SSANGYONG NEW ACTYON SPORTS 2012 Service Manual

Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2012Pages: 828, PDF Size: 91.28 MB

Page 651 of 828

09-34850-01

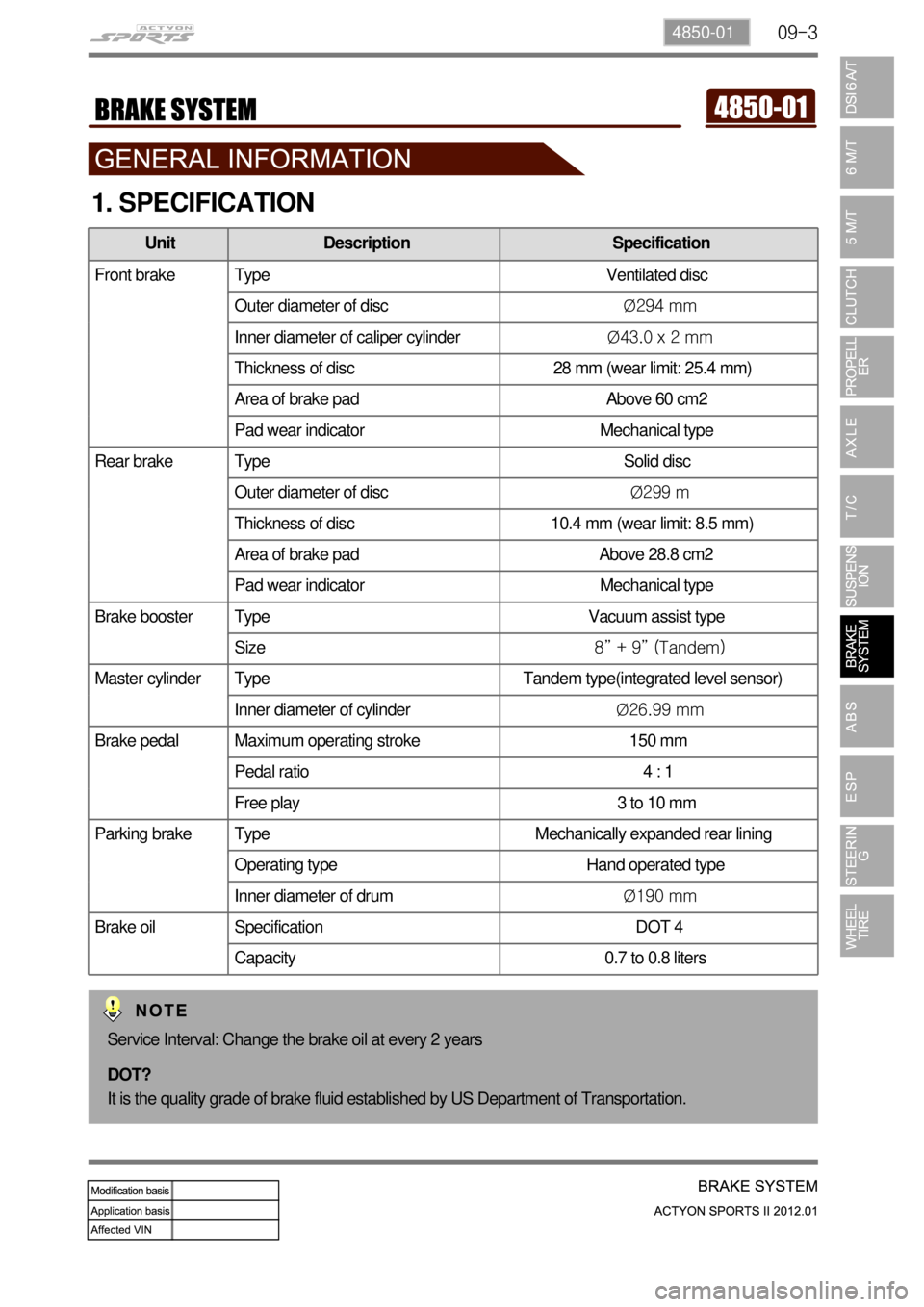

1. SPECIFICATION

Unit Description Specification

Front brake Type Ventilated disc

Outer diameter of discØ294 mm

Inner diameter of caliper cylinderØ43.0 x 2 mm

Thickness of disc 28 mm (wear limit: 25.4 mm)

Area of brake pad Above 60 cm2

Pad wear indicator Mechanical type

Rear brake Type Solid disc

Outer diameter of discØ299 m

Thickness of disc 10.4 mm (wear limit: 8.5 mm)

