engine SSANGYONG MUSSO 2003 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 298 of 1574

OM600 ENGINE MECHANICAL 1B3-33

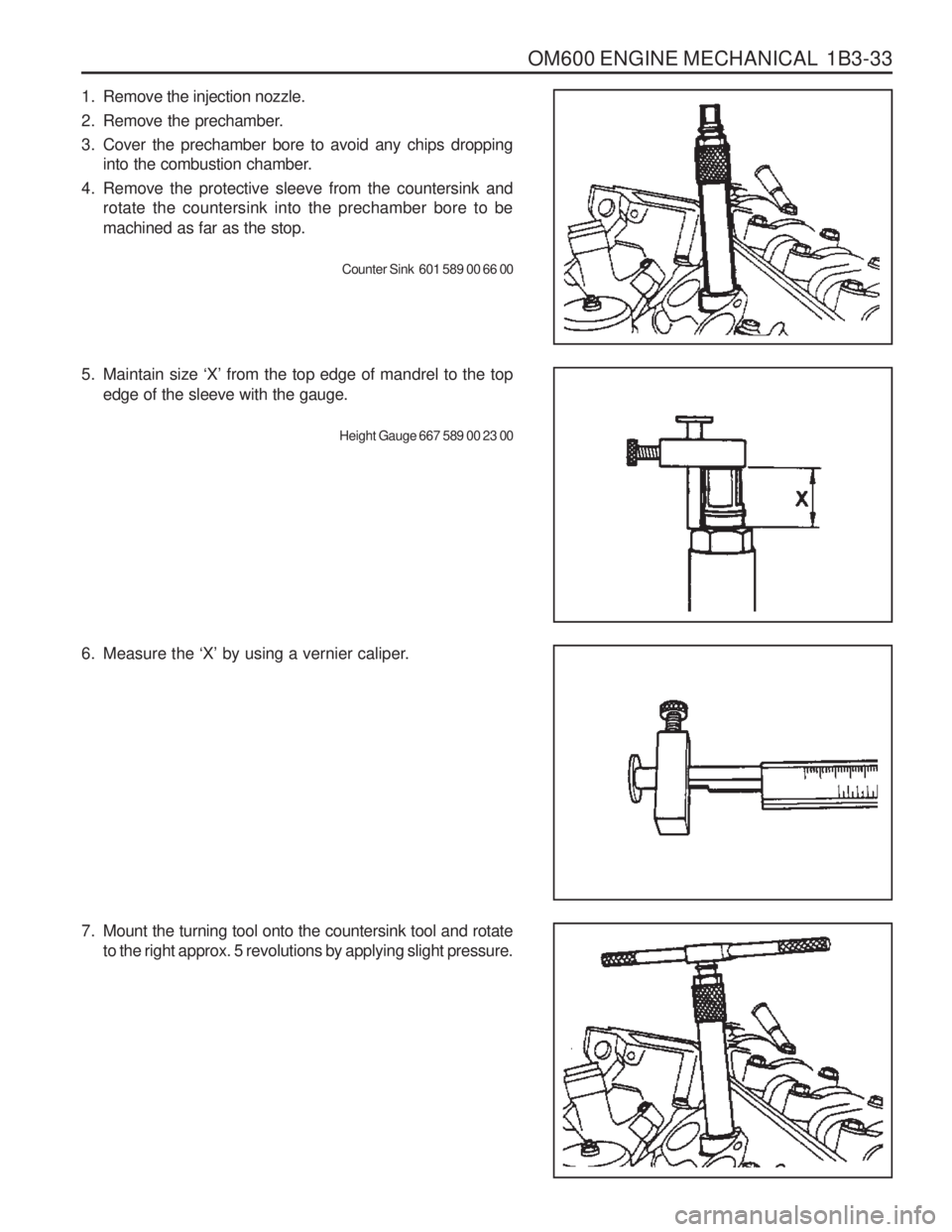

6. Measure the ‘X’ by using a vernier caliper.

7. Mount the turning tool onto the countersink tool and rotate to the right approx. 5 revolutions by applying slight pressure.

