SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1831 of 2870

EN(H4DOTC)-198

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

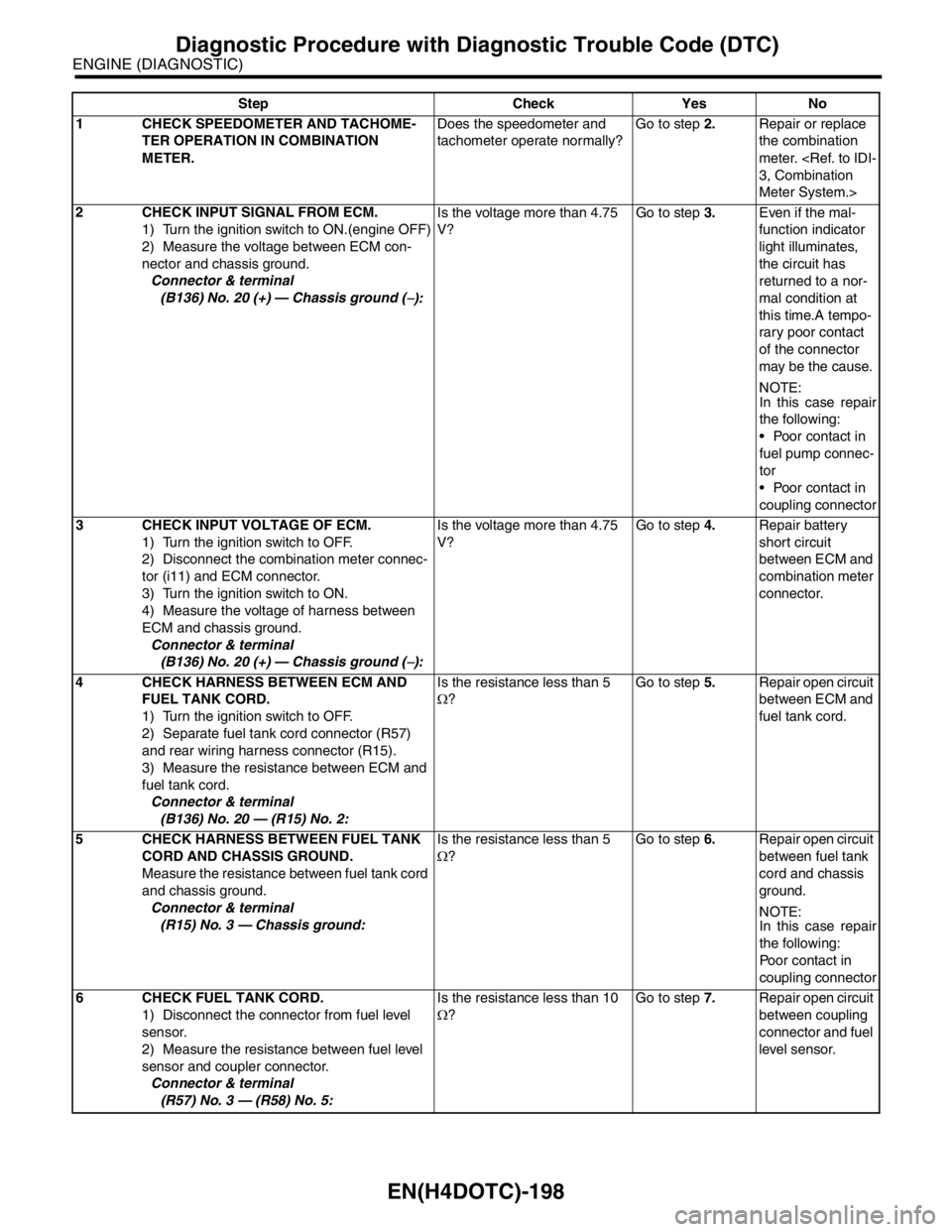

Step Check Yes No

1 CHECK SPEEDOMETER AND TACHOME-

TER OPERATION IN COMBINATION

METER.Does the speedometer and

tachometer operate normally?Go to step 2.Repair or replace

the combination

meter.

Meter System.>

2 CHECK INPUT SIGNAL FROM ECM.

1) Turn the ignition switch to ON.(engine OFF)

2) Measure the voltage between ECM con-

nector and chassis ground.

Connector & terminal

(B136) No. 20 (+) — Chassis ground (

−):Is the voltage more than 4.75

V?Go to step 3.Even if the mal-

function indicator

light illuminates,

the circuit has

returned to a nor-

mal condition at

this time.A tempo-

rary poor contact

of the connector

may be the cause.

N

OTE:

In this case repair

the following:

Poor contact in

fuel pump connec-

tor

Poor contact in

coupling connector

3 CHECK INPUT VOLTAGE OF ECM.

1) Turn the ignition switch to OFF.

2) Disconnect the combination meter connec-

tor (i11) and ECM connector.

3) Turn the ignition switch to ON.

4) Measure the voltage of harness between

ECM and chassis ground.