Area of brake pad Above 28.8 cm2

Pad wear indicator Mechanical type

Brake booster Type Vacuum assist type

Size8” + 9” (Tandem)

Master cylinder Type Tandem type(integrated level sensor)

Inner diameter of cylinderØ26.99 mm

Brake pedal Maximum operating stroke 150 mm

Pedal ratio 4 : 1

Free play 3 to 10 mm

Parking brake Type Mechanically expanded rear lining

Operating type Hand operated type

Inner diameter of drumØ190 mm

Brake oil Specification DOT 4

Capacity 0.7 to 0.8 liters

Service Interval: Change the brake oil at every 2 years

DOT?

It is the quality grade of brake fluid established by US Department of Transportation.

Page 652 of 828

09-4

2. SYSTEM OVERVIEW

1) Terms and Definition

CBS: Conventional Brake System

ABS: Anti-Lock Brake System

EBD: Electronic brake-Force Distribution

ESP: Electronic Stability Program

ABD: Automatic Braking Differential

ASR: Acceleration Slip Regulation

AYC: Active Yaw Control (Understeer and Oversteer Control)

HBA: Hydraulic Brake Assistant

ARP: Active Rollover Protection

HSA: Hill Start Assistant

Brake pad: Brake pad is a component of disk brakes used in automotive and other

applications. Brake pad is steel backing plates with friction material bound to the surface that

faces the brake disc.

Brake disc: The brake disc is a device for slowing or stopping the rotation of a wheel while it is

in motion.

Brake caliper: To stop the wheel, friction material in the form of brake pads (mounted on a

device called a brake caliper) is forced hydraulically against both sides of the disc. Friction

causes the disc and attached wheel to slow or stop.

Brake master cylinder: The brake master cylinder is a control device that converts non-

hydraulic pressure (commonly from a driver's foot) into hydraulic pressure, in order to move

other device(s) which are located at the other end of the hydraulic system, such as one or

more slave cylinders. As piston(s) move along the bore of the master cylinder, this movement

is transferred through the hydraulic fluid, to result in a movement of the slave cylinder(s). The

hydraulic pressure created by moving a piston (inside the bore of the master cylinder) toward

the slave cylinder(s) compresses the fluid evenly, but by varying the comparative surface-area

of the master cylinder and/or each slave cylinder, one will vary the amount of force and

displacement applied to each slave cylinder (relative to the amount of force and displacement

