torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1055 of 2870

SP(H4SO)-2

SPEED CONTROL SYSTEM

General Description

1. General Description

A: SPECIFICATION

B: COMPONENT

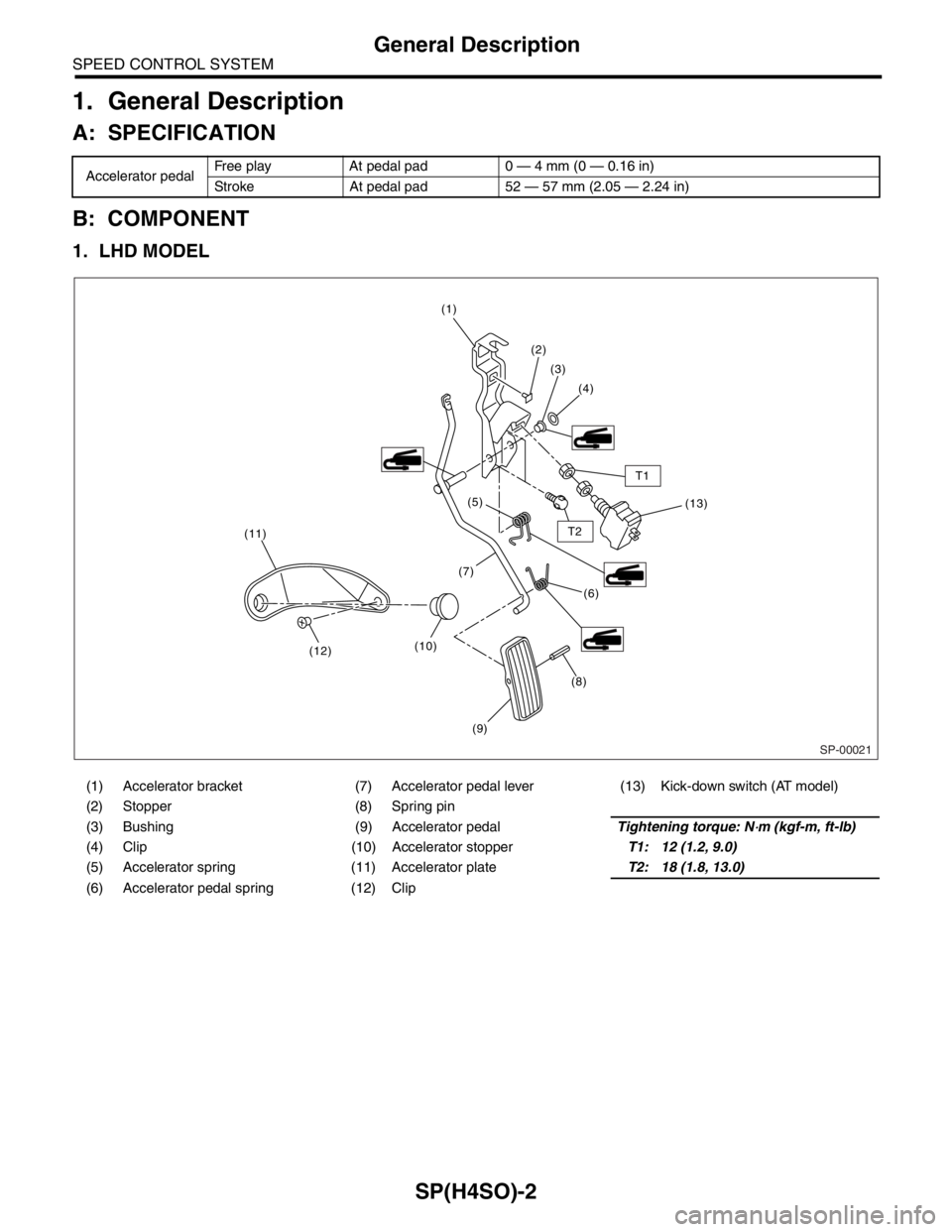

1. LHD MODEL

Accelerator pedalFree play At pedal pad 0 — 4 mm (0 — 0.16 in)

Stroke At pedal pad 52 — 57 mm (2.05 — 2.24 in)

(1) Accelerator bracket (7) Accelerator pedal lever (13) Kick-down switch (AT model)

(2) Stopper (8) Spring pin

(3) Bushing (9) Accelerator pedalTightening torque: N

⋅m (kgf-m, ft-lb)

(4) Clip (10) Accelerator stopperT1: 12 (1.2, 9.0)

(5) Accelerator spring (11) Accelerator plateT2: 18 (1.8, 13.0)

(6) Accelerator pedal spring (12) Clip

(8) (1)

(2)

(3)

(4)

(6)(13) (5)

(9) (10)(7)

(12) (11)