Connector & terminal

(B136) No. 20 (+) — Chassis ground (

−):Is the voltage more than 4.75

V?Go to step 4.Repair battery

short circuit

between ECM and

combination meter

connector.

4 CHECK HARNESS BETWEEN ECM AND

FUEL TANK CORD.

1) Turn the ignition switch to OFF.

2) Separate fuel tank cord connector (R57)

and rear wiring harness connector (R15).

3) Measure the resistance between ECM and

fuel tank cord.

Connector & terminal

(B136) No. 20 — (R15) No. 2:Is the resistance less than 5

Ω?Go to step 5.Repair open circuit

between ECM and

fuel tank cord.

5 CHECK HARNESS BETWEEN FUEL TANK

CORD AND CHASSIS GROUND.

Measure the resistance between fuel tank cord

and chassis ground.

Connector & terminal

(R15) No. 3 — Chassis ground:Is the resistance less than 5

Ω?Go to step 6.Repair open circuit

between fuel tank

cord and chassis

ground.

N

OTE:

In this case repair

the following:

Poor contact in

coupling connector

6 CHECK FUEL TANK CORD.

1) Disconnect the connector from fuel level

sensor.

2) Measure the resistance between fuel level

sensor and coupler connector.

Connector & terminal

(R57) No. 3 — (R58) No. 5:Is the resistance less than 10

Ω?Go to step 7.Repair open circuit

between coupling

connector and fuel

level sensor.

Page 1832 of 2870

EN(H4DOTC)-199

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

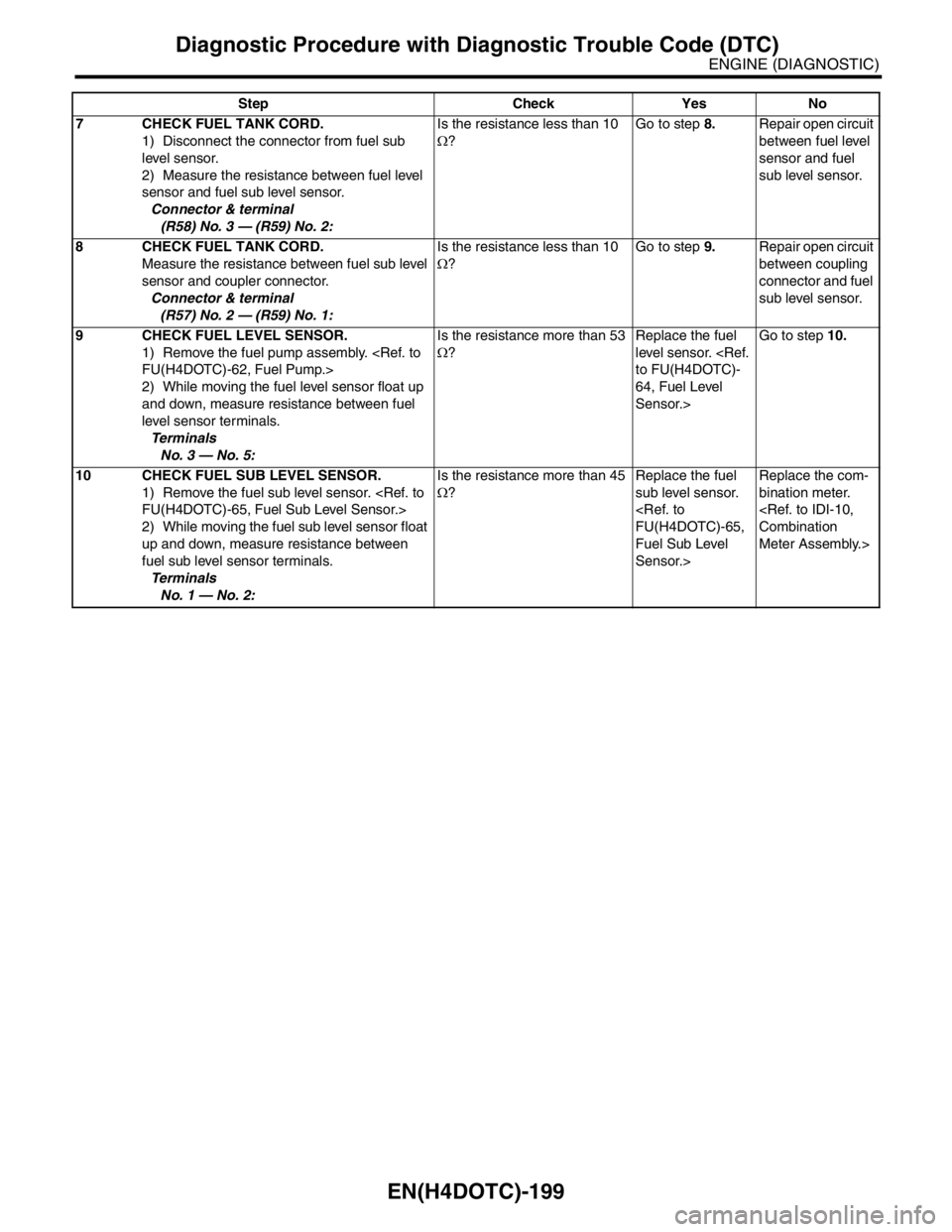

7 CHECK FUEL TANK CORD.

1) Disconnect the connector from fuel sub

level sensor.

