torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1080 of 2870

SC(H4SO)-5

STARTING/CHARGING SYSTEM

General Description

C: CAUTION

Wear working clothing, including a cap, protec-

tive goggles, and protective shoes during opera-

tion.

Remove contamination including dirt and corro-

sion before removal, installation or disassembly.

Keep the disassembled parts in order and pro-

tect them from dust or dirt.

Before removal, installation or disassembly, be

sure to clarify the failure. Avoid unnecessary re-

moval, installation, disassembly, and replacement.

Be careful not to burn yourself, because each

part in the vehicle is hot after running.

Be sure to tighten fasteners including bolts and

nuts to the specified torque.

Place shop jacks or rigid racks at the specified

points.

Before disconnecting electrical connectors of

sensors or units, be sure to disconnect the ground

cable from battery.

Page 1081 of 2870

SC(H4SO)-6

STARTING/CHARGING SYSTEM

Starter

2. Starter

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the air cleaner case. (Non-turbo model)

3) Remove the intercooler. (Turbo model)

4) Remove the air cleaner case stay. (Non-turbo

model)

MT model

AT model5) Disconnect the connector and terminal from

starter.

6) Remove the starter from transmission.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

50 N

⋅m (5.1 kgf-m, 37 ft-lb)

FU-00009

SC-00004

SC-00005

(A) Terminal

(B) Connector

SC-00006

SC-00007

SC-00007

Page 1088 of 2870

SC(H4SO)-13

STARTING/CHARGING SYSTEM

Starter

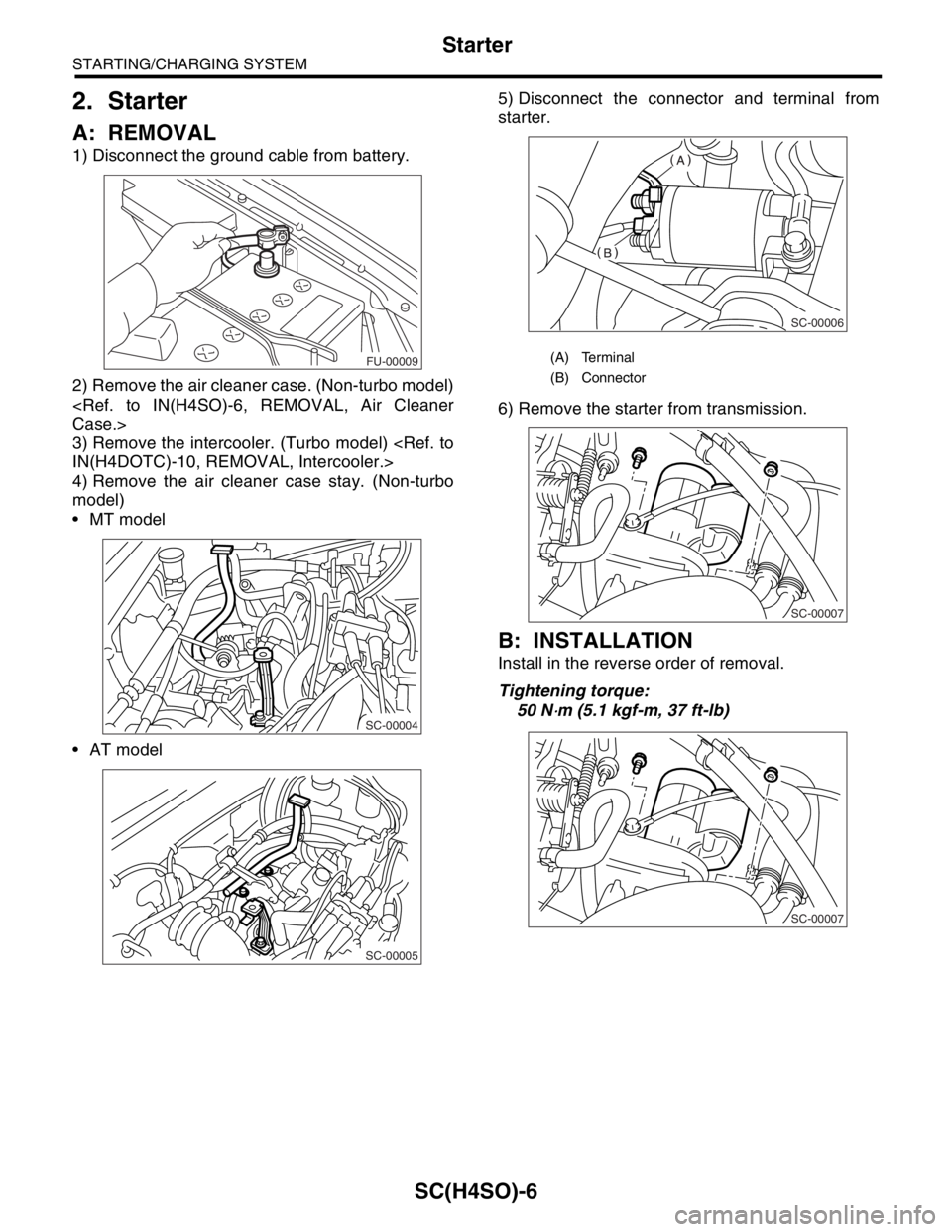

7. PINION GAP

1) Measure the pinion gap while the pinion is pulled

out as shown in the figure.

