SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1781 of 2870

EN(H4DOTC)-148

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

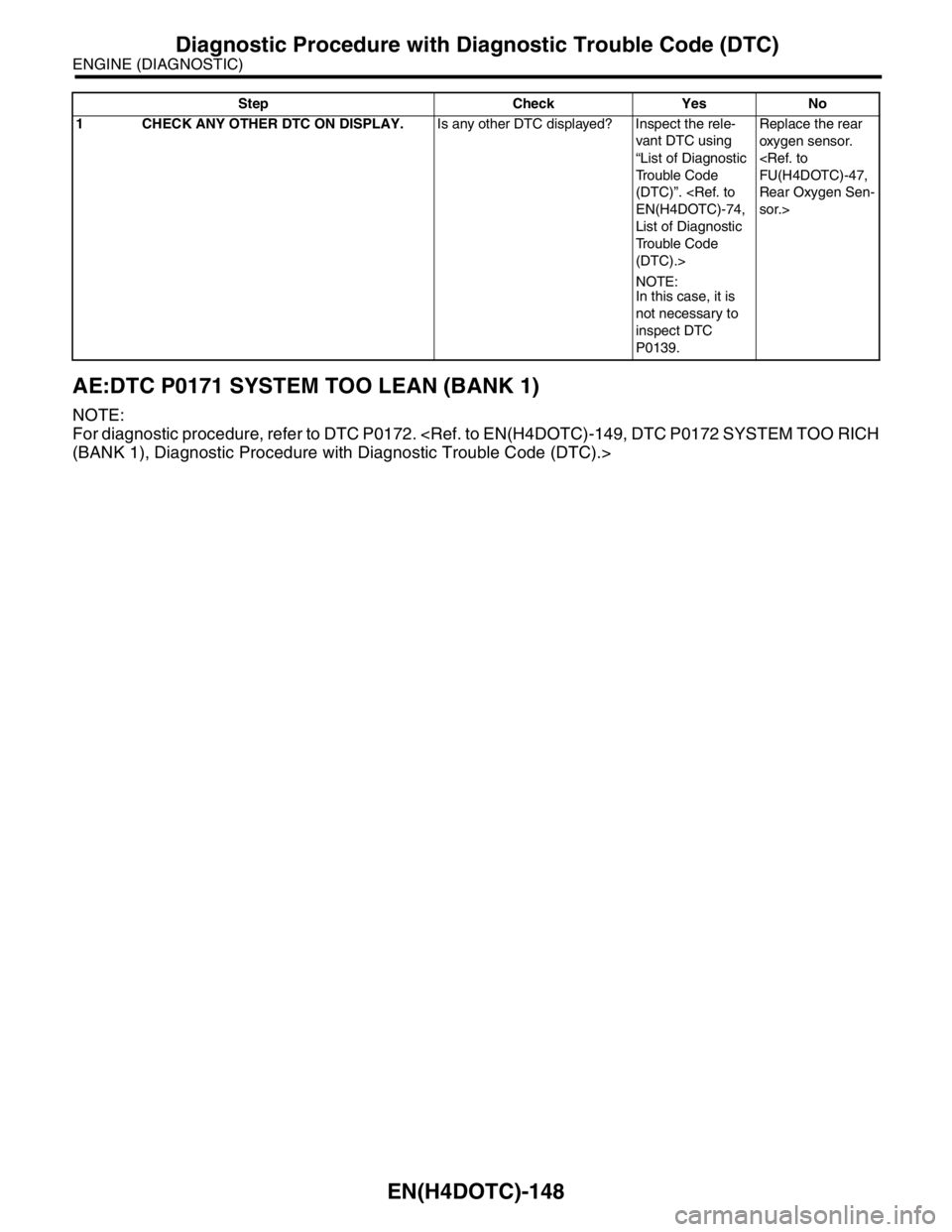

AE:DTC P0171 SYSTEM TOO LEAN (BANK 1)

NOTE:

For diagnostic procedure, refer to DTC P0172.

Step Check Yes No

1 CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Inspect the rele-

vant DTC using

“List of Diagnostic

Trouble Code

(DTC)”.

List of Diagnostic

Trouble Code

(DTC).>

N

OTE:

In this case, it is

not necessary to

inspect DTC

P0139.Replace the rear

oxygen sensor.

