SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2281 of 2870

EN(H4DOTC 2.5)-257

ENGINE (DIAGNOSTIC)

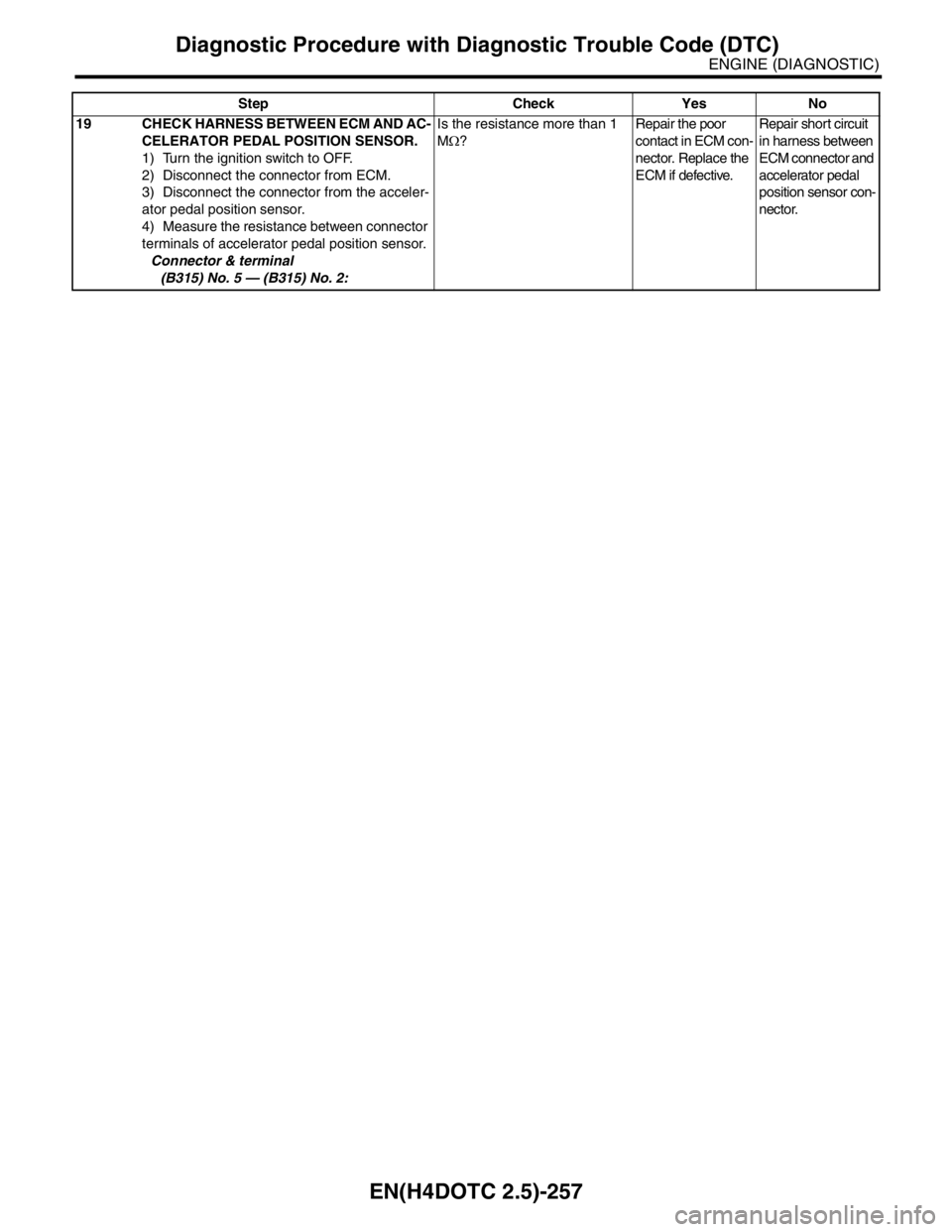

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

19 CHECK HARNESS BETWEEN ECM AND AC-

CELERATOR PEDAL POSITION SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM.