T2

T1

SP-00021

Page 1056 of 2870

SP(H4SO)-3

SPEED CONTROL SYSTEM

General Description

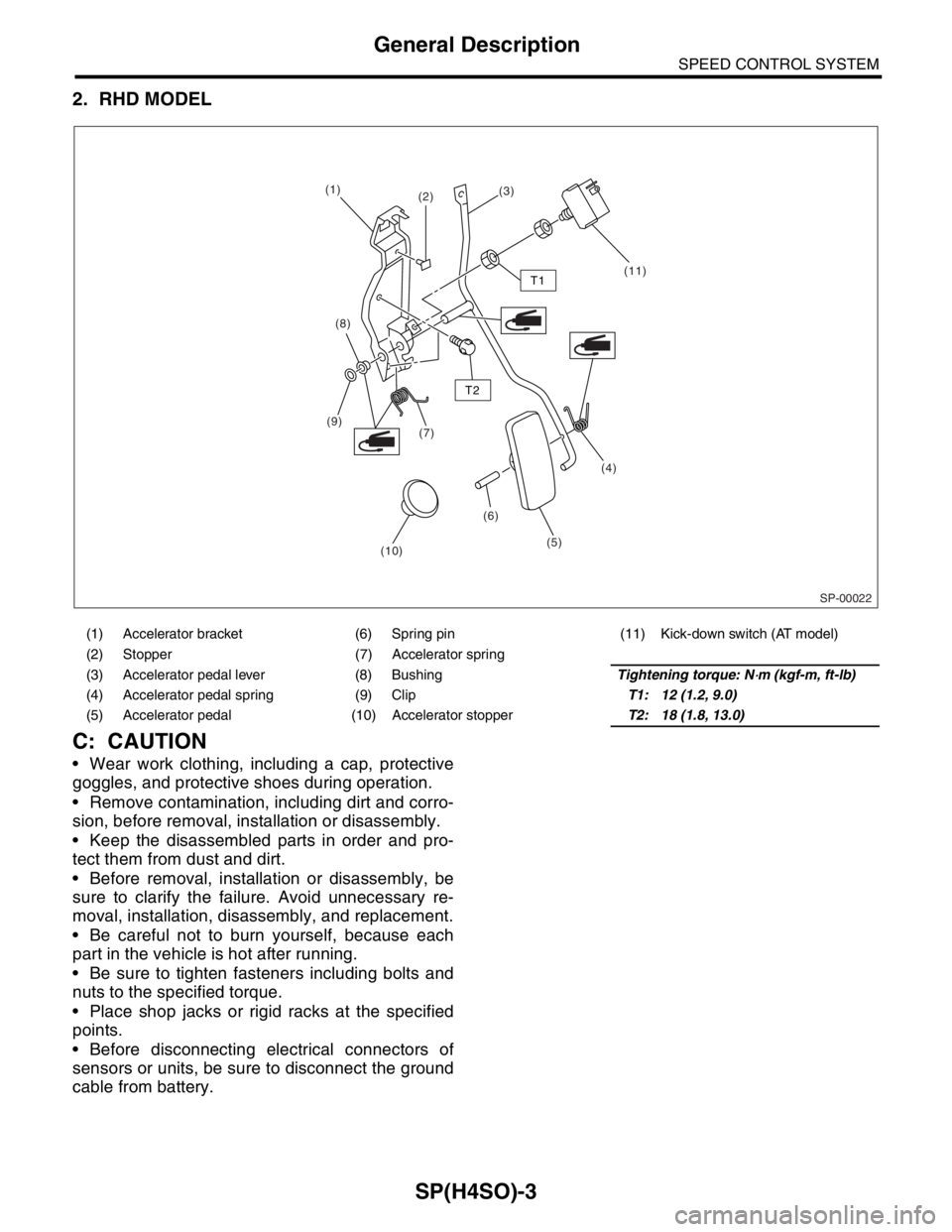

2. RHD MODEL

C: CAUTION

Wear work clothing, including a cap, protective

goggles, and protective shoes during operation.

Remove contamination, including dirt and corro-

sion, before removal, installation or disassembly.

Keep the disassembled parts in order and pro-

tect them from dust and dirt.

Before removal, installation or disassembly, be

sure to clarify the failure. Avoid unnecessary re-

moval, installation, disassembly, and replacement.

Be careful not to burn yourself, because each

part in the vehicle is hot after running.

Be sure to tighten fasteners including bolts and

nuts to the specified torque.

Place shop jacks or rigid racks at the specified

points.

Before disconnecting electrical connectors of

sensors or units, be sure to disconnect the ground

cable from battery.

(1) Accelerator bracket (6) Spring pin (11) Kick-down switch (AT model)

(2) Stopper (7) Accelerator spring

(3) Accelerator pedal lever (8) BushingTightening torque: N

⋅m (kgf-m, ft-lb)

(4) Accelerator pedal spring (9) ClipT1: 12 (1.2, 9.0)

(5) Accelerator pedal (10) Accelerator stopperT2: 18 (1.8, 13.0)

SP-00022

(1)

(2)(3)

(11)

(8)

(7) (9)

(6)(4)

(5)

(10)