Rear Oxygen Sen-

sor.>

Page 1782 of 2870

EN(H4DOTC)-149

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

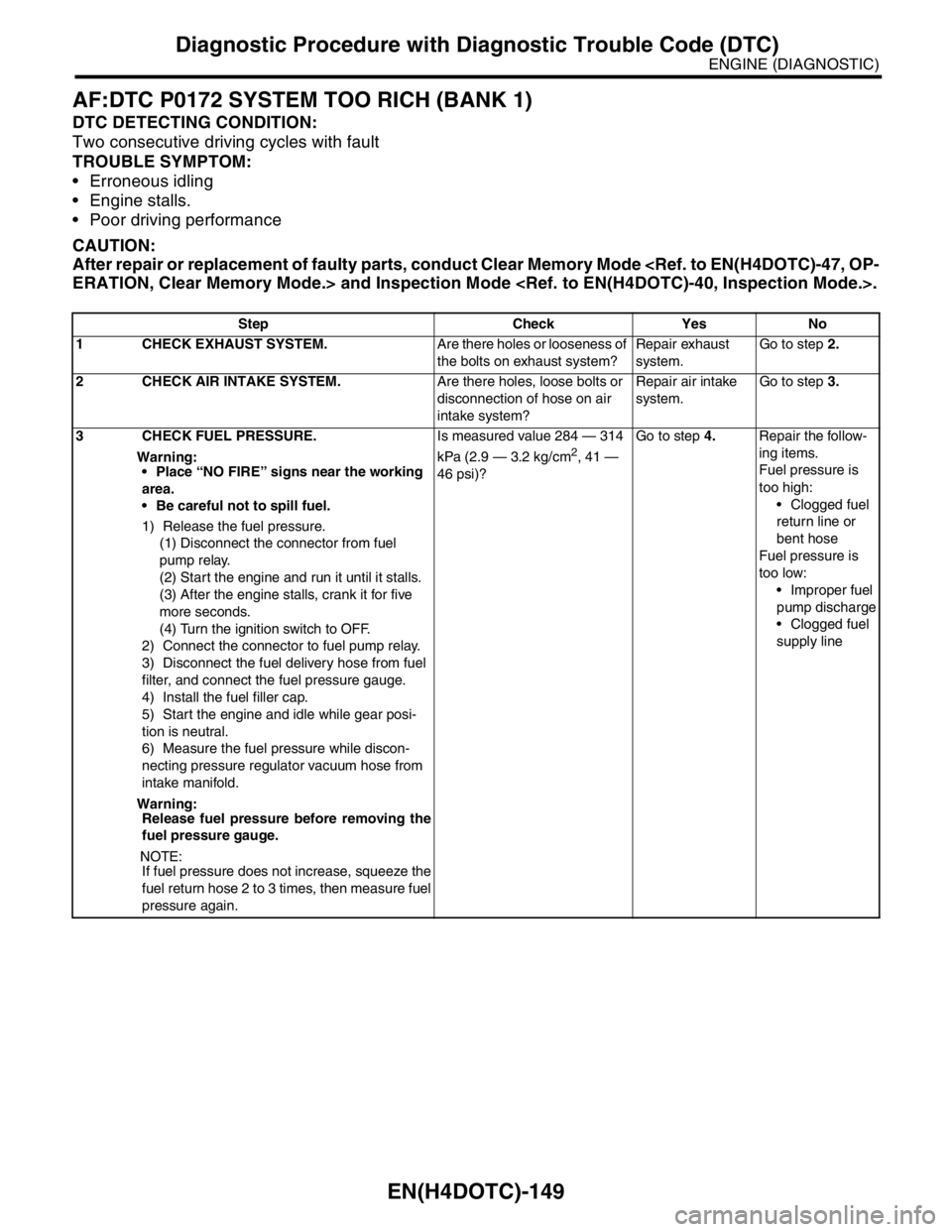

AF:DTC P0172 SYSTEM TOO RICH (BANK 1)

DTC DETECTING CONDITION:

Two consecutive driving cycles with fault

TROUBLE SYMPTOM:

Erroneous idling

Engine stalls.

Poor driving performance

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

Step Check Yes No

1 CHECK EXHAUST SYSTEM.Are there holes or looseness of

the bolts on exhaust system?Repair exhaust

system.Go to step 2.

2 CHECK AIR INTAKE SYSTEM.Are there holes, loose bolts or

disconnection of hose on air

intake system?Repair air intake

system.Go to step 3.

3 CHECK FUEL PRESSURE.

Warning:

Place “NO FIRE” signs near the working

area.

Be careful not to spill fuel.

1) Release the fuel pressure.

(1) Disconnect the connector from fuel

pump relay.

(2) Start the engine and run it until it stalls.

(3) After the engine stalls, crank it for five

more seconds.

(4) Turn the ignition switch to OFF.

2) Connect the connector to fuel pump relay.

3) Disconnect the fuel delivery hose from fuel

filter, and connect the fuel pressure gauge.

4) Install the fuel filler cap.

5) Start the engine and idle while gear posi-

tion is neutral.

6) Measure the fuel pressure while discon-

necting pressure regulator vacuum hose from

intake manifold.

Warning:

Release fuel pressure before removing the

fuel pressure gauge.

N

OTE:

If fuel pressure does not increase, squeeze the

fuel return hose 2 to 3 times, then measure fuel

pressure again.Is measured value 284 — 314

kPa (2.9 — 3.2 kg/cm

2, 41 —

46 psi)?Go to step 4.Repair the follow-

ing items.

Fuel pressure is

too high:

Clogged fuel

return line or

bent hose

Fuel pressure is

too low:

Improper fuel

pump discharge

Clogged fuel

supply line

Page 1783 of 2870

EN(H4DOTC)-150

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

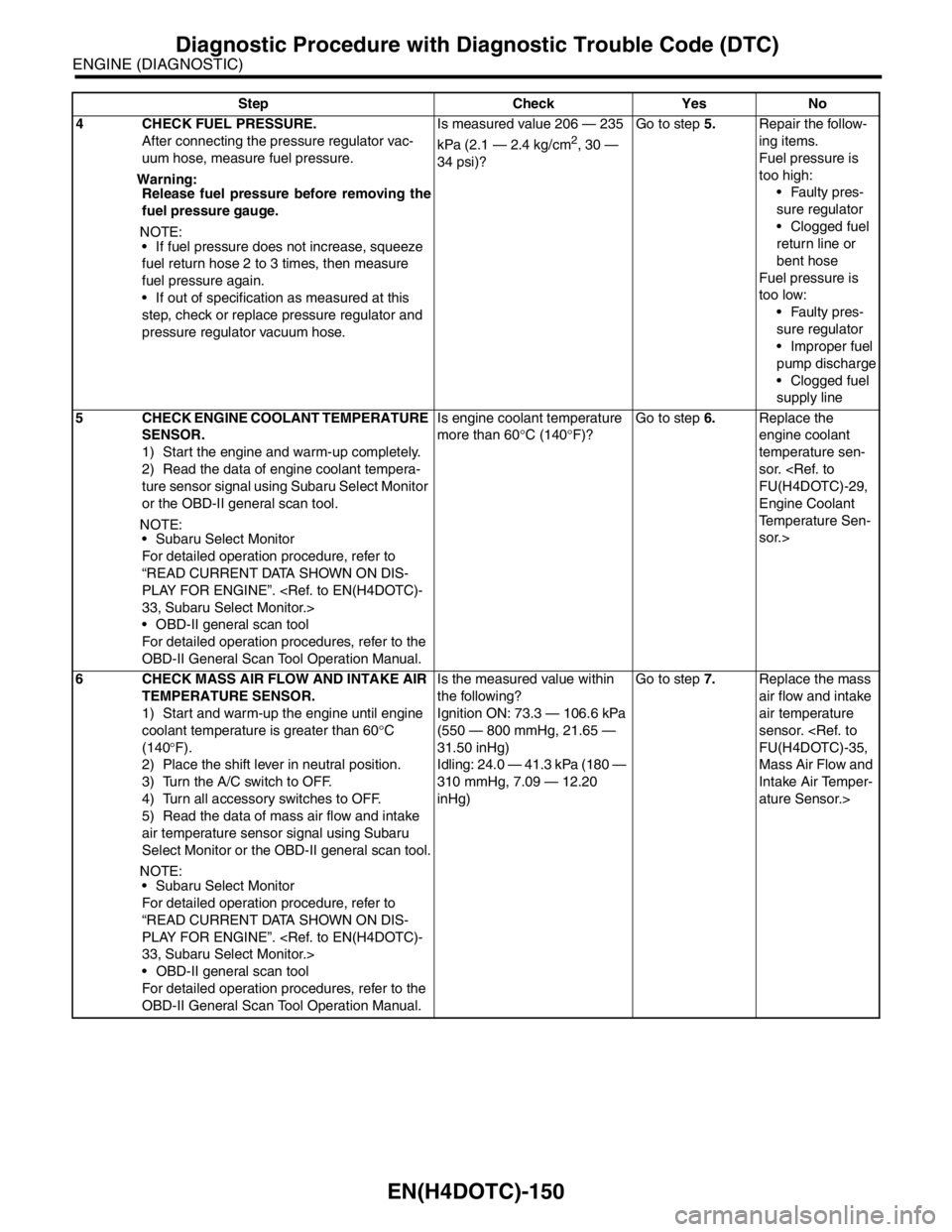

4 CHECK FUEL PRESSURE.

After connecting the pressure regulator vac-

uum hose, measure fuel pressure.

Warning:

Release fuel pressure before removing the

fuel pressure gauge.

N

OTE:

If fuel pressure does not increase, squeeze

fuel return hose 2 to 3 times, then measure

fuel pressure again.

If out of specification as measured at this

step, check or replace pressure regulator and

pressure regulator vacuum hose.Is measured value 206 — 235

kPa (2.1 — 2.4 kg/cm

2, 30 —

34 psi)?Go to step 5.Repair the follow-

ing items.

Fuel pressure is

too high:

Faulty pres-

sure regulator

Clogged fuel

return line or

bent hose

Fuel pressure is

too low:

Faulty pres-

sure regulator

Improper fuel

pump discharge

Clogged fuel

supply line

5 CHECK ENGINE COOLANT TEMPERATURE

SENSOR.

1) Start the engine and warm-up completely.

2) Read the data of engine coolant tempera-

ture sensor signal using Subaru Select Monitor

or the OBD-II general scan tool.

NOTE:

Subaru Select Monitor

For detailed operation procedure, refer to

“READ CURRENT DATA SHOWN ON DIS-

PLAY FOR ENGINE”.

OBD-II general scan tool

For detailed operation procedures, refer to the

OBD-II General Scan Tool Operation Manual.Is engine coolant temperature

more than 60°C (140°F)?Go to step 6.Replace the

engine coolant

temperature sen-

sor.

Engine Coolant

Temperature Sen-

sor.>

6 CHECK MASS AIR FLOW AND INTAKE AIR

TEMPERATURE SENSOR.

1) Start and warm-up the engine until engine

coolant temperature is greater than 60°C

(140°F).

2) Place the shift lever in neutral position.

3) Turn the A/C switch to OFF.

4) Turn all accessory switches to OFF.

5) Read the data of mass air flow and intake

air temperature sensor signal using Subaru

Select Monitor or the OBD-II general scan tool.

N

OTE:

Subaru Select Monitor

For detailed operation procedure, refer to

“READ CURRENT DATA SHOWN ON DIS-

PLAY FOR ENGINE”.

OBD-II general scan tool

For detailed operation procedures, refer to the

OBD-II General Scan Tool Operation Manual.Is the measured value within

the following?

Ignition ON: 73.3 — 106.6 kPa

(550 — 800 mmHg, 21.65 —

31.50 inHg)

Idling: 24.0 — 41.3 kPa (180 —

310 mmHg, 7.09 — 12.20

inHg)Go to step 7.Replace the mass

air flow and intake

air temperature

sensor.

