SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2271 of 2870

EN(H4DOTC 2.5)-247

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

7 CHECK HARNESS BETWEEN ECM AND AC-

CELERATOR PEDAL POSITION SENSOR.

1) Turn the ignition switch to OFF.

2) Connect the accelerator pedal position sen-

sor connector.

3) Turn the ignition switch to ON.

4) Measure the voltage between ECM con-

nector and chassis ground.

Connector & terminal

(B136) No. 16 (+) — Chassis ground (

−):Is the voltage 4.8 V? Repair the poor

contact in ECM

connector.

Replace the ECM

if defective.Repair poor con-

tact in accelerator

pedal position sen-

sor connector.

Replace the accel-

erator pedal posi-

tion sensor if

defective. Step Check Yes No

Page 2272 of 2870

EN(H4DOTC 2.5)-248

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

CF:DTC P2135 THROTTLE/PEDAL POSITION SENSOR/SWITCH “A”/“B” VOLT-

AGE RATIONALITY

DTC DETECTING CONDITION:

Immediately at fault recognition

TROUBLE SYMPTOM:

Erroneous idling

Poor driving performance

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

Page 2273 of 2870

EN(H4DOTC 2.5)-249

ENGINE (DIAGNOSTIC)

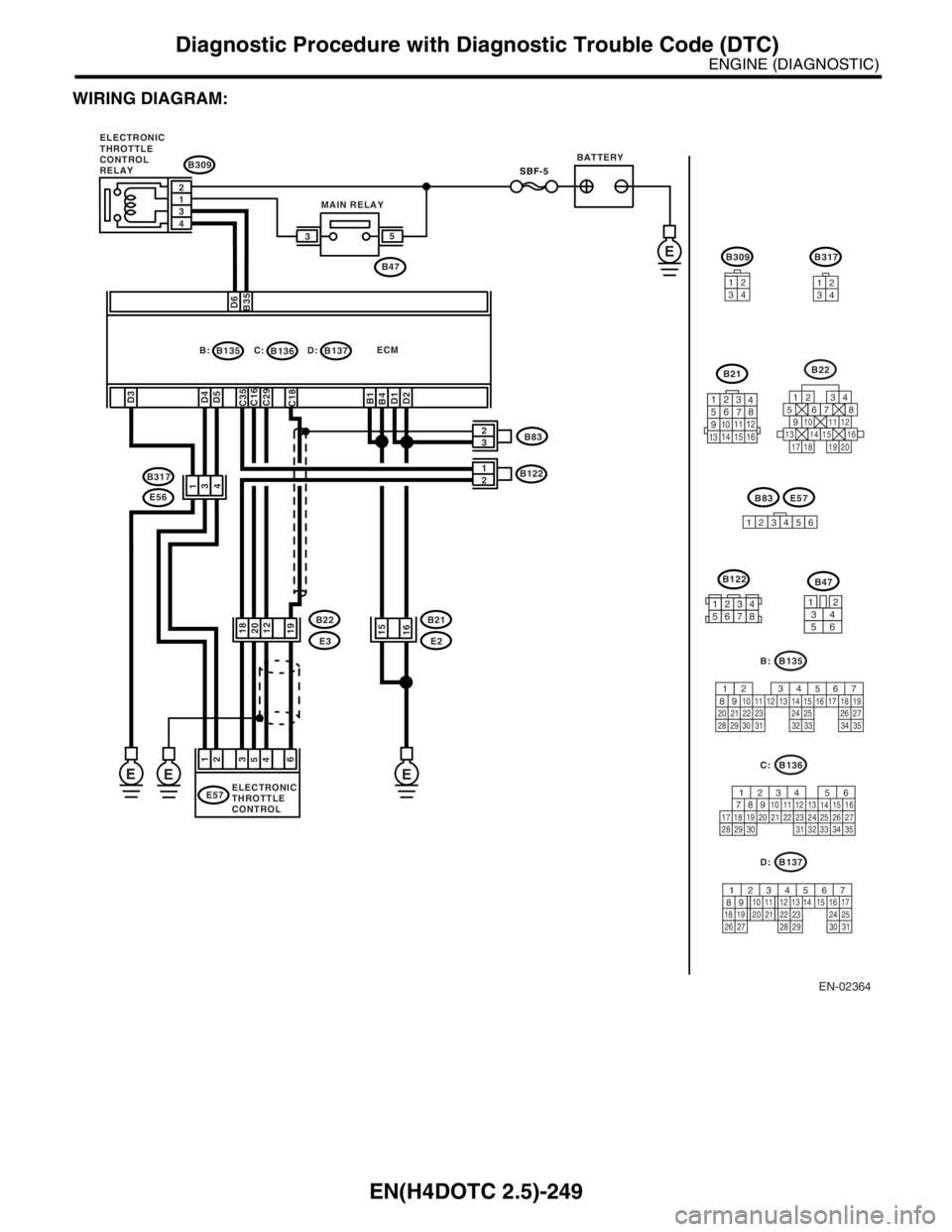

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

WIRING DIAGRAM:

EN-02364

B317

34

12

B22

125678

131415169101112

34

17181920

B21

123

4

56

78

9

1011 12

1314 15 16

B83

1

23456

B135

567

82 1

94 3

10

24 22 23 2511 12 13 14 15

26 27

2816 17 18 19

20 21

29 30 31 32 33 34 35

B:

B35D6

B135 B: C:

D4 D3

C18

B1 C35

D1 B4

D2

SBF-5

2

1

3

4

E

E57

3

6 4

1

2 2

3

15

16

E

5

EE

B137 D:ECM B309

B136

B122

1

E2 B21

E3 B22 B317

E56B47 35

2 1

4 3

D5C16C29

19122018

MAIN RELAYBATTERY

ELECTRONIC

THROTTLE

CONTROL ELECTRONIC

THROTTLE

CONTROL

RELAY

B83

B122

123456783412

56

B47

B137

567

82 1

94 3

10

22 23 11 12 13 14 15

24 25

2616 17

18 19 20 21

27 28 29 30 31

D:

B136

56

782 1

94 3

10

24 22 23 2511 12 13

1415

26 27

2816

17 18 19 20 21

33 34 29

32 30

31 35

C:

B309

34

12

E57

Page 2274 of 2870

EN(H4DOTC 2.5)-250

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

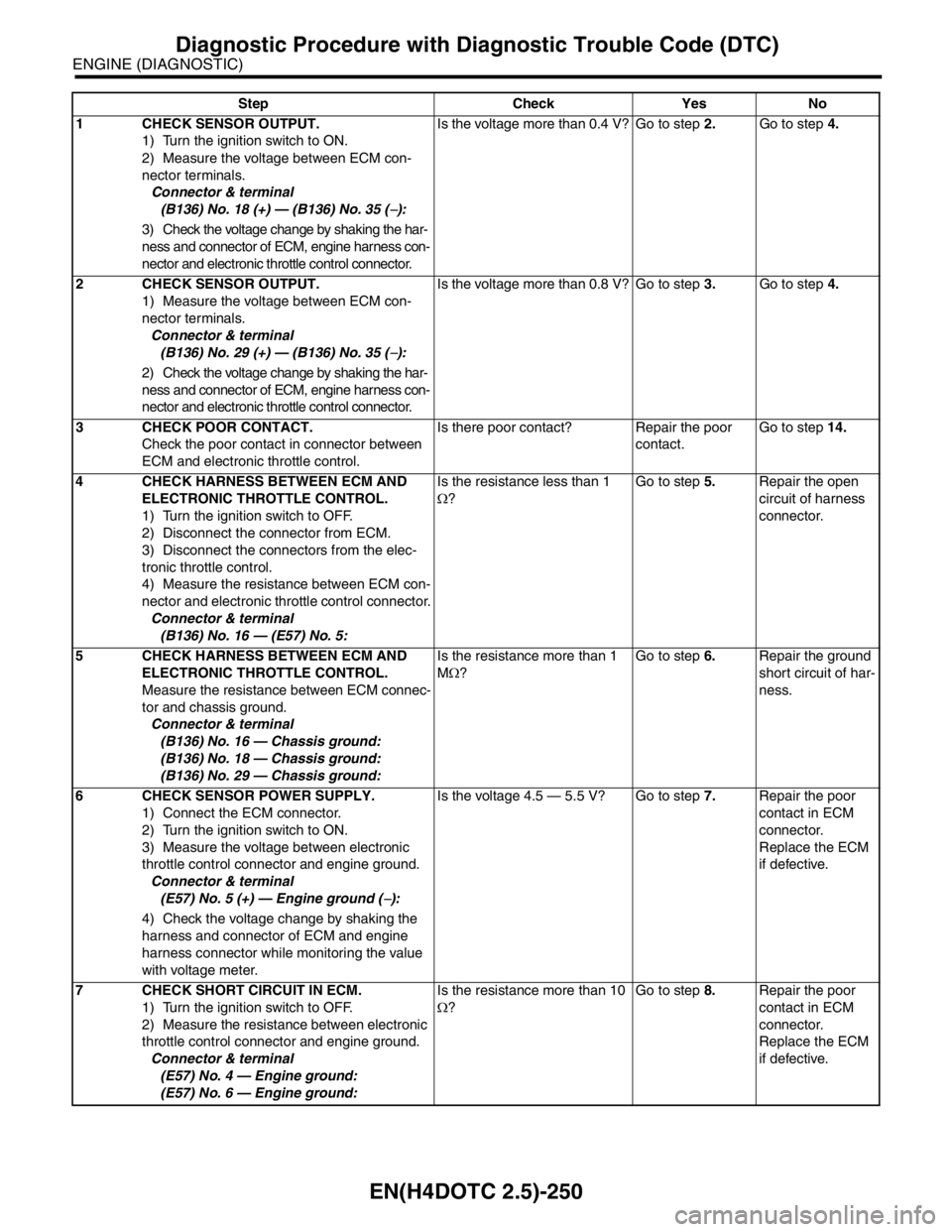

Step Check Yes No

1 CHECK SENSOR OUTPUT.

1) Turn the ignition switch to ON.

2) Measure the voltage between ECM con-

nector terminals.

Connector & terminal

(B136) No. 18 (+) — (B136) No. 35 (

−):

3) Check the voltage change by shaking the har-

ness and connector of ECM, engine harness con-

nector and electronic throttle control connector.Is the voltage more than 0.4 V? Go to step 2.Go to step 4.

2 CHECK SENSOR OUTPUT.

1) Measure the voltage between ECM con-

nector terminals.

Connector & terminal

(B136) No. 29 (+) — (B136) No. 35 (

−):

2) Check the voltage change by shaking the har-

ness and connector of ECM, engine harness con-

nector and electronic throttle control connector.Is the voltage more than 0.8 V? Go to step 3.Go to step 4.

3 CHECK POOR CONTACT.

Check the poor contact in connector between

ECM and electronic throttle control.Is there poor contact? Repair the poor

contact.Go to step 14.

4 CHECK HARNESS BETWEEN ECM AND

ELECTRONIC THROTTLE CONTROL.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM.

3) Disconnect the connectors from the elec-

tronic throttle control.

4) Measure the resistance between ECM con-

nector and electronic throttle control connector.

Connector & terminal

(B136) No. 16 — (E57) No. 5:Is the resistance less than 1

Ω?Go to step 5.Repair the open

circuit of harness

connector.

5 CHECK HARNESS BETWEEN ECM AND

ELECTRONIC THROTTLE CONTROL.

Measure the resistance between ECM connec-

tor and chassis ground.

Connector & terminal

(B136) No. 16 — Chassis ground:

(B136) No. 18 — Chassis ground:

(B136) No. 29 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 6.Repair the ground

short circuit of har-

ness.

6 CHECK SENSOR POWER SUPPLY.

1) Connect the ECM connector.

2) Turn the ignition switch to ON.

3) Measure the voltage between electronic

throttle control connector and engine ground.