2) Measure the resistance between fuel level

sensor and fuel sub level sensor.

Connector & terminal

(R58) No. 3 — (R59) No. 2:Is the resistance less than 10

Ω?Go to step 8.Repair open circuit

between fuel level

sensor and fuel

sub level sensor.

8 CHECK FUEL TANK CORD.

Measure the resistance between fuel sub level

sensor and coupler connector.

Connector & terminal

(R57) No. 2 — (R59) No. 1:Is the resistance less than 10

Ω?Go to step 9.Repair open circuit

between coupling

connector and fuel

sub level sensor.

9 CHECK FUEL LEVEL SENSOR.

1) Remove the fuel pump assembly.

2) While moving the fuel level sensor float up

and down, measure resistance between fuel

level sensor terminals.

Te r m i n a l s

No. 3 — No. 5:Is the resistance more than 53

Ω?Replace the fuel

level sensor.

64, Fuel Level

Sensor.>Go to step 10.

10 CHECK FUEL SUB LEVEL SENSOR.

1) Remove the fuel sub level sensor.

2) While moving the fuel sub level sensor float

up and down, measure resistance between

fuel sub level sensor terminals.

Te r m i n a l s

No. 1 — No. 2:Is the resistance more than 45

Ω?Replace the fuel

sub level sensor.

Fuel Sub Level

Sensor.>Replace the com-

bination meter.

