torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1133 of 2870

![SUBARU FORESTER 2004 Service Repair Manual EN(H4SO)-35

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

8. READ CURRENT DATA FOR AT

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Sel SUBARU FORESTER 2004 Service Repair Manual EN(H4SO)-35

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

8. READ CURRENT DATA FOR AT

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Sel](/img/17/57426/w960_57426-1132.png)

EN(H4SO)-35

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

8. READ CURRENT DATA FOR AT

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Selection Menu» display screen, select the {Transmission} and press the [YES] key.

3) Press the [YES] key after the information of transmission type is displayed.

4) On the «Transmission Diagnosis» display screen, select the {Current Data Display & Save} and press the

[YES] key.

5) On the «Transmission Diagnosis» display screen, select the {Data Display} and press the [YES] key.

6) Using the scroll key, scroll the display screen up or down until the desired data is shown.

A list of the support data is shown in the following table.

Description Display Unit of measure

Battery voltage Battery Voltage V

Rear vehicle speed sensor signal Rear Wheel Speed km/h or MPH

Front vehicle speed sensor signal Front Wheel Speed km/h or MPH

Engine speed signal Engine speed rpm

ATF temperature signal ATF Temp.°C or °F

Throttle position sensor Throttle Sensor Voltage V

Gear Position Gear position —

Line pressure control duty ratio Line pressure duty %

Lock up clutch control duty ratio L/U Duty %

Transfer clutch control duty ratio AWD duty %

Throttle position sensor power supply Throttle sensor power supply V

Turbine revolution signal Turbine Revolution Speed rpm

2-4 Brake timing pressure control duty ratio 2-4 B Pressure Duty %

Intake manifold pressure sensor voltage Mani. Relative Voltage V

FWD switch signal FWD SW ON or OFF

Kick down switch signal Kick Down Switch ON or OFF

Stop light switch signal Stop Light SW ON or OFF

Anti lock brake system signal ABS signal ON or OFF

Cruise control system signal Cruise Control Signal ON or OFF

Neutral/Parking range signal N/P range ON or OFF

Reverse range signal R Range ON or OFF

Drive range signal D Range ON or OFF

3rd range signal 3rd Range Signal ON or OFF

2nd range signal 2nd Range Signal ON or OFF

1st range signal 1st Range Signal ON or OFF

Shift control solenoid A Shift Solenoid #1 ON or OFF

Shift control solenoid B Shift Solenoid #2 ON or OFF

Torque control output signal #1 Torque control output signal 1 ON or OFF

Torque control output signal #2 Torque control output signal 2 ON or OFF

Torque control cut signal Torque Control Cut Sig ON or OFF

2-4 brake timing control solenoid valve 2-4B Timing Solenoid ON or OFF

Low clutch timing control solenoid valve L/C timing solenoid ON or OFF

Automatic transmission diagnosis light output signal Diagnosis Lamp ON or OFF

Page 1135 of 2870

EN(H4SO)-37

ENGINE (DIAGNOSTIC)

Inspection Mode

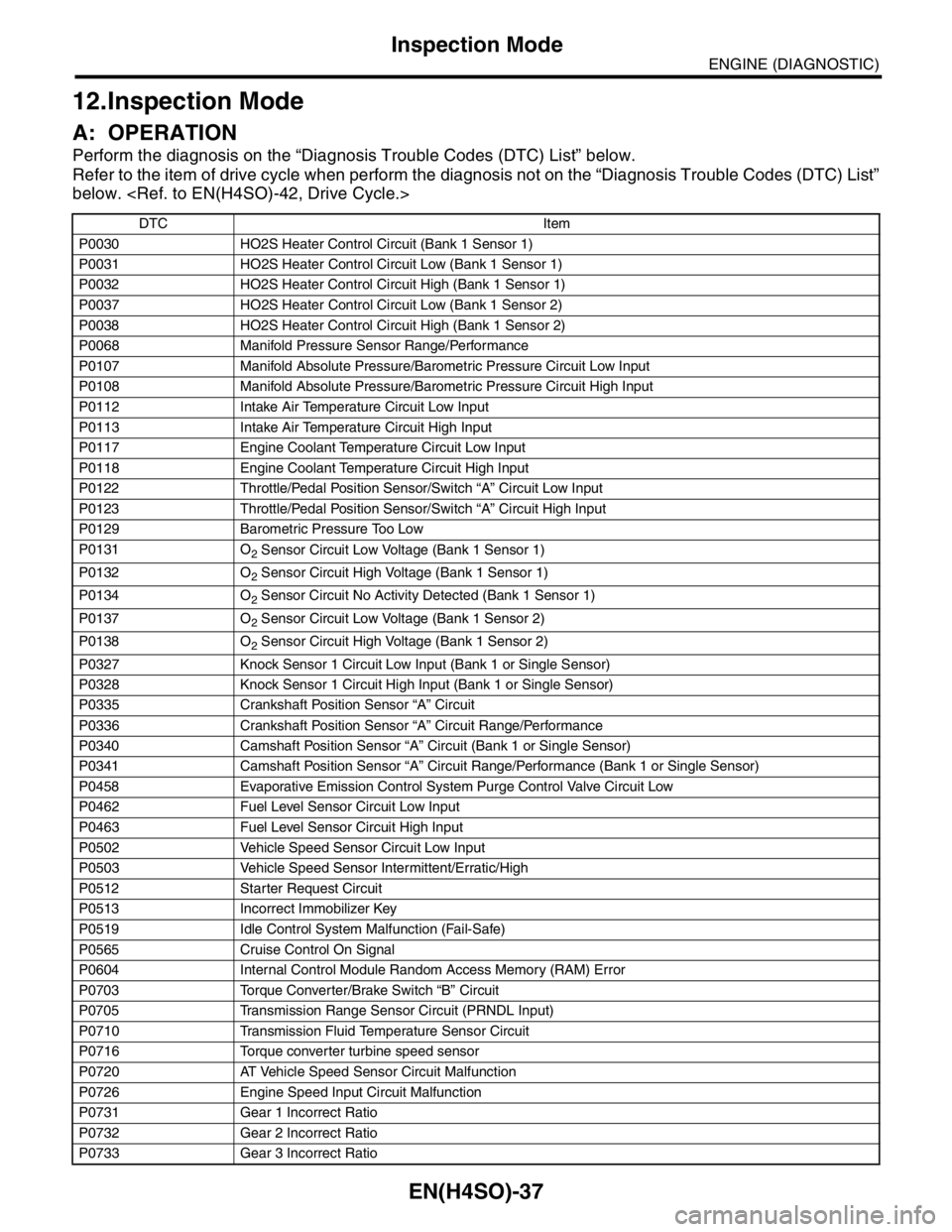

12.Inspection Mode

A: OPERATION

Perform the diagnosis on the “Diagnosis Trouble Codes (DTC) List” below.