3) Disconnect the connector from the acceler-

ator pedal position sensor.

4) Measure the resistance between connector

terminals of accelerator pedal position sensor.

Connector & terminal

(B315) No. 5 — (B315) No. 2:Is the resistance more than 1

MΩ?Repair the poor

contact in ECM con-

nector. Replace the

ECM if defective.Repair short circuit

in harness between

ECM connector and

accelerator pedal

position sensor con-

nector. Step Check Yes No

Page 2282 of 2870

EN(H4DOTC 2.5)-258

ENGINE (DIAGNOSTIC)

General Diagnostic Table

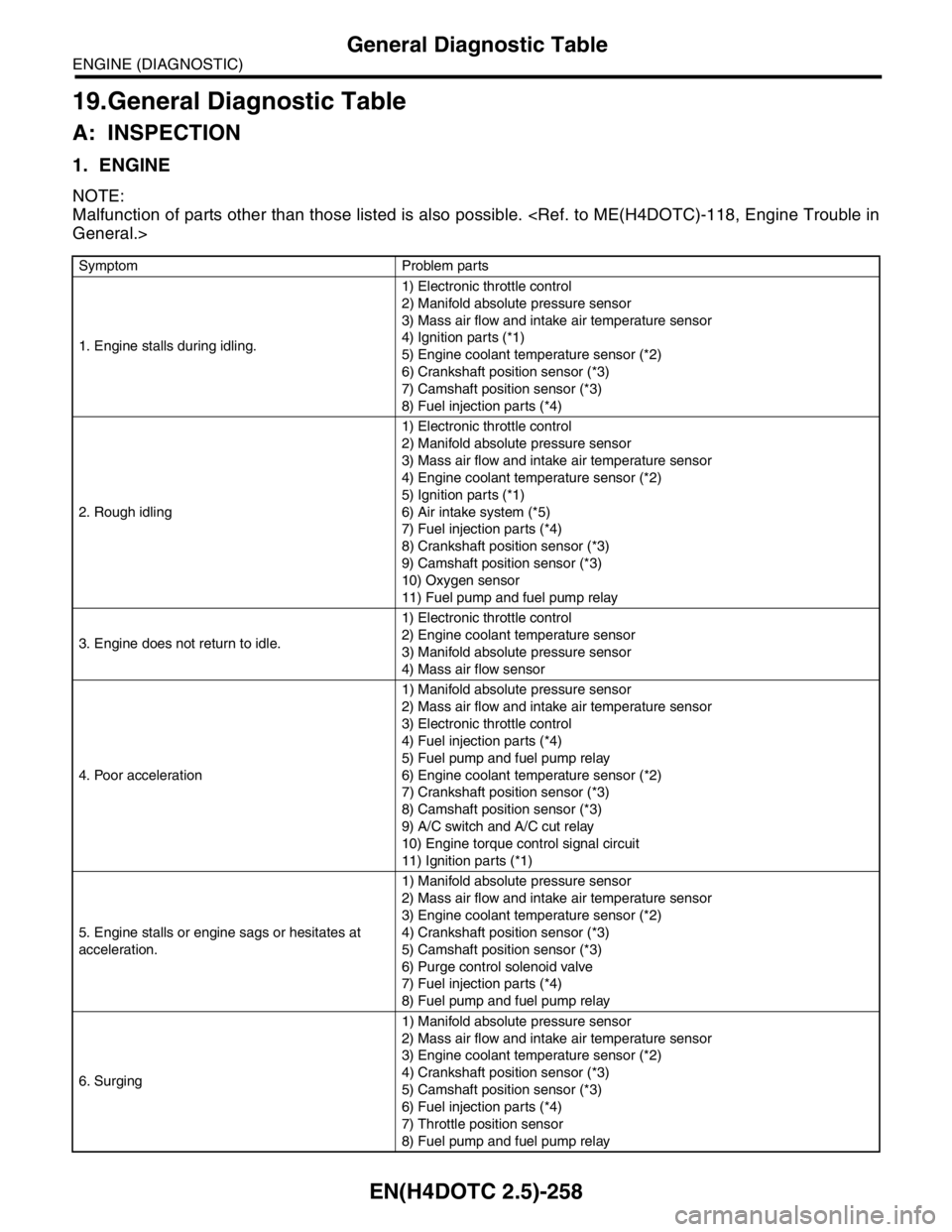

19.General Diagnostic Table

A: INSPECTION

1. ENGINE

NOTE:

Malfunction of parts other than those listed is also possible.