T1

T2

Page 1058 of 2870

SP(H4SO)-5

SPEED CONTROL SYSTEM

Accelerator Pedal

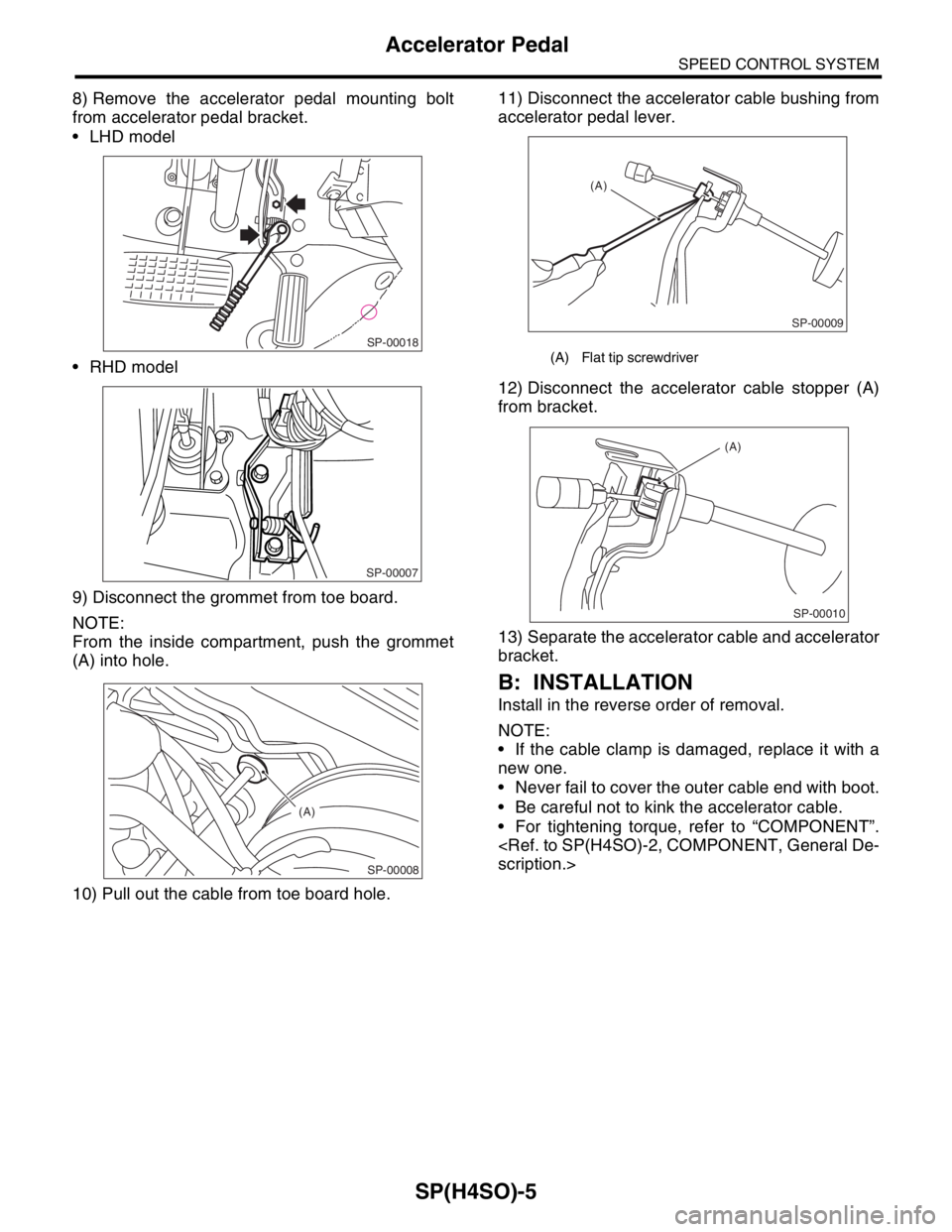

8) Remove the accelerator pedal mounting bolt

from accelerator pedal bracket.

LHD model

RHD model

9) Disconnect the grommet from toe board.

NOTE:

From the inside compartment, push the grommet

(A) into hole.

10) Pull out the cable from toe board hole.11) Disconnect the accelerator cable bushing from

accelerator pedal lever.

12) Disconnect the accelerator cable stopper (A)

from bracket.

13) Separate the accelerator cable and accelerator

bracket.

B: INSTALLATION

Install in the reverse order of removal.

NOTE:

If the cable clamp is damaged, replace it with a

new one.

Never fail to cover the outer cable end with boot.

Be careful not to kink the accelerator cable.

For tightening torque, refer to “COMPONENT”.

SP-00018

SP-00007

SP-00008

(A)

(A) Flat tip screwdriver

SP-00009

(A)

SP-00010

(A)