that was applied to the master cylinder). -

-

-

-

-

-

-

-

-

-

-

-

-

-

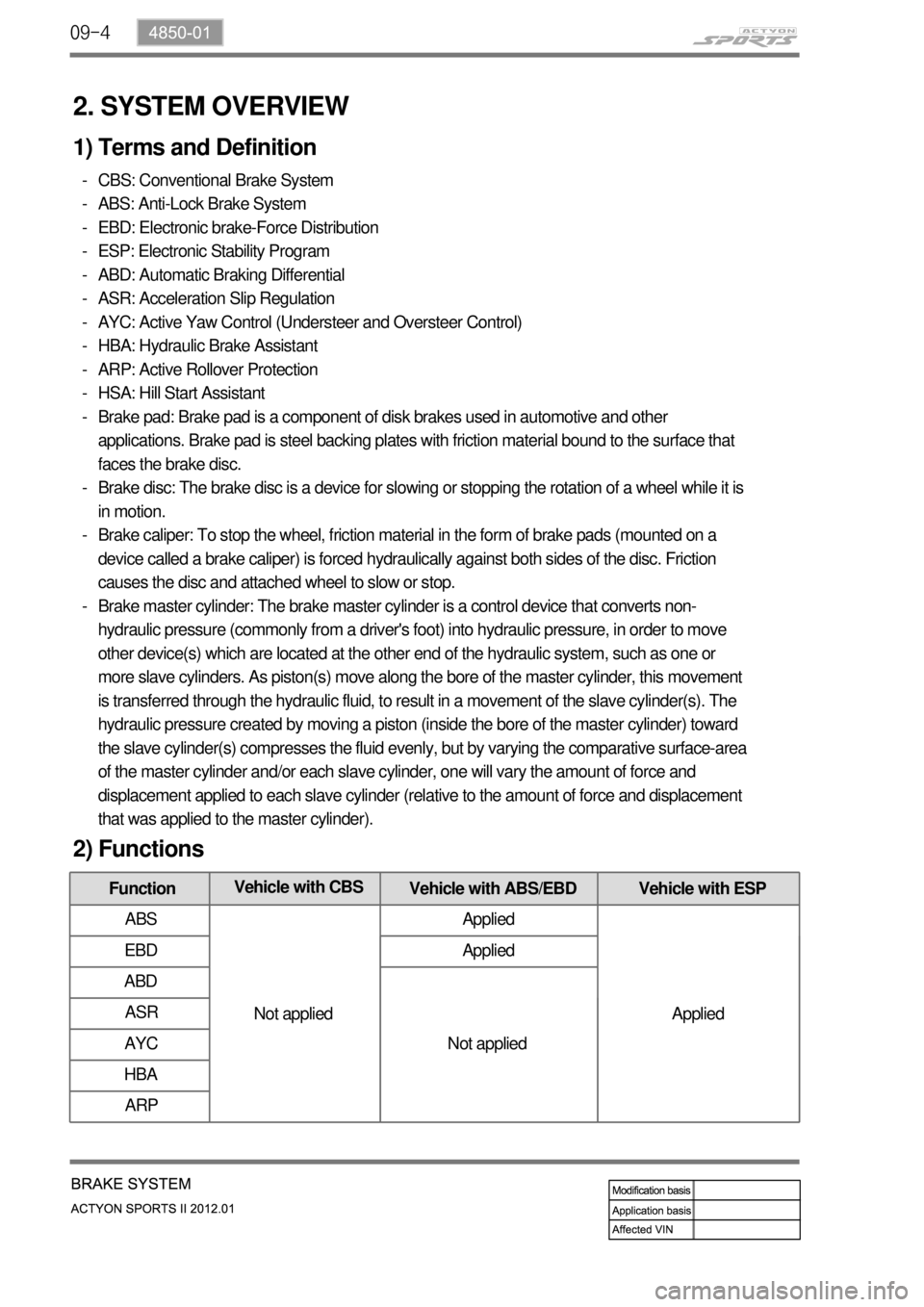

FunctionVehicle with CBS

Vehicle with ABS/EBD Vehicle with ESP

ABS

Not appliedApplied

Applied EBD Applied

ABD

Not applied ASR

AYC

HBA

ARP

2) Functions

Page 653 of 828

09-54850-01

3) Parts Arrangement

Part nameVehicle with CBSVehicle with ABS/EBDVehicle with ESP

HECU

Not appliedAppliedApplied Front wheel speed sensor

Rear wheel speed sensor

ABS warning lamp

EBD indicator

Longitudinal G sensor 2WD: N/A, 4WD: Applied Not applied

Sensor cluster

(Yaw rate sensor,

lateral/longitudinal G sensor)