Meter Assembly.> Step Check Yes No

Page 1833 of 2870

EN(H4DOTC)-200

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

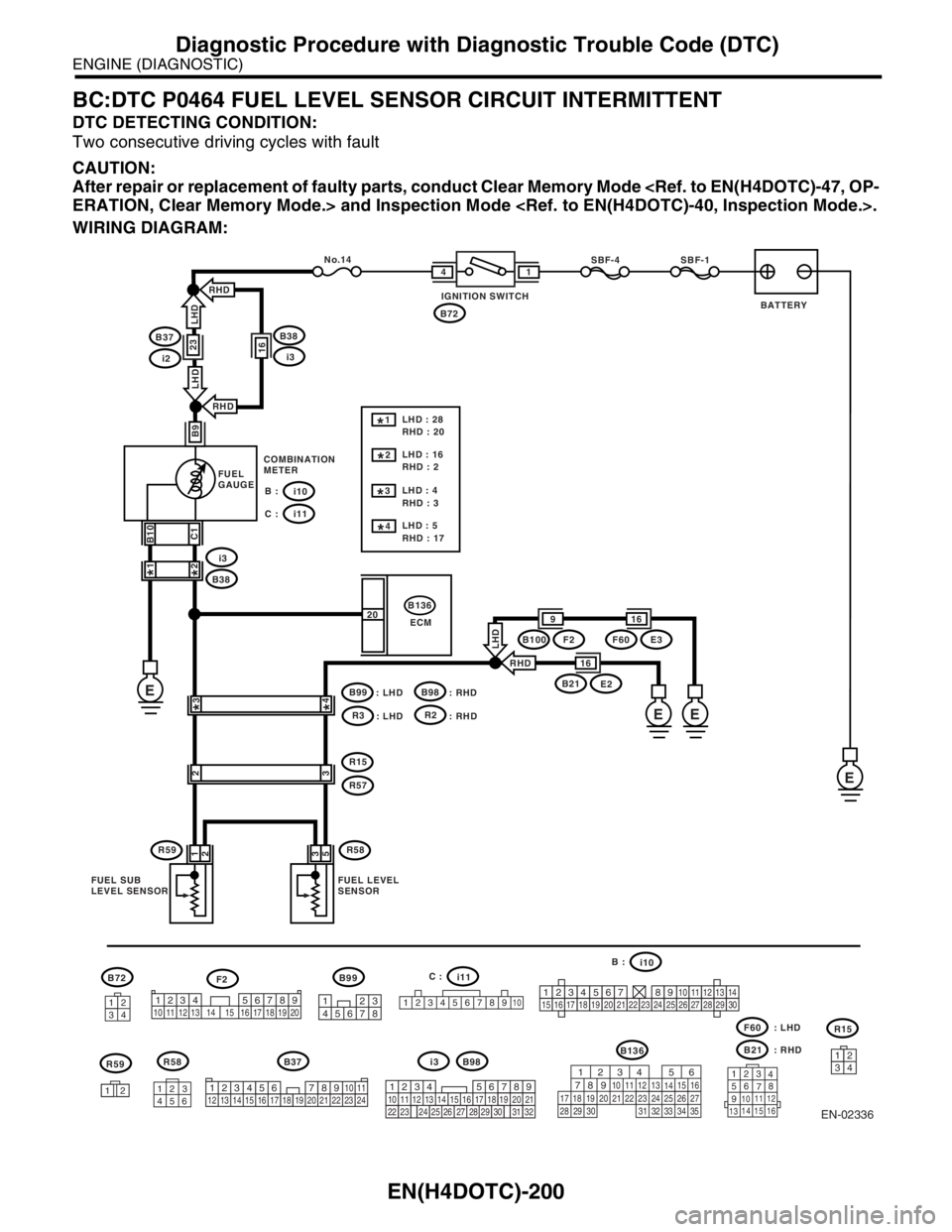

BC:DTC P0464 FUEL LEVEL SENSOR CIRCUIT INTERMITTENT

DTC DETECTING CONDITION:

Two consecutive driving cycles with fault

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

B72

R59R58

F60 : LHD

B21 : RHD

i10

B136

i11

1

23456789

10

R15

B136

ECM

i10

B38

B100F2F60E3

E2

B99

R3

i3

EE

E

RHD

RHD

LHD

FUEL

GAUGE

B :

i11 C :

C : B : COMBINATION

METER

B9 B10

C1

3*

*4

R15

R59

FUEL SUB

LEVEL SENSOR

R572

1

2R583

53

FUEL LEVEL

SENSOR

9

B21

16

16 20

3412

1213

4562123

4

56

78

9

1011 12

1314 15 16

F2LHD : 28

RHD : 20

LHD : 16

RHD : 2

*1

*2

LHD : 4

RHD : 3

LHD : 5

RHD : 17*3

*4

EN-02336

3412i3B98B37

B99

56

782 1

94 310

24 22 23 2511 12 13

1415

26 27

2816

17 18 19 20 21

33 34 29

32 30

31 35

1234567891011121314151617181920212223242526272829301234 5678910 11 12 13 14 15 16 17 18 19 20123