Page 1060 of 2870

SP(H4SO)-7

SPEED CONTROL SYSTEM

Accelerator Pedal

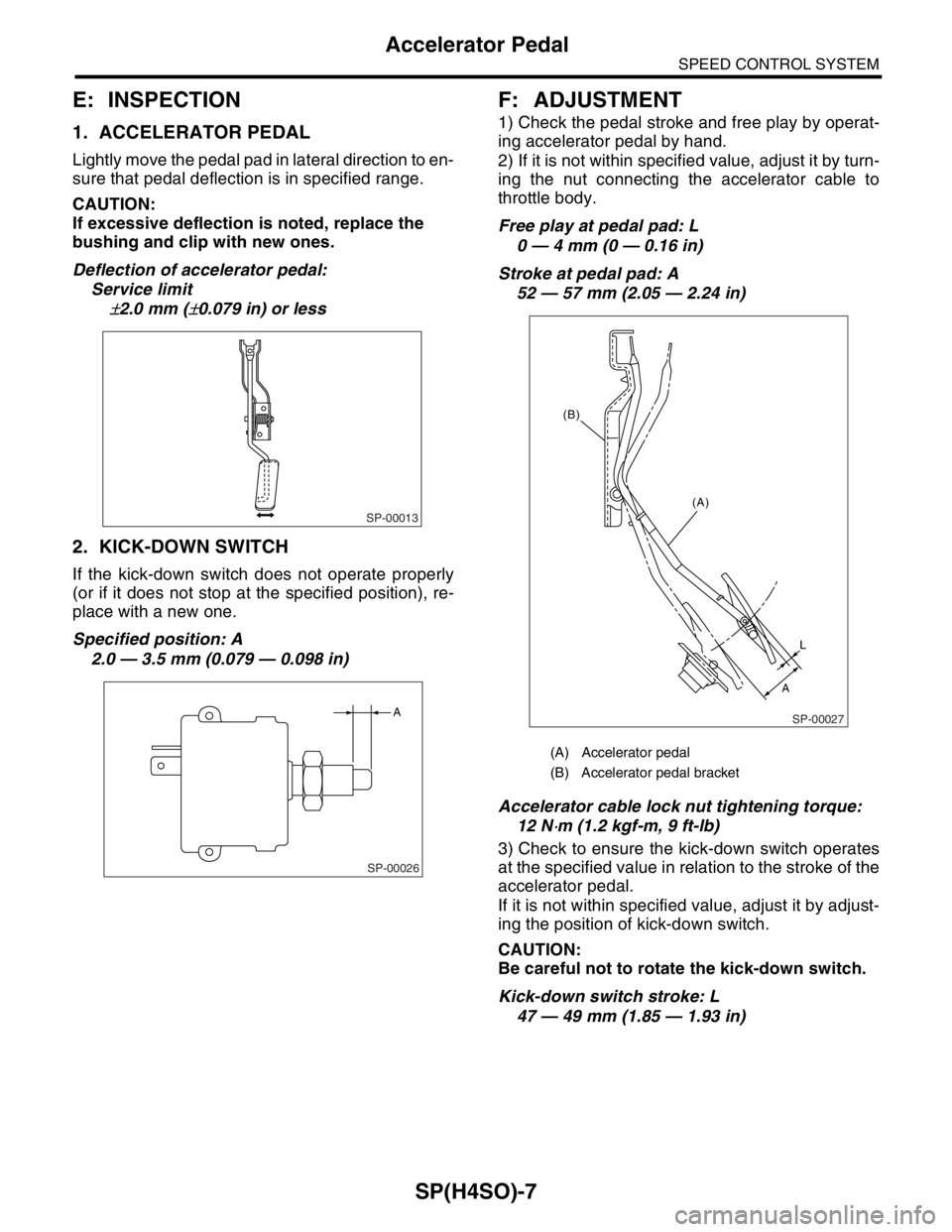

E: INSPECTION

1. ACCELERATOR PEDAL

Lightly move the pedal pad in lateral direction to en-

sure that pedal deflection is in specified range.

CAUTION:

If excessive deflection is noted, replace the

bushing and clip with new ones.

Deflection of accelerator pedal:

Service limit

±2.0 mm (±0.079 in) or less

2. KICK-DOWN SWITCH

If the kick-down switch does not operate properly

(or if it does not stop at the specified position), re-

place with a new one.

Specified position: A

2.0 — 3.5 mm (0.079 — 0.098 in)

F: ADJUSTMENT

1) Check the pedal stroke and free play by operat-

ing accelerator pedal by hand.

2) If it is not within specified value, adjust it by turn-

ing the nut connecting the accelerator cable to

throttle body.

Free play at pedal pad: L

0 — 4 mm (0 — 0.16 in)

Stroke at pedal pad: A

52 — 57 mm (2.05 — 2.24 in)

Accelerator cable lock nut tightening torque:

12 N

⋅m (1.2 kgf-m, 9 ft-lb)

3) Check to ensure the kick-down switch operates

at the specified value in relation to the stroke of the

accelerator pedal.

If it is not within specified value, adjust it by adjust-

ing the position of kick-down switch.

CAUTION:

Be careful not to rotate the kick-down switch.

Kick-down switch stroke: L

47 — 49 mm (1.85 — 1.93 in)

SP-00013

SP-00026

A

(A) Accelerator pedal

(B) Accelerator pedal bracket

SP-00027

(A)

L

A (B)