Connector & terminal

(E57) No. 5 (+) — Engine ground (

−):

4) Check the voltage change by shaking the

harness and connector of ECM and engine

harness connector while monitoring the value

with voltage meter.Is the voltage 4.5 — 5.5 V? Go to step 7.Repair the poor

contact in ECM

connector.

Replace the ECM

if defective.

7 CHECK SHORT CIRCUIT IN ECM.

1) Turn the ignition switch to OFF.

2) Measure the resistance between electronic

throttle control connector and engine ground.

Connector & terminal

(E57) No. 4 — Engine ground:

(E57) No. 6 — Engine ground:Is the resistance more than 10

Ω?Go to step 8.Repair the poor

contact in ECM

connector.

Replace the ECM

if defective.

Page 2275 of 2870

EN(H4DOTC 2.5)-251

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

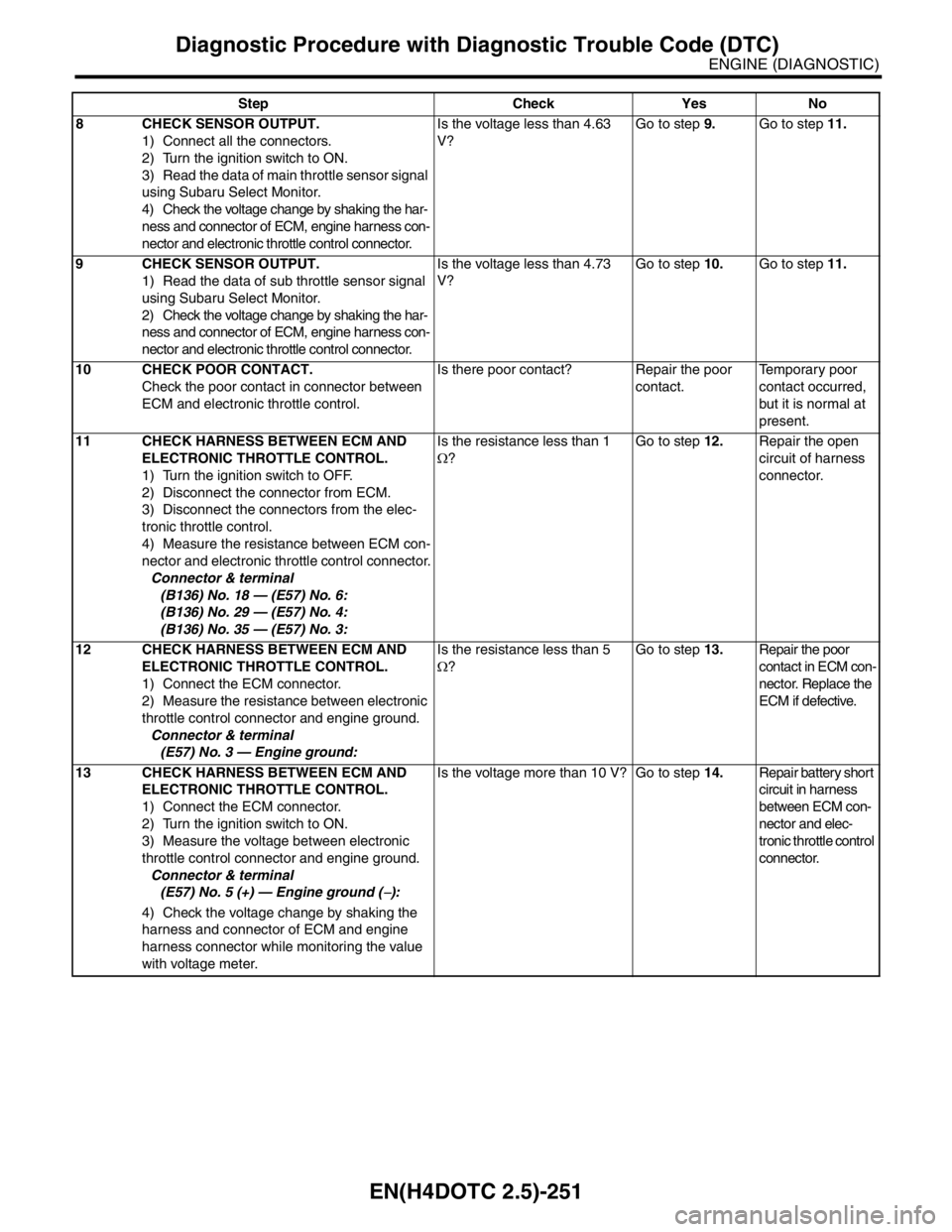

8 CHECK SENSOR OUTPUT.

1) Connect all the connectors.

2) Turn the ignition switch to ON.

3) Read the data of main throttle sensor signal

using Subaru Select Monitor.

4) Check the voltage change by shaking the har-

ness and connector of ECM, engine harness con-

nector and electronic throttle control connector.Is the voltage less than 4.63

V?Go to step 9.Go to step 11.

9 CHECK SENSOR OUTPUT.

1) Read the data of sub throttle sensor signal

using Subaru Select Monitor.

2) Check the voltage change by shaking the har-

ness and connector of ECM, engine harness con-

nector and electronic throttle control connector.Is the voltage less than 4.73

V?Go to step 10.Go to step 11.

10 CHECK POOR CONTACT.

Check the poor contact in connector between

ECM and electronic throttle control.Is there poor contact? Repair the poor

contact.Temporary poor

contact occurred,

but it is normal at

present.

11 CHECK HARNESS BETWEEN ECM AND

ELECTRONIC THROTTLE CONTROL.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM.

3) Disconnect the connectors from the elec-

tronic throttle control.

4) Measure the resistance between ECM con-

nector and electronic throttle control connector.

Connector & terminal

(B136) No. 18 — (E57) No. 6:

(B136) No. 29 — (E57) No. 4:

(B136) No. 35 — (E57) No. 3:Is the resistance less than 1

Ω?Go to step 12.Repair the open

circuit of harness

connector.

12 CHECK HARNESS BETWEEN ECM AND

ELECTRONIC THROTTLE CONTROL.

1) Connect the ECM connector.

2) Measure the resistance between electronic

throttle control connector and engine ground.