45678

219

32

1234 5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

2534

12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 2456 7

: LHDB98

: RHD

: LHD

R2

: RHD

1*2*

B37

i223

IGNITION SWITCH

SBF-4SBF-1

B72

14

E

No.14

RHD

B38

i316

LHD

LHD

RHDBATTERY

Page 1834 of 2870

EN(H4DOTC)-201

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

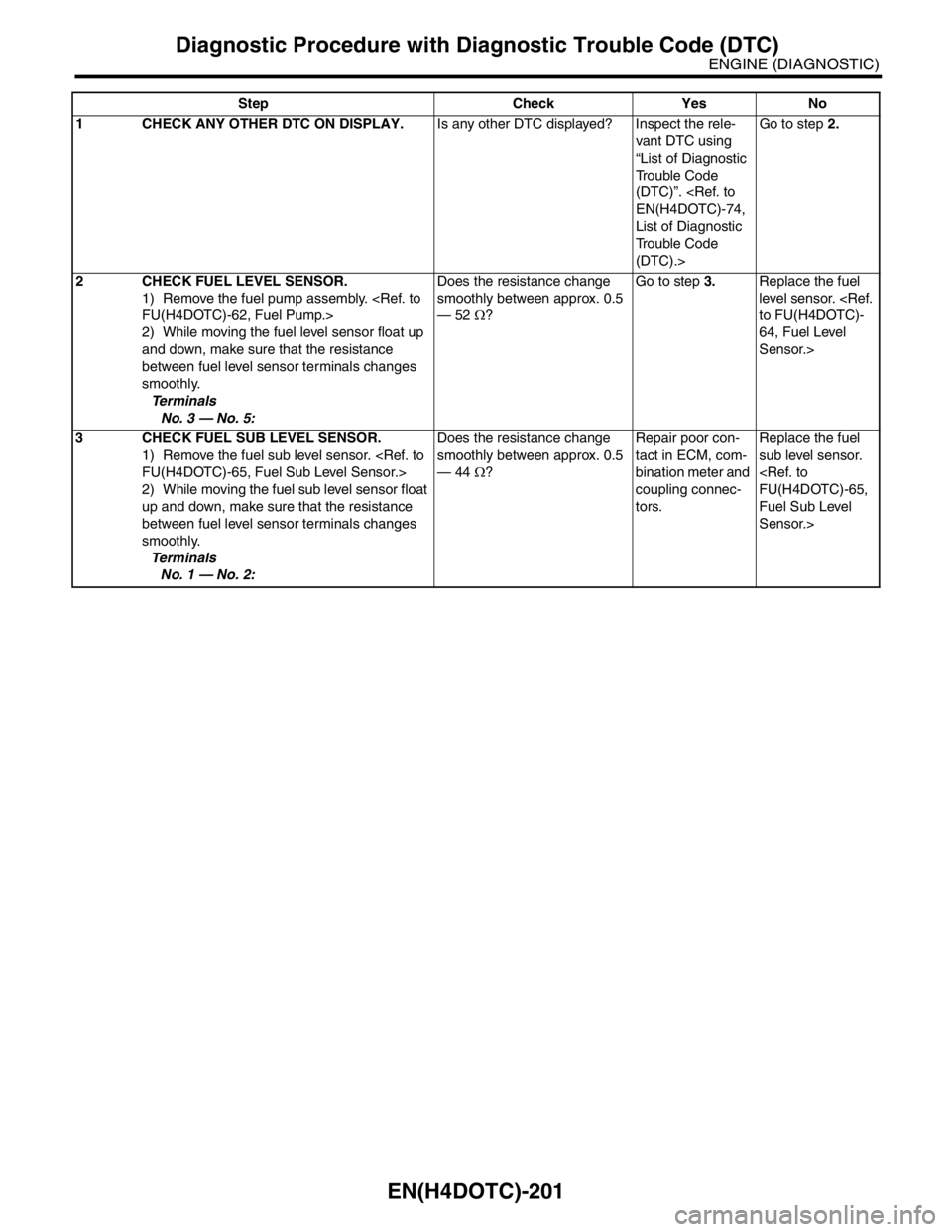

Step Check Yes No

1 CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Inspect the rele-

vant DTC using

“List of Diagnostic

Trouble Code

(DTC)”.

List of Diagnostic

Trouble Code

(DTC).>Go to step 2.

2 CHECK FUEL LEVEL SENSOR.

1) Remove the fuel pump assembly.

2) While moving the fuel level sensor float up

and down, make sure that the resistance

between fuel level sensor terminals changes

smoothly.

Te r m i n a l s

No. 3 — No. 5:Does the resistance change

smoothly between approx. 0.5

— 52 Ω?Go to step 3.Replace the fuel

level sensor.

64, Fuel Level

Sensor.>

3 CHECK FUEL SUB LEVEL SENSOR.

1) Remove the fuel sub level sensor.

2) While moving the fuel sub level sensor float

up and down, make sure that the resistance

between fuel level sensor terminals changes

smoothly.

Te r m i n a l s

No. 1 — No. 2: Does the resistance change

smoothly between approx. 0.5

— 44 Ω?Repair poor con-

tact in ECM, com-

bination meter and

coupling connec-

tors.Replace the fuel

sub level sensor.

Fuel Sub Level

Sensor.>

Page 1835 of 2870

EN(H4DOTC)-202

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

BD:DTC P0483 COOLING FAN RATIONALITY CHECK

DTC DETECTING CONDITION:

Two consecutive driving cycles with fault

TROUBLE SYMPTOM:

Occurrence of noise

Over-heating

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

NOTE:

If the vehicle, with the engine idling, is placed very close to a wall or another vehicle, preventing normal cool-

ing function, the OBD system may detect malfunction.

