 1 ........................................... M10 ×

80

2 ........................................... M10 × 102

3 ........................................... M10 × 11 5

4 ........................................... M 8 × 50

5 ........................................... M 8 × 80 OM662LA