Not applied Applied

ESP indicator

ESP OFF switch and warning

lamp

Steering wheel angle sensor

4) Components

ABS ESP+ARP

2WD 4WD 2WD 4WD

Whhel speed sensor 4 4 4 4

Sensor cluster N/A N/A Applied Applied

G-sensor N/A Applied N/A N/A

2H G-sensor - Operating - -

4H G-sensor - Operating - -

4L G-sensor - Operating - -

2H sensor cluster - - Operating Operating

4H sensor cluster - - Operating Operating

4L sensor cluster - - Operating Operating

Page 654 of 828

09-6

5) Indicators and Warning Lamps for ABS/ESP

LampIndicator/Warning Lamp

Description

EBD warning lamp ON when EBD function is failed

ABS warning lamp ON when ABS function is failed

ESP indicator Blinking when ESP function is operating

ESP OFF indicator ON when the ESP OFF switch is pressed

ESP warning lamp ON when ESP function is failed

ESP buzzer Sound when ESP function is operating

Page 655 of 828

09-74850-01

Problem Possible Cause Action

Noise or vehicle

vibration when

appliedIncorrectly mounted back plate or caliper Repair

Loosened bolt of back plate or caliper Retighten

Uneven wear of brake disc Replace

Brake pad contamination Clean or replace

Sticking brake pad on contact surface Replace

Wear or hardening of brake pad Replace

Excessive clearance between caliper and pad Repair

Uneven contact of pad Repair

Lack of lubrication in sliding parts Lubricate

Improper operation of caliper Replace

Dust cover missing Repair

Loosened suspension mounting bolt Retighten

Pulls to one side

when brakingUnbalanced tire pressure between left and right Adjust

Poor contact of brake pad Repair

Oil or grease on brake pad Replace

Scratch, uneven wear, distortion of brake disc Replace

Improperly installed brake caliper Repair

Improper operation of auto adjuster Repair

Crack or distortion of brake pad Replace

Poor braking Oil leak or contamination Repair or replace

Air in brake line Bleed air

Improper operation of brake booster Repair

Poor contact of brake pad Repair

Oil or grease on brake pad Replace

Improper operation of auto adjuster Repair

Clogged brake line Repair

Improper operation of proportioning valve Repair

3. TROUBLESHOOTING

Page 656 of 828

09-8

Problem Possible Cause Action

Increased pedal stroke Air in brake line Bleed air

Oil leak Repair

Worn brake pad Replace

Excessive clearance between push rod and master

cylinderAdjust

Worn or damaged piston seal Replace

Brake dragging Parking brake is not fully released Release

Incorrect adjustment of parking brake Adjust

Incorrectly adjusted clearance of parking brake

shoeAdjust

Faulty brake pedal return spring Replace

Incorrectly adjusted free play of brake pedal Adjust

Faulty master cylinder Replace

Lack of lubrication in sliding parts Lubricate

Faulty brake booster (vacuum leak) Repair

Wear, hardening or poor contact of brake pad Replace

Oil or water on lining Repair or replace

Fixed or broken parking brake cable Replace

Excessive stroke of brake lever Adjust notch

Faulty auto clearance adjuster Repair

Poor parking

brake

Increased stroke of

parking brake leverLoosened parking brake cable Adjust or replace

Incorrectly adjusted parking brake cable Adjus

Defective automatic lining clearance adjuster Repair or replace

Worn brake lining Replace

Page 657 of 828

09-94850-01

Problem Cause Action

Burning smell

around tireToo frequent braking in high driving speed Reduce the use of

foot brake/use

engine brake

properly Used only foot brake during downhill driving

Driving with foot on brake pedal Get off the foot

from pedal

Foreign materials such as dirt or sand in brake system Replace: caliper,

wheel cylinder,

master cylinder,

return spring

Broken return spring in shoe assembly Replace

Incorrectly adjusted parking brake cable Adjust

Incorrect wheel or wheel cover

(generating the heat)Replace

Page 658 of 828

09-10

This section describes the noise phenomena occurred possibly in the brake system operation.

Distinguish between the information given below and the actual problems and then, inspect the

vehicle and take appropriate measures.

Noise symptoms and Causes -

Symptom 1. If depressing the brake pedal when the engine is cold, "screeching" sound always

occurs and, after driving for a while, the sound disappears..

This usually occurs in the morning. When the temperature goes down, the dew condensation

phenomenon sets moisture on the brake disc as the window frost forms. Due to this moisture, the

iron within the brake disc and pad oxidizes, forming undetectable micro-rusts on the disc

surface. When starting the engine under this condition, noise may sound due to the friction of

micro-rusts. When operating the brake several times, the disc temperature goes up and the

micro-rusts come off and the noise goes away. Depending on the driving conditions, noise gets

louder when slightly depressing the brake pedal and oppositely, noise is smaller when deeply

depressing the brake pedal. This is simply a physical phenomenon, called "morning effect" in

professional terms, and does not imply any problems with the brake system.

Symptom 2. Slip or screech after the brake pad replacement.

This usually occurs when the bed-in is not made between the disc and the pad's friction material.

The bed-in is a state that the brake system normally works and gives no noise out, when, after

about 300 km city driving, the contact area of the pad friction material is enlarged and the disk is

in complete contact with the pad's friction material. Therefore, for some time after the brake

disk/pad replacement, the brake system poorly operates or noise (abnormal sound) occurs due

to the partial contact.

Symptom 3. "Groaning" sound occurs in the automatic transmission vehicle when slightly taking

the foot off the brake pedal to slowly start after waiting for the signal, or slightly depressing the

brake pedal.

This is the noise "Creep groan" that occurs when, in both the automatic and manual transmission,

slightly releasing the brake pedal in the neutral gear at downhill roads.

It frequently occurs at the low braking power and low speed, through the following process. When

operating the brake system at low speed and low pressure, adhesion and slip repeatedly take

place between the brake disk and the friction material, and this makes the braking power

inconstant, instantly increasing or decreasing, and gives out the brake noise.

