SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1811 of 2870

EN(H4DOTC)-178

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

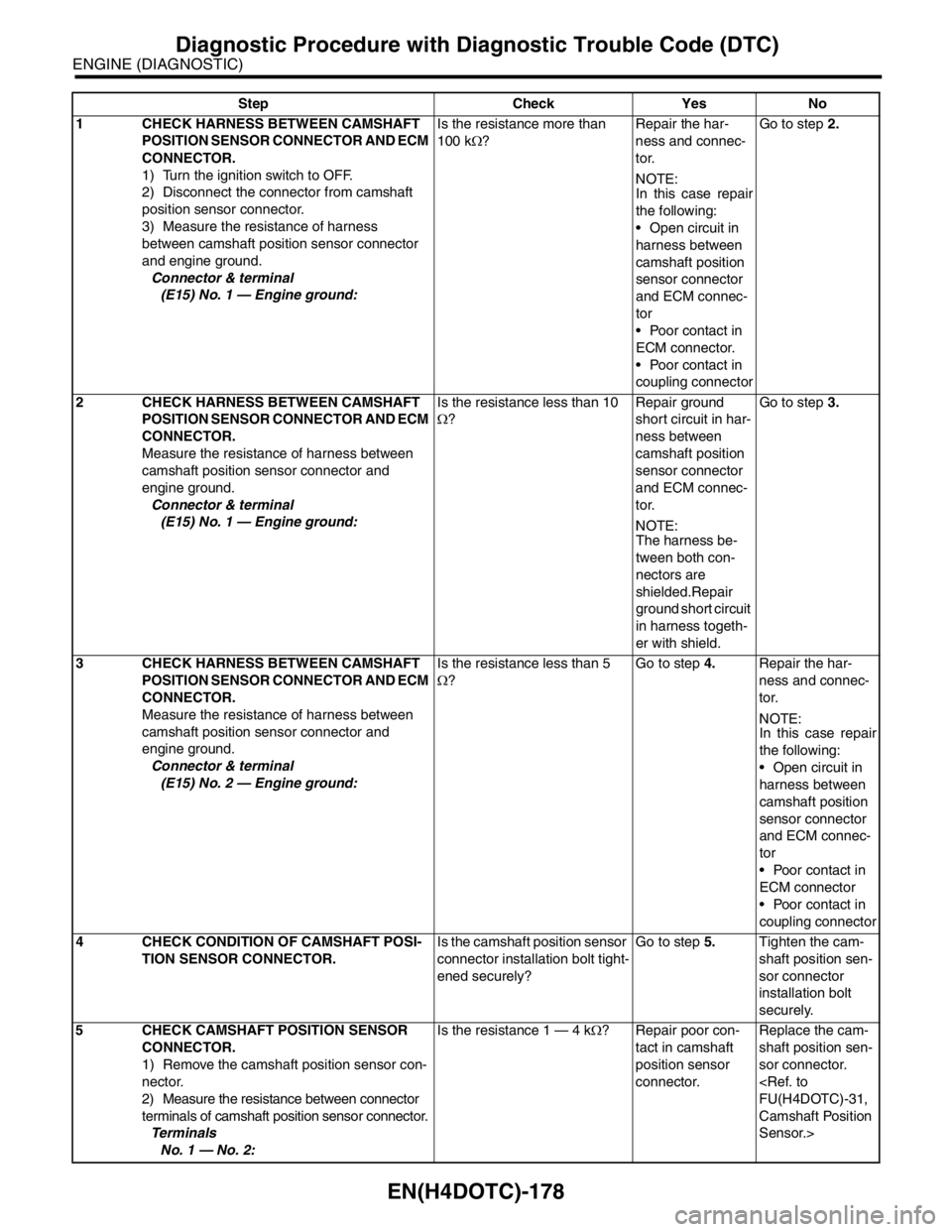

Step Check Yes No

1 CHECK HARNESS BETWEEN CAMSHAFT

POSITION SENSOR CONNECTOR AND ECM

CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from camshaft

position sensor connector.

3) Measure the resistance of harness

between camshaft position sensor connector

and engine ground.

Connector & terminal

(E15) No. 1 — Engine ground:Is the resistance more than

100 kΩ?Repair the har-

ness and connec-

tor.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

camshaft position

sensor connector

and ECM connec-

tor

Poor contact in

ECM connector.

Poor contact in

coupling connectorGo to step 2.

2 CHECK HARNESS BETWEEN CAMSHAFT

POSITION SENSOR CONNECTOR AND ECM

CONNECTOR.

Measure the resistance of harness between

camshaft position sensor connector and

engine ground.

Connector & terminal

(E15) No. 1 — Engine ground:Is the resistance less than 10

Ω?Repair ground

short circuit in har-

ness between

camshaft position

sensor connector

and ECM connec-

tor.

N

OTE:

The harness be-

tween both con-

nectors are

shielded.Repair

ground short circuit

in harness togeth-

er with shield.Go to step 3.

3 CHECK HARNESS BETWEEN CAMSHAFT

POSITION SENSOR CONNECTOR AND ECM

CONNECTOR.

Measure the resistance of harness between

camshaft position sensor connector and

engine ground.

Connector & terminal

(E15) No. 2 — Engine ground:Is the resistance less than 5

Ω?Go to step 4.Repair the har-

ness and connec-

tor.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

camshaft position

sensor connector

and ECM connec-

tor

Poor contact in

ECM connector

Poor contact in

coupling connector

4 CHECK CONDITION OF CAMSHAFT POSI-

TION SENSOR CONNECTOR.Is the camshaft position sensor

connector installation bolt tight-

ened securely?Go to step 5.Tighten the cam-

shaft position sen-

sor connector

installation bolt

securely.

5 CHECK CAMSHAFT POSITION SENSOR

CONNECTOR.

1) Remove the camshaft position sensor con-

nector.

2) Measure the resistance between connector

terminals of camshaft position sensor connector.

Te r m i n a l s

No. 1 — No. 2:Is the resistance 1 — 4 kΩ? Repair poor con-

tact in camshaft

position sensor

connector.Replace the cam-

shaft position sen-

sor connector.