Pinion gap:

0.5 — 2.0 mm (0.020 — 0.079 in)

If the motor is running with the pinion forced end-

wise on shaft, disconnect the connector from termi-

nal M of switch assembly, and then connect

terminal M to ground terminal (−) of battery with a

lead wire. Next, gently push the pinion back with

your fingertips, and then measure the pinion gap.

2) If the pinion gap is outside specified range, re-

move or add number of adjustment washers used

on the mounting surface of switch assembly until

correct pinion gap is obtained.

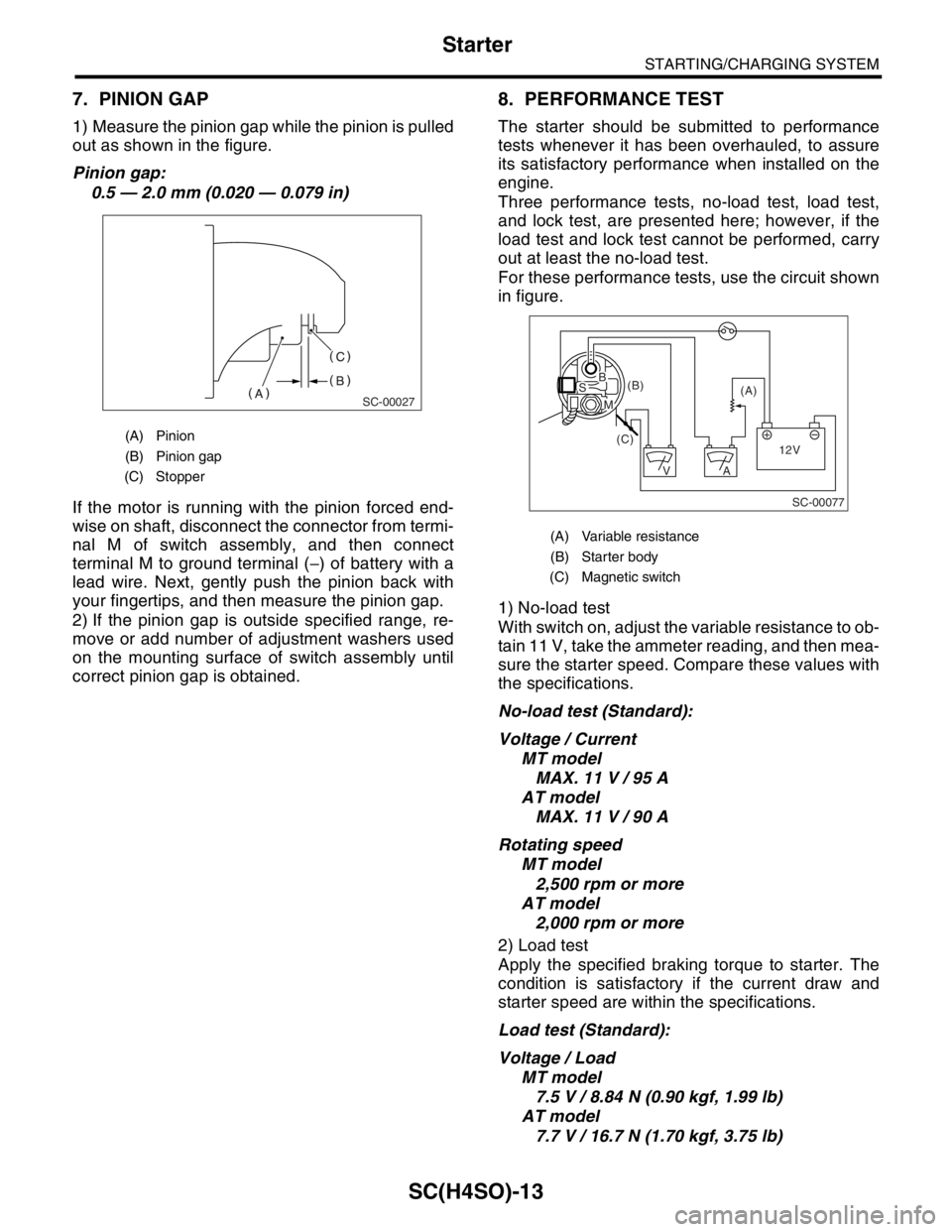

8. PERFORMANCE TEST

The starter should be submitted to performance

tests whenever it has been overhauled, to assure

its satisfactory performance when installed on the

engine.