Page 1061 of 2870

SP(H4SO)-8

SPEED CONTROL SYSTEM

Accelerator Pedal

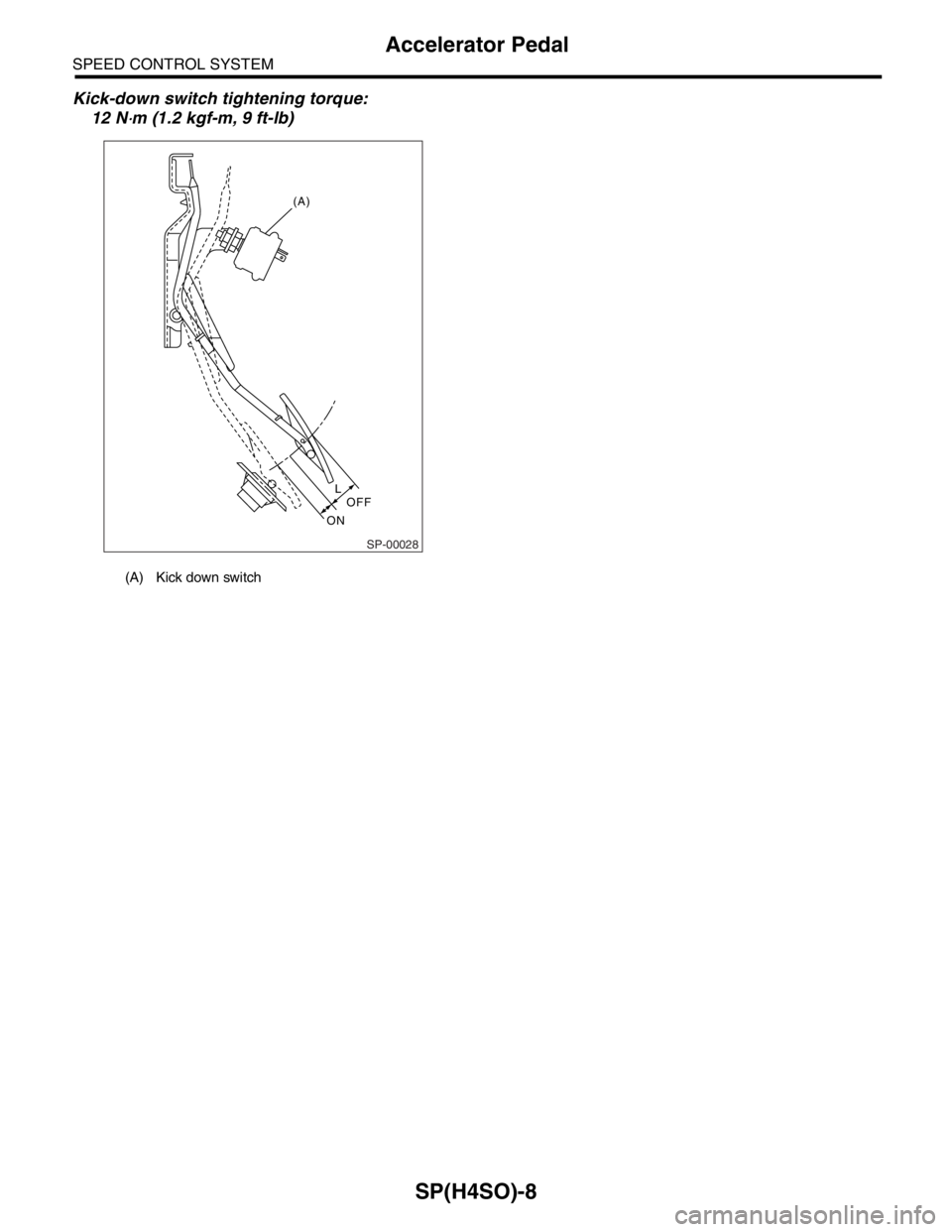

Kick-down switch tightening torque:

12 N

⋅m (1.2 kgf-m, 9 ft-lb)

(A) Kick down switch

SP-00028 (A)

L

OFF

ON

Page 1067 of 2870

IG(H4SO)-3

IGNITION

General Description

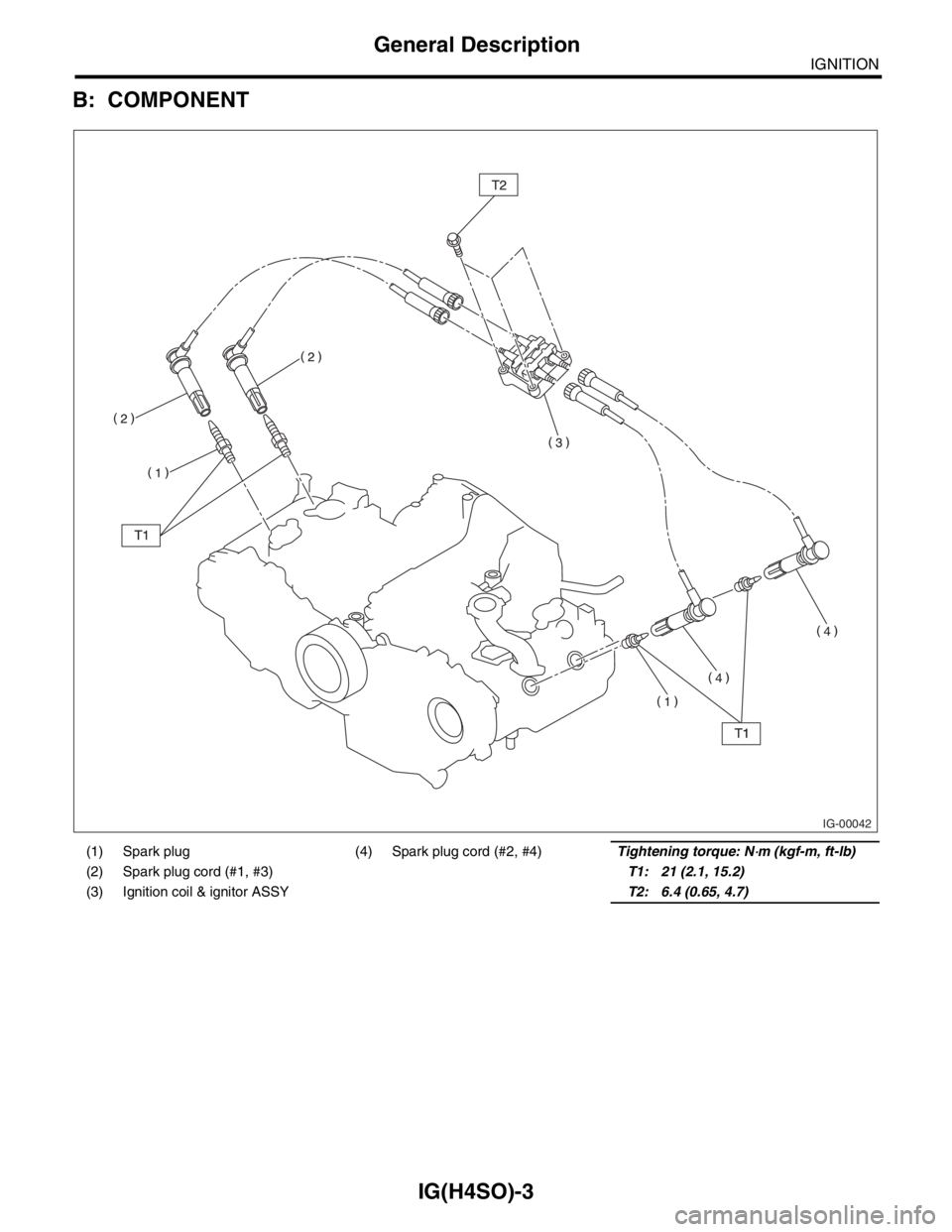

B: COMPONENT

(1) Spark plug (4) Spark plug cord (#2, #4)Tightening torque: N⋅m (kgf-m, ft-lb)

(2) Spark plug cord (#1, #3)T1: 21 (2.1, 15.2)

(3) Ignition coil & ignitor ASSYT2: 6.4 (0.65, 4.7)

IG-00042

Page 1068 of 2870

IG(H4SO)-4

IGNITION

General Description

C: CAUTION

Wear working clothing, including a cap, protec-

tive goggles, and protective shoes during opera-

tion.