Mass Air Flow and

Intake Air Temper-

ature Sensor.> Step Check Yes No

Page 1784 of 2870

EN(H4DOTC)-151

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

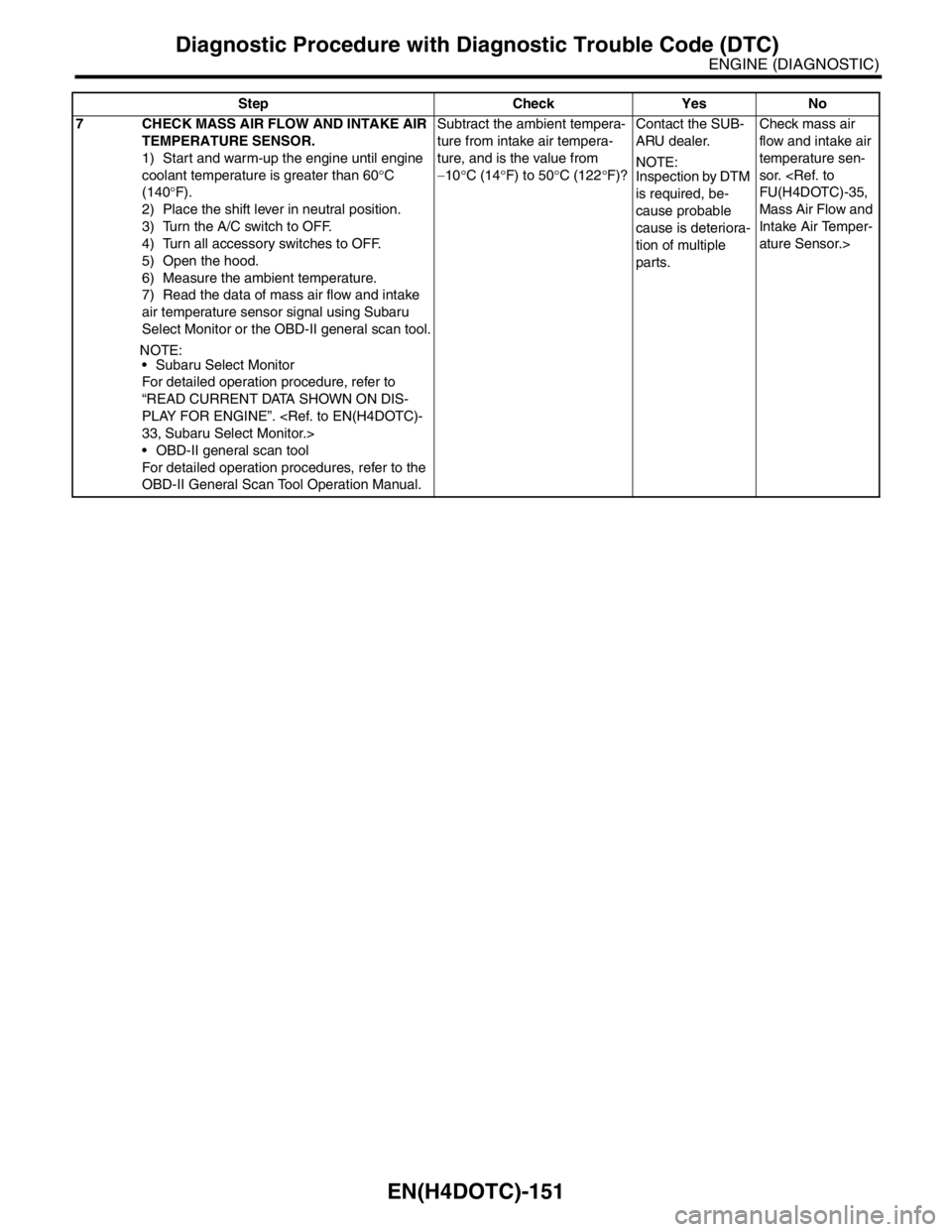

7 CHECK MASS AIR FLOW AND INTAKE AIR

TEMPERATURE SENSOR.

1) Start and warm-up the engine until engine

coolant temperature is greater than 60°C

(140°F).

2) Place the shift lever in neutral position.

3) Turn the A/C switch to OFF.

4) Turn all accessory switches to OFF.

5) Open the hood.

6) Measure the ambient temperature.

7) Read the data of mass air flow and intake

air temperature sensor signal using Subaru

Select Monitor or the OBD-II general scan tool.

N

OTE:

Subaru Select Monitor

For detailed operation procedure, refer to

“READ CURRENT DATA SHOWN ON DIS-

PLAY FOR ENGINE”.

OBD-II general scan tool

For detailed operation procedures, refer to the

OBD-II General Scan Tool Operation Manual.Subtract the ambient tempera-

ture from intake air tempera-

ture, and is the value from

−10°C (14°F) to 50°C (122°F)?Contact the SUB-

ARU dealer.

N

OTE:

Inspection by DTM

is required, be-

cause probable

cause is deteriora-

tion of multiple

parts.Check mass air

flow and intake air

temperature sen-

sor.