Page 1836 of 2870

EN(H4DOTC)-203

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

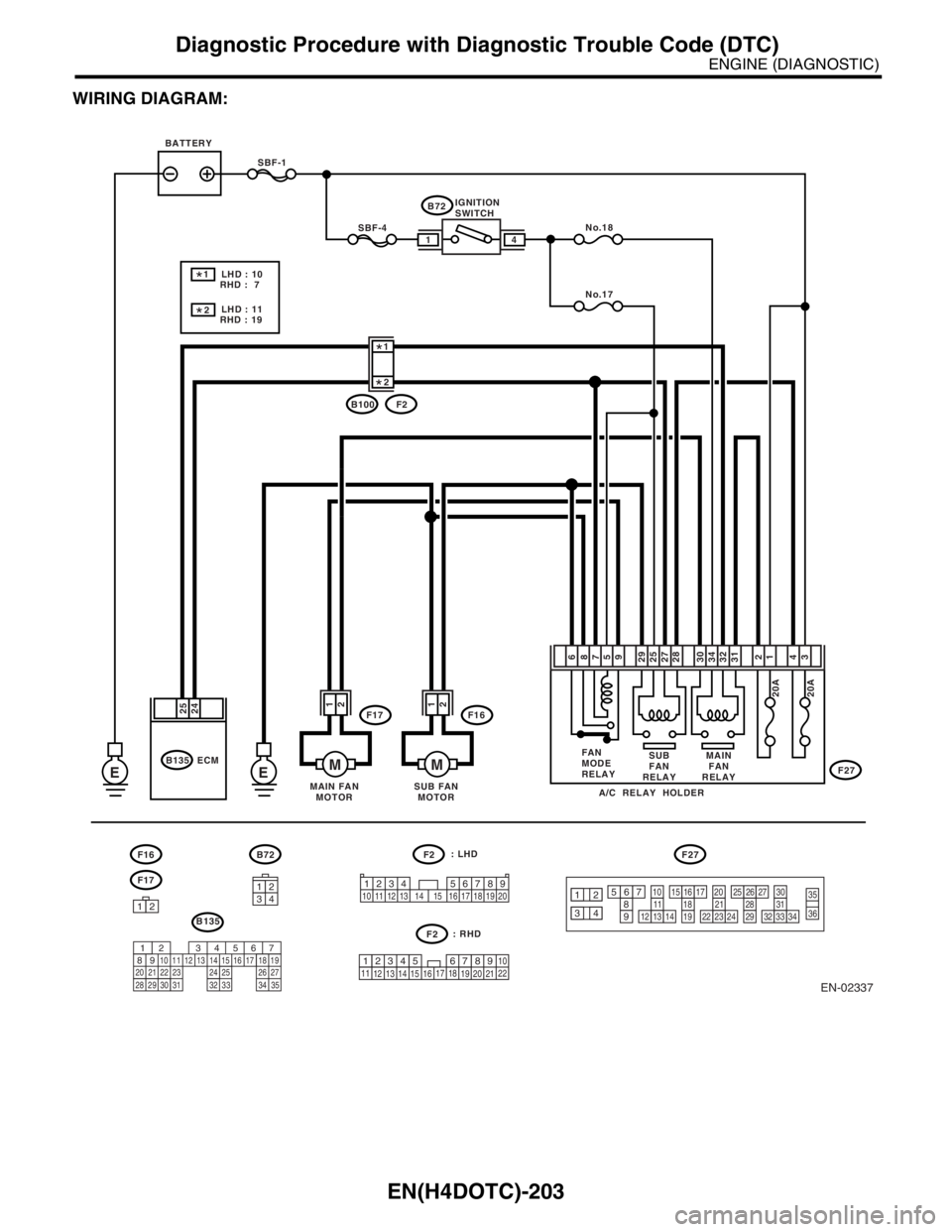

WIRING DIAGRAM:

EN-02337

No.18

No.17

EE

SBF-4

SBF-1

F17

B135 ECM

25

24F16

F16B72F2F27

F17

3412

1

2

SUB FAN

MOTOR

M

1

2

MAIN FAN

MOTOR

M

BATTERY

IGNITION

SWITCHB72

41

1234 5678910 11 12 13 14 15 16 17 18 19 203132333435

36

56789

1011121314

1516171819

2021222324

2526272829

1230

34

20A

F27 FAN

MODE

RELAY

A/C RELAY HOLDER

MAIN

FAN

RELAY SUB

FAN

RELAY

20A

29

25

27

28

30

34

32

317

5

9

2

1

4

3 8 6

B100F2

12B135

567

82 1

94 310

24 22 23 2511 12 13 14 15

26 27

2816 17 18 19

20 21

29 30 31 32 33 34 35

LHD : 10

RHD : 7

LHD : 11

RHD : 19 *

*1

2

*1

*2

: LHD

: RHD

F2

12345 678910

11

1219 20 21

13 14 15 1617

18 22

Page 1837 of 2870

EN(H4DOTC)-204

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

Step Check Yes No

1 CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Inspect the rele-

vant DTC using

“List of Diagnostic

Trouble Code

(DTC)”.

List of Diagnostic

Trouble Code

(DTC).>Check the radiator

fan, fan motor and

thermostat and

replace the ther-

mostat when it is

stuck.

Radiator Main Fan

and Fan Motor.>

Radiator Sub Fan

and Fan Motor.>

Page 1838 of 2870

EN(H4DOTC)-205

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

BE:DTC P0502 VEHICLE SPEED SENSOR CIRCUIT LOW INPUT

DTC DETECTING CONDITION:

Immediately at fault recognition

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-02338

E

i10

B135

B2259 10

No.5

: RHD

B21

F60

: LHD

: RHD

123

4

56

78

9

1011 12

1314 15 16

F2B17

i10i2B37

12

i3B38

7

E

F2

B100

B17

B21

E3

F60

9 LHD LHD

B135

26

No.17

: LHD

RHD

RHD

23

161

1B56ATMT

RHD

RHD

LHD LHD18

B37

i3

1234567891011121314151617181920212223242526272829301234 5678910 11 12 13 14 15 16 17 18 19 203412

567

82 1

94 310

24 22 23 2511 12 13 14 15

26 27

2816 17 18 19

20 21

29 30 31 32 33 34 35

B56

567

82 1

94 310

22 23 11 12 13 14 15

24 25

2616 17

18 19 20 21

27 28 29 30 3134

12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 2456 7219

32

1234

5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

25

: RHDE2

: LHD

RELAY BLOCK (BLACK)