Remove contamination including dirt and corro-

sion before removal, installation or disassembly.

Keep the disassembled parts in order and pro-

tect them from dust or dirt.

Before removal, installation or disassembly, be

sure to clarify the failure. Avoid unnecessary re-

moval, installation, disassembly, and replacement.

Be careful not to burn yourself, because each

part on the vehicle is hot after running.

Be sure to tighten fasteners including bolts and

nuts to the specified torque.

Place shop jacks or rigid racks at the specified

points.

Before disconnecting electrical connectors of

sensors or units, be sure to disconnect the ground

cable from battery.

Page 1070 of 2870

IG(H4SO)-6

IGNITION

Spark Plug

6) Remove the spark plugs with spark plug sock-

ets.

B: INSTALLATION

1. RH SIDE

Install in the reverse order of removal.

Tightening torque (Spark plug):

21 N

⋅m (2.1 kgf-m, 15.2 ft-lb)

NOTE:

The above torque should be only applied to new

spark plugs without oil on their threads.

In case their threads are lubricated, the torque

should be reduced by approx. 1/3 of the specified

torque in order to avoid over-stressing.

2. LH SIDE

Install in the reverse order of removal.

Tightening torque (Spark plug):

21 N

⋅m (2.1 kgf-m, 15.2 ft-lb)

NOTE:

The above torque should be only applied to new

spark plugs without oil on their threads.

In case their threads are lubricated, the torque

should be reduced by approx. 1/3 of the specified

torque in order to avoid over-stressing.

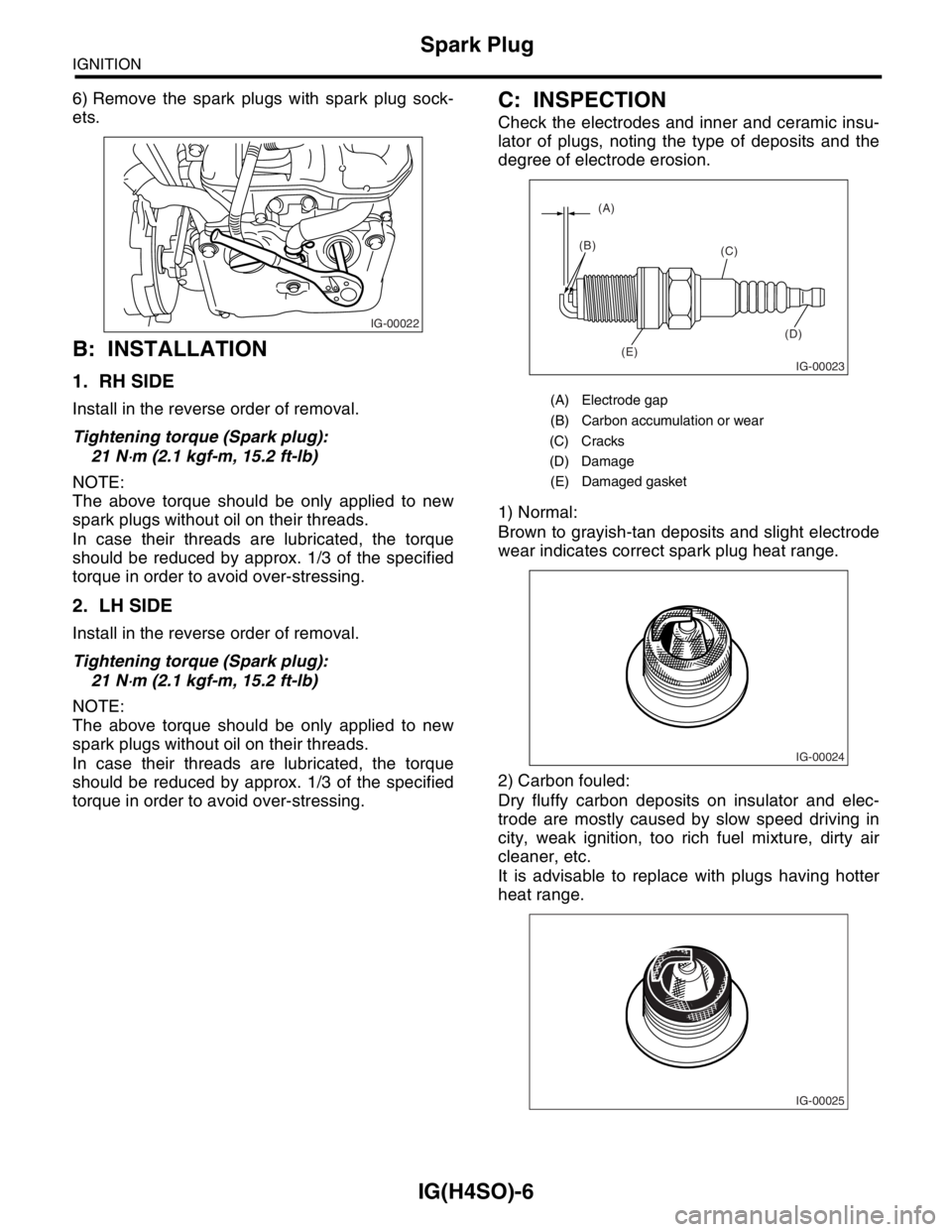

C: INSPECTION

Check the electrodes and inner and ceramic insu-

lator of plugs, noting the type of deposits and the

degree of electrode erosion.

