combination meter SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2178 of 2870

EN(H4DOTC 2.5)-154

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

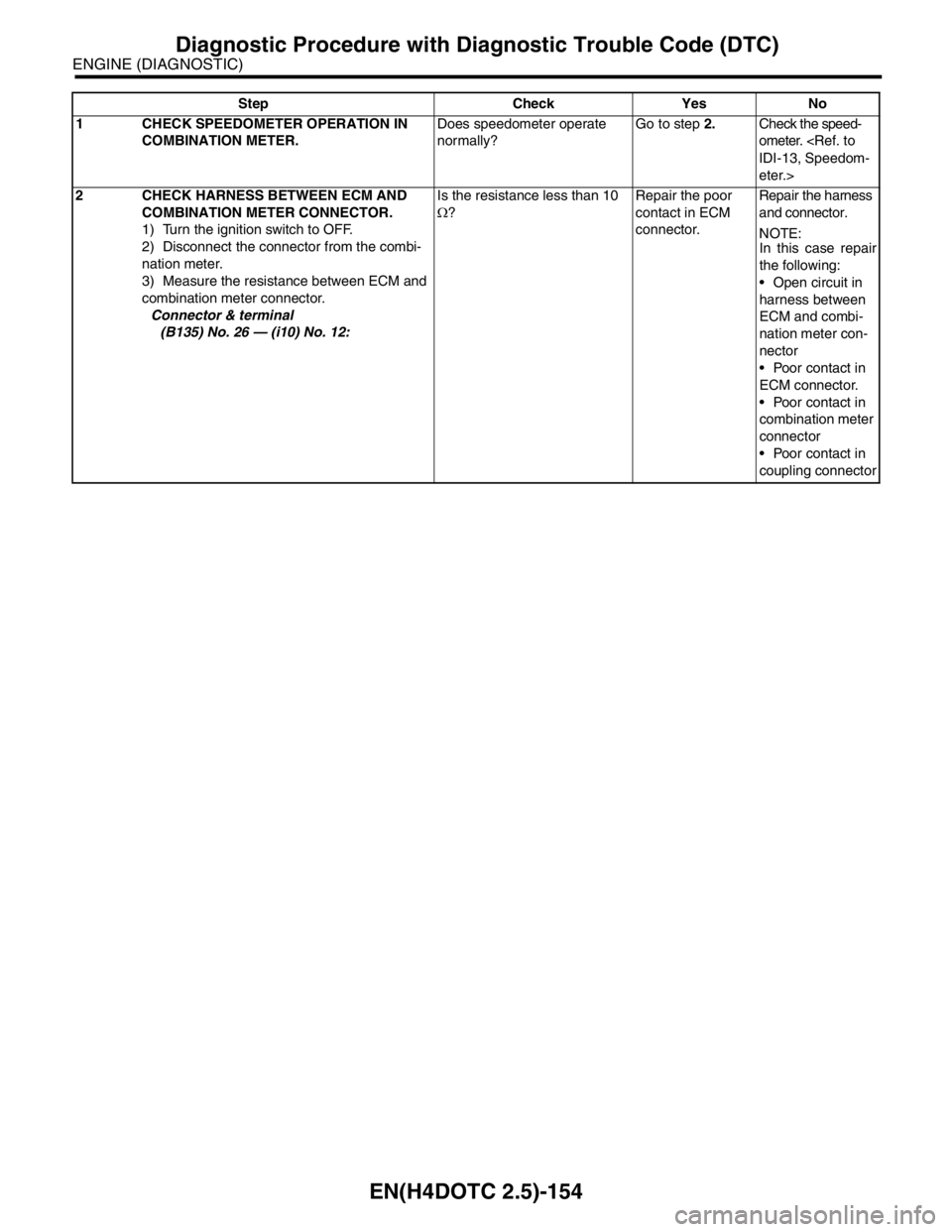

Step Check Yes No

1 CHECK SPEEDOMETER OPERATION IN

COMBINATION METER.Does speedometer operate

normally?Go to step 2.Check the speed-

ometer.

eter.>

2 CHECK HARNESS BETWEEN ECM AND

COMBINATION METER CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from the combi-

nation meter.

3) Measure the resistance between ECM and

combination meter connector.

Connector & terminal

(B135) No. 26 — (i10) No. 12:Is the resistance less than 10

Ω?Repair the poor

contact in ECM

connector.Repair the harness

and connector.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

ECM and combi-

nation meter con-

nector

Poor contact in

ECM connector.

Poor contact in

combination meter

connector

Poor contact in

coupling connector

Page 2383 of 2870

4AT-70

AUTOMATIC TRANSMISSION

Air Bleeding of Control Valve

18.Air Bleeding of Control Valve

A: PROCEDURE

1) Lift-up the vehicle with shifting the select lever to

“P” range and applying the parking brake.

2) Connect the Subaru Select Monitor to the vehi-

cle.

3) Make sure there is no trouble code using Subaru

Select Monitor.

4) Using Subaru Select Monitor, check that the

ATF temperature is in less than 60°C (140°F).

5) Power OFF the Subaru Select Monitor.

6) Turn the ignition switch to “OFF”.

7) Shift the select lever to “R” range.

8) Depress the brake pedal fully until the air bleed-

ing is completed.

9) Turn the ignition switch to ON.

10) Shift the select lever to “P” range, and then wait

for more than 3 seconds.

11) Shift the select lever to “R” range, and then wait

for more than 3 seconds.

12) Shift the select lever to “N” range, and then wait

for more than 3 seconds.

13) Shift the select lever to “D” range, and then wait

for more than 3 seconds.

14) Shift the select lever to “N” range, and then wait

for more than 3 seconds.

15) Slightly depress the accelerator pedal fully.

