SSANGYONG NEW ACTYON SPORTS 2012 Service Manual

Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2012Pages: 828, PDF Size: 91.28 MB

Page 141 of 828

02-4

2. TIGHTENING TORQUE

Component SizeBolt

QuantitySpecified torque

(Nm)Remark

(Total torque)

Main bearing capM12×8210 55±5Nm,

180˚Not re-usable

Connecting rod capM9×52840±5Nm,

90˚+10˚50 to 80 Nm

Rear coverM6×20610 ± 1 Nm-

Oil pumpM8×35SOC325 ± 2.5 Nm-

FlywheelM10×22845 ± 5 Nm,

90˚+10˚60 to 100 Nm

Crankshaft center boltM20×851200 ± 20 Nm,

180˚+20˚660 to 720 Nm

Not re-usable

Oil panM6×201810 ± 1 Nm-

M6×35210 ± 1 Nm-

M6×85210 ± 1 Nm-

M6×120210 ± 1 Nm-

M8×40225 ± 2.5 Nm-

HP pump main nutM14×1.5-8-1165 ± 5 Nm-

HP pump boltM8×55325 ± 2.5 Nm-

Cylinder headM13×15012 85Nm

270°±10°-

Camshaft capM6×301610 ± 1 Nm -

M8×60425 ± 2.5 Nm -

Exhaust stud bolt 1015±1.5Nm-

Exhaust sprocket boltM11×40130 ± 3 Nm -

Chain tensioner screw

boltM38×1.5 125±2.5Nm -

Coolant temperature

sensor120±2.0Nm -

Auto tensionerM8×30(LOW) 125±2.5Nm -

M10×75(Upper) 155±5.5Nm -

Coolant pumpM6×50 110±1.0Nm -

Page 142 of 828

02-50000-00

Component SizeBolt

QuantitySpecified torque

(Nm)Remark

(Total torque)

Hot water inlet pipeM6×16 2 10±1Nm -

AlternatorM10×90 1 25±2.5Nm -

M10×116 1 46±4.6Nm -

A/C bracketM8×25 4 7.8~11.8Nm -

A/C sub bracketM6×25 4 10±1Nm -

Intake manifoldM8×35 2 25±2.5Nm -

M8×110 6 25±2.5Nm -

Oil filter moduleM8×40 6 25±2.5Nm -

M8×20 1 25±2.5Nm -

M8×140 2 25±2.5Nm -

Knock sensorM8×28 2 20±5Nm -

Cam position sensorM8×14 1 10~14Nm -

Booster pressure

sensorM6×20 2 10±1Nm -

Exhaust manifold M8 10 40±4Nm -

Turbocharger M8 3 25±2.5Nm -

Support bolt 1 25±2.5Nm -

Support nut M8 1 25±2.5Nm -

T/C oil supply pipe M6(block side) 1 10±1.0Nm -

M6(turbo side) 1 17±2.0Nm -

T/C oil return pipeM6×16(turbo side)2 10±1Nm -

M6×16(block side)2 10±1Nm -

EGR valveM8×22 2 25±2.5Nm -

EGR pipe bolt

(Intake side)M8×16 2

25±2.5Nm -

EGR pipe bolt

(EGR cooler side)M8×16 2 25±2.5Nm -

EGR combination boltM6×16 4 10±1Nm -

M8×16 16 25±2.5Nm -

Idle pulley/Tensioner

pulley1 45±4.5Nm -

Page 143 of 828

02-6

Component SizeBolt

QuantitySpecified torque

(Nm)Remark

(Total torque)

Glow plug M5 4 20±2Nm -

Vacuum pumpM8×25 3 10±1Nm -

Timing gear case coverM12×55 3 85±8.5Nm -

M6×25 7 10±1Nm -

M6×45 1 10±1Nm -

M6×50 3 10±1Nm -

Cylinder head coverM6×35 21 10±1Nm -

Oil gauge tubeM6×16 1 10±1Nm -

Oil filter cap 1 25±2.5Nm -

Fuel railM8×35SOC 2 25±2.5Nm -

Injector clamp boltM6×60 2 10±1Nm,

120˚+10˚ -

High pressure pipe

(between HP pump and

fuel rail)M17 1 30±3Nm -

High pressure pipe

(between fuel rail and

injector)M17 4 30±3Nm -

Crank position sensorM5×14 1 8±0.4Nm -

Main wiringM6×16 5 10±1Nm -

Intake duct M8x25 4 25±2.5Nm -

Power steering pumpM8×100 3 25±2.5Nm -

Cylinder head front

coverM6×10 5 10±1Nm -

Ladder frameM8×16 5 30±3Nm -

Oil pumpM8×35 3 25±2.5Nm

-

Page 144 of 828

02-70000-00

3. CHECK AND INSPECTION

1) Cylinder

(1) Compression pressure test

Specified value ▶

Compression ratio16.5 : 1

Test conditionat normal operating temperature (80˚C)

Compression pressureStandard32 bar

Minimum18 bar

Differential limit between cylindersMaximum 3 bar

The compression pressure test is to check the conditions of internal components (piston, piston

ring, intake and exhaust vale, cylinder head gasket). This test provides current engine operating

status.