It is also a physical phenomenon and has no relation with the brake performance.BRAKE OPERATION AND NOISE ▶

Page 659 of 828

09-114850-01

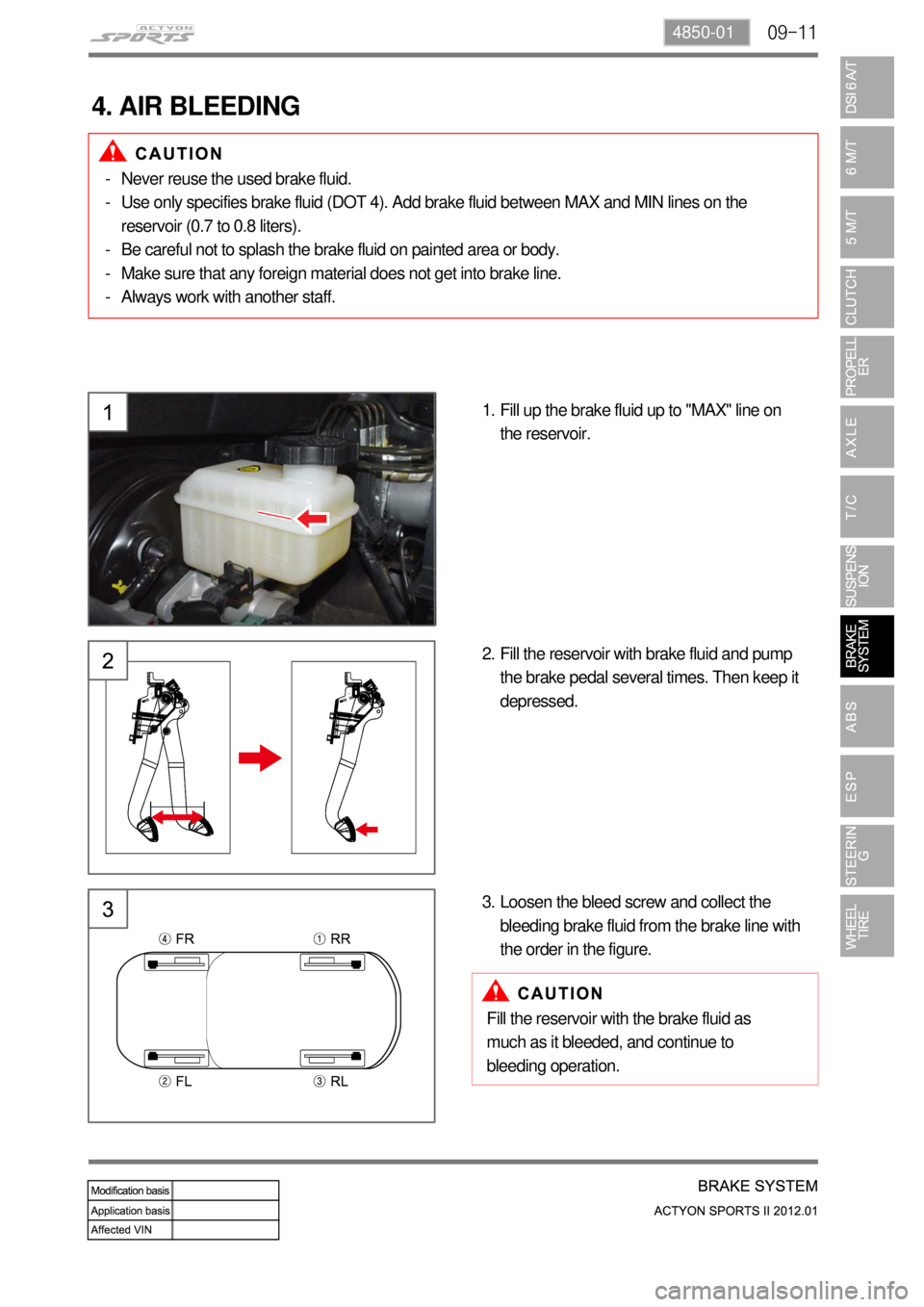

4. AIR BLEEDING

Fill up the brake fluid up to "MAX" line on

the reservoir. 1.

Fill the reservoir with brake fluid and pump

the brake pedal several times. Then keep it

depressed. 2.

Loosen the bleed screw and collect the

bleeding brake fluid from the brake line with

the order in the figure. 3.

Fill the reservoir with the brake fluid as

much as it bleeded, and continue to

bleeding operation. Never reuse the used brake fluid.

Use only specifies brake fluid (DOT 4). Add brake fluid between MAX and MIN lines on the

reservoir (0.7 to 0.8 liters).