Camshaft Position

Sensor.>

Page 1812 of 2870

EN(H4DOTC)-179

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

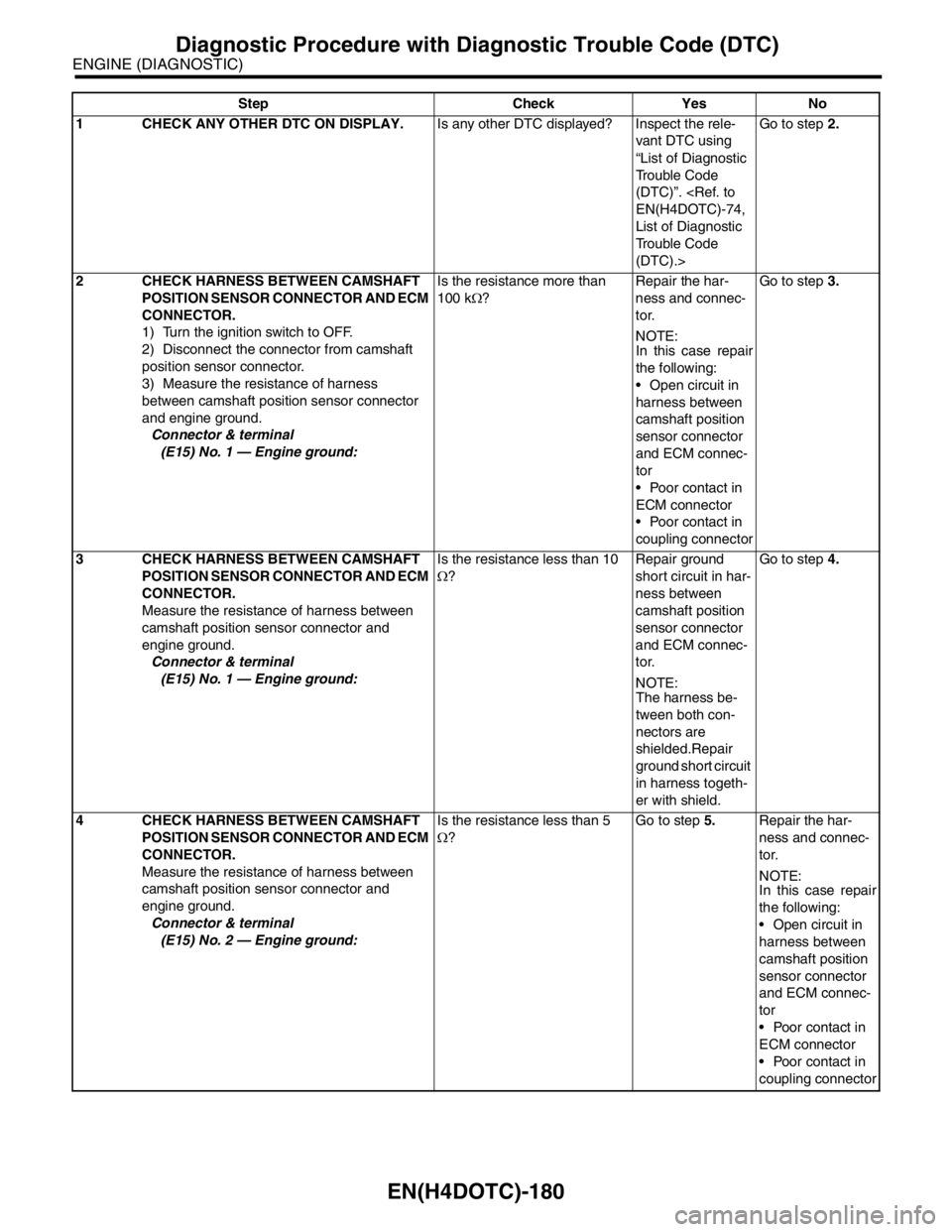

AT:DTC P0341 CAMSHAFT POSITION SENSOR “A” CIRCUIT RANGE/PERFOR-

MANCE (BANK 1 OR SINGLE SENSOR)

DTC DETECTING CONDITION:

Two consecutive driving cycles with fault

TROUBLE SYMPTOM:

Engine stalls.

Failure of engine to start

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-02331

4

3E1

E15

B20

2

1

B135 ECM

23

31 11

E

E15

12

12 34

56

7

89

10

B20

B135

567

82 1

94 310

24 22 23 2511 12 13 14 15

26 27

2816 17 18 19

20 21

29 30 31 32 33 34 35

AVCS

CAMSHAFT

POSITION

SENSOR

Page 1813 of 2870

EN(H4DOTC)-180

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

Step Check Yes No

1 CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Inspect the rele-

vant DTC using

“List of Diagnostic

Trouble Code

(DTC)”.

List of Diagnostic

Trouble Code

(DTC).>Go to step 2.

2 CHECK HARNESS BETWEEN CAMSHAFT

POSITION SENSOR CONNECTOR AND ECM

CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from camshaft

position sensor connector.

3) Measure the resistance of harness

between camshaft position sensor connector

and engine ground.

Connector & terminal

(E15) No. 1 — Engine ground:Is the resistance more than

100 kΩ?Repair the har-

ness and connec-

tor.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

camshaft position

sensor connector

and ECM connec-

tor

Poor contact in

ECM connector

Poor contact in

coupling connectorGo to step 3.

3 CHECK HARNESS BETWEEN CAMSHAFT

POSITION SENSOR CONNECTOR AND ECM

CONNECTOR.

Measure the resistance of harness between

camshaft position sensor connector and

engine ground.

Connector & terminal

(E15) No. 1 — Engine ground:Is the resistance less than 10

Ω?Repair ground

short circuit in har-

ness between

camshaft position

sensor connector

and ECM connec-

tor.

N

OTE:

The harness be-

tween both con-

nectors are

shielded.Repair

ground short circuit

in harness togeth-

er with shield.Go to step 4.

4 CHECK HARNESS BETWEEN CAMSHAFT

POSITION SENSOR CONNECTOR AND ECM

CONNECTOR.

Measure the resistance of harness between

camshaft position sensor connector and

engine ground.

Connector & terminal

(E15) No. 2 — Engine ground:Is the resistance less than 5

Ω?Go to step 5.Repair the har-

ness and connec-

tor.