Connector & terminal

(E57) No. 3 — Engine ground:Is the resistance less than 5

Ω?Go to step 13.Repair the poor

contact in ECM con-

nector. Replace the

ECM if defective.

13 CHECK HARNESS BETWEEN ECM AND

ELECTRONIC THROTTLE CONTROL.

1) Connect the ECM connector.

2) Turn the ignition switch to ON.

3) Measure the voltage between electronic

throttle control connector and engine ground.

Connector & terminal

(E57) No. 5 (+) — Engine ground (

−):

4) Check the voltage change by shaking the

harness and connector of ECM and engine

harness connector while monitoring the value

with voltage meter.Is the voltage more than 10 V? Go to step 14.Repair battery short

circuit in harness

between ECM con-

nector and elec-

tronic throttle control

connector. Step Check Yes No

Page 2276 of 2870

EN(H4DOTC 2.5)-252

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

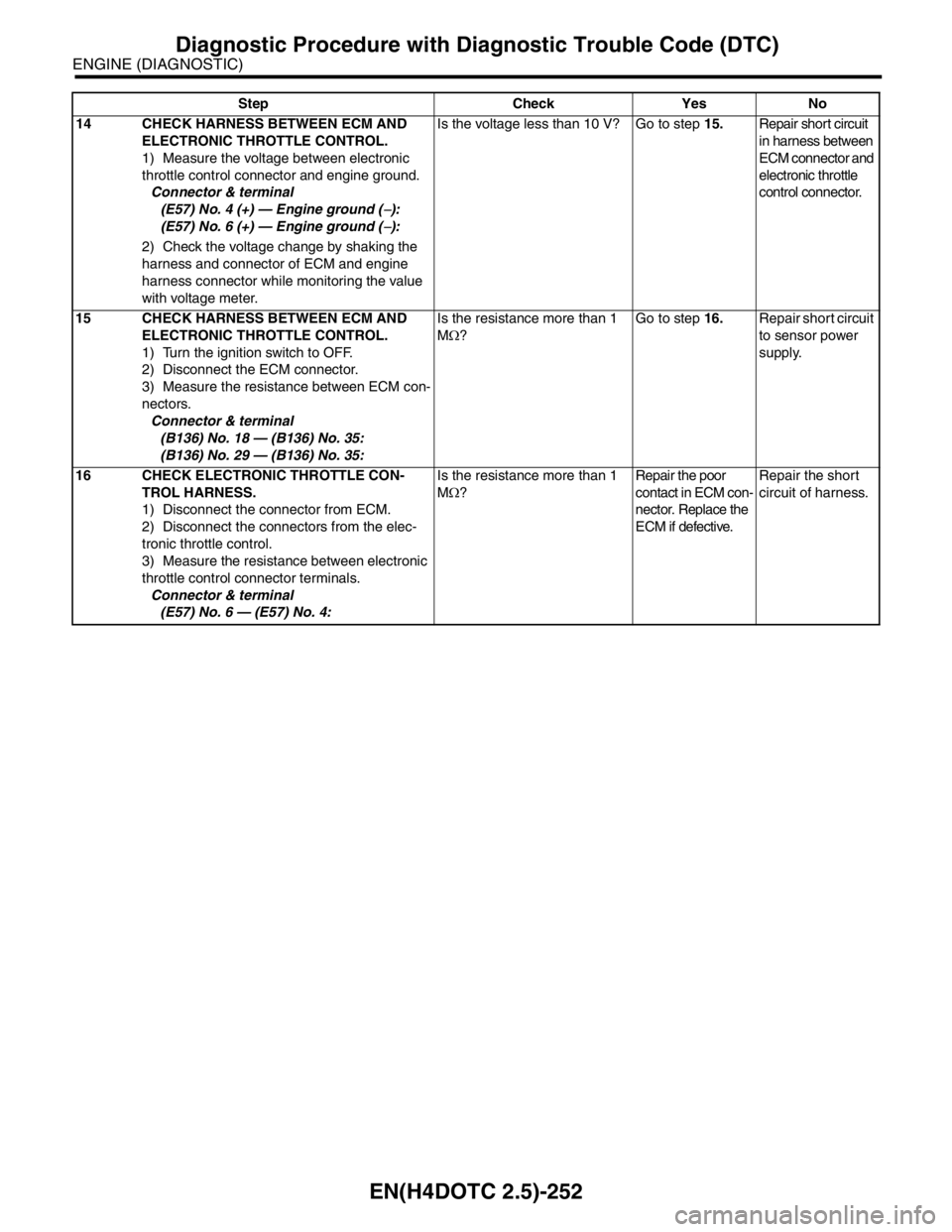

14 CHECK HARNESS BETWEEN ECM AND

ELECTRONIC THROTTLE CONTROL.

1) Measure the voltage between electronic

throttle control connector and engine ground.

Connector & terminal

(E57) No. 4 (+) — Engine ground (

−):

(E57) No. 6 (+) — Engine ground (

−):

2) Check the voltage change by shaking the

harness and connector of ECM and engine

harness connector while monitoring the value

with voltage meter.Is the voltage less than 10 V? Go to step 15.Repair short circuit

in harness between

ECM connector and

electronic throttle

control connector.

15 CHECK HARNESS BETWEEN ECM AND

ELECTRONIC THROTTLE CONTROL.

1) Turn the ignition switch to OFF.

2) Disconnect the ECM connector.

3) Measure the resistance between ECM con-

nectors.

Connector & terminal

(B136) No. 18 — (B136) No. 35:

(B136) No. 29 — (B136) No. 35:Is the resistance more than 1

MΩ?Go to step 16.Repair short circuit

to sensor power

supply.

16 CHECK ELECTRONIC THROTTLE CON-

TROL HARNESS.

1) Disconnect the connector from ECM.

2) Disconnect the connectors from the elec-

tronic throttle control.

3) Measure the resistance between electronic

throttle control connector terminals.