1) Normal:

Brown to grayish-tan deposits and slight electrode

wear indicates correct spark plug heat range.

2) Carbon fouled:

Dry fluffy carbon deposits on insulator and elec-

trode are mostly caused by slow speed driving in

city, weak ignition, too rich fuel mixture, dirty air

cleaner, etc.

It is advisable to replace with plugs having hotter

heat range.

IG-00022

(A) Electrode gap

(B) Carbon accumulation or wear

(C) Cracks

(D) Damage

(E) Damaged gasket

IG-00023

(A)

(B)

(C)

(D)

(E)

IG-00024

IG-00025

Page 1072 of 2870

IG(H4SO)-8

IGNITION

Ignition Coil & Ignitor Assembly

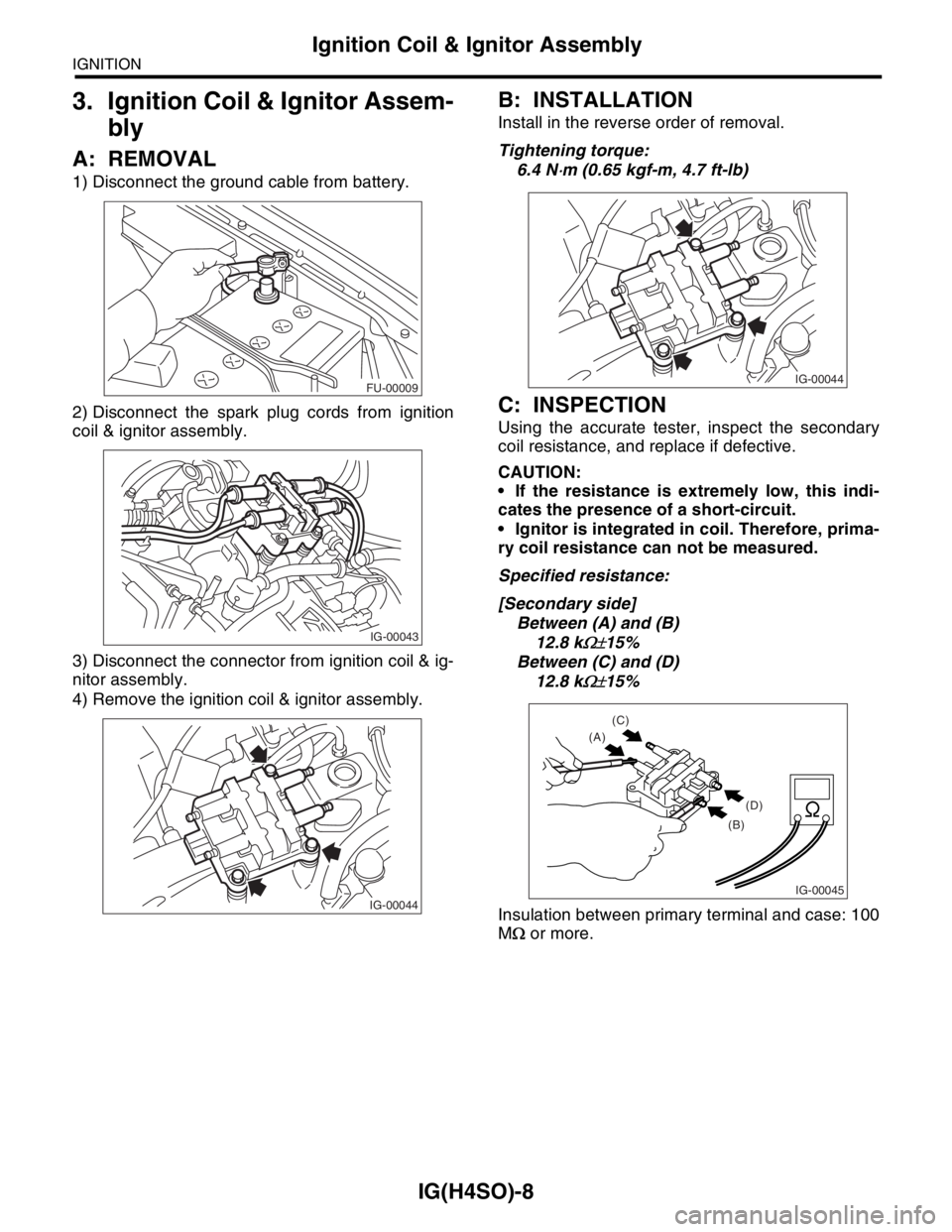

3. Ignition Coil & Ignitor Assem-

bly

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Disconnect the spark plug cords from ignition

coil & ignitor assembly.

3) Disconnect the connector from ignition coil & ig-

nitor assembly.

4) Remove the ignition coil & ignitor assembly.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

C: INSPECTION

Using the accurate tester, inspect the secondary

coil resistance, and replace if defective.

CAUTION:

If the resistance is extremely low, this indi-

cates the presence of a short-circuit.

Ignitor is integrated in coil. Therefore, prima-

ry coil resistance can not be measured.

Specified resistance:

[Secondary side]

Between (A) and (B)

12.8 k

Ω±15%

Between (C) and (D)

12.8 k

Ω±15%

Insulation between primary terminal and case: 100

MΩ or more.