16) Slightly release the accelerator pedal fully.

17) Start the engine.

18) Shift the select lever to “D” range.

19) Turn the Subaru Select Monitor switch to ON.

20) Select {Each System Check} in «Main Menu»

of Subaru Select Monitor.

21) On the «System Selection Menu» display

screen, select the “Transmission”. Air bleeding of

control valve starts on transmission. At this time,

the POWER indicator light in combination meter

blinks at 2 Hz. When the POWER indicator light

does not blink, repeat the procedures from step 4).

22) Air bleeding of control valve is finished when

blinking of POWER indicator light in combination

meter changes from 2 Hz to 0.5 Hz.

NOTE:

When blinking of POWER indicator light changes

from 2 Hz to 4 Hz during air bleeding, repeat the

procedure from step 4).

23) Shift the select lever to “N” range, and then turn

the ignition switch to OFF.

24) Shift the select lever to the “P” range, and then

finish the air bleeding.

Page 2475 of 2870

4AT(H4SO)-16

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

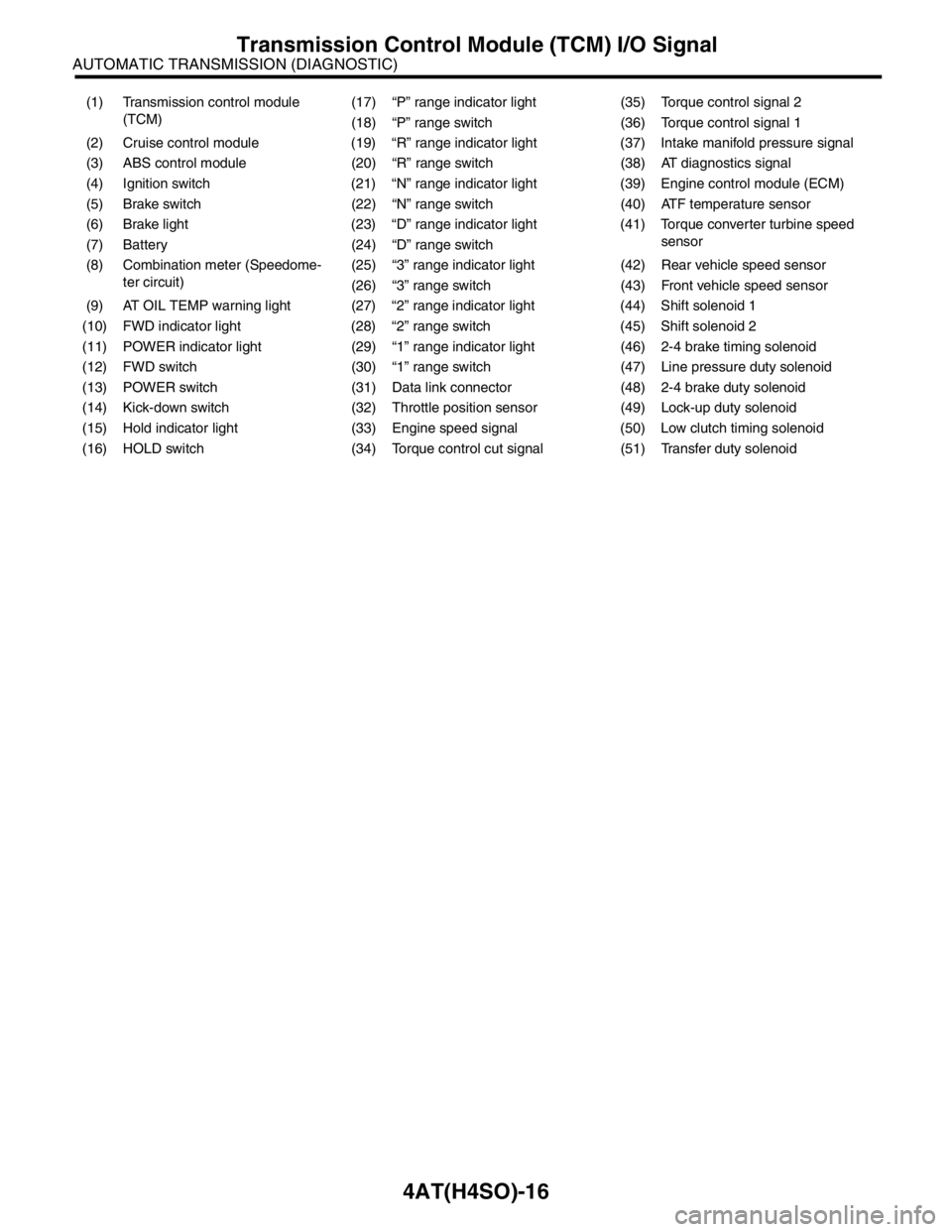

Transmission Control Module (TCM) I/O Signal

(1) Transmission control module

(TCM)(17) “P” range indicator light (35) Torque control signal 2

(18) “P” range switch (36) Torque control signal 1

(2) Cruise control module (19) “R” range indicator light (37) Intake manifold pressure signal

(3) ABS control module (20) “R” range switch (38) AT diagnostics signal

(4) Ignition switch (21) “N” range indicator light (39) Engine control module (ECM)

(5) Brake switch (22) “N” range switch (40) ATF temperature sensor

(6) Brake light (23) “D” range indicator light (41) Torque converter turbine speed

sensor

(7) Battery (24) “D” range switch

(8) Combination meter (Speedome-

ter circuit)(25) “3” range indicator light (42) Rear vehicle speed sensor

(26) “3” range switch (43) Front vehicle speed sensor

(9) AT OIL TEMP warning light (27) “2” range indicator light (44) Shift solenoid 1