Connector & terminal

(E57) No. 6 — (E57) No. 4:Is the resistance more than 1

MΩ?Repair the poor

contact in ECM con-

nector. Replace the

ECM if defective.Repair the short

circuit of harness. Step Check Yes No

Page 2277 of 2870

EN(H4DOTC 2.5)-253

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

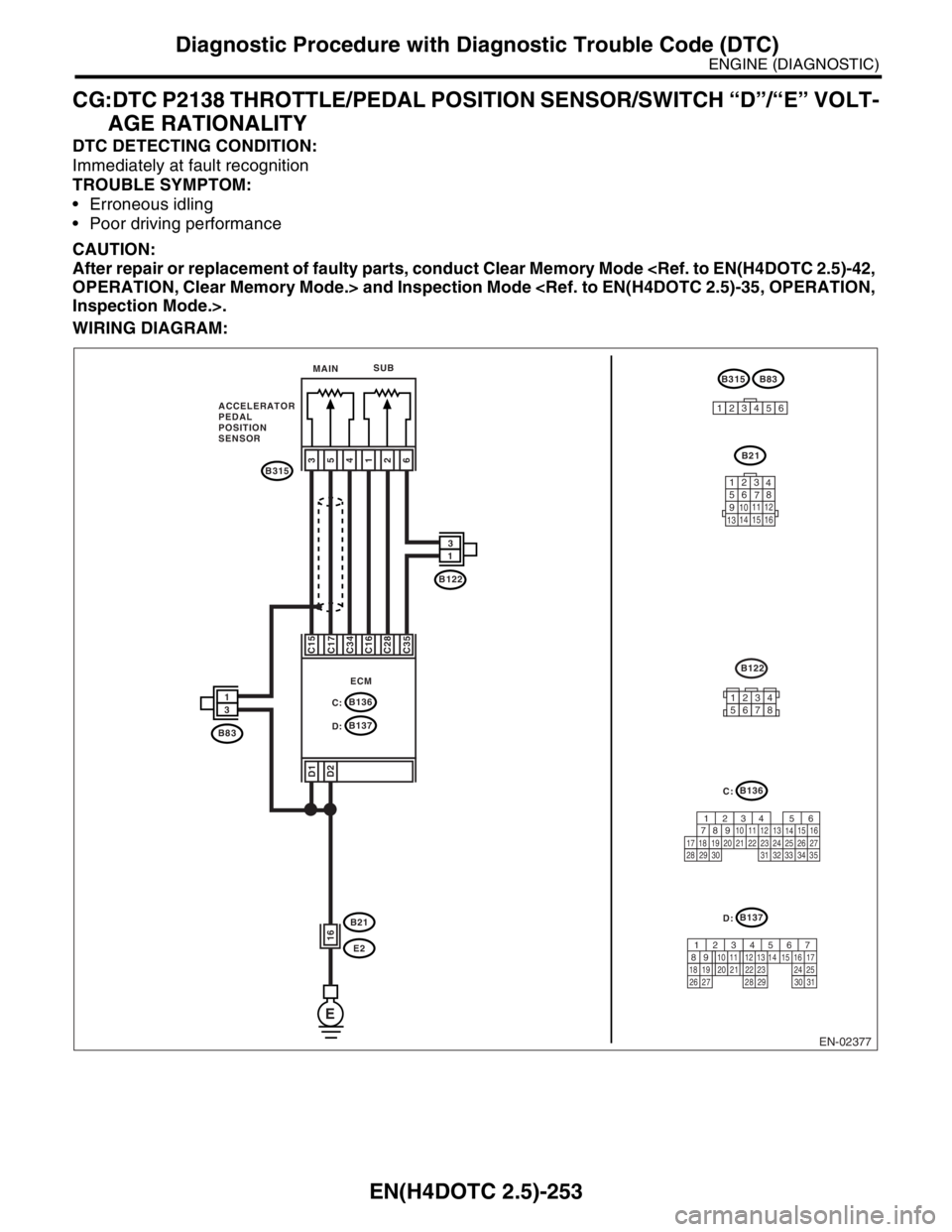

CG:DTC P2138 THROTTLE/PEDAL POSITION SENSOR/SWITCH “D”/“E” VOLT-

AGE RATIONALITY

DTC DETECTING CONDITION:

Immediately at fault recognition

TROUBLE SYMPTOM:

Erroneous idling

Poor driving performance

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-02377

B315B83

B21

E

C:ECM

B136

B137

D:

C:B136

B137

D:

B122

B21

E2

B315

1

3

354126 C15

C17

C34

C16

C28

C35

D1D2

16

123

4

56

78

9

1011 12

1314 15 16

123456

B122

56

782 1

94 310

24 22 23 2511 12 13

1415

26 27

2816

17 18 19 20 21

33 34 29

32 30

31 35

567

82 1

94 310

22 23 11 12 13 14 15

24 25

2616 17

18 19 20 21

27 28 29 30 31

MAINSUB

ACCELERATOR

PEDAL

POSITION

SENSOR

B833

112345678

Page 2278 of 2870

EN(H4DOTC 2.5)-254

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

Step Check Yes No

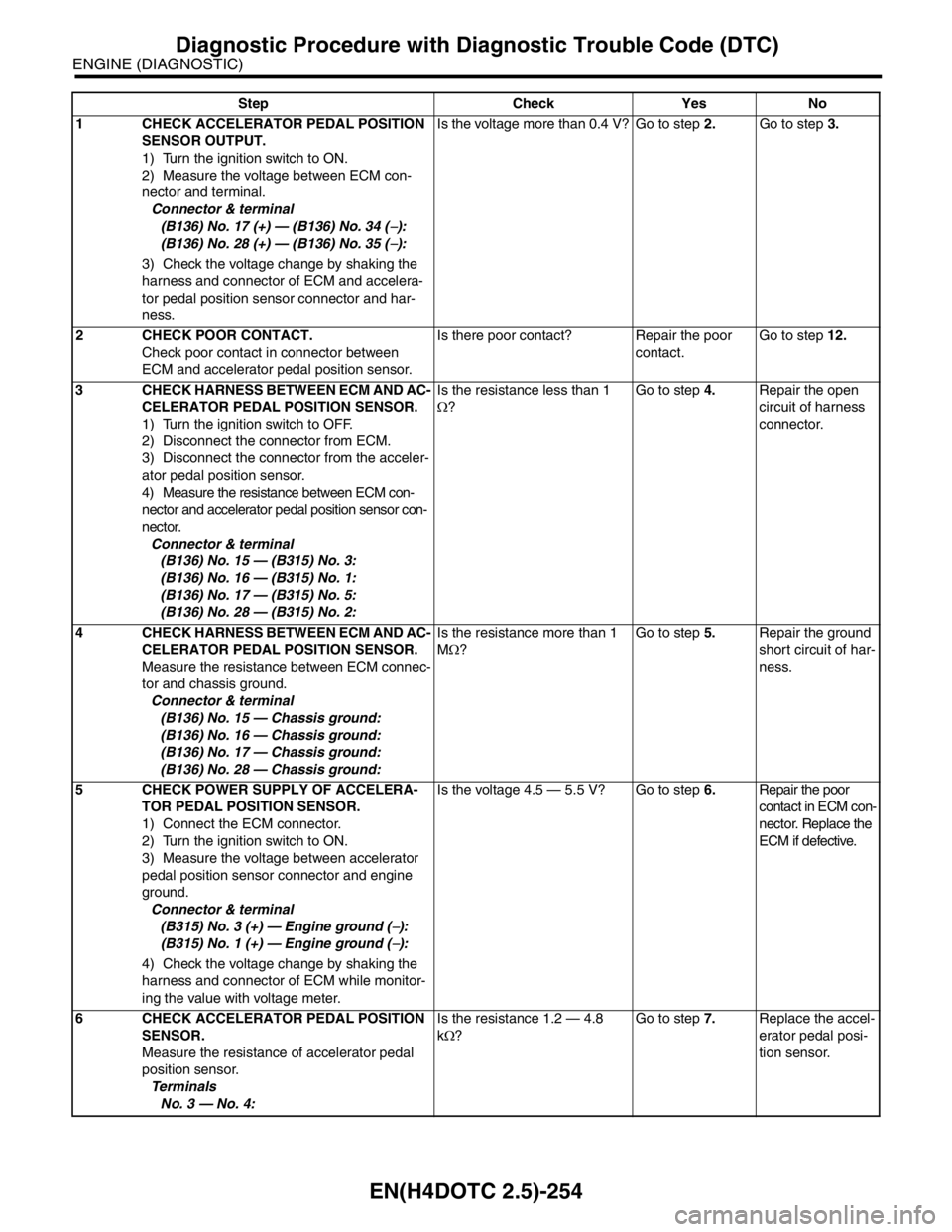

1 CHECK ACCELERATOR PEDAL POSITION

SENSOR OUTPUT.

1) Turn the ignition switch to ON.

2) Measure the voltage between ECM con-

nector and terminal.

Connector & terminal

(B136) No. 17 (+) — (B136) No. 34 (

−):

(B136) No. 28 (+) — (B136) No. 35 (

−):

3) Check the voltage change by shaking the

harness and connector of ECM and accelera-

tor pedal position sensor connector and har-

ness.Is the voltage more than 0.4 V? Go to step 2.Go to step 3.

2 CHECK POOR CONTACT.

Check poor contact in connector between

ECM and accelerator pedal position sensor.Is there poor contact? Repair the poor

contact.Go to step 12.

3 CHECK HARNESS BETWEEN ECM AND AC-

CELERATOR PEDAL POSITION SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM.

3) Disconnect the connector from the acceler-

ator pedal position sensor.

4) Measure the resistance between ECM con-

nector and accelerator pedal position sensor con-

nector.

Connector & terminal

(B136) No. 15 — (B315) No. 3:

(B136) No. 16 — (B315) No. 1:

(B136) No. 17 — (B315) No. 5:

(B136) No. 28 — (B315) No. 2:Is the resistance less than 1

Ω?Go to step 4.Repair the open

circuit of harness

connector.

4 CHECK HARNESS BETWEEN ECM AND AC-

CELERATOR PEDAL POSITION SENSOR.

Measure the resistance between ECM connec-

tor and chassis ground.

Connector & terminal

(B136) No. 15 — Chassis ground:

(B136) No. 16 — Chassis ground:

(B136) No. 17 — Chassis ground:

(B136) No. 28 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 5.Repair the ground

short circuit of har-

ness.

5 CHECK POWER SUPPLY OF ACCELERA-

TOR PEDAL POSITION SENSOR.

1) Connect the ECM connector.

2) Turn the ignition switch to ON.

3) Measure the voltage between accelerator

pedal position sensor connector and engine

ground.

Connector & terminal

(B315) No. 3 (+) — Engine ground (

−):

(B315) No. 1 (+) — Engine ground (

−):

4) Check the voltage change by shaking the

harness and connector of ECM while monitor-

ing the value with voltage meter.Is the voltage 4.5 — 5.5 V? Go to step 6.Repair the poor

contact in ECM con-

nector. Replace the

ECM if defective.

6 CHECK ACCELERATOR PEDAL POSITION

SENSOR.

Measure the resistance of accelerator pedal

position sensor.

Te r m i n a l s

No. 3 — No. 4:Is the resistance 1.2 — 4.8

kΩ?Go to step 7.Replace the accel-

erator pedal posi-

tion sensor.