Refer to the item of drive cycle when perform the diagnosis not on the “Diagnosis Trouble Codes (DTC) List”

below.

DTC Item

P0030 HO2S Heater Control Circuit (Bank 1 Sensor 1)

P0031 HO2S Heater Control Circuit Low (Bank 1 Sensor 1)

P0032 HO2S Heater Control Circuit High (Bank 1 Sensor 1)

P0037 HO2S Heater Control Circuit Low (Bank 1 Sensor 2)

P0038 HO2S Heater Control Circuit High (Bank 1 Sensor 2)

P0068 Manifold Pressure Sensor Range/Performance

P0107 Manifold Absolute Pressure/Barometric Pressure Circuit Low Input

P0108 Manifold Absolute Pressure/Barometric Pressure Circuit High Input

P0112 Intake Air Temperature Circuit Low Input

P0113 Intake Air Temperature Circuit High Input

P0117 Engine Coolant Temperature Circuit Low Input

P0118 Engine Coolant Temperature Circuit High Input

P0122 Throttle/Pedal Position Sensor/Switch “A” Circuit Low Input

P0123 Throttle/Pedal Position Sensor/Switch “A” Circuit High Input

P0129 Barometric Pressure Too Low

P0131 O

2 Sensor Circuit Low Voltage (Bank 1 Sensor 1)

P0132 O

2 Sensor Circuit High Voltage (Bank 1 Sensor 1)

P0134 O

2 Sensor Circuit No Activity Detected (Bank 1 Sensor 1)

P0137 O

2 Sensor Circuit Low Voltage (Bank 1 Sensor 2)

P0138 O

2 Sensor Circuit High Voltage (Bank 1 Sensor 2)

P0327 Knock Sensor 1 Circuit Low Input (Bank 1 or Single Sensor)

P0328 Knock Sensor 1 Circuit High Input (Bank 1 or Single Sensor)

P0335 Crankshaft Position Sensor “A” Circuit

P0336 Crankshaft Position Sensor “A” Circuit Range/Performance

P0340 Camshaft Position Sensor “A” Circuit (Bank 1 or Single Sensor)

P0341 Camshaft Position Sensor “A” Circuit Range/Performance (Bank 1 or Single Sensor)

P0458 Evaporative Emission Control System Purge Control Valve Circuit Low

P0462 Fuel Level Sensor Circuit Low Input

P0463 Fuel Level Sensor Circuit High Input

P0502 Vehicle Speed Sensor Circuit Low Input

P0503 Vehicle Speed Sensor Intermittent/Erratic/High

P0512 Starter Request Circuit

P0513 Incorrect Immobilizer Key

P0519 Idle Control System Malfunction (Fail-Safe)

P0565 Cruise Control On Signal

P0604 Internal Control Module Random Access Memory (RAM) Error

P0703 Torque Converter/Brake Switch “B” Circuit

P0705 Transmission Range Sensor Circuit (PRNDL Input)

P0710 Transmission Fluid Temperature Sensor Circuit

P0716 Torque converter turbine speed sensor

P0720 AT Vehicle Speed Sensor Circuit Malfunction

P0726 Engine Speed Input Circuit Malfunction

P0731 Gear 1 Incorrect Ratio

P0732 Gear 2 Incorrect Ratio

P0733 Gear 3 Incorrect Ratio

Page 1136 of 2870

EN(H4SO)-38

ENGINE (DIAGNOSTIC)