Be careful not to splash the brake fluid on painted area or body.

Make sure that any foreign material does not get into brake line.

Always work with another staff. -

-

-

-

-

Page 660 of 828

09-12

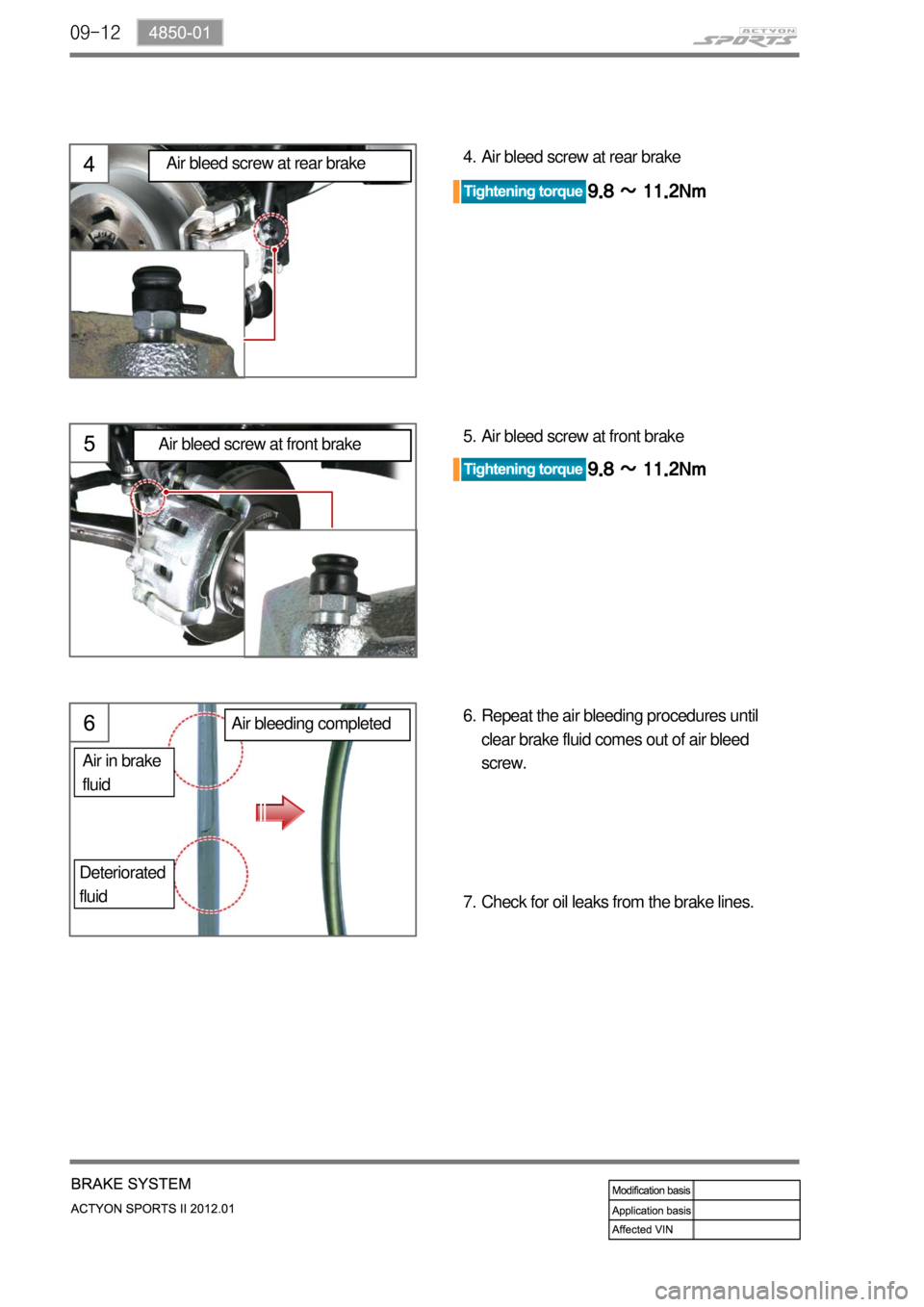

Air bleed screw at front brake 5.Air bleed screw at rear brake 4.

Repeat the air bleeding procedures until

clear brake fluid comes out of air bleed

screw. 6.

Check for oil leaks from the brake lines. 7.

Air in brake

fluid

Deteriorated

fluid

Air bleed screw at front brake

Air bleed screw at rear brake

Air bleeding completed