FU-00009

IG-00043

IG-00044

IG-00044

IG-00045

(C)

(A)

(D)

(B)

Page 1077 of 2870

SC(H4SO)-2

STARTING/CHARGING SYSTEM

General Description

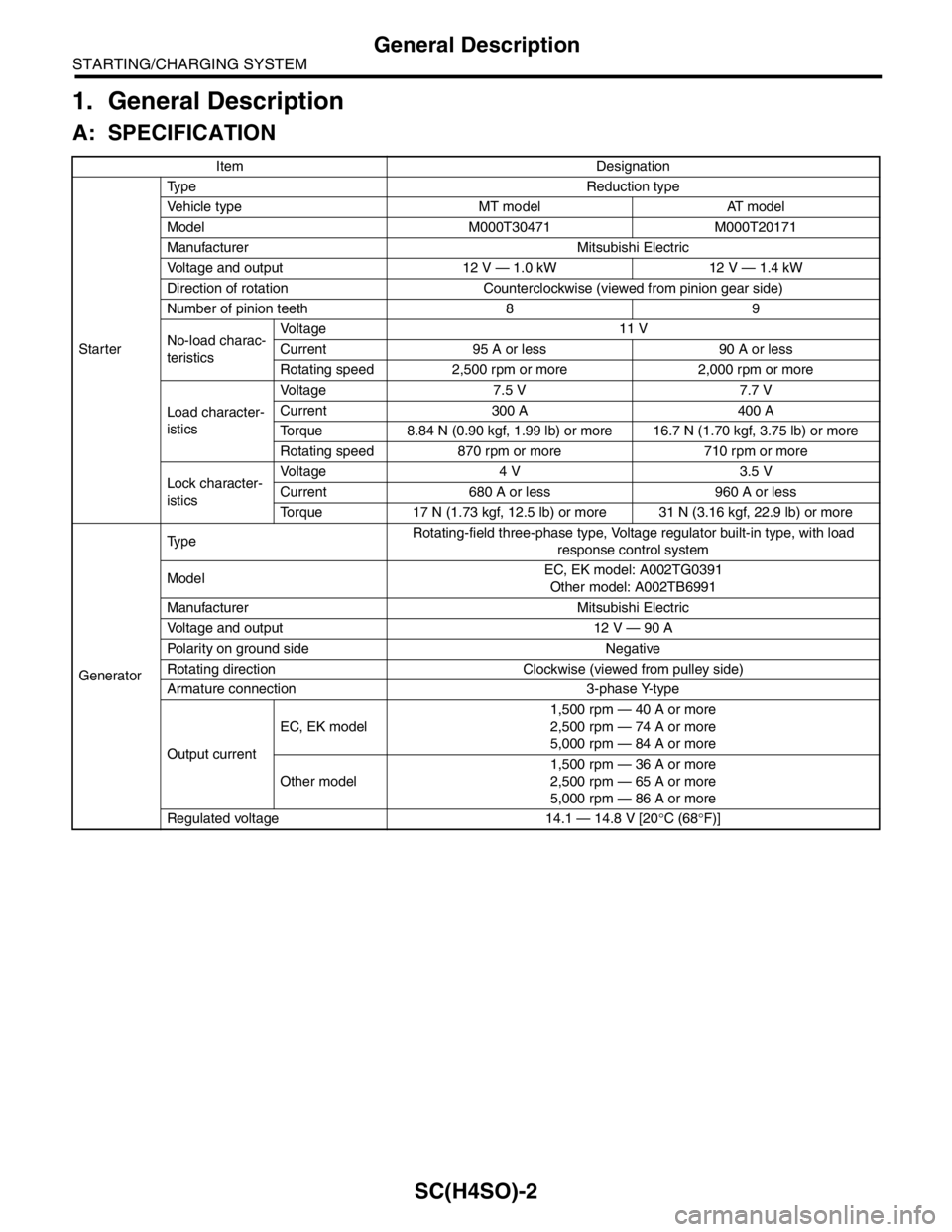

1. General Description

A: SPECIFICATION

Item Designation

StarterType Reduction type

Vehicle type MT model AT model

Model M000T30471 M000T20171

Manufacturer Mitsubishi Electric

Voltage and output 12 V — 1.0 kW 12 V — 1.4 kW

Direction of rotation Counterclockwise (viewed from pinion gear side)

Number of pinion teeth 8 9

No-load charac-

teristicsVo l t a g e 1 1 V

Current 95 A or less 90 A or less

Rotating speed 2,500 rpm or more 2,000 rpm or more

Load character-

isticsVoltage 7.5 V 7.7 V

Current 300 A 400 A

Torque 8.84 N (0.90 kgf, 1.99 lb) or more 16.7 N (1.70 kgf, 3.75 lb) or more

Rotating speed 870 rpm or more 710 rpm or more

Lock character-

isticsVo l t a g e 4 V 3 . 5 V

Current 680 A or less 960 A or less

Torque 17 N (1.73 kgf, 12.5 lb) or more 31 N (3.16 kgf, 22.9 lb) or more

GeneratorTy p eRotating-field three-phase type, Voltage regulator built-in type, with load

response control system

ModelEC, EK model: A002TG0391

Other model: A002TB6991

Manufacturer Mitsubishi Electric

Voltage and output 12 V — 90 A

Polarity on ground side Negative

Rotating direction Clockwise (viewed from pulley side)

Armature connection 3-phase Y-type

Output currentEC, EK model1,500 rpm — 40 A or more

2,500 rpm — 74 A or more

5,000 rpm — 84 A or more

Other model1,500 rpm — 36 A or more

2,500 rpm — 65 A or more

5,000 rpm — 86 A or more

Regulated voltage 14.1 — 14.8 V [20°C (68°F)]