Symptom Problem parts

1. Engine stalls during idling.1) Electronic throttle control

2) Manifold absolute pressure sensor

3) Mass air flow and intake air temperature sensor

4) Ignition parts (*1)

5) Engine coolant temperature sensor (*2)

6) Crankshaft position sensor (*3)

7) Camshaft position sensor (*3)

8) Fuel injection parts (*4)

2. Rough idling1) Electronic throttle control

2) Manifold absolute pressure sensor

3) Mass air flow and intake air temperature sensor

4) Engine coolant temperature sensor (*2)

5) Ignition parts (*1)

6) Air intake system (*5)

7) Fuel injection parts (*4)

8) Crankshaft position sensor (*3)

9) Camshaft position sensor (*3)

10) Oxygen sensor

11) Fuel pump and fuel pump relay

3. Engine does not return to idle.1) Electronic throttle control

2) Engine coolant temperature sensor

3) Manifold absolute pressure sensor

4) Mass air flow sensor

4. Poor acceleration1) Manifold absolute pressure sensor

2) Mass air flow and intake air temperature sensor

3) Electronic throttle control

4) Fuel injection parts (*4)

5) Fuel pump and fuel pump relay

6) Engine coolant temperature sensor (*2)

7) Crankshaft position sensor (*3)

8) Camshaft position sensor (*3)

9) A/C switch and A/C cut relay

10) Engine torque control signal circuit

11) Ignition parts (*1)

5. Engine stalls or engine sags or hesitates at

acceleration.1) Manifold absolute pressure sensor

2) Mass air flow and intake air temperature sensor

3) Engine coolant temperature sensor (*2)

4) Crankshaft position sensor (*3)

5) Camshaft position sensor (*3)

6) Purge control solenoid valve

7) Fuel injection parts (*4)

8) Fuel pump and fuel pump relay

6. Surging1) Manifold absolute pressure sensor

2) Mass air flow and intake air temperature sensor

3) Engine coolant temperature sensor (*2)

4) Crankshaft position sensor (*3)

5) Camshaft position sensor (*3)

6) Fuel injection parts (*4)

7) Throttle position sensor

8) Fuel pump and fuel pump relay

Page 2283 of 2870

EN(H4DOTC 2.5)-259

ENGINE (DIAGNOSTIC)