NOTE:

In this case repair

the following:

Open circuit in

harness between

camshaft position

sensor connector

and ECM connec-

tor

Poor contact in

ECM connector

Poor contact in

coupling connector

Page 1814 of 2870

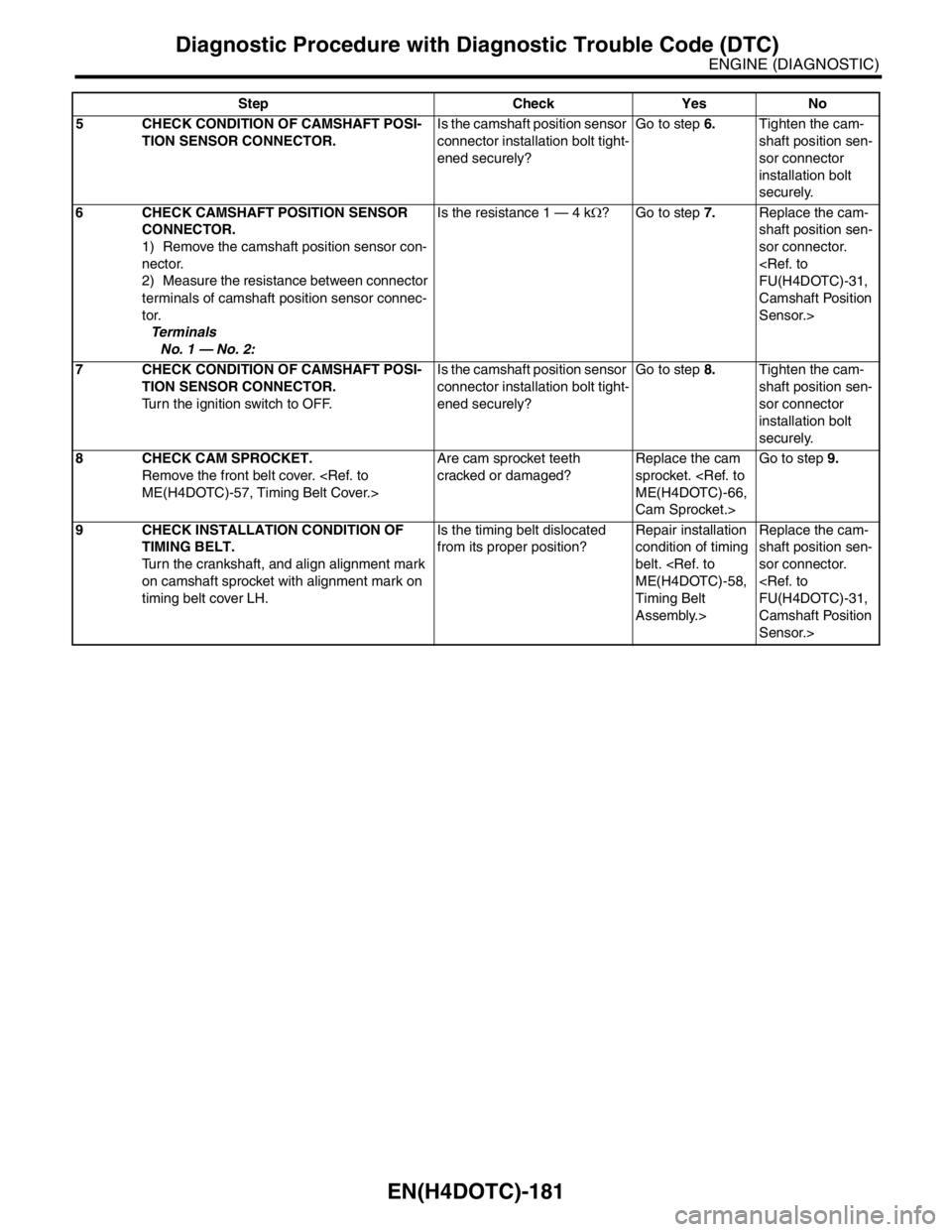

EN(H4DOTC)-181

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

5 CHECK CONDITION OF CAMSHAFT POSI-

TION SENSOR CONNECTOR.Is the camshaft position sensor

connector installation bolt tight-

ened securely?Go to step 6.Tighten the cam-

shaft position sen-

sor connector

installation bolt

securely.

6 CHECK CAMSHAFT POSITION SENSOR

CONNECTOR.

1) Remove the camshaft position sensor con-

nector.

2) Measure the resistance between connector

terminals of camshaft position sensor connec-

tor.

Te r m i n a l s

No. 1 — No. 2:Is the resistance 1 — 4 kΩ? Go to step 7.Replace the cam-

shaft position sen-

sor connector.

Camshaft Position

Sensor.>

7 CHECK CONDITION OF CAMSHAFT POSI-

TION SENSOR CONNECTOR.

Turn the ignition switch to OFF.Is the camshaft position sensor

connector installation bolt tight-

ened securely?Go to step 8.Tighten the cam-

shaft position sen-

sor connector

installation bolt

securely.

8 CHECK CAM SPROCKET.

Remove the front belt cover.

cracked or damaged?Replace the cam

sprocket.

Cam Sprocket.>Go to step 9.

9 CHECK INSTALLATION CONDITION OF

TIMING BELT.

Turn the crankshaft, and align alignment mark

on camshaft sprocket with alignment mark on

timing belt cover LH.Is the timing belt dislocated

from its proper position?Repair installation

condition of timing

belt.

Timing Belt

Assembly.>Replace the cam-

shaft position sen-

sor connector.