Before cranking the engine, make sure that the test wiring, tools and persons are keeping

away from moving components of engine (e.g., belt and cooling fan).

Park the vehicle on the level ground and apply the parking brake.

Do not allow anybody to be in front of the vehicle. -

-

-

Measurement ▶

<007e0088009900940047009b008f008c0047008c0095008e00900095008c0047009c00970047009b00960047009500960099009400880093004700960097008c00990088009b00900095008e0047009b008c00940097008c00990088009b009c0099008c00

47004f005f005700b6006a00500055>

Disconnect the fuel rail pressure sensor connector to cut off the fuel injection.

Remove the air cleaner duct and glow plugs. -

-

-

Place the diagram sheet to compression

pressure tester and install it into the plug

hole. 1.

Page 145 of 828

02-8

(2) Cylinder pressure leakage test

If the measured value of the compression pressure test is not within the specifications, perform

the cylinder pressure leakage test.Specified value ▶

Perform this test in the sequence of firing order.

Do not test the cylinder pressure leakage with wet type test procedure. (do not inject the

engine oil into the combustion chamber) -

-

Test condition: normal engine operating

temperature (80˚C)Specified value

Whole engine below 25%

at valve and cylinder head gasket below 10%

at piston ring below 20%

Crank the engine for approx. 10 seconds

by using the start motor. 2.

Record the test result and measure the

compression pressure of other cylinders

with same manner. 3.

If the measured value is out of specified

value, perform the cylinder pressure

leakage test. 4.

Page 146 of 828

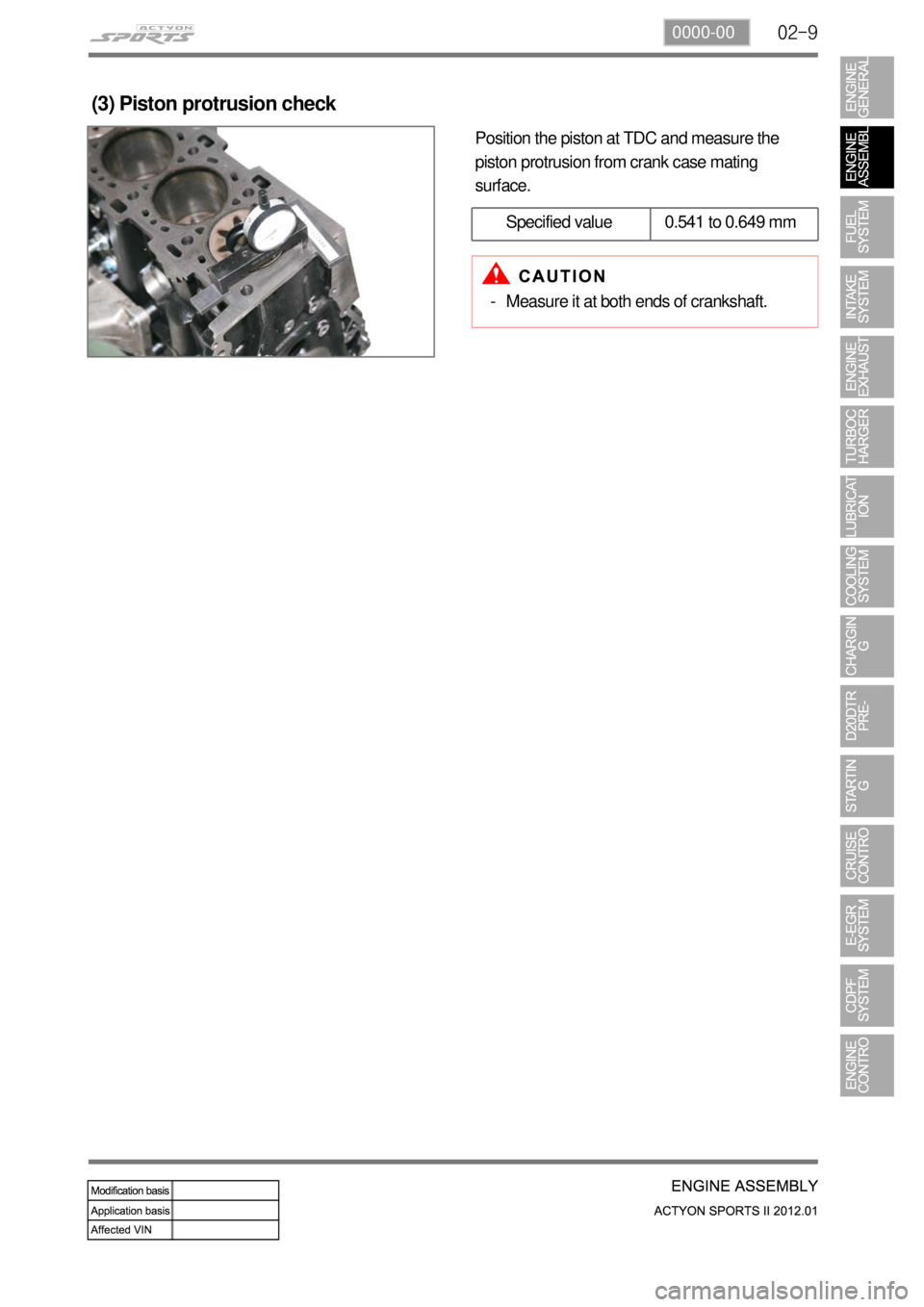

02-90000-00

Position the piston at TDC and measure the

piston protrusion from crank case mating

surface.