Three performance tests, no-load test, load test,

and lock test, are presented here; however, if the

load test and lock test cannot be performed, carry

out at least the no-load test.

For these performance tests, use the circuit shown

in figure.

1) No-load test

With switch on, adjust the variable resistance to ob-

tain 11 V, take the ammeter reading, and then mea-

sure the starter speed. Compare these values with

the specifications.

No-load test (Standard):

Voltage / Current

MT model

MAX. 11 V / 95 A

AT model

MAX. 11 V / 90 A

Rotating speed

MT model

2,500 rpm or more

AT model

2,000 rpm or more

2) Load test

Apply the specified braking torque to starter. The

condition is satisfactory if the current draw and

starter speed are within the specifications.

Load test (Standard):

Voltage / Load

MT model

7.5 V / 8.84 N (0.90 kgf, 1.99 lb)

AT model

7.7 V / 16.7 N (1.70 kgf, 3.75 lb)

(A) Pinion

(B) Pinion gap

(C) Stopper

SC-00027

(A) Variable resistance

(B) Starter body

(C) Magnetic switch

SC-00077

(A) (B)

(C)

12V +

AV

BS

M

Page 1089 of 2870

SC(H4SO)-14

STARTING/CHARGING SYSTEM

Starter

Current / Speed

MT model

300 A / 870 rpm or more

AT model

400 A / 710 rpm or more

3) Lock test

With the starter stalled, or not rotating, measure the

torque developed and current draw when the volt-

age is adjusted to the specified voltage.

Lock test (Standard):