General Diagnostic Table

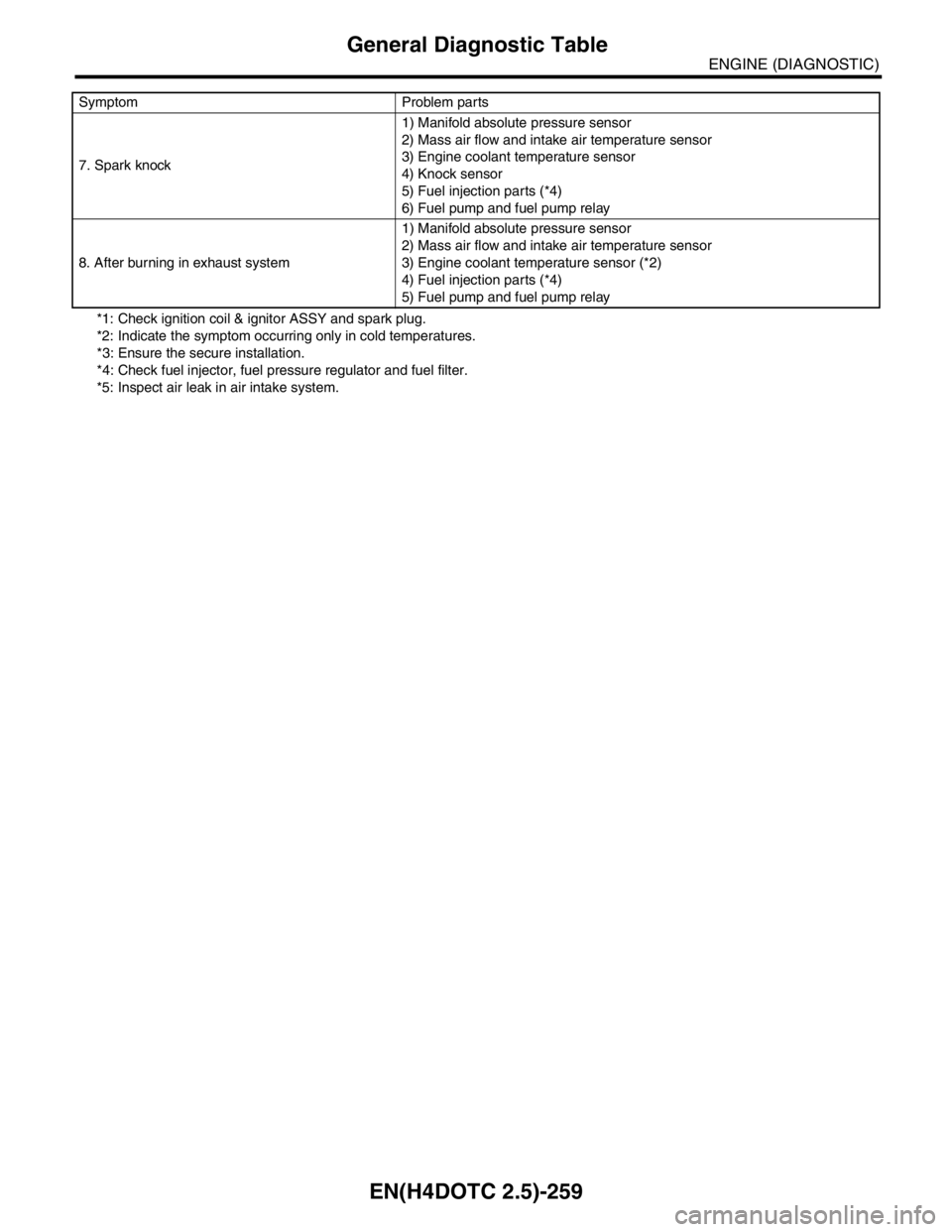

*1: Check ignition coil & ignitor ASSY and spark plug.

*2: Indicate the symptom occurring only in cold temperatures.

*3: Ensure the secure installation.

*4: Check fuel injector, fuel pressure regulator and fuel filter.

*5: Inspect air leak in air intake system. 7. Spark knock1) Manifold absolute pressure sensor

2) Mass air flow and intake air temperature sensor

3) Engine coolant temperature sensor

4) Knock sensor

5) Fuel injection parts (*4)

6) Fuel pump and fuel pump relay

8. After burning in exhaust system1) Manifold absolute pressure sensor

2) Mass air flow and intake air temperature sensor

3) Engine coolant temperature sensor (*2)

4) Fuel injection parts (*4)

5) Fuel pump and fuel pump relay Symptom Problem parts

Page 2284 of 2870

EN(H4DOTC 2.5)-260

ENGINE (DIAGNOSTIC)

General Diagnostic Table

Page 2285 of 2870

FUJI HEAVY INDUSTRIES LTD. G8080GE5

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

TRANSMISSION SECTION

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.CONTROL SYSTEM CS

AUTOMATIC TRANSMISSION 4AT

AUTOMATIC TRANSMISSION

(DIAGNOSTIC)4AT(H4SO)