Camshaft Position

Sensor.> Step Check Yes No

Page 1815 of 2870

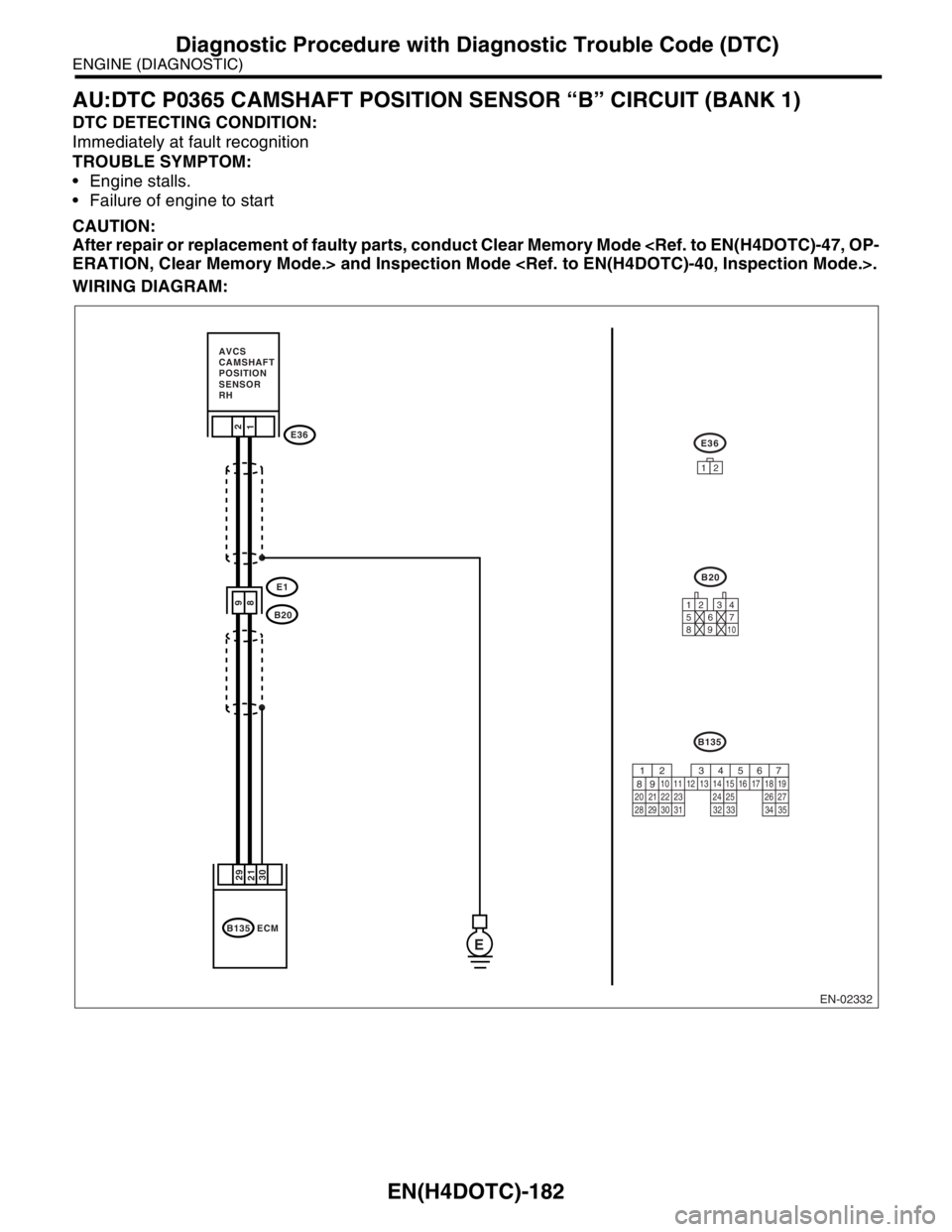

EN(H4DOTC)-182

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AU:DTC P0365 CAMSHAFT POSITION SENSOR “B” CIRCUIT (BANK 1)

DTC DETECTING CONDITION:

Immediately at fault recognition

TROUBLE SYMPTOM:

Engine stalls.

Failure of engine to start

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-02332

9

8E1

E36

B20

AVCS

CAMSHAFT

POSITION

SENSOR

RH

2

1

B135 ECM

29

30 21

E

E36

12

12 34

56

7

89

10

B20

B135

567

82 1

94 310

24 22 23 2511 12 13 14 15

26 27

2816 17 18 19

20 21

29 30 31 32 33 34 35

Page 1816 of 2870

EN(H4DOTC)-183

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

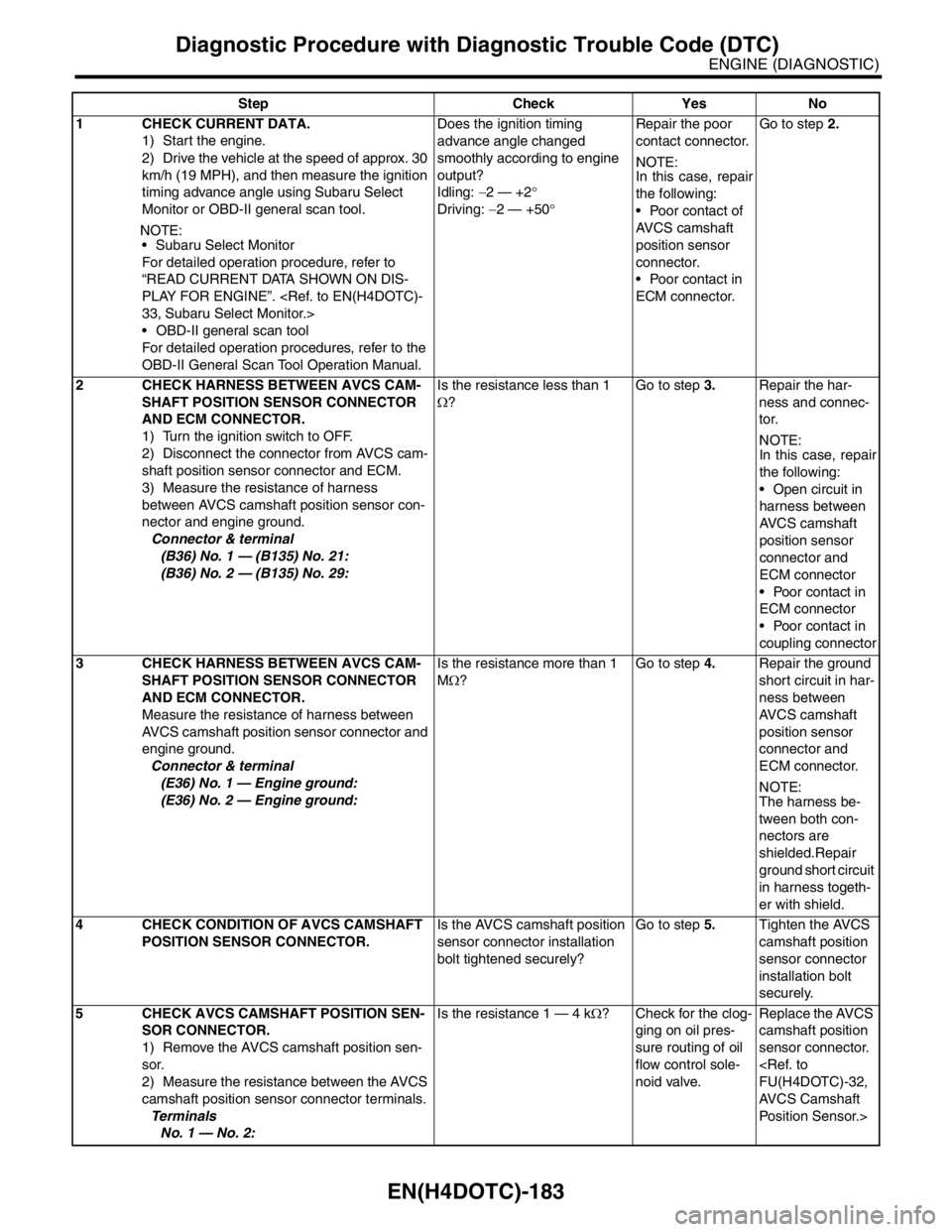

Step Check Yes No

1 CHECK CURRENT DATA.

1) Start the engine.