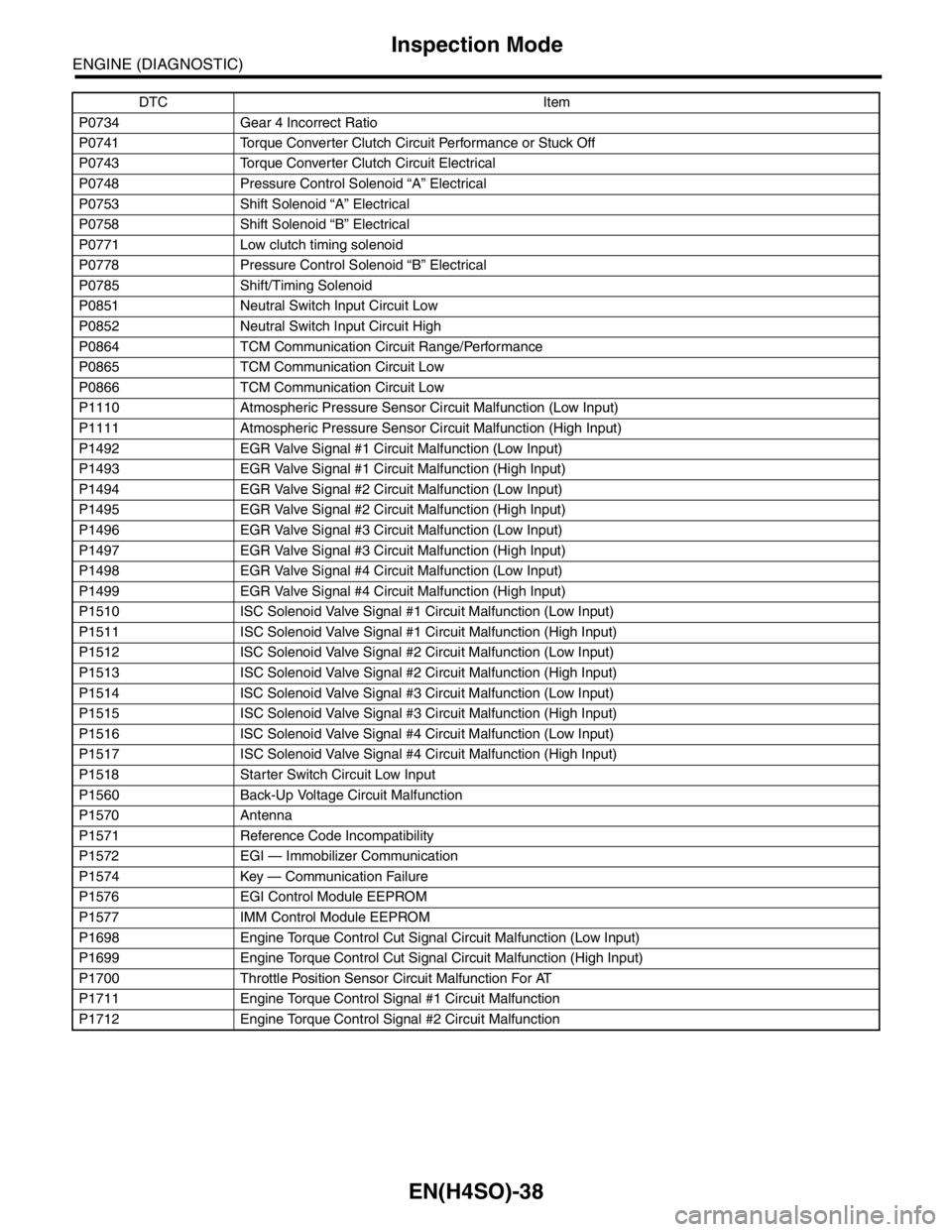

Inspection Mode

P0734 Gear 4 Incorrect Ratio

P0741 Torque Converter Clutch Circuit Performance or Stuck Off

P0743 Torque Converter Clutch Circuit Electrical

P0748 Pressure Control Solenoid “A” Electrical

P0753 Shift Solenoid “A” Electrical

P0758 Shift Solenoid “B” Electrical

P0771 Low clutch timing solenoid

P0778 Pressure Control Solenoid “B” Electrical

P0785 Shift/Timing Solenoid

P0851 Neutral Switch Input Circuit Low

P0852 Neutral Switch Input Circuit High

P0864 TCM Communication Circuit Range/Performance

P0865 TCM Communication Circuit Low

P0866 TCM Communication Circuit Low

P1110 Atmospheric Pressure Sensor Circuit Malfunction (Low Input)

P1111 Atmospheric Pressure Sensor Circuit Malfunction (High Input)

P1492 EGR Valve Signal #1 Circuit Malfunction (Low Input)

P1493 EGR Valve Signal #1 Circuit Malfunction (High Input)

P1494 EGR Valve Signal #2 Circuit Malfunction (Low Input)

P1495 EGR Valve Signal #2 Circuit Malfunction (High Input)

P1496 EGR Valve Signal #3 Circuit Malfunction (Low Input)

P1497 EGR Valve Signal #3 Circuit Malfunction (High Input)

P1498 EGR Valve Signal #4 Circuit Malfunction (Low Input)

P1499 EGR Valve Signal #4 Circuit Malfunction (High Input)

P1510 ISC Solenoid Valve Signal #1 Circuit Malfunction (Low Input)

P1511 ISC Solenoid Valve Signal #1 Circuit Malfunction (High Input)

P1512 ISC Solenoid Valve Signal #2 Circuit Malfunction (Low Input)

P1513 ISC Solenoid Valve Signal #2 Circuit Malfunction (High Input)

P1514 ISC Solenoid Valve Signal #3 Circuit Malfunction (Low Input)

P1515 ISC Solenoid Valve Signal #3 Circuit Malfunction (High Input)

P1516 ISC Solenoid Valve Signal #4 Circuit Malfunction (Low Input)

P1517 ISC Solenoid Valve Signal #4 Circuit Malfunction (High Input)

P1518 Starter Switch Circuit Low Input

P1560 Back-Up Voltage Circuit Malfunction

P1570 Antenna

P1571 Reference Code Incompatibility

P1572 EGI — Immobilizer Communication

P1574 Key — Communication Failure

P1576 EGI Control Module EEPROM

P1577 IMM Control Module EEPROM

P1698 Engine Torque Control Cut Signal Circuit Malfunction (Low Input)

P1699 Engine Torque Control Cut Signal Circuit Malfunction (High Input)

P1700 Throttle Position Sensor Circuit Malfunction For AT

P1711 Engine Torque Control Signal #1 Circuit Malfunction

P1712 Engine Torque Control Signal #2 Circuit MalfunctionDTC Item

Page 1172 of 2870

EN(H4SO)-74

ENGINE (DIAGNOSTIC)