Voltage / Current

MT model

4 V / 680 A or less

AT model

3.5 V / 960 A or less

Torque

MT model

17.0 N (1.73 kgf, 3.82 lb) or more

AT model

31.0 N (3.16 kgf, 6.97 lb) or more

Page 1096 of 2870

SC(H4SO)-21

STARTING/CHARGING SYSTEM

Battery

4. Battery

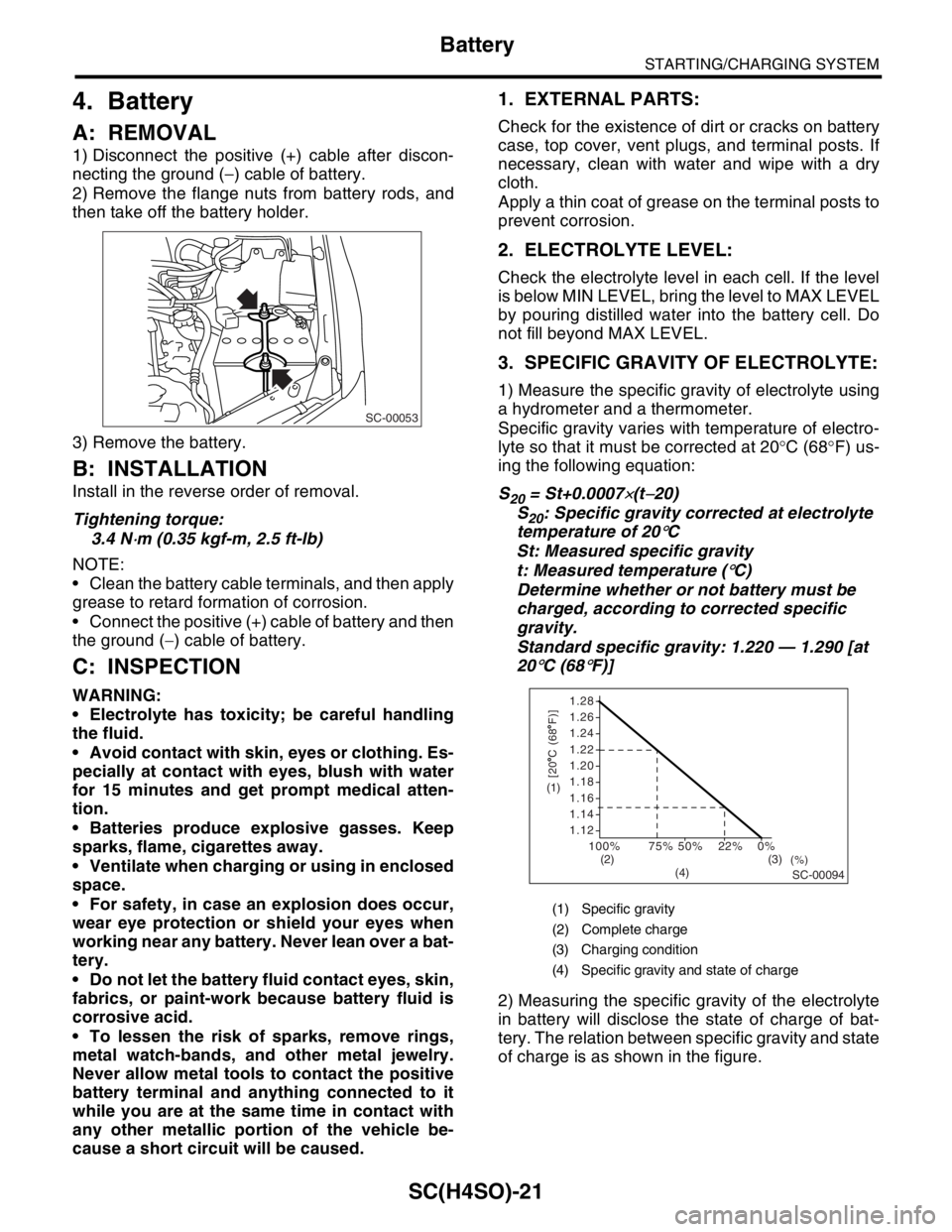

A: REMOVAL

1) Disconnect the positive (+) cable after discon-

necting the ground (−) cable of battery.

2) Remove the flange nuts from battery rods, and

then take off the battery holder.

3) Remove the battery.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

3.4 N

⋅m (0.35 kgf-m, 2.5 ft-lb)

NOTE:

Clean the battery cable terminals, and then apply

grease to retard formation of corrosion.

Connect the positive (+) cable of battery and then

the ground (−) cable of battery.

C: INSPECTION

WARNING:

Electrolyte has toxicity; be careful handling

the fluid.

Avoid contact with skin, eyes or clothing. Es-

pecially at contact with eyes, blush with water

for 15 minutes and get prompt medical atten-

tion.

Batteries produce explosive gasses. Keep

sparks, flame, cigarettes away.

Ventilate when charging or using in enclosed

space.

For safety, in case an explosion does occur,

wear eye protection or shield your eyes when

working near any battery. Never lean over a bat-

tery.

Do not let the battery fluid contact eyes, skin,

fabrics, or paint-work because battery fluid is

corrosive acid.

To lessen the risk of sparks, remove rings,

metal watch-bands, and other metal jewelry.

Never allow metal tools to contact the positive

battery terminal and anything connected to it

while you are at the same time in contact with

any other metallic portion of the vehicle be-

cause a short circuit will be caused.

1. EXTERNAL PARTS:

Check for the existence of dirt or cracks on battery

case, top cover, vent plugs, and terminal posts. If

necessary, clean with water and wipe with a dry

cloth.

Apply a thin coat of grease on the terminal posts to

prevent corrosion.

2. ELECTROLYTE LEVEL:

Check the electrolyte level in each cell. If the level

is below MIN LEVEL, bring the level to MAX LEVEL

by pouring distilled water into the battery cell. Do

not fill beyond MAX LEVEL.