AUTOMATIC TRANSMISSION

(DIAGNOSTIC)4AT(H4DOTC)

AUTOMATIC TRANSMISSION

(DIAGNOSTIC)4AT(H4DOTC 2.5)

MANUAL TRANSMISSION AND

DIFFERENTIAL5MT

CLUTCH SYSTEM CL

Page 2286 of 2870

CONTROL SYSTEM

CS

Page

1. General Description ....................................................................................2

2. Select Lever ................................................................................................8

3. Select Cable ..............................................................................................13

4. N-R Lock Solenoid ....................................................................................16

5. MT Gear Shift Lever ..................................................................................17

6. MT Drive Select Lever...............................................................................23

7. Drive Select Cable ....................................................................................25

8. General Diagnostic Table..........................................................................26

Page 2287 of 2870

CS-2

CONTROL SYSTEM

General Description

1. General Description

A: SPECIFICATION

Item Specification

Swing torque of rod against lever N (kgf, Ib) 3.7 (0.38, 0.83) or less

Page 2288 of 2870

CS-3

CONTROL SYSTEM

General Description

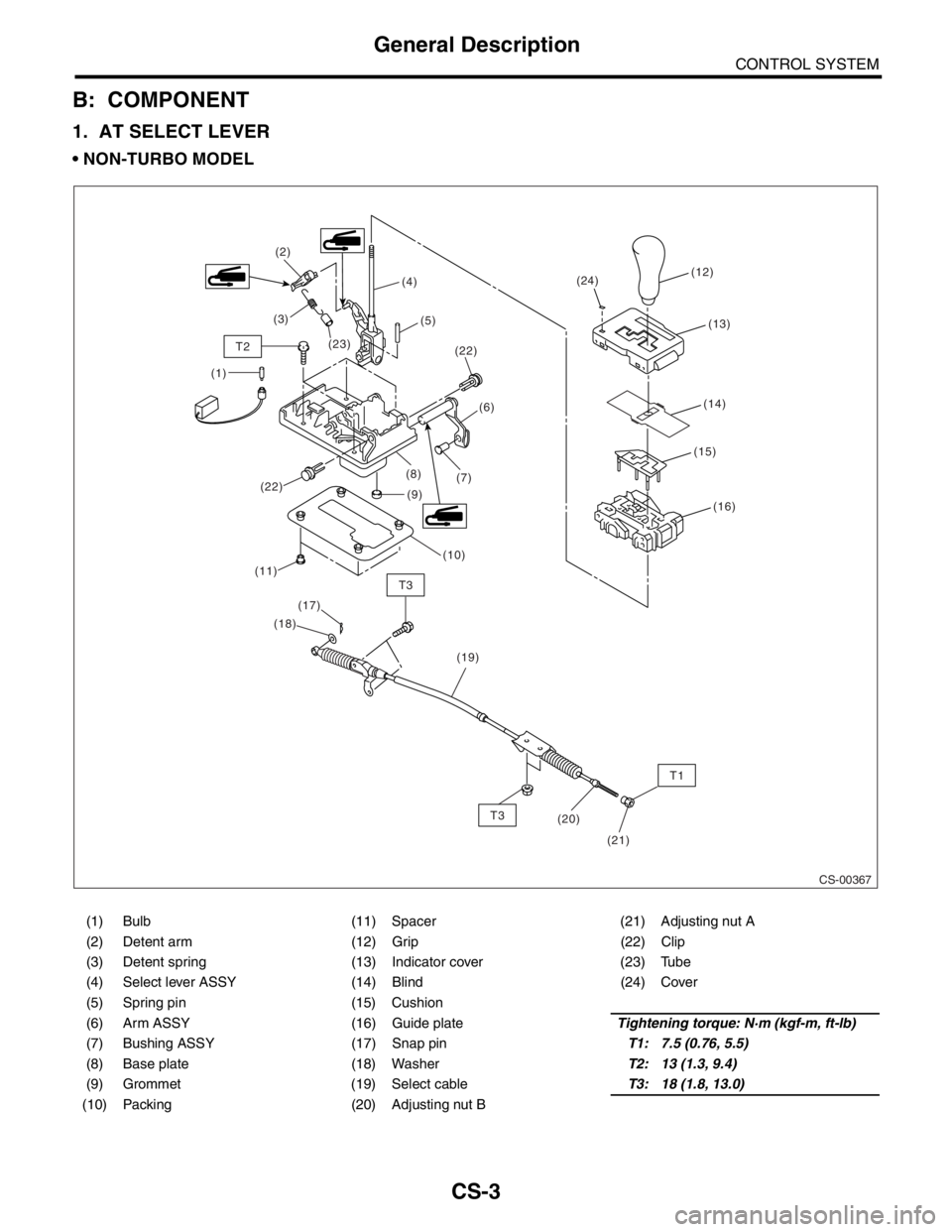

B: COMPONENT

1. AT SELECT LEVER

NON-TURBO MODEL

CS-00367

T3

T2

T3

T1

(10) (22)

(9) (8)

(7)(6) (5) (4) (2)

(3)

(1)(22)(12)

(13)

(15)

(16)

(21) (20) (19) (17)

(14)

(11)

(18)

(23)

(24)

(1) Bulb (11) Spacer (21) Adjusting nut A

(2) Detent arm (12) Grip (22) Clip

(3) Detent spring (13) Indicator cover (23) Tube

(4) Select lever ASSY (14) Blind (24) Cover

(5) Spring pin (15) Cushion

(6) Arm ASSY (16) Guide plateTightening torque: N·m (kgf-m, ft-lb)

(7) Bushing ASSY (17) Snap pinT1: 7.5 (0.76, 5.5)

(8) Base plate (18) WasherT2: 13 (1.3, 9.4)

(9) Grommet (19) Select cableT3: 18 (1.8, 13.0)