2) Drive the vehicle at the speed of approx. 30

km/h (19 MPH), and then measure the ignition

timing advance angle using Subaru Select

Monitor or OBD-II general scan tool.

N

OTE:

Subaru Select Monitor

For detailed operation procedure, refer to

“READ CURRENT DATA SHOWN ON DIS-

PLAY FOR ENGINE”.

OBD-II general scan tool

For detailed operation procedures, refer to the

OBD-II General Scan Tool Operation Manual.Does the ignition timing

advance angle changed

smoothly according to engine

output?

Idling: −2 — +2°

Driving: −2 — +50°Repair the poor

contact connector.

N

OTE:

In this case, repair

the following:

Poor contact of

AVCS camshaft

position sensor

connector.

Poor contact in

ECM connector.Go to step 2.

2 CHECK HARNESS BETWEEN AVCS CAM-

SHAFT POSITION SENSOR CONNECTOR

AND ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from AVCS cam-

shaft position sensor connector and ECM.

3) Measure the resistance of harness

between AVCS camshaft position sensor con-

nector and engine ground.

Connector & terminal

(B36) No. 1 — (B135) No. 21:

(B36) No. 2 — (B135) No. 29:Is the resistance less than 1

Ω?Go to step 3.Repair the har-

ness and connec-

tor.

N

OTE:

In this case, repair

the following:

Open circuit in

harness between

AVCS camshaft

position sensor

connector and

ECM connector

Poor contact in

ECM connector

Poor contact in

coupling connector

3 CHECK HARNESS BETWEEN AVCS CAM-

SHAFT POSITION SENSOR CONNECTOR

AND ECM CONNECTOR.

Measure the resistance of harness between

AVCS camshaft position sensor connector and

engine ground.

Connector & terminal

(E36) No. 1 — Engine ground:

(E36) No. 2 — Engine ground:Is the resistance more than 1

MΩ?Go to step 4.Repair the ground

short circuit in har-

ness between

AVCS camshaft

position sensor

connector and

ECM connector.

NOTE:

The harness be-

tween both con-

nectors are

shielded.Repair

ground short circuit

in harness togeth-

er with shield.

4 CHECK CONDITION OF AVCS CAMSHAFT

POSITION SENSOR CONNECTOR.Is the AVCS camshaft position

sensor connector installation

bolt tightened securely?Go to step 5.Tighten the AVCS

camshaft position

sensor connector

installation bolt

securely.

5 CHECK AVCS CAMSHAFT POSITION SEN-

SOR CONNECTOR.

1) Remove the AVCS camshaft position sen-

sor.

2) Measure the resistance between the AVCS

camshaft position sensor connector terminals.

Te r m i n a l s

No. 1 — No. 2:Is the resistance 1 — 4 kΩ? Check for the clog-

ging on oil pres-

sure routing of oil

flow control sole-

noid valve.Replace the AVCS

camshaft position

sensor connector.