(10) FWD indicator light (28) “2” range switch (45) Shift solenoid 2

(11) POWER indicator light (29) “1” range indicator light (46) 2-4 brake timing solenoid

(12) FWD switch (30) “1” range switch (47) Line pressure duty solenoid

(13) POWER switch (31) Data link connector (48) 2-4 brake duty solenoid

(14) Kick-down switch (32) Throttle position sensor (49) Lock-up duty solenoid

(15) Hold indicator light (33) Engine speed signal (50) Low clutch timing solenoid

(16) HOLD switch (34) Torque control cut signal (51) Transfer duty solenoid

Page 2485 of 2870

4AT(H4SO)-26

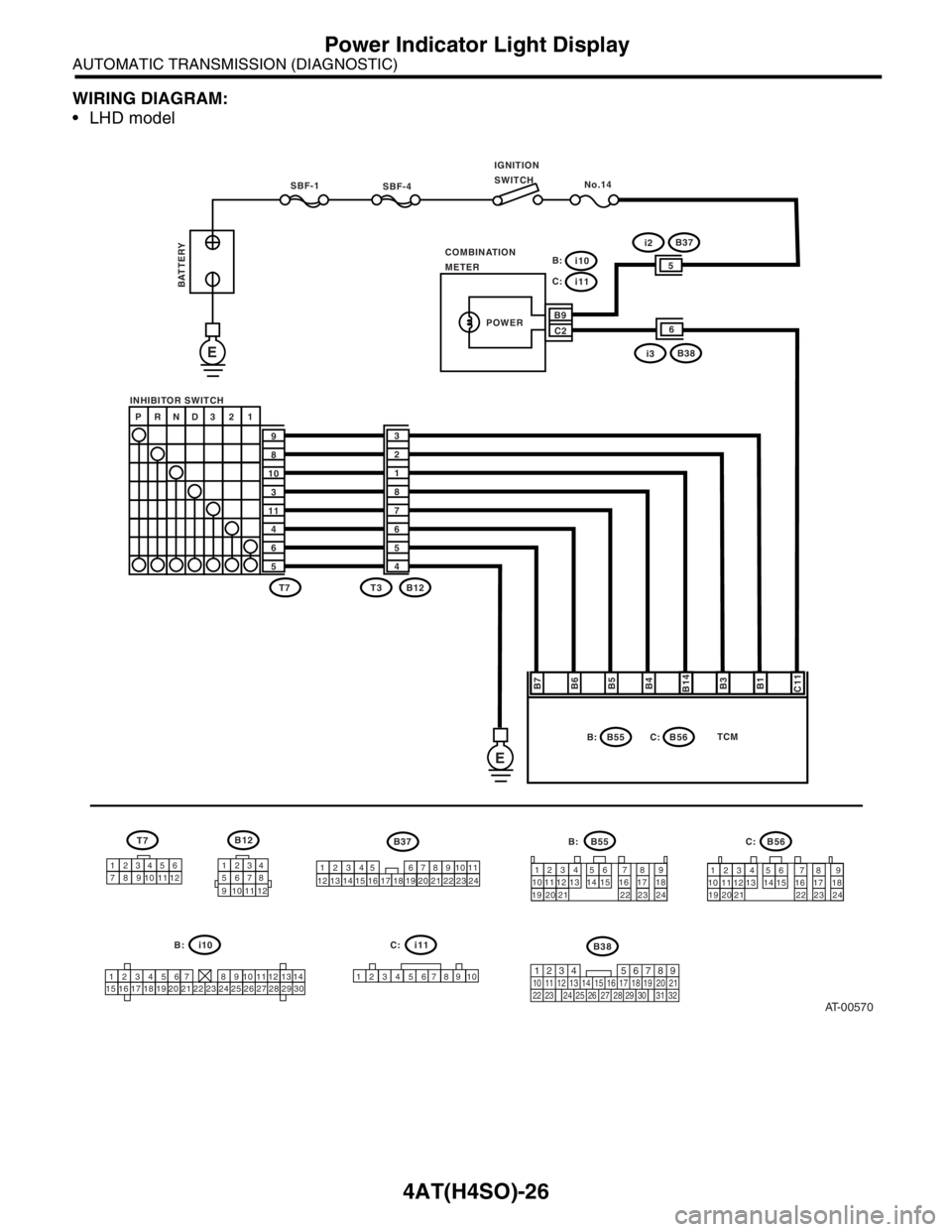

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Power Indicator Light Display

WIRING DIAGRAM:

LHD model

AT-00570

SBF-4No.14

COMBINATION

METERIGNITION

SWITCH

SBF-1

INHIBITOR SWITCH

E

E

BATTERY

B7

B6

B5

B4

B14

B3

B1

C11

P RND3 2 1

9

8

10

3

11

4

6

53

2

1

8

7

6

5

4

T7

T7B12

B55

B55 B37B56 T3 B12

1234

1234 56

12345656 12345

789

71234567891

0 897 7

8 8

9 9

10 11 12

10 11 10 11

12

13

10 11 12 1312 13

14

1415 14 15

16 16

17 18 17 18

19 20 21 19 20 21

22 23 24 22 23 241234 56 7 8 9

101112

13

1415

1516

1617

1718

1819

1920

2021

2122

2223

2324

24 25 26 27 28 29 30

B:

C:

B9

C2i2B37

POWER

B:

B56 C:TCM

i10 B:i11

1234

5678

9 101112

i10

i11

C:

i3B38

5

6

219

32

1234 5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

25

B38

6

C: B:

Page 2486 of 2870

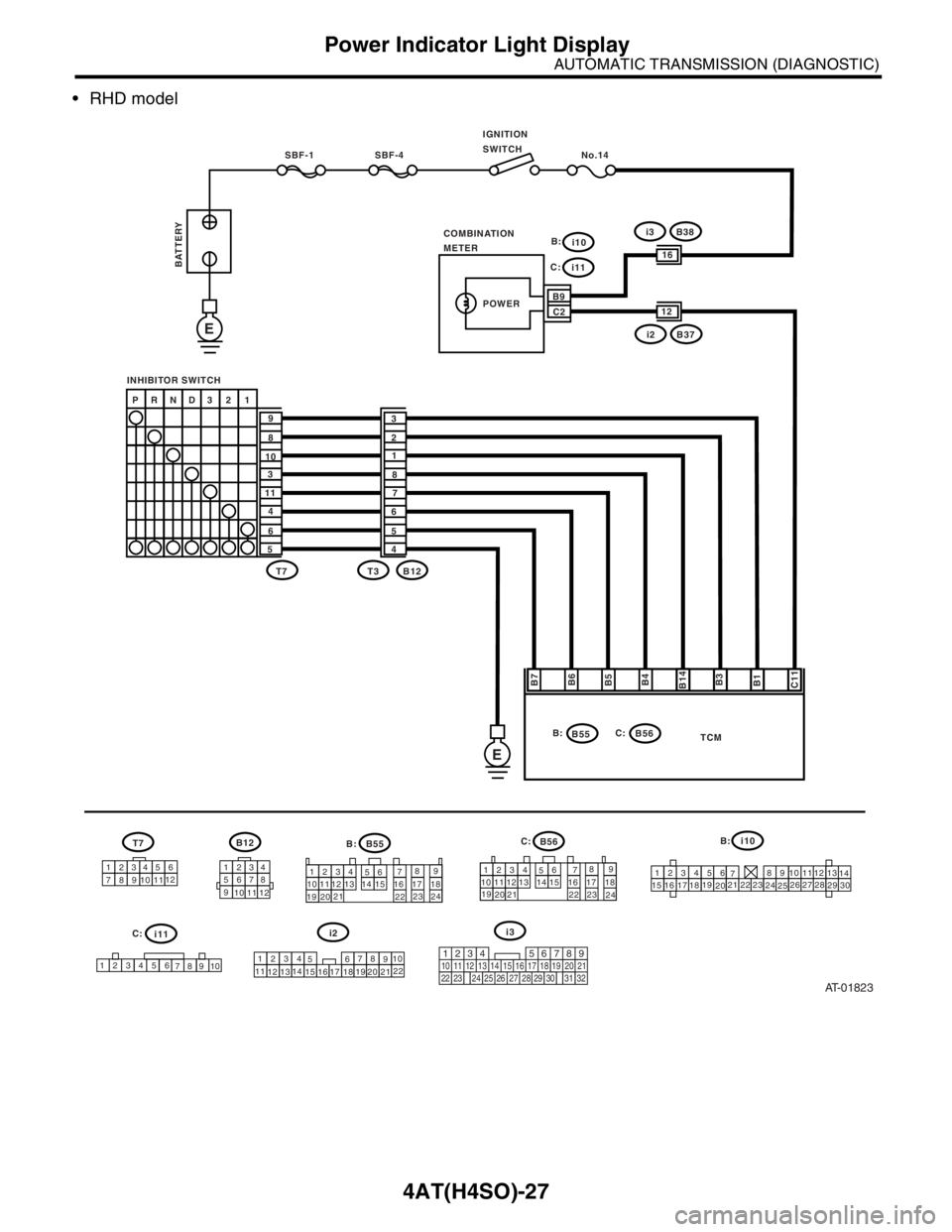

4AT(H4SO)-27

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Power Indicator Light Display

RHD model

AT-01823

SBF-4 No.14

COMBINATION

METER SBF-1

INHIBITOR SWITCH

E

E

B7

B6

B5

B4

B14

B3

B1

C11

P RND3 2 1

9

8

10

3

11

4

6

53

2

1

8

7

6

5

4

T7

T7B12

B55

B55

i2B56 T3 B12

12341234

5678

9

10

11

121234 56

123456 56

1234

5 7897

123456

7891089 7

68

79

8 10 1112

10 11

910 12

1310 1112

13

11

121414

15

131416

1517 18

16 192021

17 18192223 24

20 21221234

56789

101112

13

1415

15 16

16 17

17 18

18

1919

2020

2121

2222

2323

2424

2526

2728

29

30

i10

i11

B916

C2i3B38

POWER

B: C:B:

B56 C:

TCM

i10 B:

i11

IGNITION

SWITCH

BATTERY

12

i2B37

i3

219

32

1234 5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

25

C:

B:

C:

Page 2487 of 2870

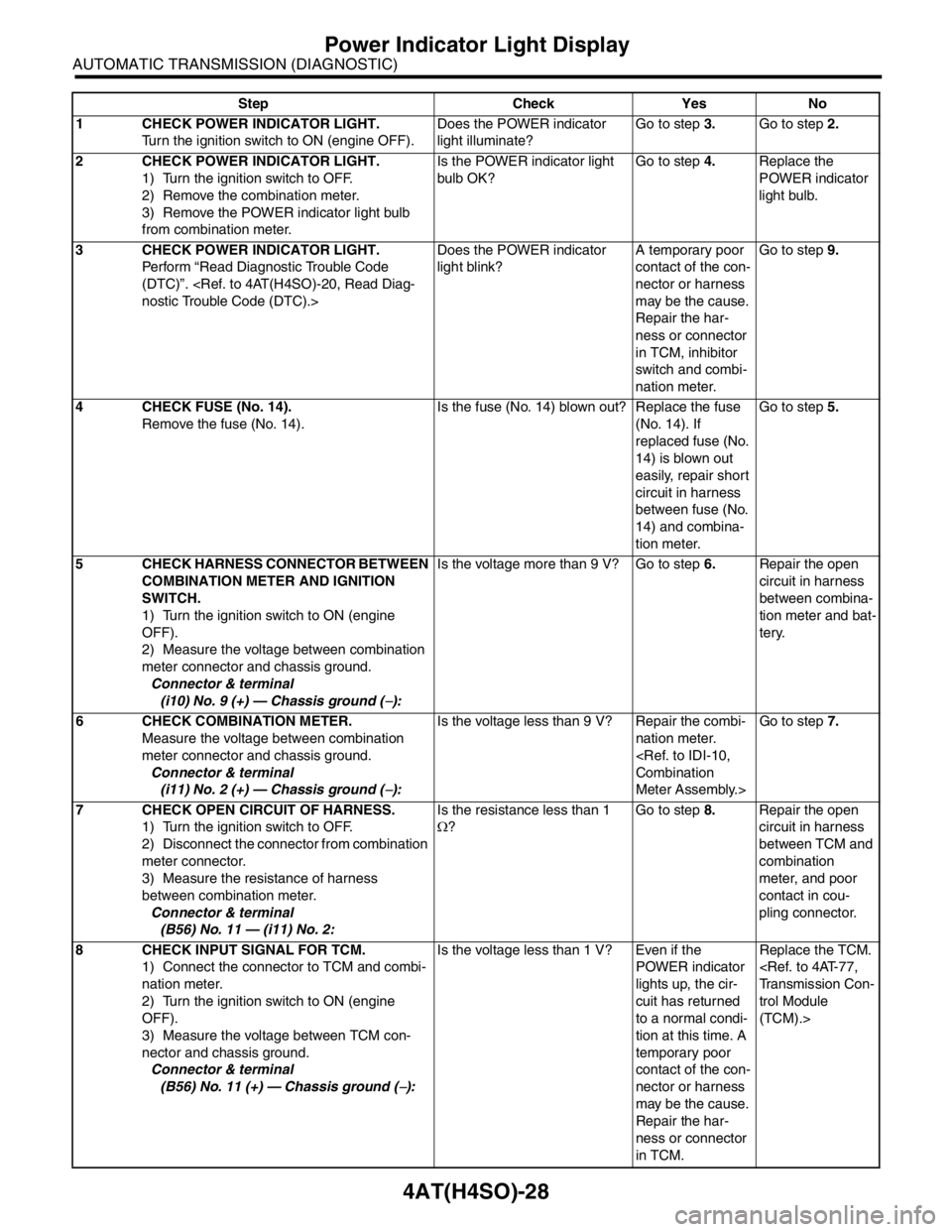

4AT(H4SO)-28

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Power Indicator Light Display

Step Check Yes No

1 CHECK POWER INDICATOR LIGHT.

Turn the ignition switch to ON (engine OFF).Does the POWER indicator

light illuminate?Go to step 3.Go to step 2.

2 CHECK POWER INDICATOR LIGHT.

1) Turn the ignition switch to OFF.

2) Remove the combination meter.

3) Remove the POWER indicator light bulb

from combination meter.Is the POWER indicator light

bulb OK?Go to step 4.Replace the

POWER indicator

light bulb.

3 CHECK POWER INDICATOR LIGHT.

Perform “Read Diagnostic Trouble Code

(DTC)”.

light blink?A temporary poor

contact of the con-

nector or harness

may be the cause.

Repair the har-

ness or connector

in TCM, inhibitor

switch and combi-

nation meter.Go to step 9.

4 CHECK FUSE (No. 14).

Remove the fuse (No. 14).Is the fuse (No. 14) blown out? Replace the fuse

(No. 14). If

replaced fuse (No.

14) is blown out

easily, repair short

circuit in harness

between fuse (No.

14) and combina-

tion meter.Go to step 5.

5 CHECK HARNESS CONNECTOR BETWEEN

COMBINATION METER AND IGNITION

SWITCH.

1) Turn the ignition switch to ON (engine

OFF).

2) Measure the voltage between combination

meter connector and chassis ground.

Connector & terminal

(i10) No. 9 (+) — Chassis ground (

−):Is the voltage more than 9 V? Go to step 6.Repair the open

circuit in harness

between combina-

tion meter and bat-

tery.

6 CHECK COMBINATION METER.

Measure the voltage between combination

meter connector and chassis ground.

Connector & terminal

(i11) No. 2 (+) — Chassis ground (

−):Is the voltage less than 9 V? Repair the combi-

nation meter.

Meter Assembly.>Go to step 7.

7 CHECK OPEN CIRCUIT OF HARNESS.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from combination

meter connector.

3) Measure the resistance of harness

between combination meter.

Connector & terminal

(B56) No. 11 — (i11) No. 2:Is the resistance less than 1

Ω?Go to step 8.Repair the open

circuit in harness

between TCM and

combination

meter, and poor

contact in cou-

pling connector.

8 CHECK INPUT SIGNAL FOR TCM.

1) Connect the connector to TCM and combi-

nation meter.

2) Turn the ignition switch to ON (engine

OFF).

3) Measure the voltage between TCM con-

nector and chassis ground.

Connector & terminal

(B56) No. 11 (+) — Chassis ground (

−):Is the voltage less than 1 V? Even if the

POWER indicator

lights up, the cir-

cuit has returned

to a normal condi-

tion at this time. A

temporary poor

contact of the con-

nector or harness

may be the cause.