Mass Air Flow and

Intake Air Temper-

ature Sensor.> Step Check Yes No

Page 1785 of 2870

EN(H4DOTC)-152

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

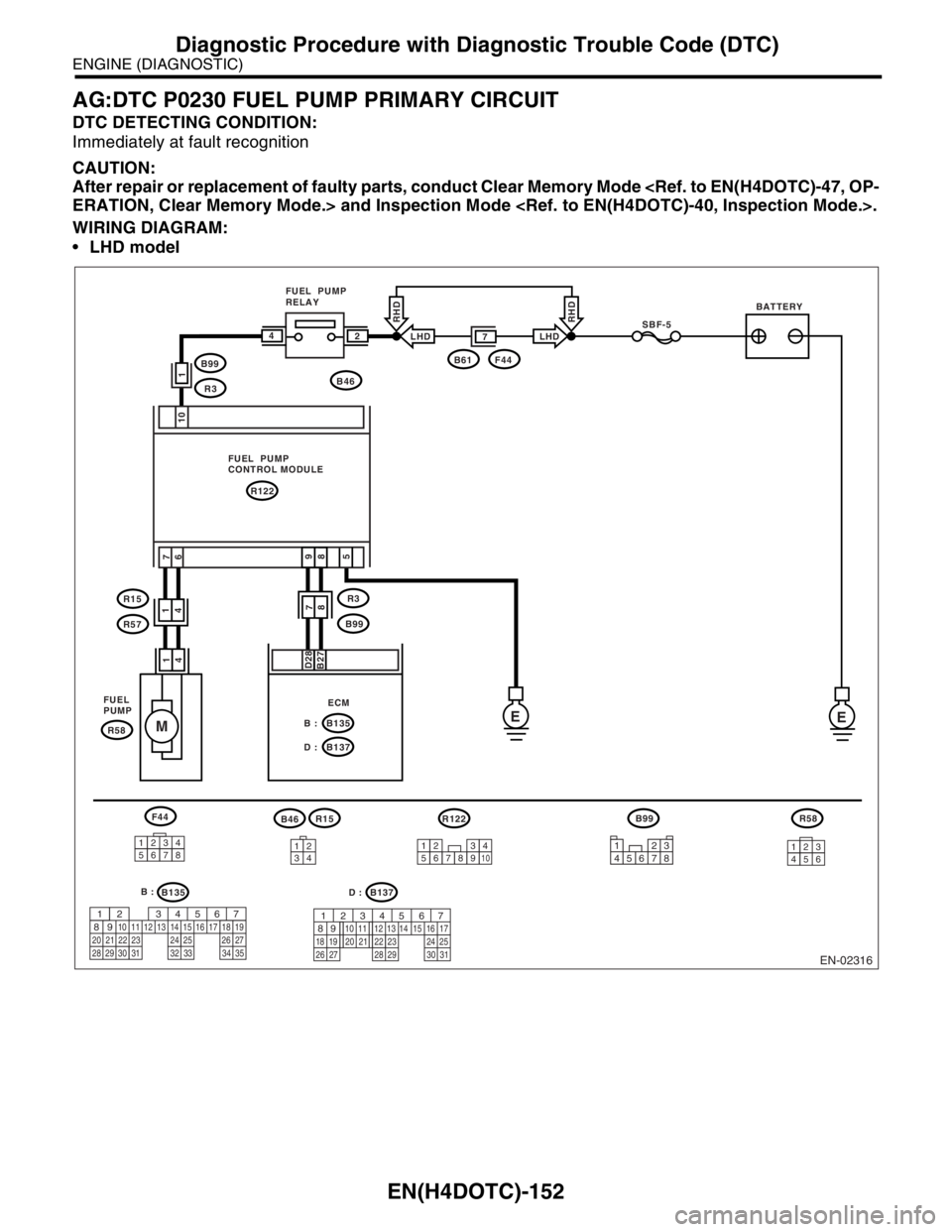

AG:DTC P0230 FUEL PUMP PRIMARY CIRCUIT

DTC DETECTING CONDITION:

Immediately at fault recognition

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

LHD model

EN-02316

F44

B135B137

B46R122

EE

M

RHDRHD 10 7

6

FUEL PUMP

RELAY

FUEL PUMP

CONTROL MODULE

FUEL

PUMP

SBF-5

B61

B46

R122

B135 B :

B137 D :

R15

R57

R58

R3

ECM

B99

B99R58

B99

R3

F44

7LHD LHDBATTERY

1

1

4

D28

B27

123456783412123456789102356

24

1

4

9

85

14

7

8

R15

567

82 1

94 310

24 22 23 2511 12 13 14 15

26 27

2816 17 18 19

20 21

29 30 31 32 33 34 35567

82 1

94 310

22 23 11 12 13 14 15

24 25

2616 17

18 19 20 21

27 28 29 30 31

123

45678

B :

D :