10111213

1415161718

1920212223

2425262728

2930313233

3435363738

12

934

56

78

B225 BATTERY IGNITION

RELAY

COMBINATION

METERVEHICLE

SPEED

SENSOR

ECM TCM

Page 1839 of 2870

EN(H4DOTC)-206

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

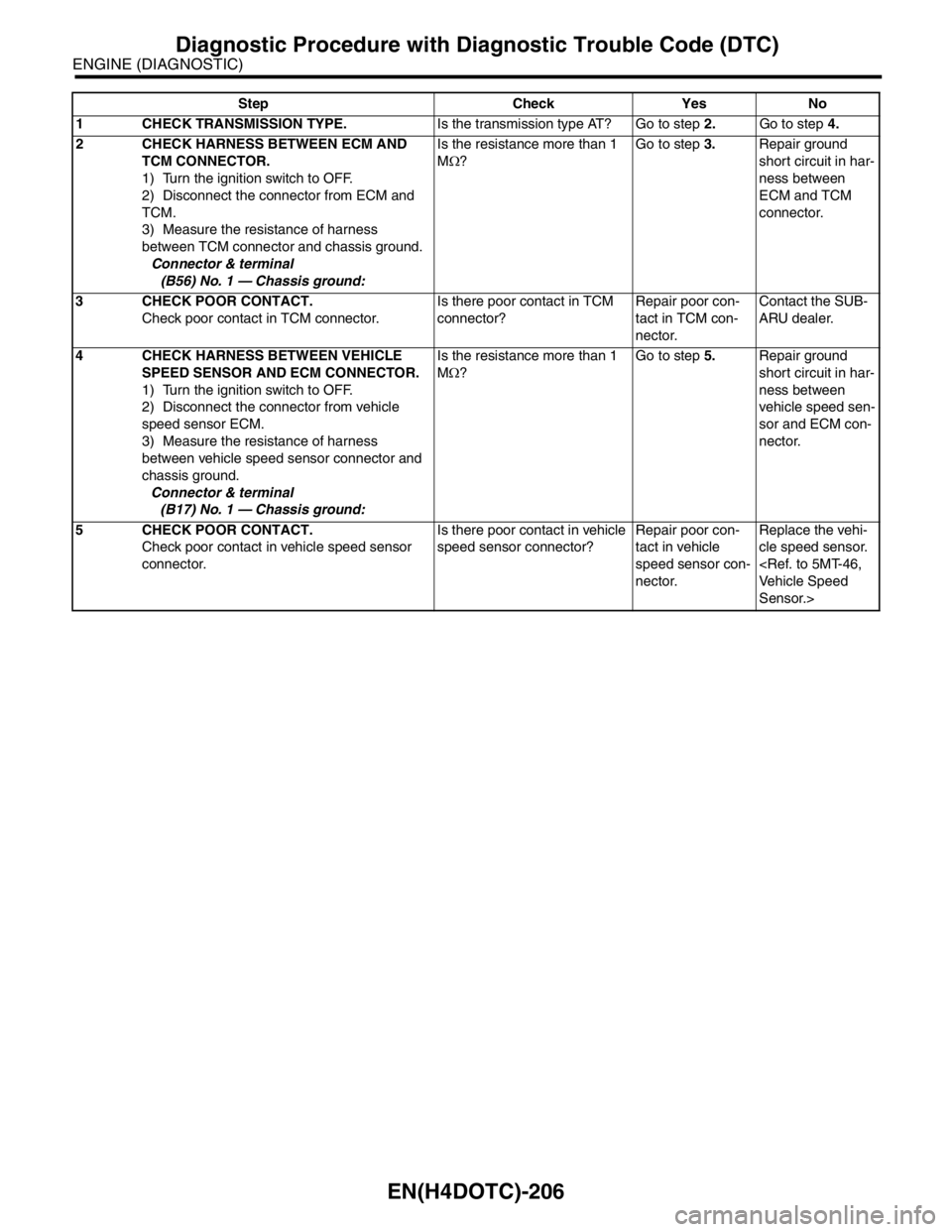

Step Check Yes No

1 CHECK TRANSMISSION TYPE.Is the transmission type AT? Go to step 2.Go to step 4.

2 CHECK HARNESS BETWEEN ECM AND

TCM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM and

TCM.

3) Measure the resistance of harness

between TCM connector and chassis ground.

Connector & terminal

(B56) No. 1 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 3.Repair ground

short circuit in har-

ness between

ECM and TCM

connector.

3 CHECK POOR CONTACT.

Check poor contact in TCM connector.Is there poor contact in TCM

connector?Repair poor con-

tact in TCM con-

nector.Contact the SUB-

ARU dealer.

4 CHECK HARNESS BETWEEN VEHICLE

SPEED SENSOR AND ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from vehicle

speed sensor ECM.

3) Measure the resistance of harness

between vehicle speed sensor connector and

chassis ground.

Connector & terminal

(B17) No. 1 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 5.Repair ground

short circuit in har-

ness between

vehicle speed sen-

sor and ECM con-

nector.

5 CHECK POOR CONTACT.

Check poor contact in vehicle speed sensor

connector.Is there poor contact in vehicle

speed sensor connector?Repair poor con-

tact in vehicle

speed sensor con-

nector.Replace the vehi-

cle speed sensor.