Repair the har-

ness or connector

in TCM.Replace the TCM.

trol Module

(TCM).>

Page 2488 of 2870

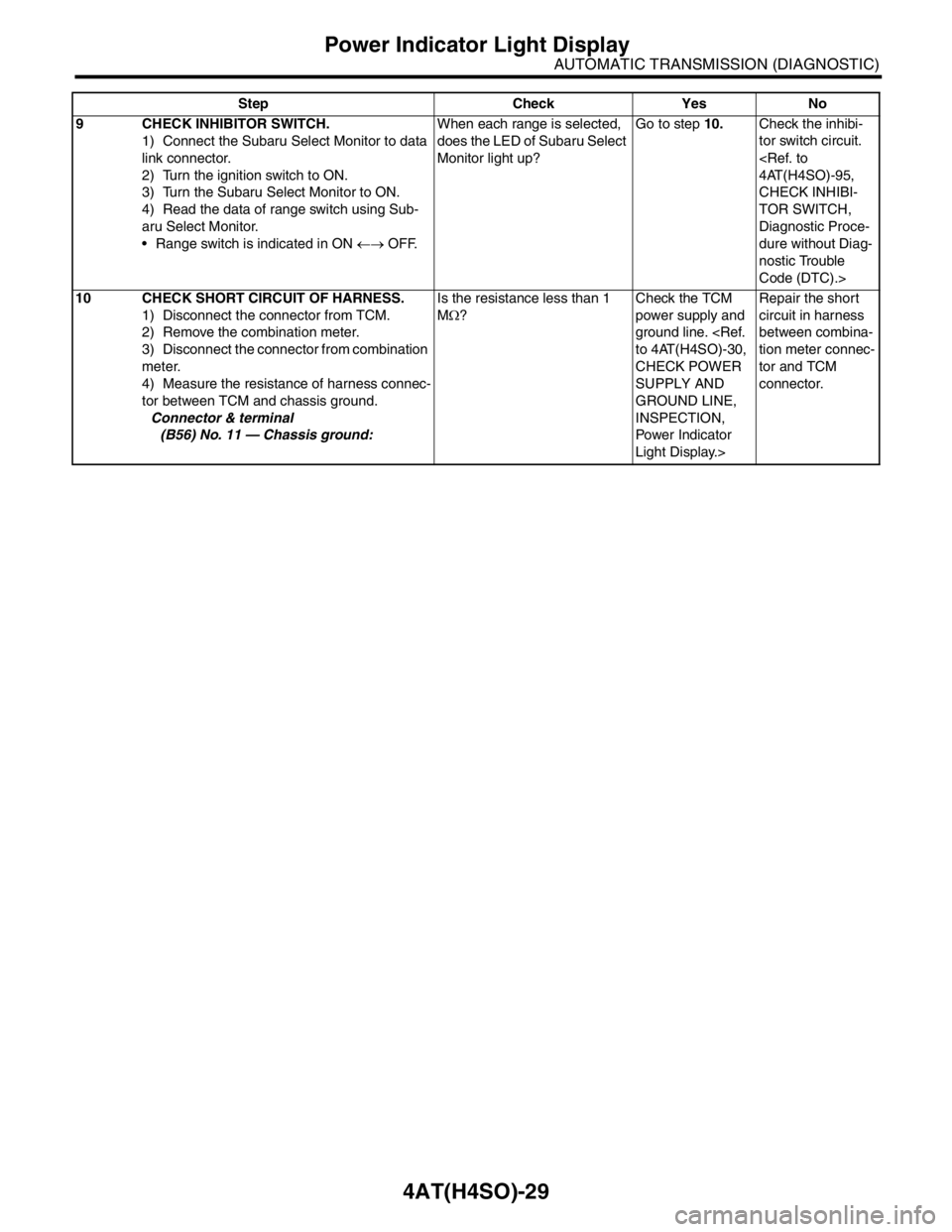

4AT(H4SO)-29

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Power Indicator Light Display

9 CHECK INHIBITOR SWITCH.

1) Connect the Subaru Select Monitor to data

link connector.

2) Turn the ignition switch to ON.

3) Turn the Subaru Select Monitor to ON.

4) Read the data of range switch using Sub-

aru Select Monitor.

Range switch is indicated in ON ←→ OFF.When each range is selected,

does the LED of Subaru Select

Monitor light up?Go to step 10.Check the inhibi-

tor switch circuit.

CHECK INHIBI-

TOR SWITCH,

Diagnostic Proce-

dure without Diag-

nostic Trouble

Code (DTC).>

10 CHECK SHORT CIRCUIT OF HARNESS.

1) Disconnect the connector from TCM.

2) Remove the combination meter.

3) Disconnect the connector from combination

meter.

4) Measure the resistance of harness connec-

tor between TCM and chassis ground.

Connector & terminal

(B56) No. 11 — Chassis ground:Is the resistance less than 1

MΩ?Check the TCM

power supply and

ground line.