Page 1786 of 2870

EN(H4DOTC)-153

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

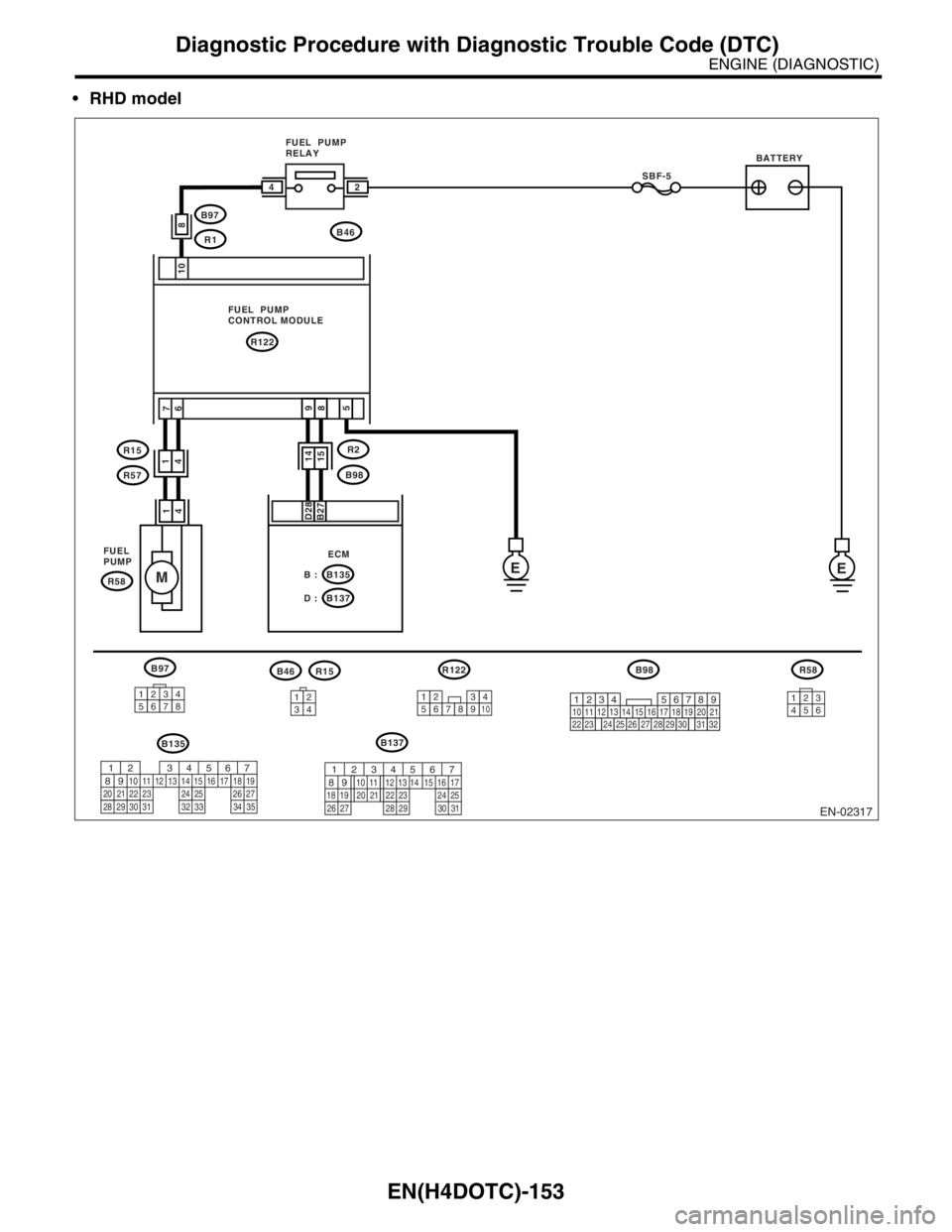

RHD model

EN-02317

B97

B135B137

R122

EE

M

10 7

6

FUEL PUMP

RELAY

FUEL PUMP

CONTROL MODULE

FUEL

PUMP

SBF-5

B46

R122

B135 B :

B137 D :

R15

R57

R58

R2

ECM

B98

B98R58

B97

R1

BATTERY

8

1

4

D28

B27

123456783412123456789102356

24

1

4

9

85

14

14

15

219

32

1234

5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

25

567

82 1

94 310

24 22 23 2511 12 13 14 15

26 27

2816 17 18 19

20 21

29 30 31 32 33 34 35567

82 1

94 310

22 23 11 12 13 14 15

24 25

2616 17

18 19 20 21

27 28 29 30 31

B46R15

Page 1787 of 2870

EN(H4DOTC)-154

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

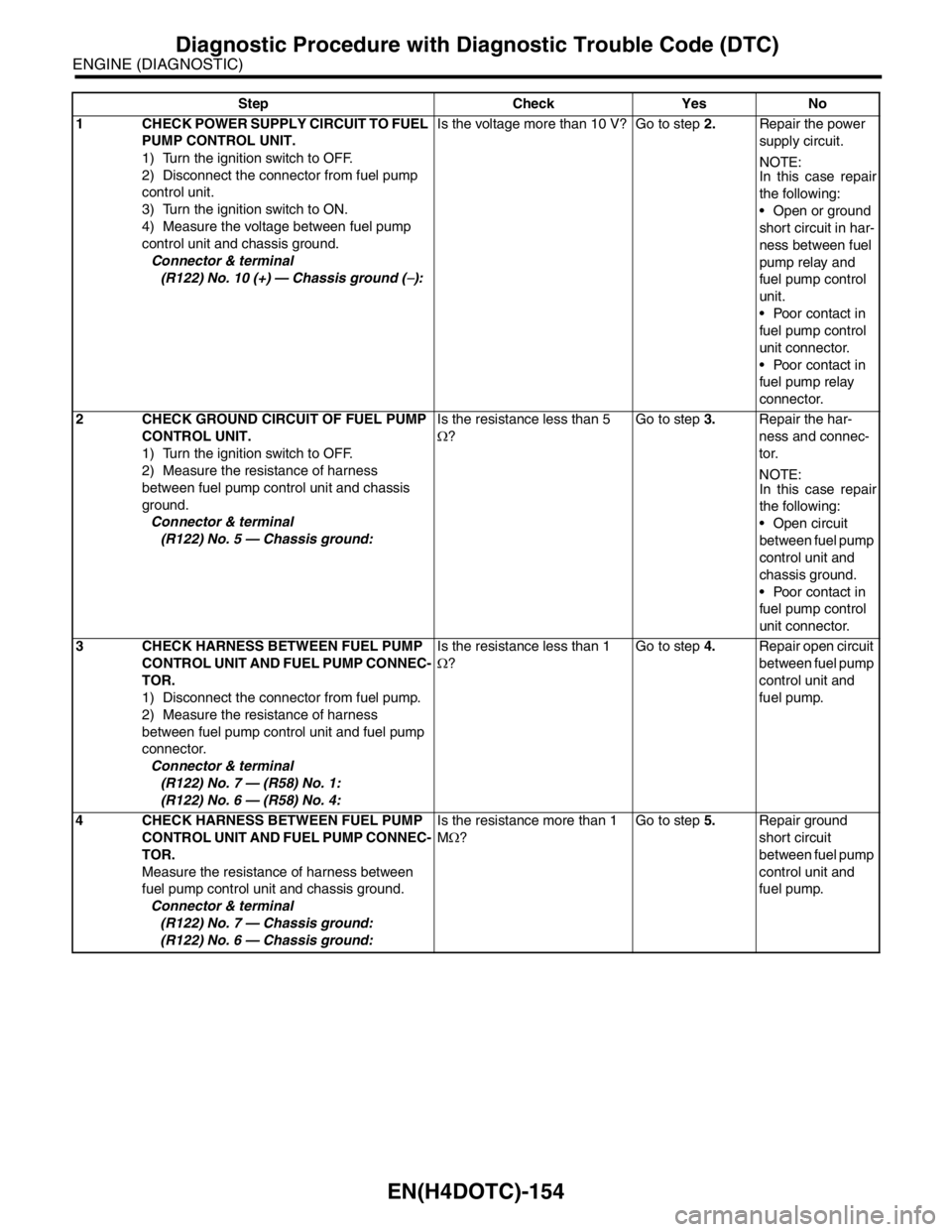

Step Check Yes No

1 CHECK POWER SUPPLY CIRCUIT TO FUEL

PUMP CONTROL UNIT.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from fuel pump

control unit.

3) Turn the ignition switch to ON.

4) Measure the voltage between fuel pump

control unit and chassis ground.

Connector & terminal

(R122) No. 10 (+) — Chassis ground (

−):Is the voltage more than 10 V? Go to step 2.Repair the power

supply circuit.

N

OTE:

In this case repair

the following:

Open or ground

short circuit in har-

ness between fuel

pump relay and

fuel pump control

unit.

Poor contact in

fuel pump control

unit connector.

Poor contact in

fuel pump relay

connector.