(10) Packing (20) Adjusting nut B

Page 2289 of 2870

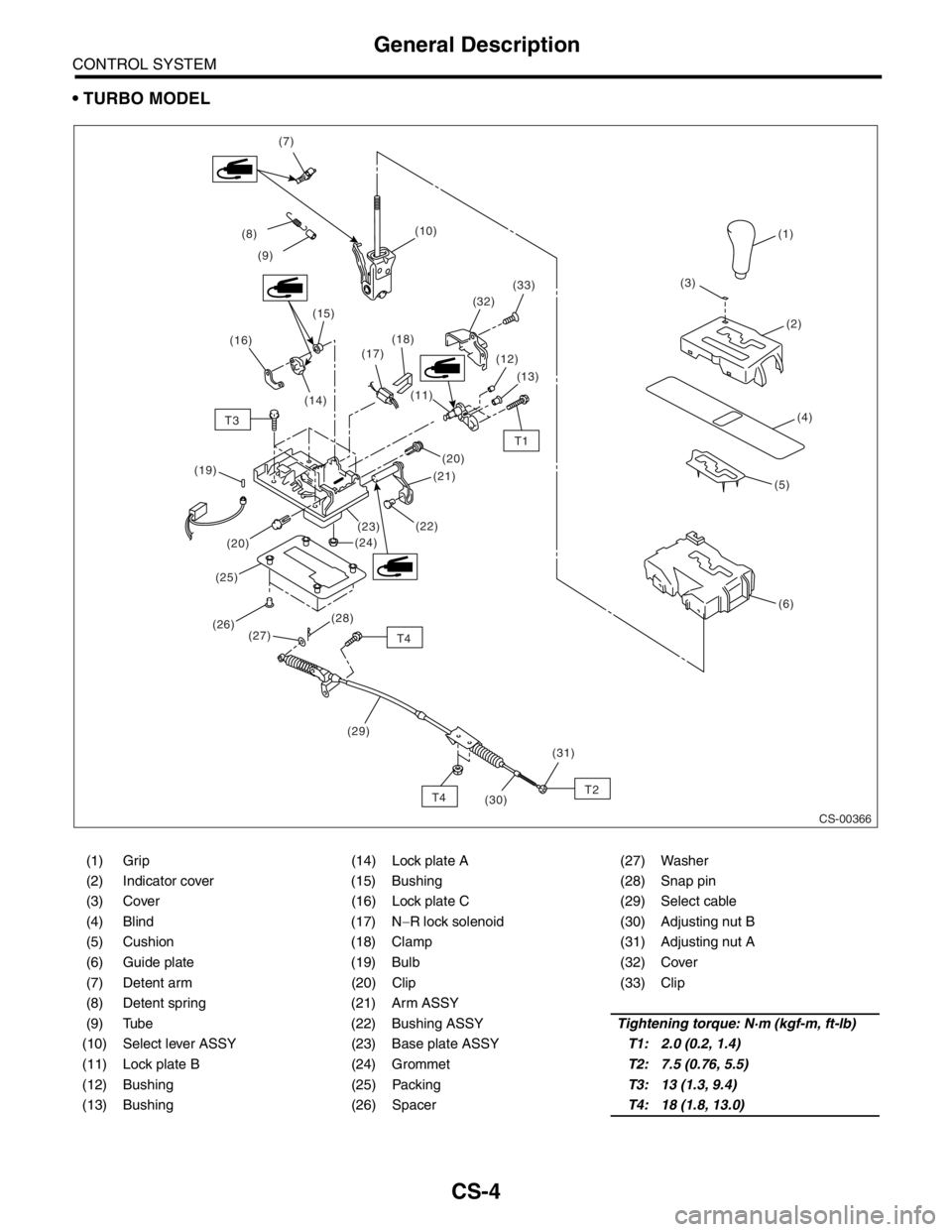

CS-4

CONTROL SYSTEM

General Description

TURBO MODEL

CS-00366

T2

T4 T4T1 T3

(31) (29) (27)(28) (20)

(25)(22) (19)

(23)

(24)(21)

(30) (20)(12)

(11)(13) (18)(3)

(17)(10)

(8)

(9)(7)

(15)

(26)(1)

(2)

(4)

(5)

(6) (33)

(32)

(14)

(16)

(1) Grip (14) Lock plate A (27) Washer

(2) Indicator cover (15) Bushing (28) Snap pin

(3) Cover (16) Lock plate C (29) Select cable

(4) Blind (17) N−R lock solenoid (30) Adjusting nut B

(5) Cushion (18) Clamp (31) Adjusting nut A

(6) Guide plate (19) Bulb (32) Cover

(7) Detent arm (20) Clip (33) Clip

(8) Detent spring (21) Arm ASSY

(9) Tube (22) Bushing ASSYTightening torque: N·m (kgf-m, ft-lb)

(10) Select lever ASSY (23) Base plate ASSYT1: 2.0 (0.2, 1.4)

(11) Lock plate B (24) GrommetT2: 7.5 (0.76, 5.5)

(12) Bushing (25) PackingT3: 13 (1.3, 9.4)

(13) Bushing (26) SpacerT4: 18 (1.8, 13.0)