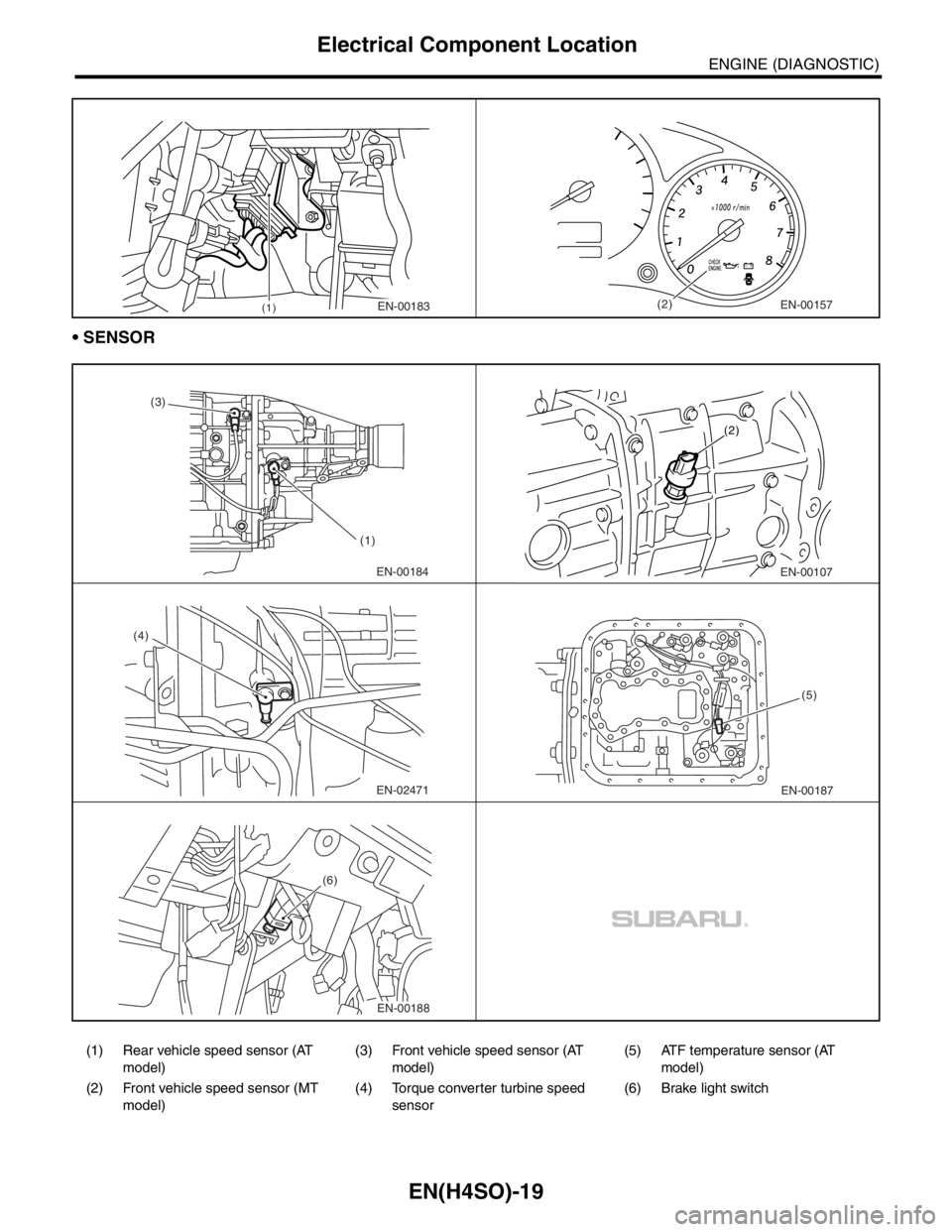

3. SPECIFIC GRAVITY OF ELECTROLYTE:

1) Measure the specific gravity of electrolyte using

a hydrometer and a thermometer.

Specific gravity varies with temperature of electro-

lyte so that it must be corrected at 20°C (68°F) us-

ing the following equation:

S

20 = St+0.0007×(t−20)

S

20: Specific gravity corrected at electrolyte

temperature of 20

°C

St: Measured specific gravity

t: Measured temperature (

°C)

Determine whether or not battery must be

charged, according to corrected specific

gravity.

Standard specific gravity: 1.220 — 1.290 [at

20

°C (68°F)]

2) Measuring the specific gravity of the electrolyte

in battery will disclose the state of charge of bat-

tery. The relation between specific gravity and state

of charge is as shown in the figure.

SC-00053

(1) Specific gravity

(2) Complete charge

(3) Charging condition

(4) Specific gravity and state of charge

1.28

1.26

1.24

1.22

1.20

1.18

1.16

1.14

1.12

100%

(%)75% 50% 22% 0%

SC-00094

[20 C (68 F)](1)

(2) (3)

(4)