2 CHECK GROUND CIRCUIT OF FUEL PUMP

CONTROL UNIT.

1) Turn the ignition switch to OFF.

2) Measure the resistance of harness

between fuel pump control unit and chassis

ground.

Connector & terminal

(R122) No. 5 — Chassis ground:Is the resistance less than 5

Ω?Go to step 3.Repair the har-

ness and connec-

tor.

N

OTE:

In this case repair

the following:

Open circuit

between fuel pump

control unit and

chassis ground.

Poor contact in

fuel pump control

unit connector.

3 CHECK HARNESS BETWEEN FUEL PUMP

CONTROL UNIT AND FUEL PUMP CONNEC-

TOR.

1) Disconnect the connector from fuel pump.

2) Measure the resistance of harness

between fuel pump control unit and fuel pump

connector.

Connector & terminal

(R122) No. 7 — (R58) No. 1:

(R122) No. 6 — (R58) No. 4:Is the resistance less than 1

Ω?Go to step 4.Repair open circuit

between fuel pump

control unit and

fuel pump.

4 CHECK HARNESS BETWEEN FUEL PUMP

CONTROL UNIT AND FUEL PUMP CONNEC-

TOR.

Measure the resistance of harness between

fuel pump control unit and chassis ground.

Connector & terminal

(R122) No. 7 — Chassis ground:

(R122) No. 6 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 5.Repair ground

short circuit

between fuel pump

control unit and

fuel pump.

Page 1788 of 2870

EN(H4DOTC)-155

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

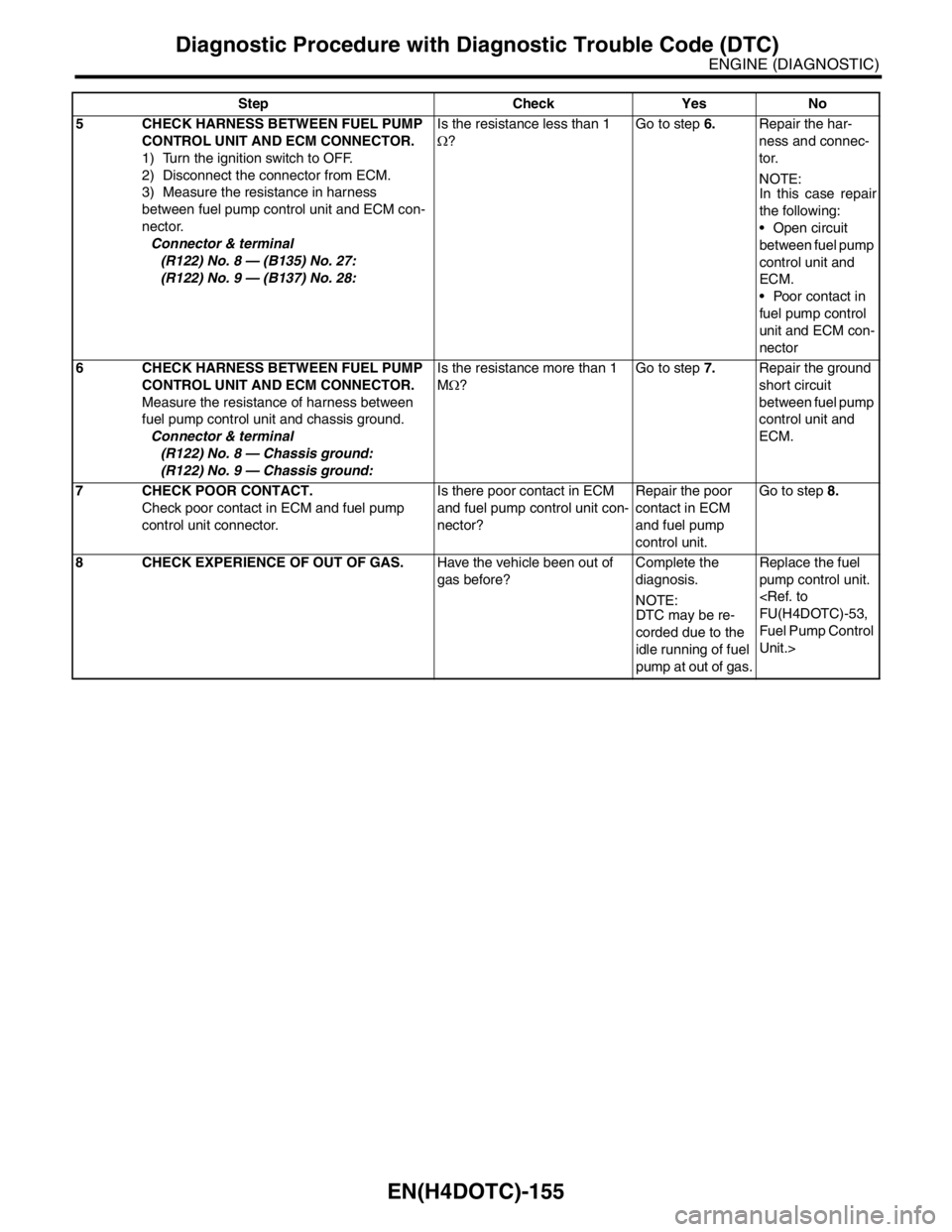

5 CHECK HARNESS BETWEEN FUEL PUMP

CONTROL UNIT AND ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM.

3) Measure the resistance in harness

between fuel pump control unit and ECM con-

nector.

Connector & terminal

(R122) No. 8 — (B135) No. 27:

(R122) No. 9 — (B137) No. 28:Is the resistance less than 1

Ω?Go to step 6.Repair the har-

ness and connec-

tor.

N

OTE:

In this case repair

the following:

Open circuit

between fuel pump

control unit and

ECM.

Poor contact in

fuel pump control

unit and ECM con-

nector

6 CHECK HARNESS BETWEEN FUEL PUMP

CONTROL UNIT AND ECM CONNECTOR.