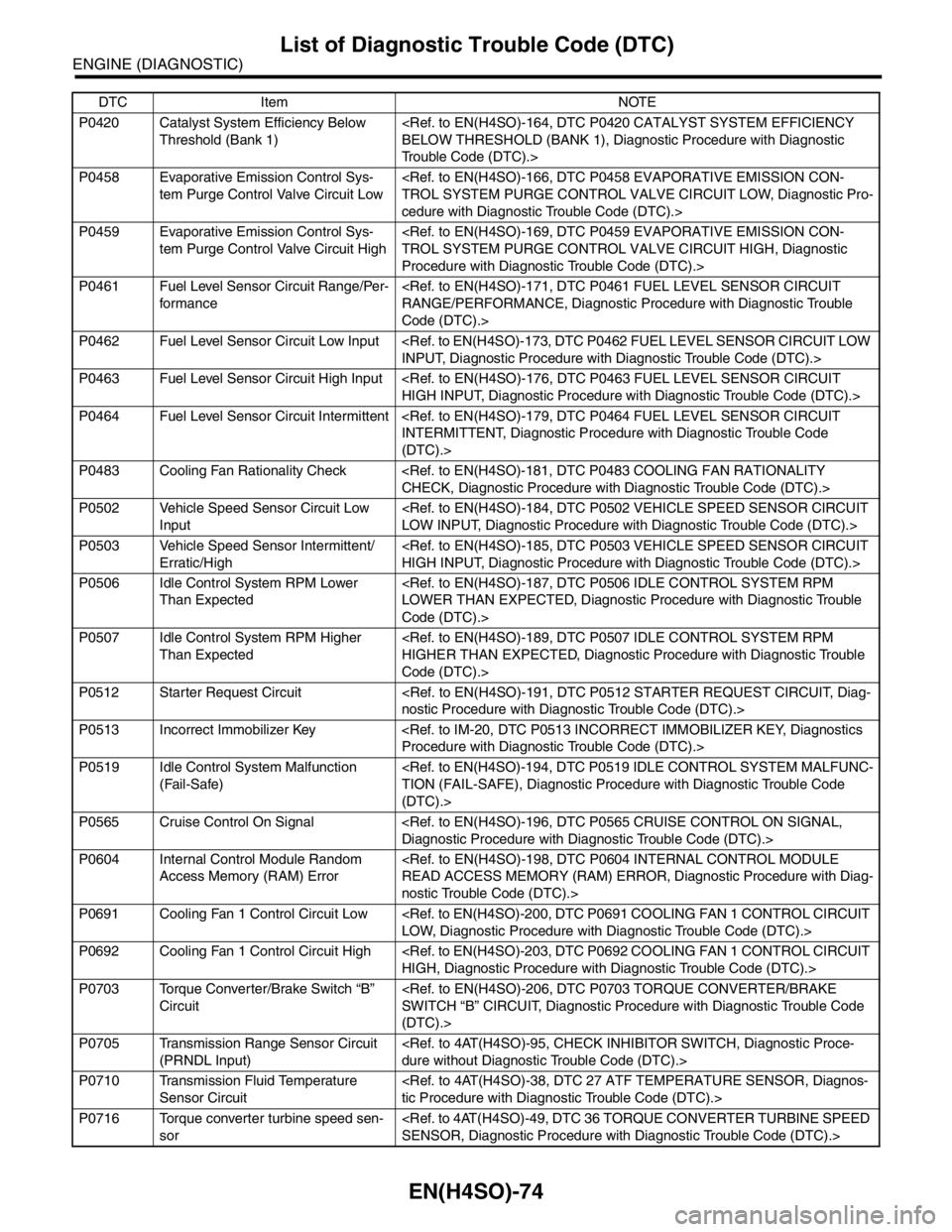

List of Diagnostic Trouble Code (DTC)

P0420 Catalyst System Efficiency Below

Threshold (Bank 1)

Trouble Code (DTC).>

P0458 Evaporative Emission Control Sys-

tem Purge Control Valve Circuit Low

cedure with Diagnostic Trouble Code (DTC).>

P0459 Evaporative Emission Control Sys-

tem Purge Control Valve Circuit High

Procedure with Diagnostic Trouble Code (DTC).>

P0461 Fuel Level Sensor Circuit Range/Per-

formance

Code (DTC).>

P0462 Fuel Level Sensor Circuit Low Input

P0463 Fuel Level Sensor Circuit High Input

P0464 Fuel Level Sensor Circuit Intermittent

(DTC).>

P0483 Cooling Fan Rationality Check

P0502 Vehicle Speed Sensor Circuit Low

Input

P0503 Vehicle Speed Sensor Intermittent/

Erratic/High

P0506 Idle Control System RPM Lower

Than Expected

Code (DTC).>

P0507 Idle Control System RPM Higher

Than Expected

Code (DTC).>

P0512 Starter Request Circuit

P0513 Incorrect Immobilizer Key

P0519 Idle Control System Malfunction

(Fail-Safe)

(DTC).>

P0565 Cruise Control On Signal

P0604 Internal Control Module Random

Access Memory (RAM) Error

nostic Trouble Code (DTC).>

P0691 Cooling Fan 1 Control Circuit Low

P0692 Cooling Fan 1 Control Circuit High

P0703 Torque Converter/Brake Switch “B”

Circuit

(DTC).>

P0705 Transmission Range Sensor Circuit

(PRNDL Input)

P0710 Transmission Fluid Temperature

Sensor Circuit

P0716 Torque converter turbine speed sen-

sor

Page 1173 of 2870

EN(H4SO)-75

ENGINE (DIAGNOSTIC)

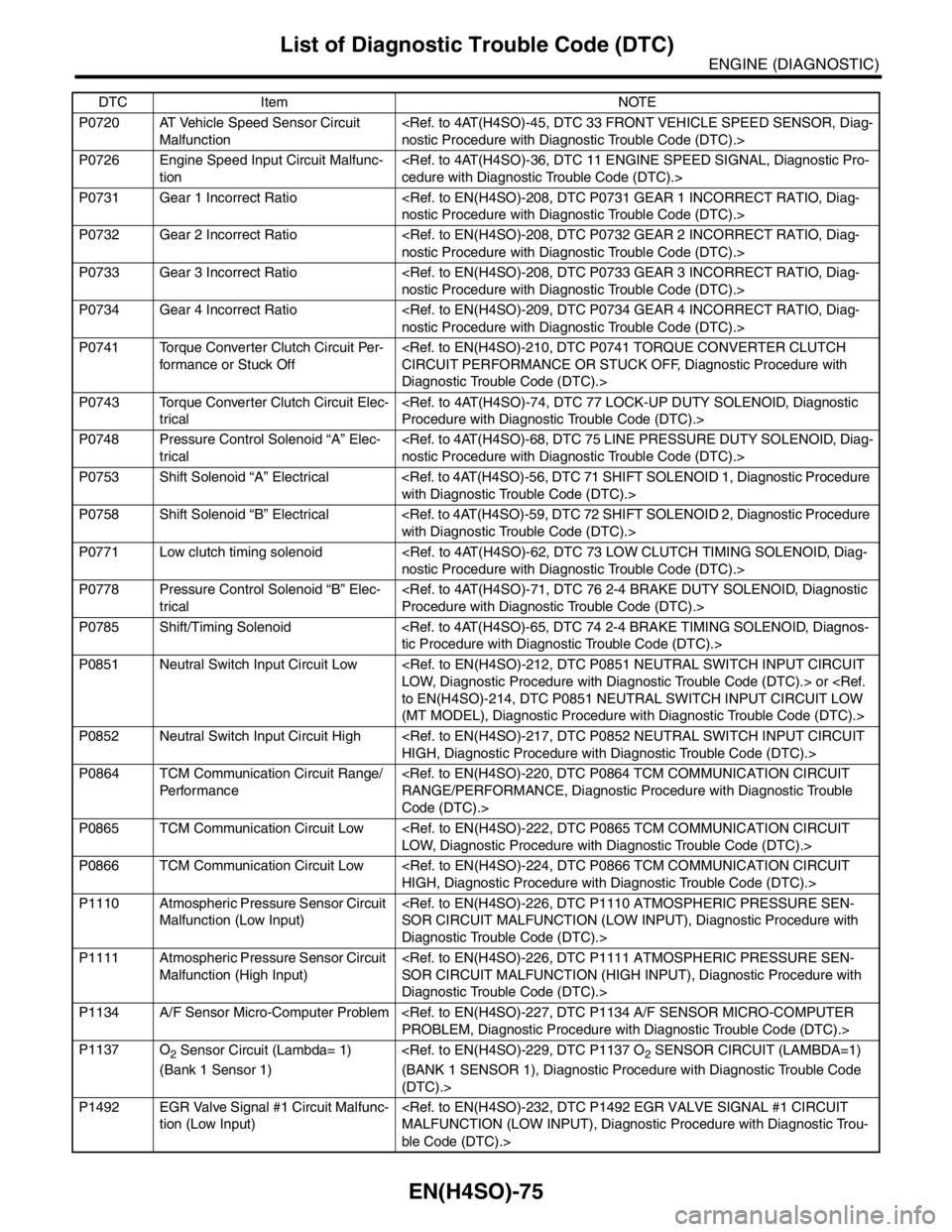

List of Diagnostic Trouble Code (DTC)