CHECK POWER

SUPPLY AND

GROUND LINE,

INSPECTION,

Power Indicator

Light Display.>Repair the short

circuit in harness

between combina-

tion meter connec-

tor and TCM

connector. Step Check Yes No

Page 2496 of 2870

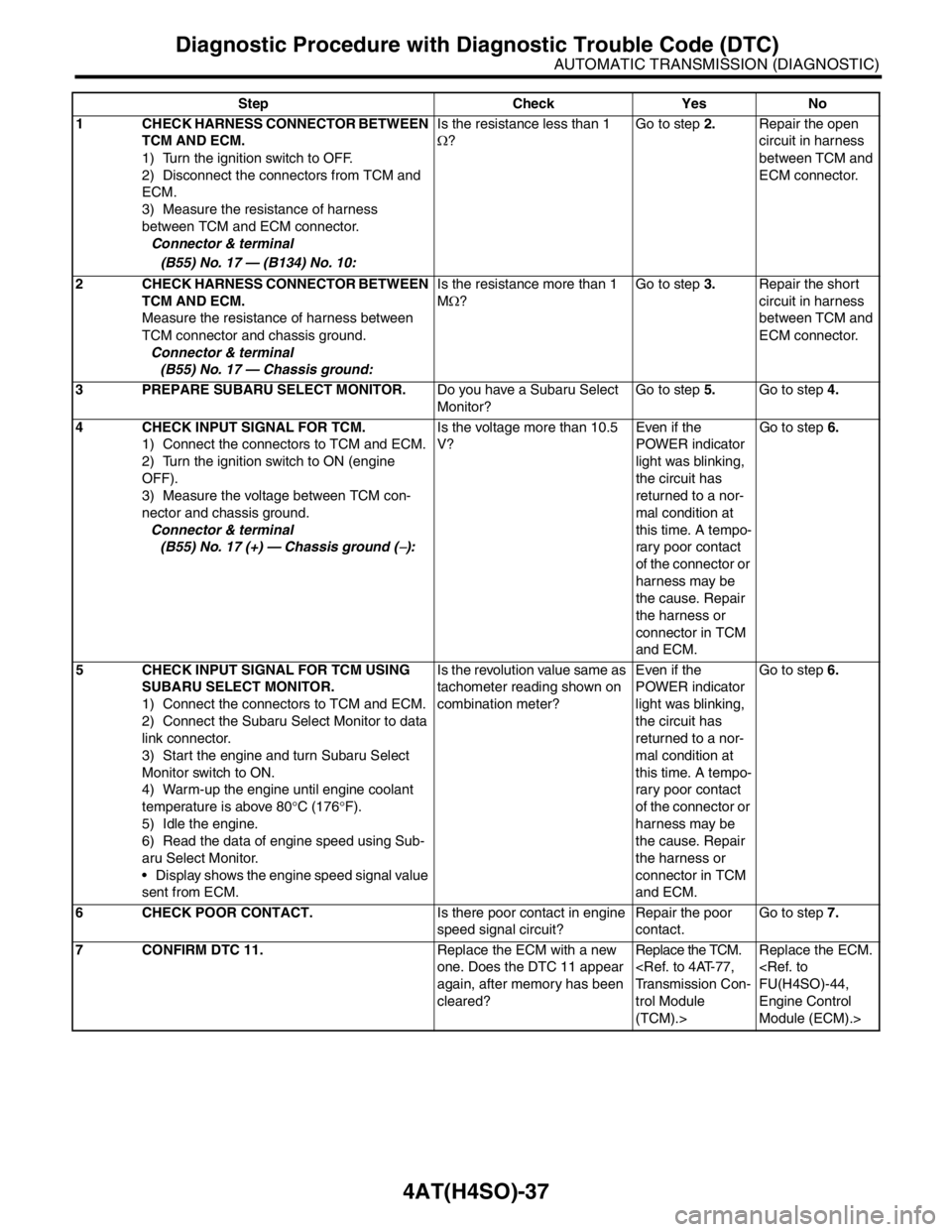

4AT(H4SO)-37

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

Step Check Yes No

1 CHECK HARNESS CONNECTOR BETWEEN

TCM AND ECM.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from TCM and

ECM.

3) Measure the resistance of harness

between TCM and ECM connector.

Connector & terminal

(B55) No. 17 — (B134) No. 10:Is the resistance less than 1

Ω?Go to step 2.Repair the open

circuit in harness

between TCM and

ECM connector.

2 CHECK HARNESS CONNECTOR BETWEEN

TCM AND ECM.

Measure the resistance of harness between

TCM connector and chassis ground.

Connector & terminal

(B55) No. 17 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 3.Repair the short

circuit in harness

between TCM and

ECM connector.

3 PREPARE SUBARU SELECT MONITOR.Do you have a Subaru Select

Monitor?Go to step 5.Go to step 4.

4 CHECK INPUT SIGNAL FOR TCM.

1) Connect the connectors to TCM and ECM.

2) Turn the ignition switch to ON (engine

OFF).

3) Measure the voltage between TCM con-

nector and chassis ground.

Connector & terminal

(B55) No. 17 (+) — Chassis ground (

−):Is the voltage more than 10.5

V?Even if the

POWER indicator

light was blinking,

the circuit has

returned to a nor-

mal condition at

this time. A tempo-

rary poor contact

of the connector or

harness may be

the cause. Repair

the harness or

connector in TCM

and ECM.Go to step 6.

5 CHECK INPUT SIGNAL FOR TCM USING

SUBARU SELECT MONITOR.

1) Connect the connectors to TCM and ECM.

2) Connect the Subaru Select Monitor to data

link connector.

3) Start the engine and turn Subaru Select

Monitor switch to ON.

4) Warm-up the engine until engine coolant

temperature is above 80°C (176°F).

5) Idle the engine.

6) Read the data of engine speed using Sub-

aru Select Monitor.

Display shows the engine speed signal value

sent from ECM.Is the revolution value same as

tachometer reading shown on

combination meter?Even if the

POWER indicator

light was blinking,

the circuit has

returned to a nor-

mal condition at

this time. A tempo-

rary poor contact

of the connector or

harness may be

the cause. Repair

the harness or

connector in TCM

and ECM.Go to step 6.

6 CHECK POOR CONTACT.Is there poor contact in engine

speed signal circuit?Repair the poor

contact.Go to step 7.

7 CONFIRM DTC 11.Replace the ECM with a new

one. Does the DTC 11 appear

again, after memory has been

cleared?Replace the TCM.

trol Module

(TCM).>Replace the ECM.

Engine Control

Module (ECM).>

Page 2504 of 2870

4AT(H4SO)-45

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

D: DTC 33 FRONT VEHICLE SPEED SENSOR

DTC DETECTING CONDITION:

The vehicle speed signal is abnormal.