Page 1117 of 2870

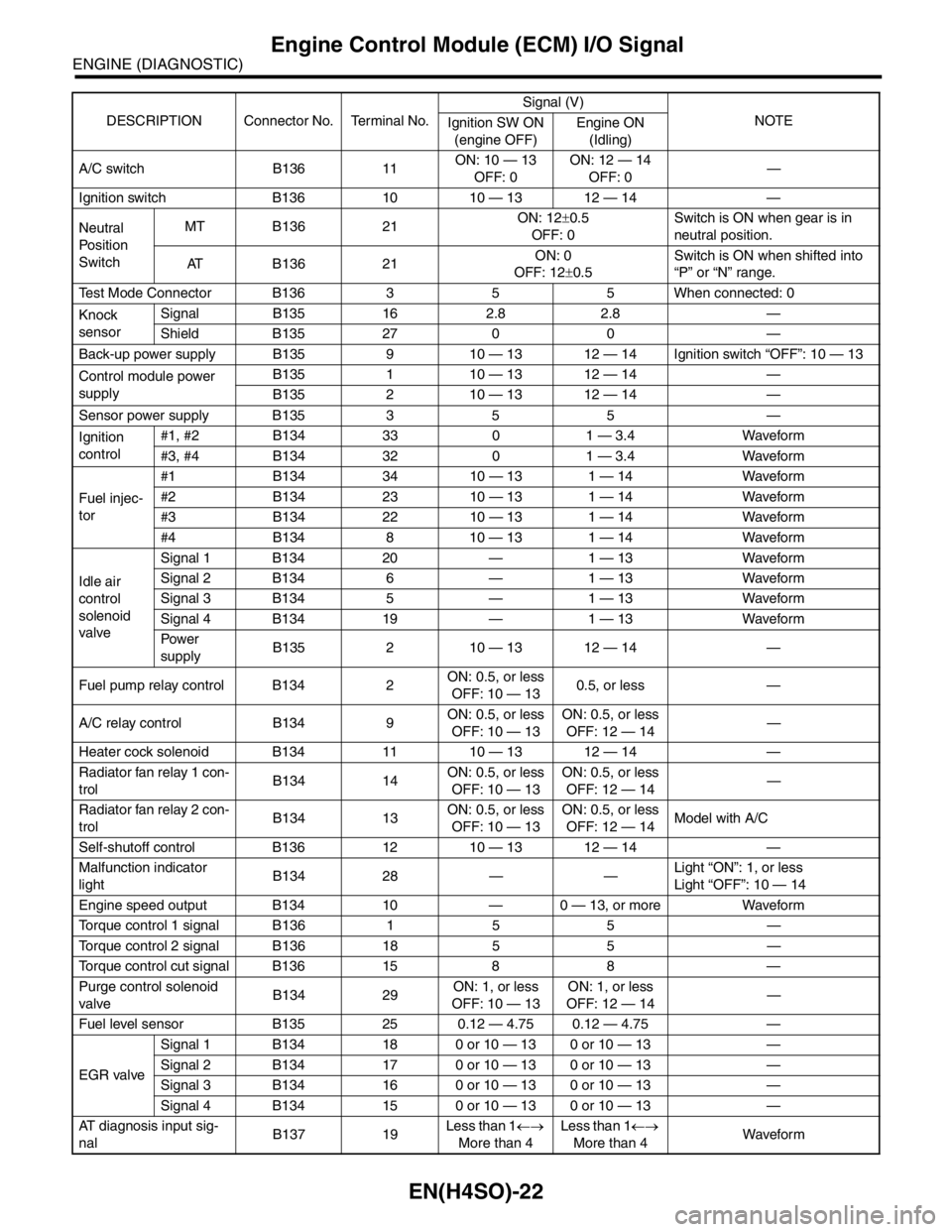

EN(H4SO)-19

ENGINE (DIAGNOSTIC)

Electrical Component Location

SENSOR

(1) Rear vehicle speed sensor (AT

model)(3) Front vehicle speed sensor (AT

model)(5) ATF temperature sensor (AT

model)

(2) Front vehicle speed sensor (MT

model)(4) Torque converter turbine speed

sensor(6) Brake light switch

(1)EN-00183(2)EN-00157

EN-00184 (3)

(1)EN-00107 (2)

EN-02471 (4)EN-00187(5)

EN-00188 (6)

Page 1120 of 2870

EN(H4SO)-22

ENGINE (DIAGNOSTIC)

Engine Control Module (ECM) I/O Signal

A/C switch B136 11ON: 10 — 13

OFF: 0ON: 12 — 14

OFF: 0—

Ignition switch B136 10 10 — 13 12 — 14 —

Neutral

Po si ti o n

SwitchMT B136 21ON: 12±0.5

OFF: 0Switch is ON when gear is in

neutral position.

AT B136 21ON: 0

OFF: 12±0.5Switch is ON when shifted into

“P” or “N” range.