P0720 AT Vehicle Speed Sensor Circuit

Malfunction

P0726 Engine Speed Input Circuit Malfunc-

tion

P0731 Gear 1 Incorrect Ratio

P0732 Gear 2 Incorrect Ratio

P0733 Gear 3 Incorrect Ratio

P0734 Gear 4 Incorrect Ratio

P0741 Torque Converter Clutch Circuit Per-

formance or Stuck Off

Diagnostic Trouble Code (DTC).>

P0743 Torque Converter Clutch Circuit Elec-

trical

P0748 Pressure Control Solenoid “A” Elec-

trical

P0753 Shift Solenoid “A” Electrical

P0758 Shift Solenoid “B” Electrical

P0771 Low clutch timing solenoid

P0778 Pressure Control Solenoid “B” Elec-

trical

P0785 Shift/Timing Solenoid

P0851 Neutral Switch Input Circuit Low

(MT MODEL), Diagnostic Procedure with Diagnostic Trouble Code (DTC).>

P0852 Neutral Switch Input Circuit High

P0864 TCM Communication Circuit Range/

Pe r fo r ma nc e

Code (DTC).>

P0865 TCM Communication Circuit Low

P0866 TCM Communication Circuit Low

P1110 Atmospheric Pressure Sensor Circuit

Malfunction (Low Input)

Diagnostic Trouble Code (DTC).>

P1111 Atmospheric Pressure Sensor Circuit

Malfunction (High Input)

Diagnostic Trouble Code (DTC).>

P1134 A/F Sensor Micro-Computer Problem

P1137 O

2 Sensor Circuit (Lambda= 1)

(Bank 1 Sensor 1)

(DTC).>

P1492 EGR Valve Signal #1 Circuit Malfunc-

tion (Low Input)

ble Code (DTC).> DTC Item NOTE

Page 1175 of 2870

EN(H4SO)-77

ENGINE (DIAGNOSTIC)

List of Diagnostic Trouble Code (DTC)

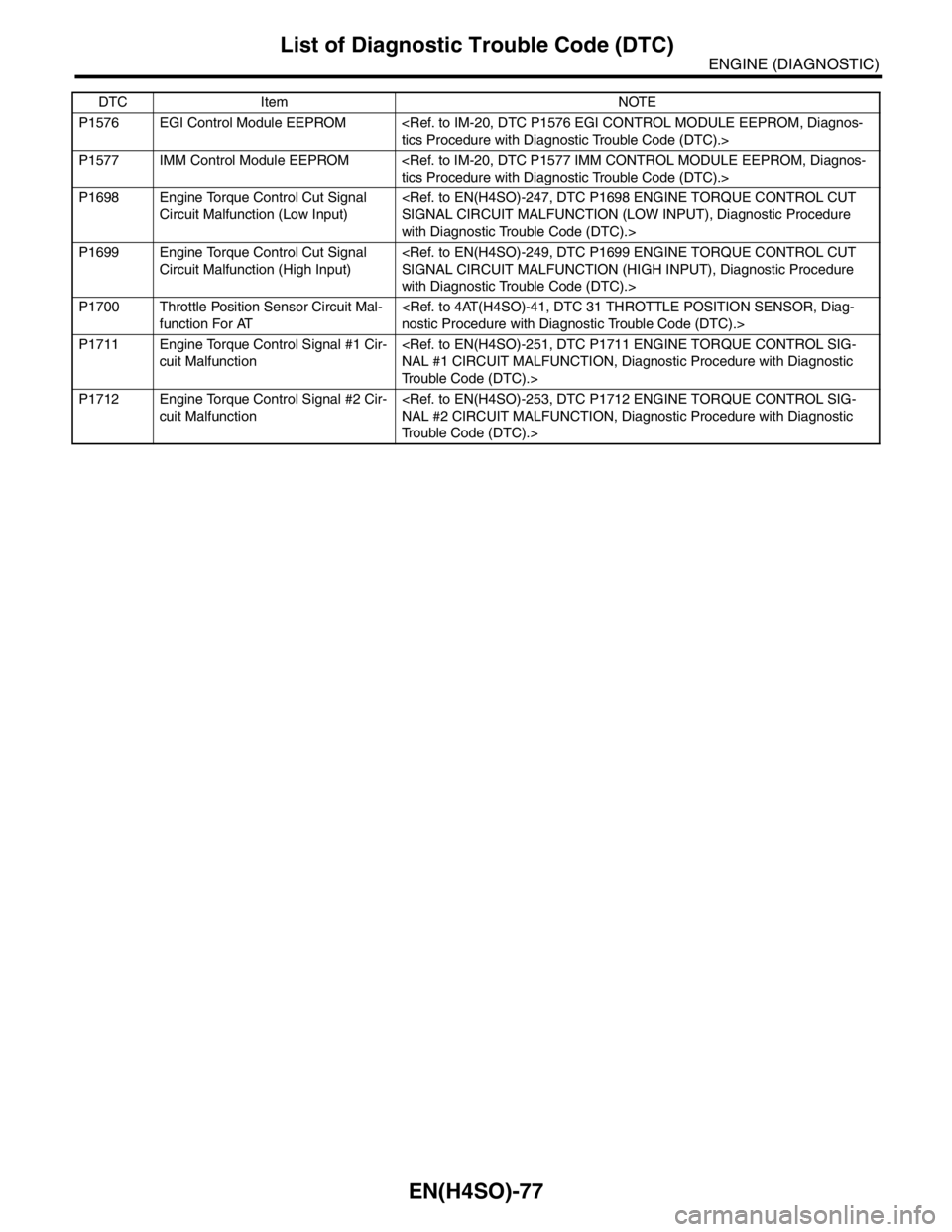

P1576 EGI Control Module EEPROM

P1577 IMM Control Module EEPROM

P1698 Engine Torque Control Cut Signal

Circuit Malfunction (Low Input)

with Diagnostic Trouble Code (DTC).>

P1699 Engine Torque Control Cut Signal

Circuit Malfunction (High Input)