1. Remove the injection nozzle.

2. Remove the prechamber.

3. Cover the prechamber bore to avoid any chips droppinginto the combustion chamber.

4. Remove the protective sleeve from the countersink and rotate the countersink into the prechamber bore to be machined as far as the stop.

Counter Sink 601 589 00 66 00

5. Maintain size ‘X’ from the top edge of mandrel to the top

edge of the sleeve with the gauge.

Height Gauge 667 589 00 23 00

Page 299 of 1574

1B3-34 OM600 ENGINE MECHANICAL8. Remeasure size ‘X ’ and compare it with the first

measurement and determine the thickness of spacer ring.

Size before machining 25.7 mm

Size after machining 25.5 mm

Ex

The spacer ring should be selected so that it is at least 0.1mm and not more than 0.3mm thicker than the measured on the sealing surface. In this example, thenecessary thickness of spacer ring should be within0.3 ~ 0.5mm and the thickness of spacer ring to beinstalled is 0.3mm.

9. Remove the countersink tool and clean the chips.

Notice If the sealing surface is not completely flat, remachine the sealing surface.

10. emove rag from the prechamber bore and crank the engine with starter motor to threw out any chips which may have

got into the combustion chamber.

11. Insert the proper spacer ring into the prechamber sealing surface.

12. Punch a mark on the cylinder head above the prechambersealing surface which has been machined.

13. Install the prechambers.

Notice If the cylinder head is removed, the projection ‘C’ is

measured in place of size ‘X’ and the appropriate size of

spacer ring selected.

Normal Projection (c) 7.6 - 8.1mm

Page 300 of 1574

OM600 ENGINE MECHANICAL 1B3-35

TDC (TDC SENSOR BRACKET) SETTING Preceding Work : Removal of No.1 cylinder prechamber

1 Measuring Device

2 Dial Gauge

3 Cylinder Head

4 Piston................................................ Set at TDC

Tools Service 001 589 32 21 00 Dial Gauge601 589 07 21 00 Deqth Gauge667 589 01 21 00 Fixing Device Notice

� The TDC sensor bra cket must be adjusted in case of

followings.

� When replacing the TDC sensor bracket.

� When replacing the crankshaft, the hub or the vibration

damper.

� When replacing or installing the timing case cover.

� After engine overhauling.

� If the cylinder head is removed, the measuring pin of the dial gauge can be positioned on the piston crown. This is done by placing the magnetic dial holder on the mating surface of the crankcase.

Page 301 of 1574

1B3-36 OM600 ENGINE MECHANICAL Setting (with cylinder head installed)

1. Remove the prechamber of No. 1 cylinder.

2. Position the piston of No.1 cylinder at BTDC 10.

3. Install the measuring device into the prechamber bore andposition the dial gauge with a preload of 5mm. Dial Gauge 001 589 53 21 00

Depth Gauge 601 589 07 21 00

4. Slowly rotate the crankshaft in the direction of engine rotation until the large pointer on the dial gauge stops (TDC position). Notice The position of TDC is when the large pointer on the dial gauge is stopped before moving back.

5. remove the reinstall the measuring device and position the dial gauge scale at ‘0’.

6. Slowly rotate the crankshaft in the direction of engine rotation until the dial gauge has moved back (counterclockwise) by3.65mm.

7. Insert fixing device into the sensor bracket. Notice The pin on the vibration damper must engage into the slot of the fixing device. Fixing Device 667 589 01 21 00

8. If the pin does not engage, adjust the setting of the sensor bracket by removing and tightening of the sensor bracketbolts.

Tightening Torque 10 Nm

Notice

The timing mark on the damper must be positioned at ATDC 20.