Page 2279 of 2870

EN(H4DOTC 2.5)-255

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

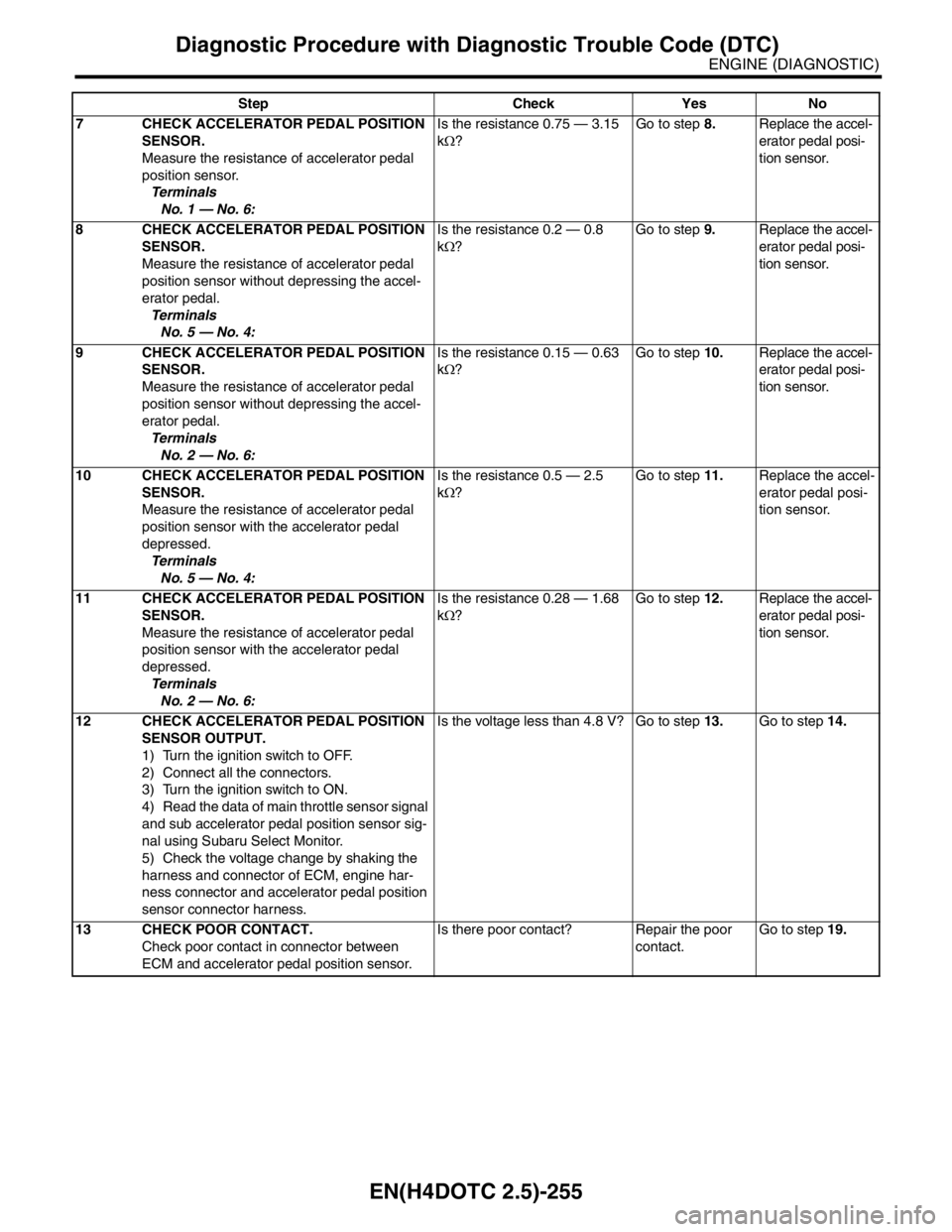

7 CHECK ACCELERATOR PEDAL POSITION

SENSOR.

Measure the resistance of accelerator pedal

position sensor.

Te r m i n a l s

No. 1 — No. 6:Is the resistance 0.75 — 3.15

kΩ?Go to step 8.Replace the accel-

erator pedal posi-

tion sensor.

8 CHECK ACCELERATOR PEDAL POSITION

SENSOR.

Measure the resistance of accelerator pedal

position sensor without depressing the accel-

erator pedal.

Te r m i n a l s

No. 5 — No. 4:Is the resistance 0.2 — 0.8

kΩ?Go to step 9.Replace the accel-

erator pedal posi-

tion sensor.

9 CHECK ACCELERATOR PEDAL POSITION

SENSOR.

Measure the resistance of accelerator pedal

position sensor without depressing the accel-

erator pedal.

Te r m i n a l s

No. 2 — No. 6:Is the resistance 0.15 — 0.63

kΩ?Go to step 10.Replace the accel-

erator pedal posi-

tion sensor.

10 CHECK ACCELERATOR PEDAL POSITION

SENSOR.

Measure the resistance of accelerator pedal

position sensor with the accelerator pedal

depressed.

Te r m i n a l s

No. 5 — No. 4:Is the resistance 0.5 — 2.5

kΩ?Go to step 11.Replace the accel-

erator pedal posi-

tion sensor.

11 CHECK ACCELERATOR PEDAL POSITION

SENSOR.

Measure the resistance of accelerator pedal

position sensor with the accelerator pedal

depressed.

Te r m i n a l s

No. 2 — No. 6:Is the resistance 0.28 — 1.68

kΩ?Go to step 12.Replace the accel-

erator pedal posi-

tion sensor.

12 CHECK ACCELERATOR PEDAL POSITION

SENSOR OUTPUT.

1) Turn the ignition switch to OFF.

2) Connect all the connectors.

3) Turn the ignition switch to ON.

4) Read the data of main throttle sensor signal

and sub accelerator pedal position sensor sig-

nal using Subaru Select Monitor.

5) Check the voltage change by shaking the

harness and connector of ECM, engine har-

ness connector and accelerator pedal position

sensor connector harness.Is the voltage less than 4.8 V? Go to step 13.Go to step 14.