with Diagnostic Trouble Code (DTC).>

P1700 Throttle Position Sensor Circuit Mal-

function For AT

P1711 Engine Torque Control Signal #1 Cir-

cuit Malfunction

Trouble Code (DTC).>

P1712 Engine Torque Control Signal #2 Cir-

cuit Malfunction

Trouble Code (DTC).> DTC Item NOTE

Page 1284 of 2870

EN(H4SO)-186

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

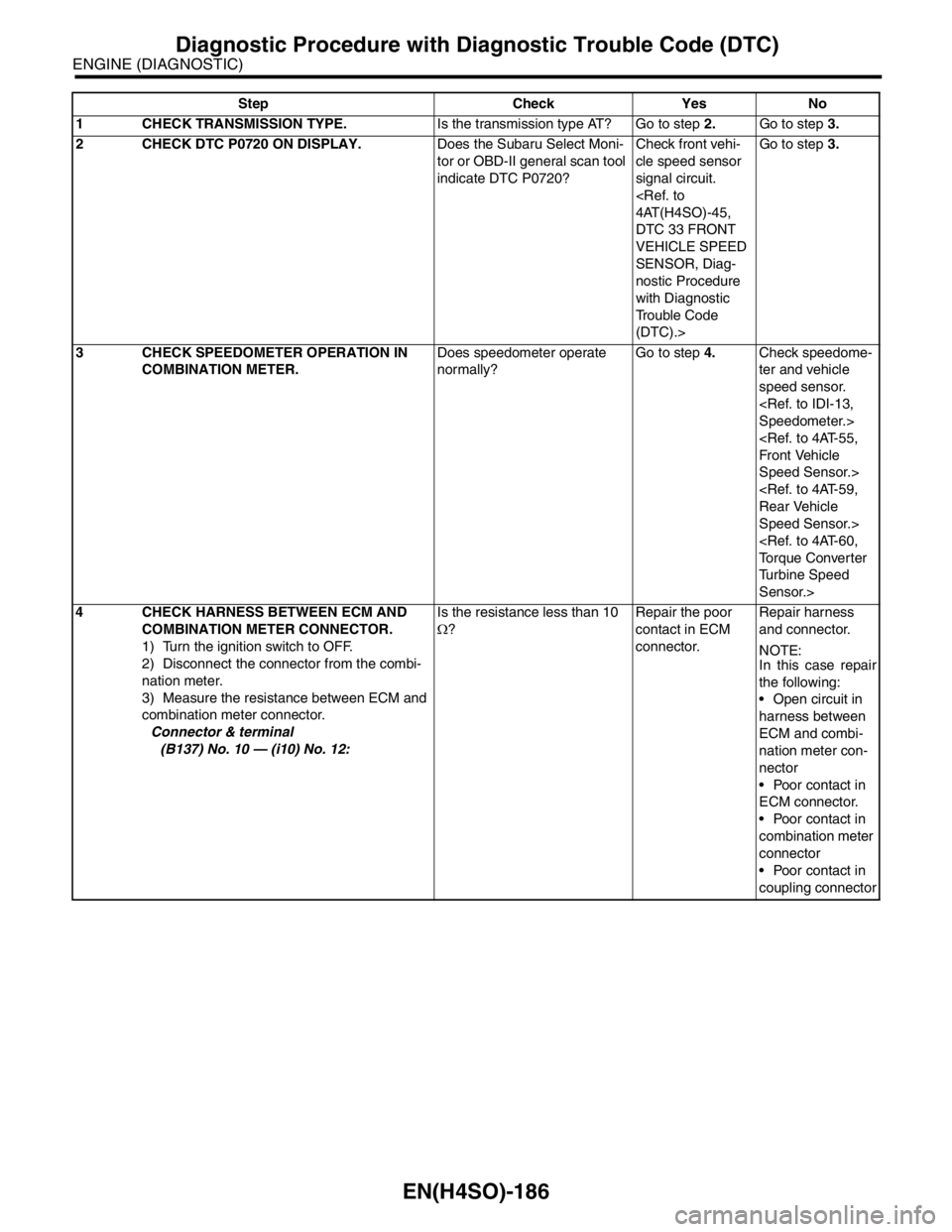

Step Check Yes No

1 CHECK TRANSMISSION TYPE.Is the transmission type AT? Go to step 2.Go to step 3.

2 CHECK DTC P0720 ON DISPLAY.Does the Subaru Select Moni-

tor or OBD-II general scan tool

indicate DTC P0720?Check front vehi-

cle speed sensor

signal circuit.

DTC 33 FRONT

VEHICLE SPEED

SENSOR, Diag-

nostic Procedure

with Diagnostic

Trouble Code

(DTC).>Go to step 3.

3 CHECK SPEEDOMETER OPERATION IN

COMBINATION METER.Does speedometer operate

normally?Go to step 4.Check speedome-

ter and vehicle

speed sensor.

Speed Sensor.>

Speed Sensor.>

Turbine Speed

Sensor.>

4 CHECK HARNESS BETWEEN ECM AND

COMBINATION METER CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from the combi-

nation meter.

3) Measure the resistance between ECM and

combination meter connector.

Connector & terminal

(B137) No. 10 — (i10) No. 12:Is the resistance less than 10

Ω?Repair the poor

contact in ECM

connector.Repair harness

and connector.

NOTE:

In this case repair

the following:

Open circuit in

harness between

ECM and combi-

nation meter con-

nector

Poor contact in

ECM connector.