Page 2290 of 2870

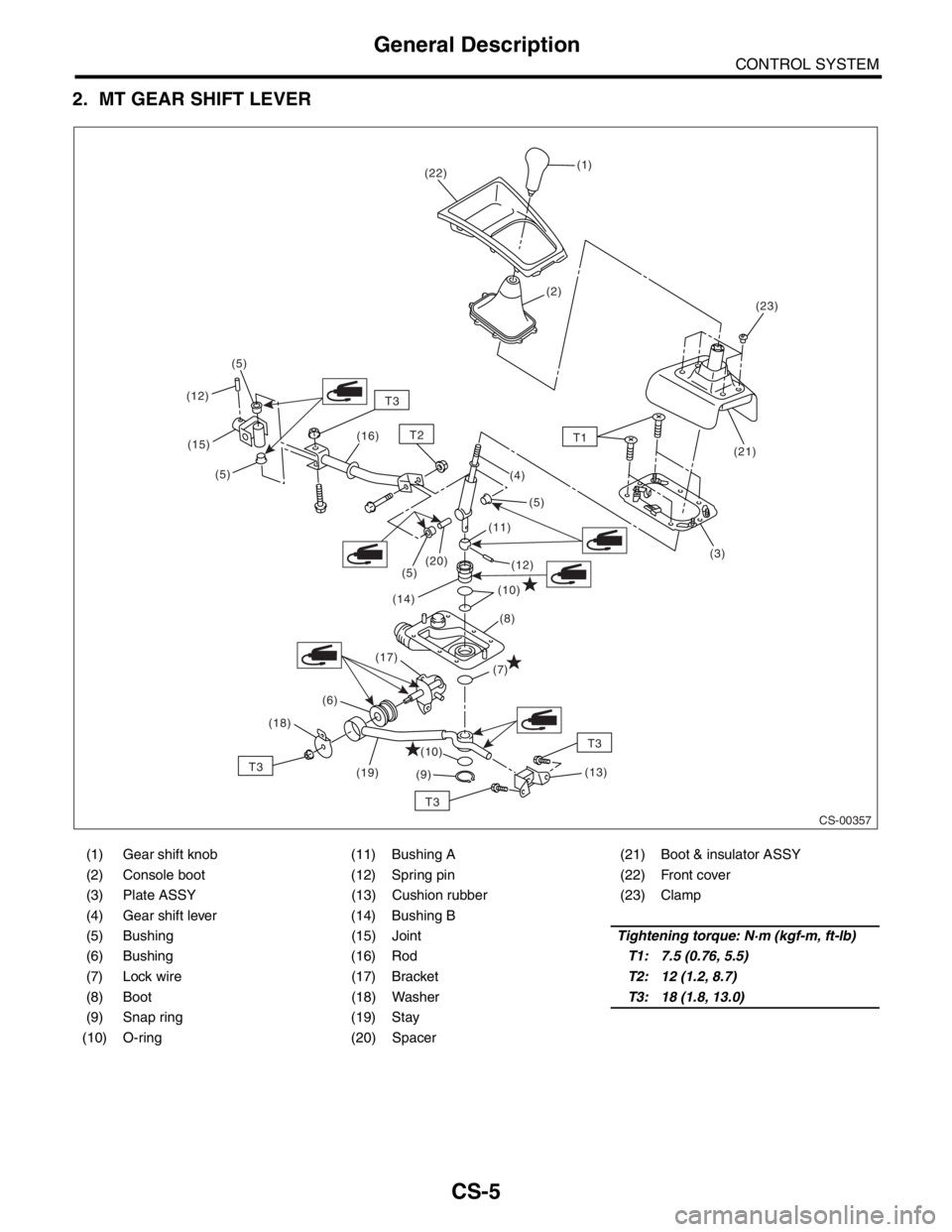

CS-5

CONTROL SYSTEM

General Description

2. MT GEAR SHIFT LEVER

(1) Gear shift knob (11) Bushing A (21) Boot & insulator ASSY

(2) Console boot (12) Spring pin (22) Front cover

(3) Plate ASSY (13) Cushion rubber (23) Clamp

(4) Gear shift lever (14) Bushing B

(5) Bushing (15) JointTightening torque: N·m (kgf-m, ft-lb)

(6) Bushing (16) RodT1: 7.5 (0.76, 5.5)

(7) Lock wire (17) BracketT2: 12 (1.2, 8.7)

(8) Boot (18) WasherT3: 18 (1.8, 13.0)

(9) Snap ring (19) Stay

(10) O-ring (20) Spacer

CS-00357

T2

(5) (5)

(5) (5)

(4)

(6)(3) (2)(1)

(18)(21)(23) (22)

(20)

(19)(17)T1

(14)

(13) (16)

(15)

(12) (12)

(11)

(10)

(10)

(9)(8)

(7)

T3

T3

T3

T3