Page 302 of 1574

OM600 ENGINE MECHANICAL 1B3-37

CYLINDER HEAD1 Fuel Injection Pipe ..................................... 18Nm

2 Cylinder Head

3 Gasket ................................................... Replace

4 Bolt ............................................................ 25Nm

5 Washer

6 Clamp

7 Heater Feed Pipe

8 Bolt

9 Washer

10 Bolt 11 Nozzle Washer ....................................... Replace

12 Fuel Injection Nozzle ............................ 35-40 Nm

13 Hexagon Socket Bolt ................................. 25 Nm

14 Washer

15 Bolt ........................................................... 25 Nm

16 Cylinder Head Bolt ..............................See Table

17 Cylinder Head Cover

18 Bolt ........................................................... 10 Nm

19 Gasket

2 0 Camshaft 21 Camshaft Drive Sprocket

....................... Replace

22 Washer

23 Bolt(12-Sided) .................................. 25Nm + 90 °

24 Sliding Rail

25 Sliding Rail Pin

26 Sliding Rail Pin

27 Chain Tensioner ....................................... 80 Nm

28 Gasket ................................................... Replace

29 Cooling Fan .............................................. Check

30 Hexagon Socket Bolt ................................. 45 Nm

31 Tensioning Lever

32 Bolt ........................................................... 25 Nm

33 Bolt

34 Nut ............................................................ 23 Nm

35 Fuel Filter

36 Turbo Charger

37 Intake Duct

38 Gasket ................................................... Replace

39 Intake Manifold

Page 303 of 1574

1B3-38 OM600 ENGINE MECHANICAL

000 589 77 03 00 Box Wrench Insert

001 589 65 09 00 Socket Wrench Insert

102 589 03 40 00 Magnetic Bar

116 589 02 34 00 Threaded Pin

116 589 03 07 00 T Type Socket Wrench

116 589 20 33 00 Sliding Hammer

601 589 00 10 00 Cylinder Head Bolt Wrench

602 589 00 40 00 Engine Lock

603 589 00 40 00 Counter Holder

Tools Required

Cylinder Bolts (12-sided socket head) (Engine cold) M8 Cylinder Head Bolts

Tightening Torque

stage1 stage2stage3

10 Nm35 Nm

180 °

25 Nm

Tightening Sequence for Cylinder Head Bolts OM 662LA Engine

OM 661LA Engine

Page 304 of 1574

OM600 ENGINE MECHANICAL 1B3-39

Length(L) When New80mm

102mm 115mm

Thread Dia.

M10 M10M10Max. Length(L) 82mm

104mm 117mm

The twelve-sided socket head bolts are tightened with each stages of torque and torque angle. It is not necessary to retighten the cylinder head bolts at the 1000~1500km inspection or after 1000~1500km of repairs.

Notice The cylinder head may only be removed when the engine has cooled down. The cylinder head is removed together with the exhaust manifold. As the cylinder head bolts undergo a permanent tightening. They require to bereplaced if they exceed the maximum lengthes indicatedin the table.

Page 305 of 1574

1B3-40 OM600 ENGINE MECHANICAL Disassembly Procedure

1. Completely drain the coolant from the radiator and cylinderblock.

2. Remove the cooling fan shroud.

3. Hold the fan with counter holder and remove the bolt and then remove the cooling fan. Notice Keep the fan in vertical position.

Counter Holder 603 589 00 40 00

5. Remove the nut.

6. Remove the nut on the tensioning lever and insert therod(F12 ´ 180mm). By pushing the rod to the arrow direction,

pull back the bolt.

7. Push the tensioning lever to the opposite direction to release the spring tension and remove the poly V-belt.

4. Remove the bracket oil dipstick tube.

Page 306 of 1574

OM600 ENGINE MECHANICAL 1B3-41

8. Remove the air cleaner cover and element and thenremove the air cleaner housing.

9. Remove the oil return hose and plug.

Notice Cover them to prevent chips from coming into.

10. Unscrew the EGR pipe mounting bolts onto the exhaust manifold.

11. Remove the duct bracket from the cylinder head.

12. Unscrew the intake duct mounting bolts onto the intake manifold.

13. Separate the connecting rod from the control lever.

Page 307 of 1574

1B3-42 OM600 ENGINE MECHANICAL

14. Pull out the accelerator control linkage.

15. Remove the fuel injection line(1) from the fuel injectionnozzle(12).

Box Wrench Inset 000 589 77 03 00

16. Remove the fuel injection line from the fuel injection pump. Box Wrench Insert 000 589 77 03 00

17. Remove the bracket mounting bolts and then remove the fuel injection line(1).