13 CHECK POOR CONTACT.

Check poor contact in connector between

ECM and accelerator pedal position sensor.Is there poor contact? Repair the poor

contact.Go to step 19. Step Check Yes No

Page 2280 of 2870

EN(H4DOTC 2.5)-256

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

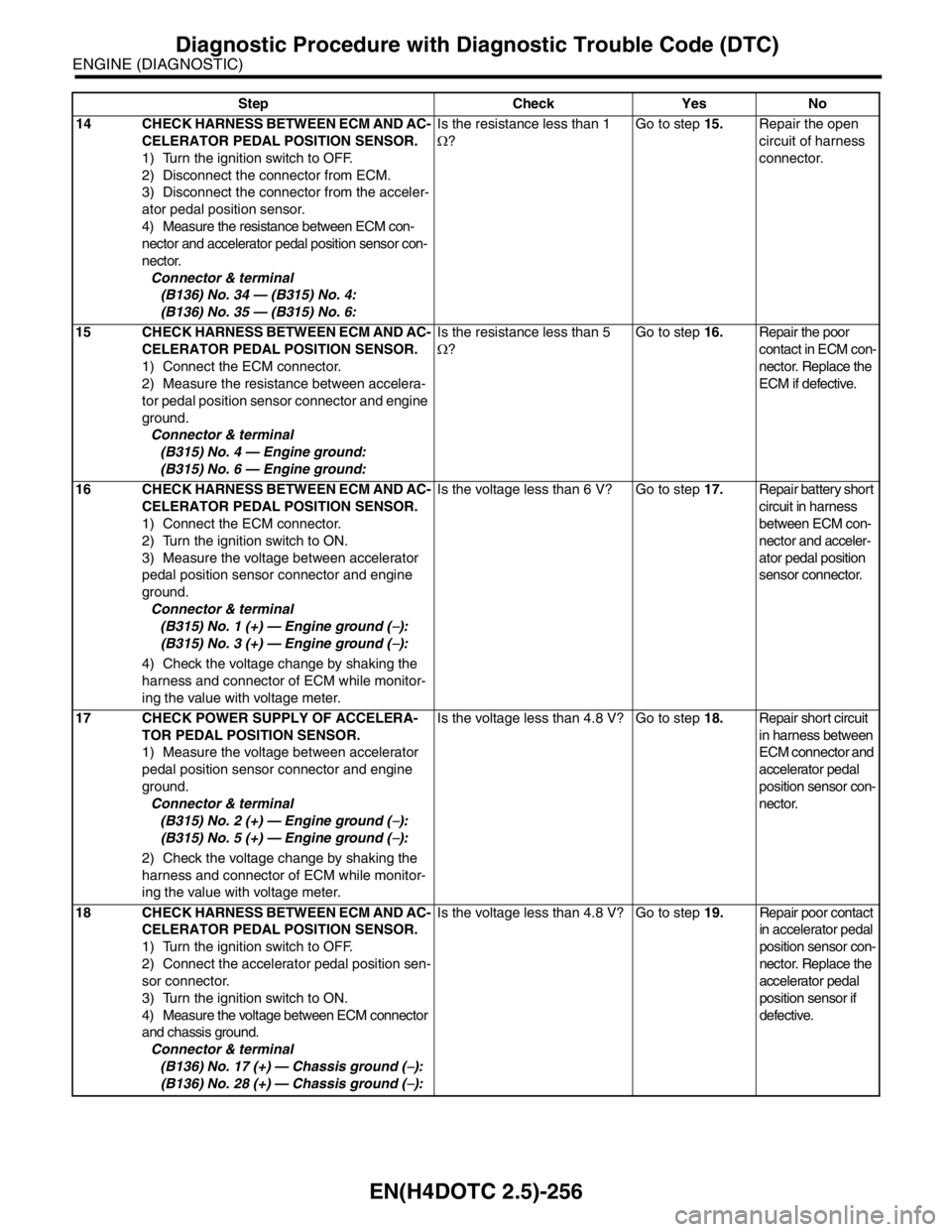

14 CHECK HARNESS BETWEEN ECM AND AC-

CELERATOR PEDAL POSITION SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM.

3) Disconnect the connector from the acceler-

ator pedal position sensor.

4) Measure the resistance between ECM con-

nector and accelerator pedal position sensor con-

nector.

Connector & terminal

(B136) No. 34 — (B315) No. 4:

(B136) No. 35 — (B315) No. 6:Is the resistance less than 1

Ω?Go to step 15.Repair the open

circuit of harness

connector.

15 CHECK HARNESS BETWEEN ECM AND AC-

CELERATOR PEDAL POSITION SENSOR.

1) Connect the ECM connector.

2) Measure the resistance between accelera-

tor pedal position sensor connector and engine

ground.

Connector & terminal

(B315) No. 4 — Engine ground:

(B315) No. 6 — Engine ground:Is the resistance less than 5

Ω?Go to step 16.Repair the poor

contact in ECM con-

nector. Replace the

ECM if defective.

16 CHECK HARNESS BETWEEN ECM AND AC-

CELERATOR PEDAL POSITION SENSOR.

1) Connect the ECM connector.

2) Turn the ignition switch to ON.

3) Measure the voltage between accelerator

pedal position sensor connector and engine

ground.

Connector & terminal

(B315) No. 1 (+) — Engine ground (

−):

(B315) No. 3 (+) — Engine ground (

−):

4) Check the voltage change by shaking the

harness and connector of ECM while monitor-

ing the value with voltage meter.Is the voltage less than 6 V? Go to step 17.Repair battery short

circuit in harness

between ECM con-

nector and acceler-

ator pedal position

sensor connector.

17 CHECK POWER SUPPLY OF ACCELERA-

TOR PEDAL POSITION SENSOR.

1) Measure the voltage between accelerator

pedal position sensor connector and engine

ground.

Connector & terminal

(B315) No. 2 (+) — Engine ground (

−):

(B315) No. 5 (+) — Engine ground (

−):

2) Check the voltage change by shaking the

harness and connector of ECM while monitor-

ing the value with voltage meter.Is the voltage less than 4.8 V? Go to step 18.Repair short circuit

in harness between

ECM connector and

accelerator pedal

position sensor con-

nector.

18 CHECK HARNESS BETWEEN ECM AND AC-

CELERATOR PEDAL POSITION SENSOR.

1) Turn the ignition switch to OFF.

2) Connect the accelerator pedal position sen-

sor connector.

3) Turn the ignition switch to ON.

4) Measure the voltage between ECM connector

and chassis ground.

Connector & terminal

(B136) No. 17 (+) — Chassis ground (

−):

(B136) No. 28 (+) — Chassis ground (

−):Is the voltage less than 4.8 V? Go to step 19.Repair poor contact

in accelerator pedal

position sensor con-

nector. Replace the

accelerator pedal

position sensor if

defective. Step Check Yes No