(3) Piston protrusion check

Specified value 0.541 to 0.649 mm

Measure it at both ends of crankshaft. -

Page 147 of 828

02-10

2) Cylinder Head

(1) Cylinder head mating surface check

Specified value ▶

Total height "A"142.9 to 143.1 mm

Minimum height after machining142.4 mm

FlatnessLongitudinal direction0.08 mm

Transverse direction0.0 mm

Parallel deviation of cylinder headbelow 0.1 mm

Peak-to valley of surface0.004 mm

valve recess "a"Intake valve0.1 to 0.7 mm

Exhaust valve0.1 to 0.7 mm

Measure the cylinder head height "A". 1.

If the height is less than the limit, the

cylinder head must be replaced. -

Insert the valves into the valve guides and

measure the recesses. 2.

If the measured value is out of the

specified range, machine the valve seat

as much as necessary until the specified

value is achieved. -

Valve recess “a0.1 to 0.7 mm

(2) Cylinder head pressure Leak test

<007000940094008c0099009a008c0047009b008f008c0047008a00a0009300900095008b008c00990047008f008c0088008b0047009e0090009b008f0047009b008f008c004700970099008c009a009a009c0099008c0047009700930088009b008c004700

900095009b00960047009e0088009900940047009e0088009b>er (approx. 60°C) and pressurize

with compressed air to 2 bar.

Page 148 of 828

02-110000-00

4. GUIDELINES ON ENGINE SERVICE

To prevent personal injuries and vehicle damages that can be caused by mistakes during engine

and unit inspection/repair and to secure optimum engine performance and safety after service

works, basic cautions and service work guidelines that can be easily forgotten during engine

service works are described in.

Cautions before service works

For safe and correct works, you must observe the working procedures and instructions in this

manual. And, use the designated tools as follow:

Engine stand / Heavy duty engine jack

To prevent the engine from starting abruptly, do not allow anybody to get in the vehicle while

servicing in engine compartment.

Before work on engine and each electrical equipment, be sure to disconnect battery negative

(-) terminal.

Before service works, be sure to prepare the works by cleaning and aligning work areas.

Do not allow the foreign material get into the fuel injection system.

When removing the engine, use only the safety hook on engine and engine hanger. Do not

support the bottom of oil pan with a jack.

Engine and accessories ▶

-

-

-

-

-

-

▶

Completely drain the engine oil, coolant and fuel from engine before removal.

Before disassembling/assembling the engine components, carefully read the working

procedures in this manual.

Make sure to keep the specified tightening torques during installation.

Clean and properly lubricate the parts before reassembly.

Carefully check that there are not any interference while servicing. -

-

-

-

-

Page 149 of 828

02-12

Electrical equipment ▶

Electric devices should be handled more carefully.

Currently, the engine has a lot of electric devices. there could be poor engine performance,

incomplete combustion and other abnormal symptoms due to short circuit or poor contact.

Before work on engine and each electrical equipment, be sure to disconnect battery negative

(-) terminal.

When replacing the electric device, use only genuine part and check the conditions of

connections and grounds. Loosened connection or ground make cause a fire and personal

injury. -

-Fuel and lubrication system ▶

Do not allow the fluid and engine oil to make contact with the body paintwork and hoses.

If work on the fluid system such as fuel and oil, working area should be well ventilated and

smoking should be prohibited.

Gasket or seal on the fuel/lubrication system should be replaced with new ones and bolts and

nuts should be tightened as specified.

After removal/installation works, be sure to check whether there is leak on the connecting

section. -

-

-

-

If fine dust or foreign material enters into DI engine's fuel system, there can be serious damages

in HP pump and injectors. Thus, be sure to plug the inlets of removed fuel line components with

cap and protect removed parts not to be contaminated with dirt. (Refer to cleanness in this

manual while working on DI engine fuel system)

Page 150 of 828

02-130000-00

D20DTR Engine

1. BELT LAYOUT

It is single drive type and uses FEAD (Front End Accessories Drive) design to make a compact

layout.

Components ▶

HPS (Hydraulic Power Steering)

1 Crankshaft pulley (DDU)

2 Auto tensioner

3 Tensioner pulley

4 Vacuum pump

5 A/C compressor pulley

6 Alternator pulley

7 Water pump pulley

8 Idle pulley #1

9 Idle pulley #2

10 Power steering pump pulley