AVCS Camshaft

Position Sensor.>

Page 1817 of 2870

EN(H4DOTC)-184

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

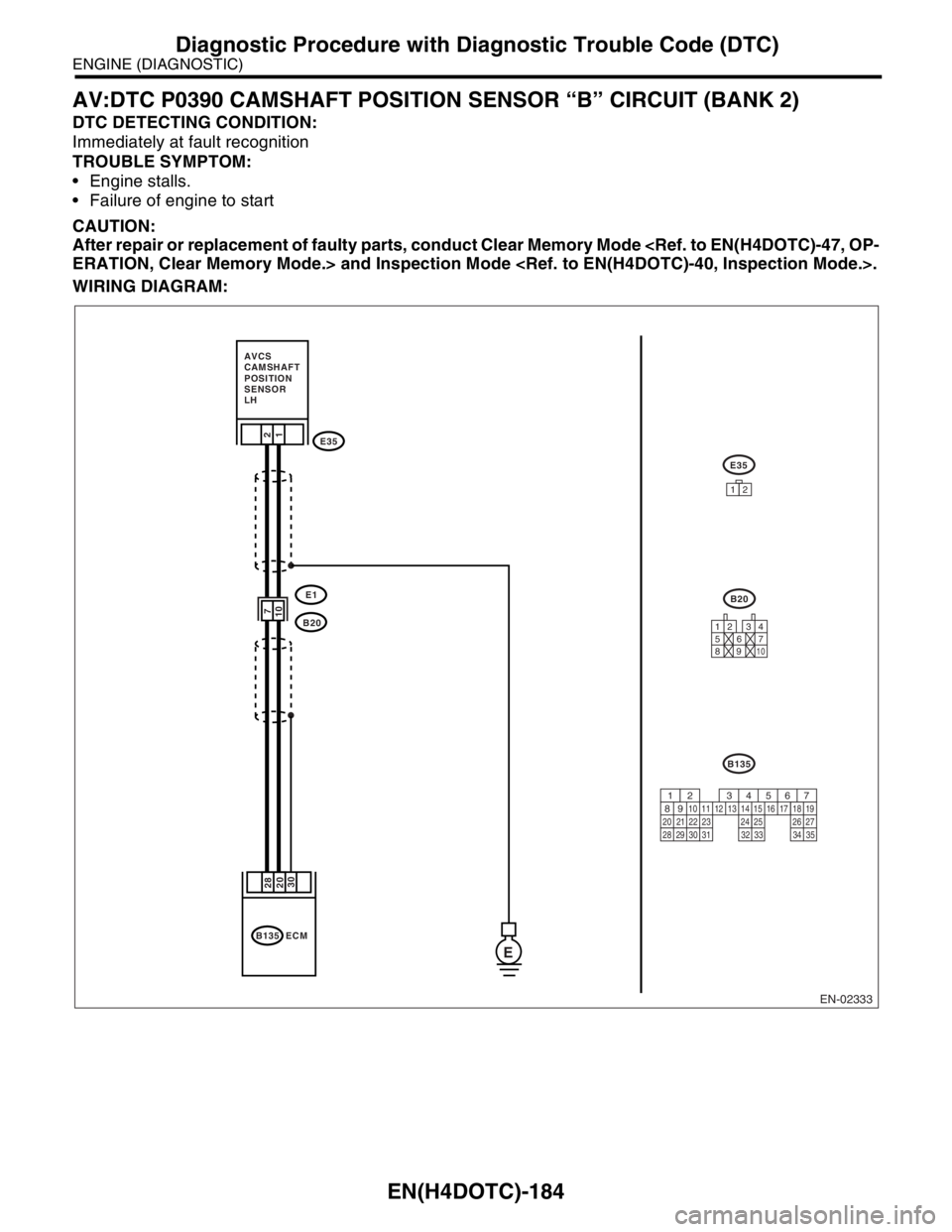

AV:DTC P0390 CAMSHAFT POSITION SENSOR “B” CIRCUIT (BANK 2)

DTC DETECTING CONDITION:

Immediately at fault recognition

TROUBLE SYMPTOM:

Engine stalls.

Failure of engine to start

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-02333

E1

E35

B20

2

1

B135

ECM

28

30 20

E

E35

12

12 34

56

7

89

10

B20

B135

AVCS

CAMSHAFT

POSITION

SENSOR

LH

567

82 1

94 310

24 22 23 2511 12 13 14 15

26 27

2816 17 18 19

20 21

29 30 31 32 33 34 35

7

10

Page 1818 of 2870

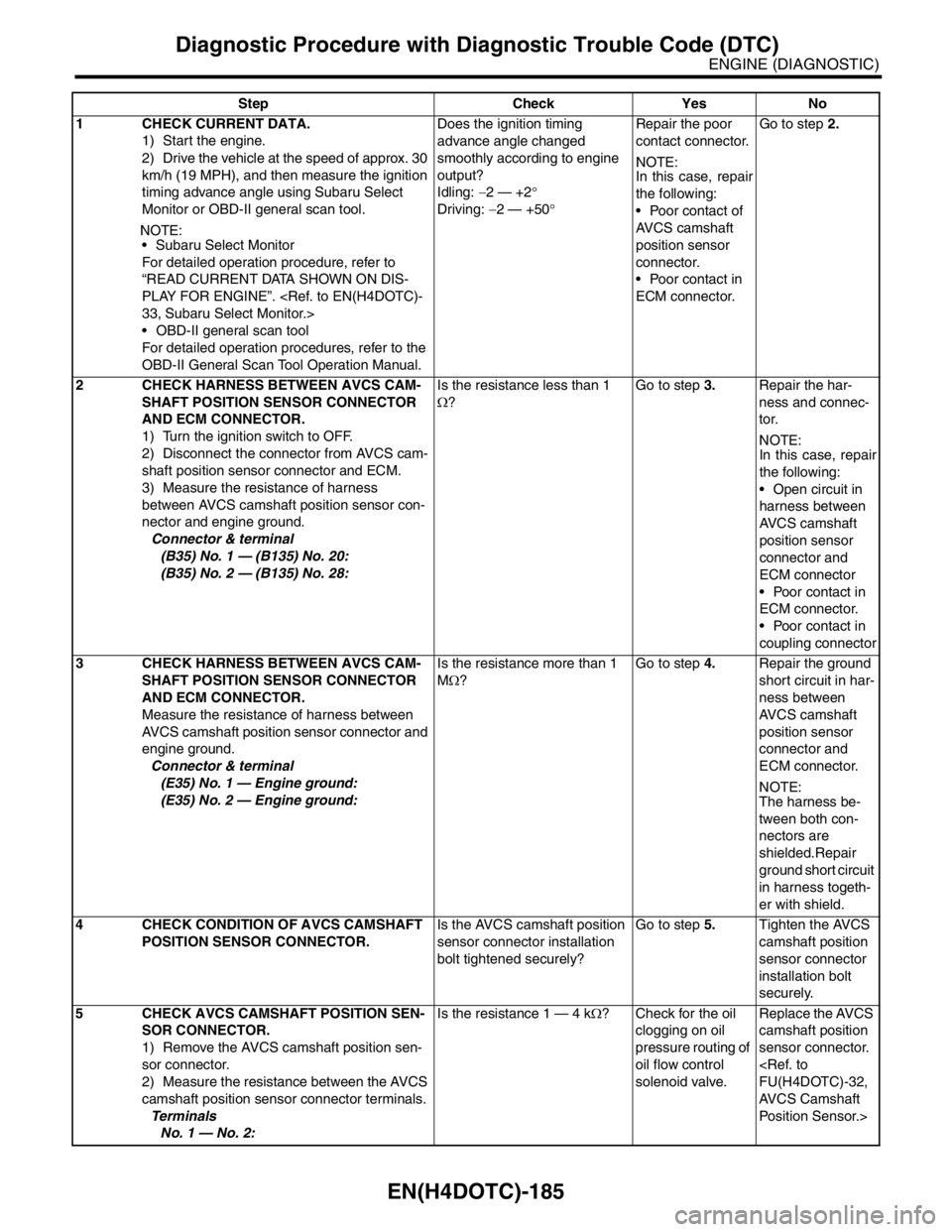

EN(H4DOTC)-185

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

Step Check Yes No

1 CHECK CURRENT DATA.

1) Start the engine.

2) Drive the vehicle at the speed of approx. 30

km/h (19 MPH), and then measure the ignition

timing advance angle using Subaru Select

Monitor or OBD-II general scan tool.

N

OTE:

Subaru Select Monitor

For detailed operation procedure, refer to

“READ CURRENT DATA SHOWN ON DIS-

PLAY FOR ENGINE”.

OBD-II general scan tool

For detailed operation procedures, refer to the

OBD-II General Scan Tool Operation Manual.Does the ignition timing

advance angle changed

smoothly according to engine

output?

Idling: −2 — +2°

Driving: −2 — +50°Repair the poor

contact connector.

N

OTE:

In this case, repair

the following:

Poor contact of

AVCS camshaft

position sensor

connector.

Poor contact in

ECM connector.Go to step 2.