Poor contact in

combination meter

connector

Poor contact in

coupling connector

Page 1304 of 2870

EN(H4SO)-206

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

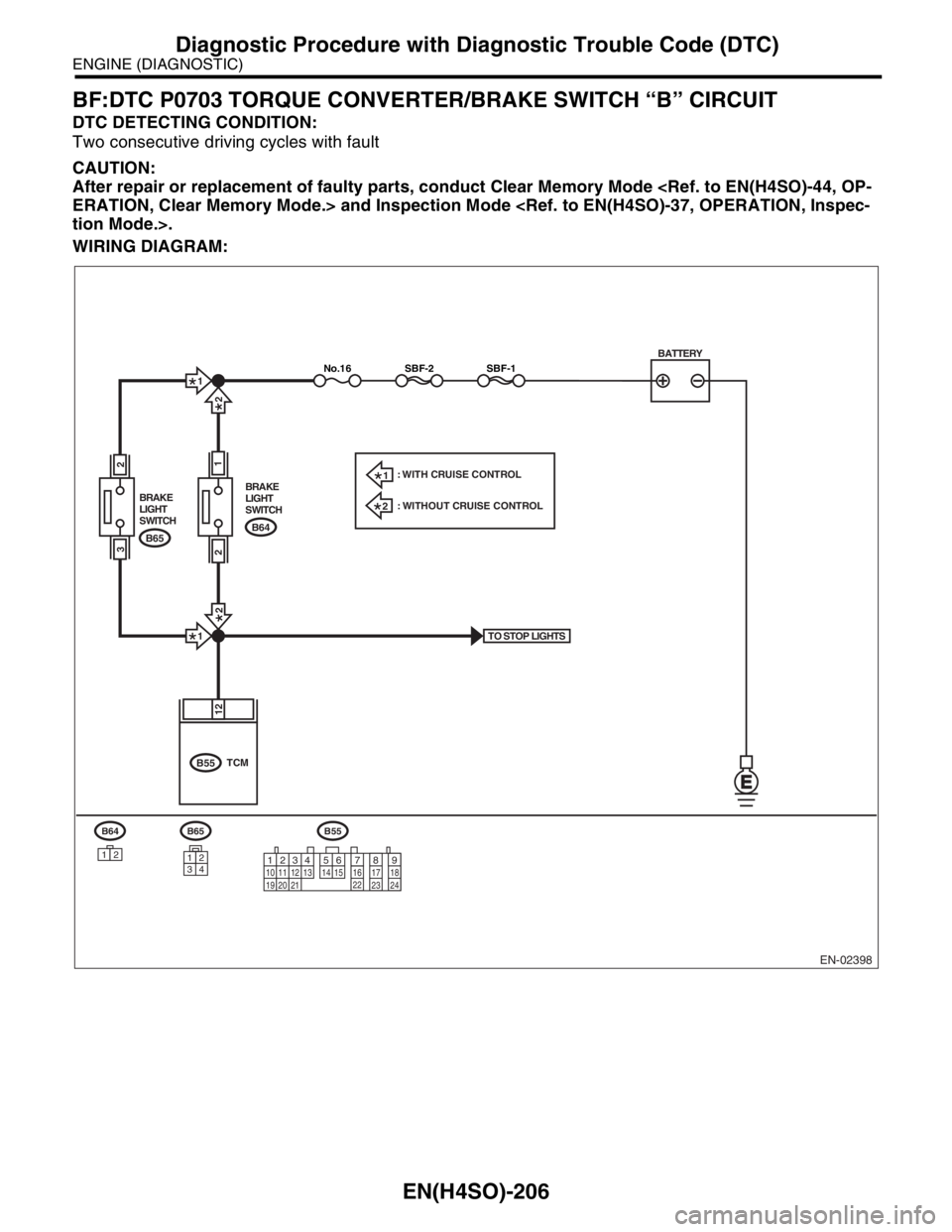

BF:DTC P0703 TORQUE CONVERTER/BRAKE SWITCH “B” CIRCUIT

DTC DETECTING CONDITION:

Two consecutive driving cycles with fault

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-02398

BATTERY

B65

34

12

TO STOP LIGHTS

SBF-1SBF-2No.16

B65 BRAKE

LIGHT

SWITCH

2

3

B64 BRAKE

LIGHT

SWITCH

1

B64

12

B55

B55

12

TCM

2

1

2

2

1

2

1: WITH CRUISE CONTROL

: WITHOUT CRUISE CONTROL

12

789 56 3410 11 12

19 20 2113 14 15 16 17 18

22

23

24

Page 1307 of 2870

EN(H4SO)-209

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

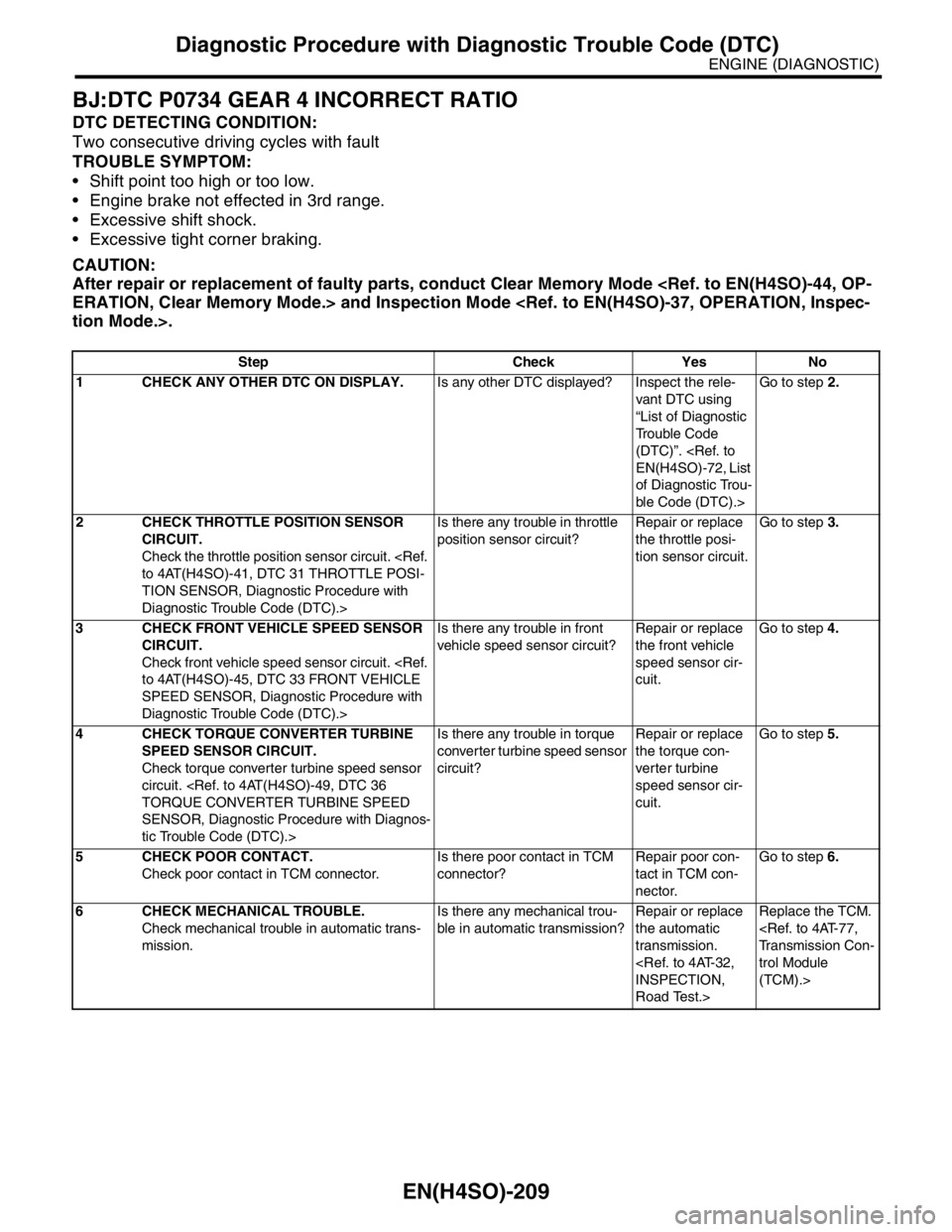

BJ:DTC P0734 GEAR 4 INCORRECT RATIO

DTC DETECTING CONDITION:

Two consecutive driving cycles with fault

TROUBLE SYMPTOM:

Shift point too high or too low.