Test Mode Connector B136 3 5 5 When connected: 0

Knock

sensorSignal B135 16 2.8 2.8 —

Shield B135 27 0 0 —

Back-up power supply B135 9 10 — 13 12 — 14 Ignition switch “OFF”: 10 — 13

Control module power

supplyB135 1 10 — 13 12 — 14 —

B135 2 10 — 13 12 — 14 —

Sensor power supply B135 3 5 5 —

Ignition

control#1, #2 B134 33 0 1 — 3.4 Waveform

#3, #4 B134 32 0 1 — 3.4 Waveform

Fuel injec-

tor#1 B134 34 10 — 13 1 — 14 Waveform

#2 B134 23 10 — 13 1 — 14 Waveform

#3 B134 22 10 — 13 1 — 14 Waveform

#4 B134 8 10 — 13 1 — 14 Waveform

Idle air

control

solenoid

valveSignal 1 B134 20 — 1 — 13 Waveform

Signal 2 B134 6 — 1 — 13 Waveform

Signal 3 B134 5 — 1 — 13 Waveform

Signal 4 B134 19 — 1 — 13 Waveform

Pow er

supplyB135 2 10 — 13 12 — 14 —

Fuel pump relay control B134 2ON: 0.5, or less

OFF: 10 — 130.5, or less —

A/C relay control B134 9ON: 0.5, or less

OFF: 10 — 13ON: 0.5, or less

OFF: 12 — 14—

Heater cock solenoid B134 11 10 — 13 12 — 14 —

Radiator fan relay 1 con-

trolB134 14ON: 0.5, or less

OFF: 10 — 13ON: 0.5, or less

OFF: 12 — 14—

Radiator fan relay 2 con-

trolB134 13ON: 0.5, or less

OFF: 10 — 13ON: 0.5, or less

OFF: 12 — 14Model with A/C

Self-shutoff control B136 12 10 — 13 12 — 14 —

Malfunction indicator

lightB134 28 — —Light “ON”: 1, or less

Light “OFF”: 10 — 14

Engine speed output B134 10 — 0 — 13, or more Waveform

Torque control 1 signal B136 1 5 5 —

Torque control 2 signal B136 18 5 5 —

Torque control cut signal B136 15 8 8 —

Purge control solenoid

valveB134 29ON: 1, or less

OFF: 10 — 13ON: 1, or less

OFF: 12 — 14—

Fuel level sensor B135 25 0.12 — 4.75 0.12 — 4.75 —

EGR valveSignal 1 B134 18 0 or 10 — 13 0 or 10 — 13 —

Signal 2 B134 17 0 or 10 — 13 0 or 10 — 13 —

Signal 3 B134 16 0 or 10 — 13 0 or 10 — 13 —

Signal 4 B134 15 0 or 10 — 13 0 or 10 — 13 —

AT diagnosis input sig-

nalB137 19Less than 1←→

More than 4Less than 1←→

More than 4Wavefor m DESCRIPTION Connector No. Terminal No.Signal (V)

NOTE

Ignition SW ON

(engine OFF)Engine ON

(Idling)

Page 1128 of 2870

![SUBARU FORESTER 2004 Service Repair Manual EN(H4SO)-30

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

4. READ CURRENT DATA FOR ENGINE. (NORMAL MODE)

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) SUBARU FORESTER 2004 Service Repair Manual EN(H4SO)-30

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

4. READ CURRENT DATA FOR ENGINE. (NORMAL MODE)

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2)](/img/17/57426/w960_57426-1127.png)

EN(H4SO)-30

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

4. READ CURRENT DATA FOR ENGINE. (NORMAL MODE)

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Selection Menu» display screen, select the {Engine} and press the [YES] key.

3) Press the [YES] key after the information of engine type was displayed.

4) On the «Engine Diagnosis» display screen, select the {Current Data Display/Save}, and then press the

[YES] key.

5) On the «Data Display Menu» display screen, select the {Data Display} and press the [YES] key.

6) Using the scroll key, scroll the display screen up or down until the desired data is shown.

A list of the support data is shown in the following table.

Description Display Unit of measure

Battery voltage Battery Voltage V

Vehicle speed signal Meter vehicle speed km/h or MPH

Engine speed signal Engine speed rpm

Engine coolant temperature signal Engine coolant temperature°C or (°F)

Ignition timing signal Ignition timing deg

Throttle position signal Amount of intake air %

Throttle position signal Throttle Sensor Voltage V

Injection pulse width Fuel injection pulse width ms

Idle air control signal ISC Steps STEP

Engine load data Engine load %

Front oxygen (A/F) sensor resistance A/F sensor resistance value 1 ohm

Front oxygen (A/F) sensor output signal A/F sensor current value 1 —

Rear oxygen sensor output signalRear oxygen sensor voltage

valueV

Short term fuel trim A/F Compensation 1 %

Knock sensor signal Knock Correction deg

Atmospheric absolute pressure signal Atmospheric pressure mmHg, kPa, inHg or psi

Intake manifold relative pressure signal Mani. Relative Pressure mmHg, kPa, inHg or psi

Intake manifold absolute pressure signalIntake manifold absolute pres-

suremmHg, kPa, inHg or psi

A/F correction (short term fuel trim) by rear oxygen sensor A/F Compensation 3 %

Long term whole fuel trim A/F learning 1 %

Front oxygen (A/F) sensor heater current Front O2 heater current value A

Rear oxygen sensor heater current Rear O2 heater current value A

Canister purge control solenoid valve duty ratio CPC Valve Duty Ratio %

Fuel level signal Fuel level voltage V

Intake air temperature signal Intake air temperature°C or (°F)