Measure the resistance of harness between

fuel pump control unit and chassis ground.

Connector & terminal

(R122) No. 8 — Chassis ground:

(R122) No. 9 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 7.Repair the ground

short circuit

between fuel pump

control unit and

ECM.

7 CHECK POOR CONTACT.

Check poor contact in ECM and fuel pump

control unit connector.Is there poor contact in ECM

and fuel pump control unit con-

nector?Repair the poor

contact in ECM

and fuel pump

control unit.Go to step 8.

8 CHECK EXPERIENCE OF OUT OF GAS.Have the vehicle been out of

gas before?Complete the

diagnosis.

N

OTE:

DTC may be re-

corded due to the

idle running of fuel

pump at out of gas.Replace the fuel

pump control unit.

Fuel Pump Control

Unit.> Step Check Yes No

Page 1789 of 2870

EN(H4DOTC)-156

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

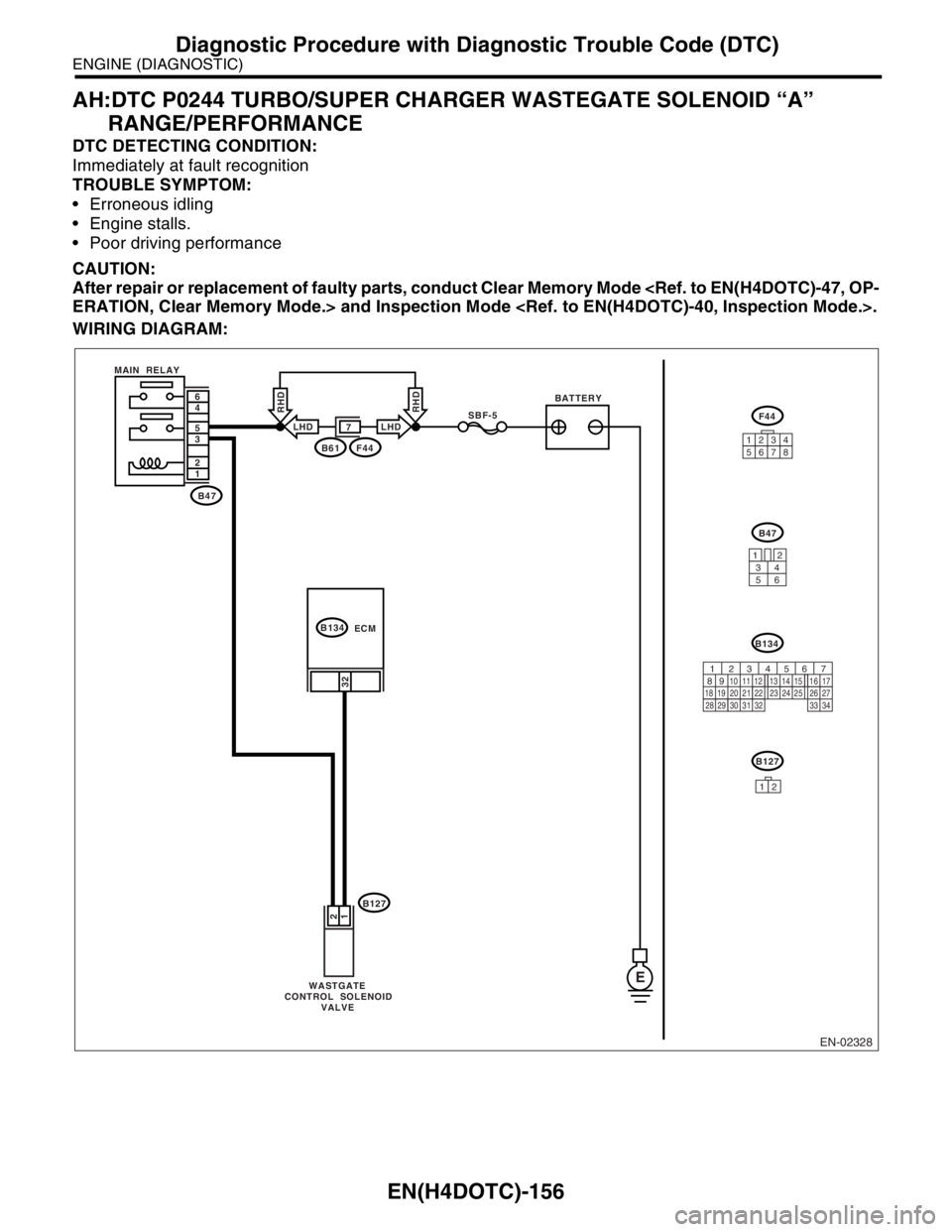

AH:DTC P0244 TURBO/SUPER CHARGER WASTEGATE SOLENOID “A”

RANGE/PERFORMANCE

DTC DETECTING CONDITION:

Immediately at fault recognition

TROUBLE SYMPTOM:

Erroneous idling

Engine stalls.

Poor driving performance

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-02328

MAIN RELAY

B47 1 2 3 5 4 6

BATTERY

E

B61F44

F44

B47

B134

B127

B134

B127

WASTGATE

CONTROL SOLENOID

VALVEECM

32 1 2

7LHD

RHD

LHD

RHDSBF-5

12345678

3412

56

12

56 7

82 1

94 310

24 22 23 25 11 12 13 14 15

26 27

2816 17

18 19 20 21

33 34 29

32 30 31

Page 1790 of 2870

EN(H4DOTC)-157

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

Step Check Yes No

1 CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Inspect the rele-

vant DTC using

“List of Diagnostic

Trouble Code

(DTC)”.

List of Diagnostic

Trouble Code

(DTC).>

N

OTE:

In this case, it is

not necessary to

inspect DTC

P0244.Replace the

wastegate control

solenoid valve.

Wastegate Con-

trol Solenoid Valve

Assembly.>