Sensor.>

Page 1840 of 2870

EN(H4DOTC)-207

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

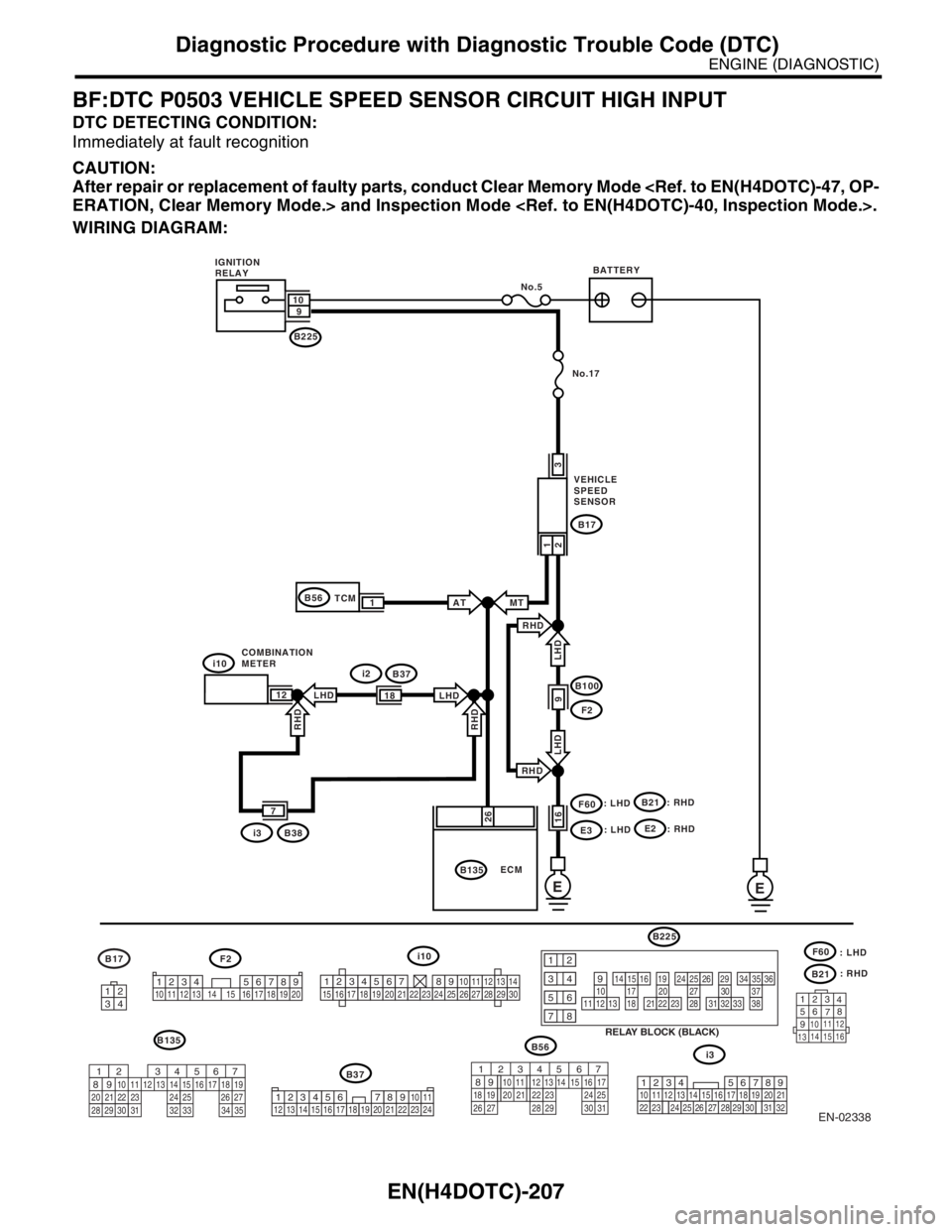

BF:DTC P0503 VEHICLE SPEED SENSOR CIRCUIT HIGH INPUT

DTC DETECTING CONDITION:

Immediately at fault recognition

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-02338

E

i10

B135

B2259 10

No.5

: RHD

B21

F60

: LHD

: RHD

123

4

56

78

9

1011 12

1314 15 16

F2B17

i10i2B37

12

i3B38

7

E

F2

B100

B17

B21

E3

F60

9 LHD LHD

B135

26

No.17

: LHD

RHD

RHD

23

161

1B56ATMT

RHD

RHD

LHD LHD18

B37

i3

1234567891011121314151617181920212223242526272829301234 5678910 11 12 13 14 15 16 17 18 19 203412

567

82 1

94 310

24 22 23 2511 12 13 14 15

26 27

2816 17 18 19

20 21

29 30 31 32 33 34 35

B56

567

82 1

94 310

22 23 11 12 13 14 15

24 25

2616 17

18 19 20 21

27 28 29 30 3134

12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 2456 7219

32

1234

5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

25

: RHDE2

: LHD

RELAY BLOCK (BLACK)

10111213

1415161718

1920212223

2425262728

2930313233

3435363738

12

934

56

78

B225 BATTERY IGNITION

RELAY

COMBINATION

METERVEHICLE

SPEED

SENSOR

ECM TCM