Learned ignition timing Ignition learning value deg

EGR signal EGR Steps STEP

Ignition switch signal Ignition SW ON or OFF

Test mode connector signal Test mode signal ON or OFF

Neutral position switch signal Neutral SW ON or OFF

Air conditioning switch signal A/C SW ON or OFF

Air conditioning compressor signal A/C Compressor Signal ON or OFF

Radiator main fan relay signal Radiator fan relay 1 ON or OFF

Fuel pump relay signal Fuel pump relay ON or OFF

Knocking signal Knock signal ON or OFF

Radiator sub fan relay signal Radiator fan relay 2 ON or OFF

Power steering switch signal Power steering SW input signal ON or OFF

Engine torque control signal #1 AT coordinate request signal 1 ON or OFF

Engine torque control signal #2 AT coordinate request signal 2 ON or OFF

Page 1129 of 2870

EN(H4SO)-31

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

NOTE:

For detailed operation procedure, refer to the “SUBARU SELECT MONITOR OPERATION MANUAL”.

Engine torque control permission signalAT coordinate permission sig-

nalON or OFF

Rear oxygen sensor rich signal Rear O2 monitor ON or OFF

Starter switch signal Starter SW ON or OFF

Idle switch signal Soft idle SW ON or OFF

Crankshaft position sensor signal Crankshaft position signal ON or OFF

Camshaft position sensor signal Camshaft position signal ON or OFF

Rear defogger switch signal Rear defogger SW ON or OFF

Blower fan switch signal Blower fan SW ON or OFF

Small light switch signal Light SW ON or OFF

AT vehicle ID signal AT/MT identification terminal AT or MT

A/C middle pressure switch signal A/C middle pressure SW ON or OFFDescription Display Unit of measure

Page 1132 of 2870

![SUBARU FORESTER 2004 Service Repair Manual EN(H4SO)-34

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

7. LED OPERATION MODE FOR ENGINE

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «Syste SUBARU FORESTER 2004 Service Repair Manual EN(H4SO)-34

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

7. LED OPERATION MODE FOR ENGINE

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «Syste](/img/17/57426/w960_57426-1131.png)

EN(H4SO)-34

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

7. LED OPERATION MODE FOR ENGINE

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Selection Menu» display screen, select the {Engine} and press the [YES] key.

3) Press the [YES] key after the information of engine type was displayed.

4) On the «Engine Diagnosis» display screen, select the {Current Data Display/Save}, and then press the

[YES] key.

5) On the «Data Display Menu» display screen, select the {Data & LED Display} and press the [YES] key.

6) Using the scroll key, scroll the display screen up or down until the desired data is shown.

A list of the support data is shown in the following table.

NOTE:

For detailed operation procedure, refer to the “SUBARU SELECT MONITOR OPERATION MANUAL”.

Description Display Message LED “ON” requirements

Ignition switch signal Ignition SW ON or OFF When ignition switch is ON

Test mode connector signal Test mode signal ON or OFF When test mode connector is connected.

Neutral position switch signal Neutral SW ON or OFF When neutral position signal is entered.

Air conditioning switch signal A/C SW ON or OFF When air conditioning switch is ON

Air conditioning relay signal A/C Compressor Relay ON or OFF When air conditioning relay is in function.

Radiator main fan relay signal Radiator fan relay 1 ON or OFF When radiator main fan relay is in function.

Fuel pump relay signal Fuel pump relay ON or OFF When fuel pump relay is in function.

Knocking signal Knock signal ON or OFF When knocking signal is input.

Radiator sub fan relay signal Radiator fan relay 2 ON or OFF When radiator sub fan relay is in function.

Engine torque control signal #1 AT coordinate request signal 1 ON or OFFWhen engine torque control signal 1 is

entered

Engine torque control signal #2 AT coordinate request signal 2 ON or OFFWhen engine torque control signal 2 is

entered

Engine torque control permission

signalAT coordinate permission sig-

nalON or OFFWhen engine torque control permission sig-

nal is entered.

Front oxygen (A/F) sensor rich sig-

nalFront O2 Rich Signal #1 ON or OFFWhen front oxygen (A/F) sensor mixture ratio

is rich.

Rear oxygen sensor rich signal RrO2 monitor ON or OFFWhen rear oxygen sensor mixture ratio is

rich.

Starter switch signal Starter SW ON or OFF When starter switch signal is entered.

Idle switch signal Idle Switch Signal ON or OFF When idle switch signal is entered.

Crankshaft position sensor signal Crankshaft position signal ON or OFFWhen crankshaft position sensor signal is

input.

Camshaft position sensor signal Camshaft position signal ON or OFFWhen camshaft position sensor signal is

entered.