2 CHECK HARNESS BETWEEN AVCS CAM-

SHAFT POSITION SENSOR CONNECTOR

AND ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from AVCS cam-

shaft position sensor connector and ECM.

3) Measure the resistance of harness

between AVCS camshaft position sensor con-

nector and engine ground.

Connector & terminal

(B35) No. 1 — (B135) No. 20:

(B35) No. 2 — (B135) No. 28:Is the resistance less than 1

Ω?Go to step 3.Repair the har-

ness and connec-

tor.

N

OTE:

In this case, repair

the following:

Open circuit in

harness between

AVCS camshaft

position sensor

connector and

ECM connector

Poor contact in

ECM connector.

Poor contact in

coupling connector

3 CHECK HARNESS BETWEEN AVCS CAM-

SHAFT POSITION SENSOR CONNECTOR

AND ECM CONNECTOR.

Measure the resistance of harness between

AVCS camshaft position sensor connector and

engine ground.

Connector & terminal

(E35) No. 1 — Engine ground:

(E35) No. 2 — Engine ground:Is the resistance more than 1

MΩ?Go to step 4.Repair the ground

short circuit in har-

ness between

AVCS camshaft

position sensor

connector and

ECM connector.

NOTE:

The harness be-

tween both con-

nectors are

shielded.Repair

ground short circuit

in harness togeth-

er with shield.

4 CHECK CONDITION OF AVCS CAMSHAFT

POSITION SENSOR CONNECTOR.Is the AVCS camshaft position

sensor connector installation

bolt tightened securely?Go to step 5.Tighten the AVCS

camshaft position

sensor connector

installation bolt

securely.

5 CHECK AVCS CAMSHAFT POSITION SEN-

SOR CONNECTOR.

1) Remove the AVCS camshaft position sen-

sor connector.

2) Measure the resistance between the AVCS

camshaft position sensor connector terminals.

Te r m i n a l s

No. 1 — No. 2:Is the resistance 1 — 4 kΩ? Check for the oil

clogging on oil

pressure routing of

oil flow control

solenoid valve.Replace the AVCS

camshaft position

sensor connector.

AVCS Camshaft

Position Sensor.>

Page 1819 of 2870

EN(H4DOTC)-186

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

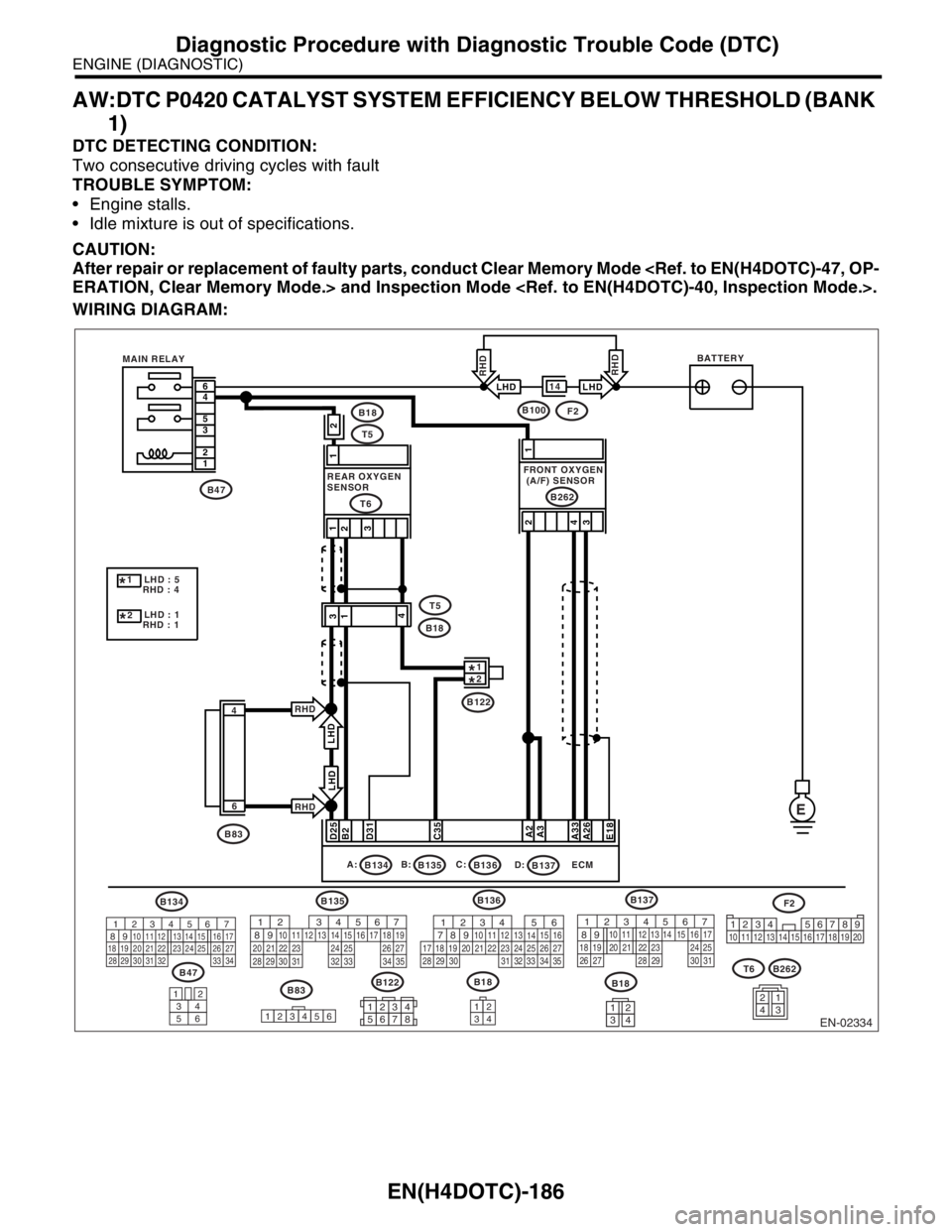

AW:DTC P0420 CATALYST SYSTEM EFFICIENCY BELOW THRESHOLD (BANK

1)

DTC DETECTING CONDITION:

Two consecutive driving cycles with fault

TROUBLE SYMPTOM:

Engine stalls.

Idle mixture is out of specifications.