The circuit in combination meter is faulty.

The harness connector between TCM and vehicle speed sensor is in short or open.

TROUBLE SYMPTOM:

Erroneous idling.

Engine stalls.

Poor driving performance.

Page 2510 of 2870

4AT(H4SO)-51

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

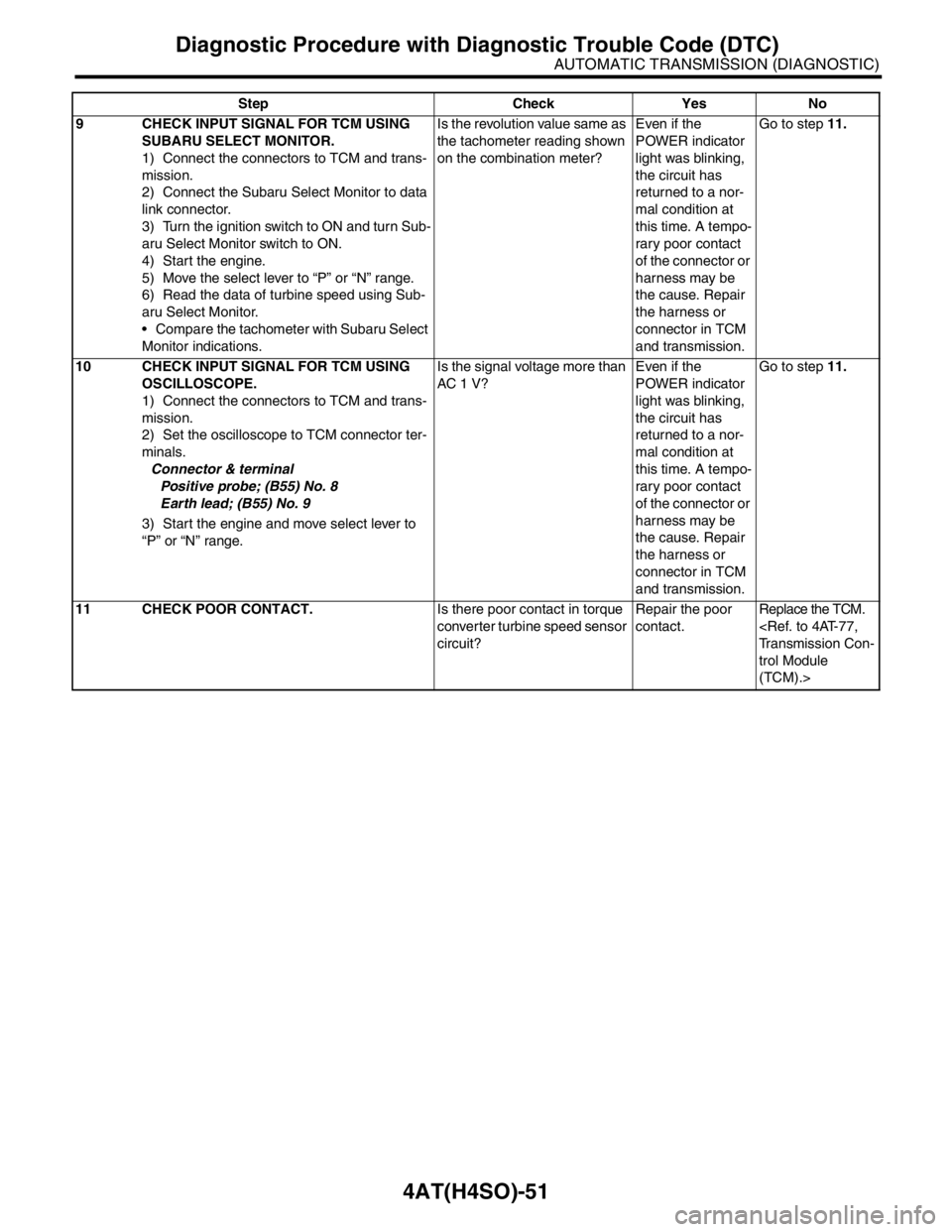

9 CHECK INPUT SIGNAL FOR TCM USING

SUBARU SELECT MONITOR.

1) Connect the connectors to TCM and trans-

mission.

2) Connect the Subaru Select Monitor to data

link connector.

3) Turn the ignition switch to ON and turn Sub-

aru Select Monitor switch to ON.

4) Start the engine.

5) Move the select lever to “P” or “N” range.

6) Read the data of turbine speed using Sub-

aru Select Monitor.

Compare the tachometer with Subaru Select

Monitor indications.Is the revolution value same as

the tachometer reading shown

on the combination meter?Even if the

POWER indicator

light was blinking,

the circuit has

returned to a nor-

mal condition at

this time. A tempo-

rary poor contact

of the connector or

harness may be

the cause. Repair

the harness or

connector in TCM

and transmission.Go to step 11.

10 CHECK INPUT SIGNAL FOR TCM USING

OSCILLOSCOPE.

1) Connect the connectors to TCM and trans-

mission.

2) Set the oscilloscope to TCM connector ter-

minals.

Connector & terminal

Positive probe; (B55) No. 8

Earth lead; (B55) No. 9

3) Start the engine and move select lever to

“P” or “N” range.Is the signal voltage more than

AC 1 V?Even if the

POWER indicator

light was blinking,

the circuit has

returned to a nor-

mal condition at

this time. A tempo-

rary poor contact

of the connector or

harness may be

the cause. Repair

the harness or

connector in TCM

and transmission.Go to step 11.

11 CHECK POOR CONTACT.Is there poor contact in torque

converter turbine speed sensor

circuit?Repair the poor

contact.Replace the TCM.

trol Module

(TCM).> Step Check Yes No