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-02334

BATTERY

MAIN RELAY

E

6

4

5

3

2

1

2

4

31

FRONT OXYGEN

(A/F) SENSOR

D25

B2

D31

C35

A2

A3

A33

A26

E18

REAR OXYGEN

SENSOR

T6

B47

B47

34

12

56

B134B137

B83

1

23456

B18

B262

34

12

B134A:

B135B:

B136ECM C:

B135

B83 LHD : 5

RHD : 4

LHD : 1

RHD : 1

*1

*2F2 B100

567

82 1

94 310

22 23 11 12 13 14 15

24 25

2616 17

18 19 20 21

27 28 29 30 31

F2

1234 5678910 11 12 13 14 15 16 17 18 19 20567

82 1

94 310

24 22 23 2511 12 13 14 15

26 27

2816 17 18 19

20 21

29 30 31 32 33 34 3556 7

82 1

94 310

24 22 23 25 11 12 13 14 15

26 27

2816 17

18 19 20 21

33 34 29

32 30 31

B136

56

782 1

94 310

24 22 23 2511 12 13

1415

26 27

2816

17 18 19 20 21

33 34 29

32 30

31 35

B122

12345678

B262T6B1812341234

1

2

31

B18

T5

3

1

4

4

6

B137

D:

14RHD

RHDLHD LHD

2

B122*2*1

B18

T5

RHD

LHD

RHD

LHD

Page 1820 of 2870

EN(H4DOTC)-187

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

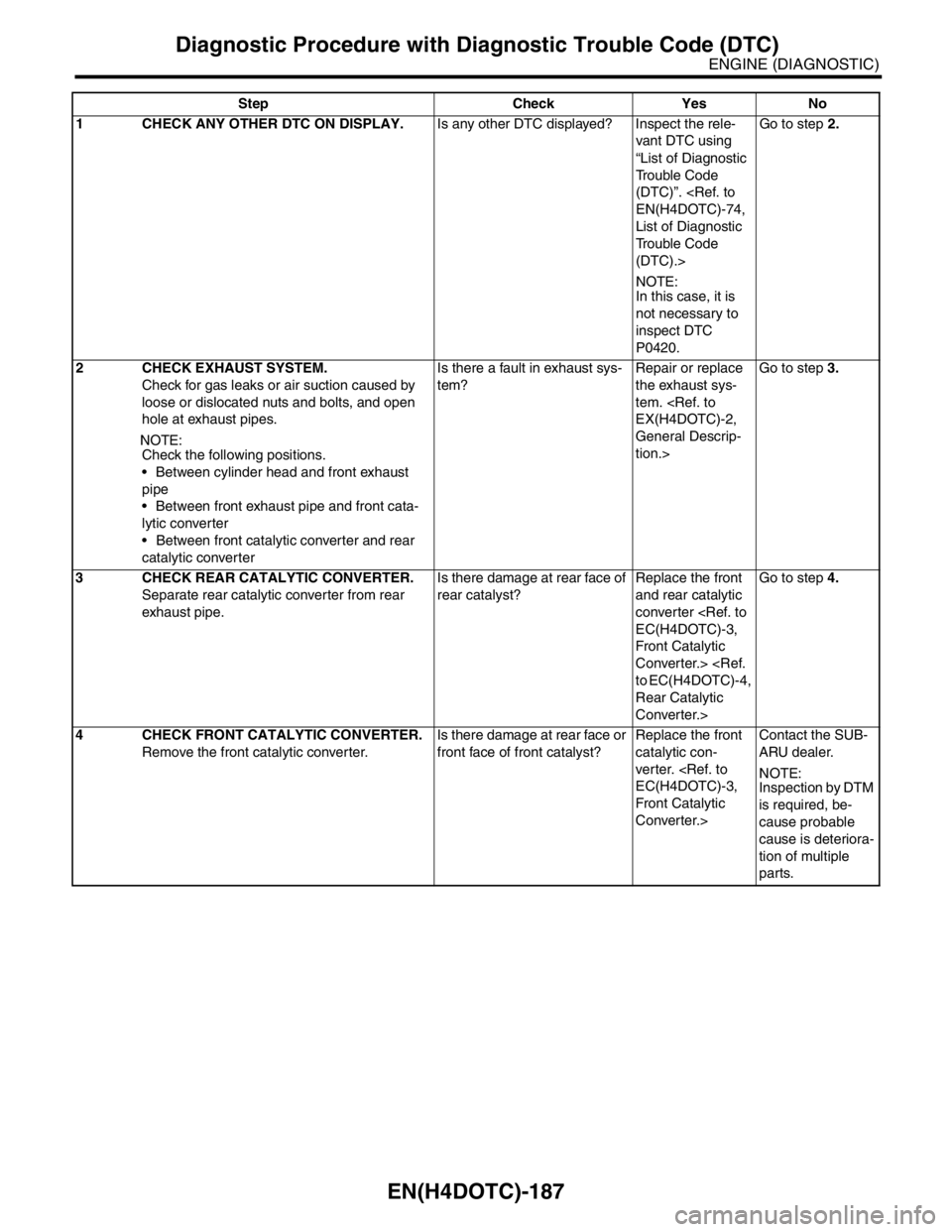

Step Check Yes No

1 CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Inspect the rele-

vant DTC using

“List of Diagnostic

Trouble Code

(DTC)”.

List of Diagnostic

Trouble Code

(DTC).>

N

OTE:

In this case, it is

not necessary to

inspect DTC

P0420.Go to step 2.

2 CHECK EXHAUST SYSTEM.

Check for gas leaks or air suction caused by

loose or dislocated nuts and bolts, and open

hole at exhaust pipes.

N

OTE:

Check the following positions.

Between cylinder head and front exhaust

pipe

Between front exhaust pipe and front cata-

lytic converter

Between front catalytic converter and rear

catalytic converterIs there a fault in exhaust sys-

tem?Repair or replace

the exhaust sys-

tem.

General Descrip-

tion.>Go to step 3.

3 CHECK REAR CATALYTIC CONVERTER.

Separate rear catalytic converter from rear

exhaust pipe.Is there damage at rear face of

rear catalyst?Replace the front

and rear catalytic

converter

Front Catalytic

Converter.>

Rear Catalytic

Converter.>Go to step 4.

4 CHECK FRONT CATALYTIC CONVERTER.

Remove the front catalytic converter.Is there damage at rear face or

front face of front catalyst?Replace the front

catalytic con-

verter.

Front Catalytic

Converter.>Contact the SUB-

ARU dealer.

NOTE:

Inspection by DTM

is required, be-

cause probable

cause is deteriora-

tion of multiple

parts.