Engine brake not effected in 3rd range.

Excessive shift shock.

Excessive tight corner braking.

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

Step Check Yes No

1 CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Inspect the rele-

vant DTC using

“List of Diagnostic

Trouble Code

(DTC)”.

of Diagnostic Trou-

ble Code (DTC).>Go to step 2.

2 CHECK THROTTLE POSITION SENSOR

CIRCUIT.

Check the throttle position sensor circuit.

TION SENSOR, Diagnostic Procedure with

Diagnostic Trouble Code (DTC).>Is there any trouble in throttle

position sensor circuit?Repair or replace

the throttle posi-

tion sensor circuit.Go to step 3.

3 CHECK FRONT VEHICLE SPEED SENSOR

CIRCUIT.

Check front vehicle speed sensor circuit.

SPEED SENSOR, Diagnostic Procedure with

Diagnostic Trouble Code (DTC).>Is there any trouble in front

vehicle speed sensor circuit?Repair or replace

the front vehicle

speed sensor cir-

cuit.Go to step 4.

4 CHECK TORQUE CONVERTER TURBINE

SPEED SENSOR CIRCUIT.

Check torque converter turbine speed sensor

circuit.

SENSOR, Diagnostic Procedure with Diagnos-

tic Trouble Code (DTC).>Is there any trouble in torque

converter turbine speed sensor

circuit?Repair or replace

the torque con-

ver ter turbine

speed sensor cir-

cuit.Go to step 5.

5 CHECK POOR CONTACT.

Check poor contact in TCM connector.Is there poor contact in TCM

connector?Repair poor con-

tact in TCM con-

nector.Go to step 6.

6 CHECK MECHANICAL TROUBLE.

Check mechanical trouble in automatic trans-

mission.Is there any mechanical trou-

ble in automatic transmission?Repair or replace

the automatic

transmission.

Road Test.>Replace the TCM.

trol Module

(TCM).>

Page 1308 of 2870

EN(H4SO)-210

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

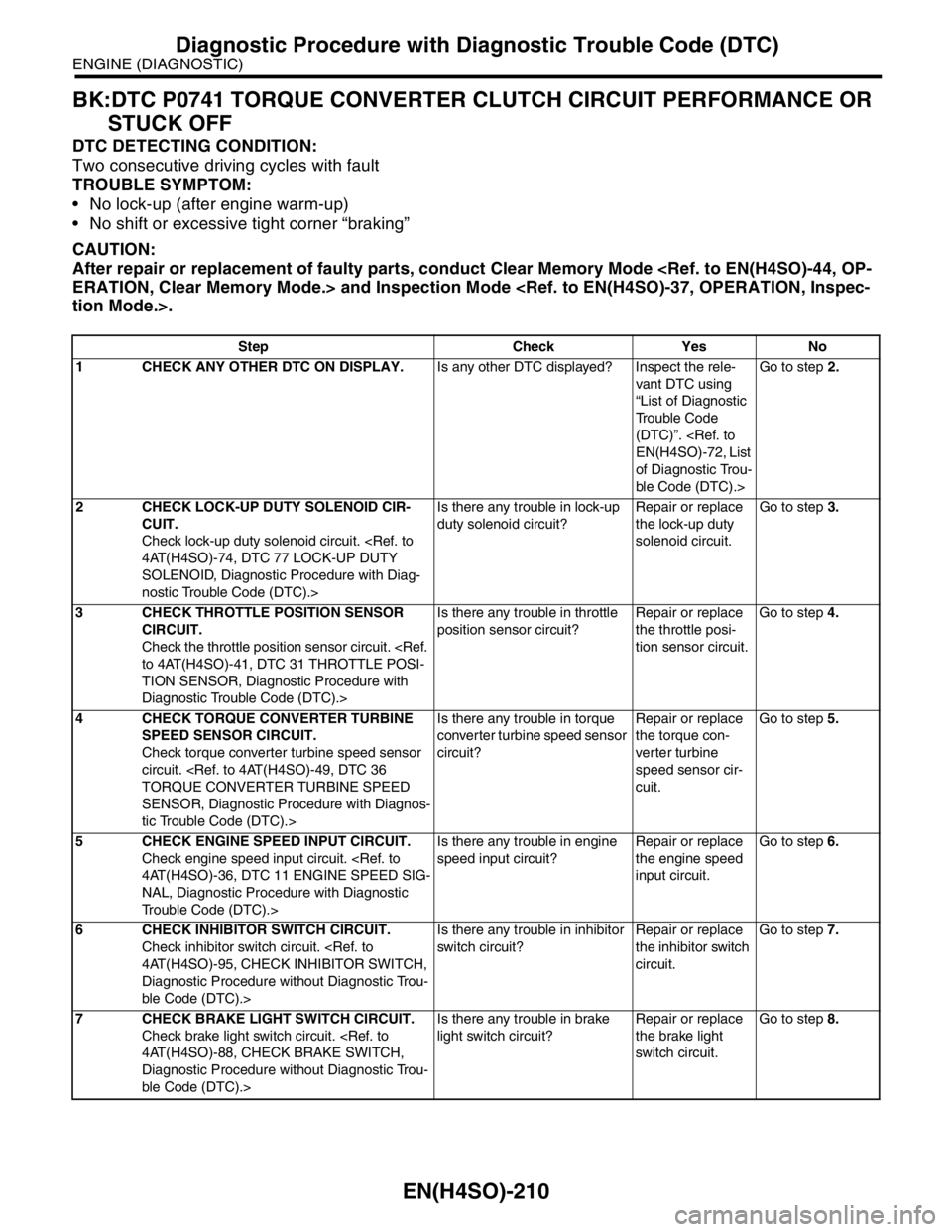

BK:DTC P0741 TORQUE CONVERTER CLUTCH CIRCUIT PERFORMANCE OR

STUCK OFF

DTC DETECTING CONDITION:

Two consecutive driving cycles with fault

TROUBLE SYMPTOM:

No lock-up (after engine warm-up)

No shift or excessive tight corner “braking”

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

Step Check Yes No

1 CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Inspect the rele-

vant DTC using

“List of Diagnostic

Trouble Code

(DTC)”.

of Diagnostic Trou-

ble Code (DTC).>Go to step 2.

2 CHECK LOCK-UP DUTY SOLENOID CIR-

CUIT.

Check lock-up duty solenoid circuit.

SOLENOID, Diagnostic Procedure with Diag-

nostic Trouble Code (DTC).>Is there any trouble in lock-up

duty solenoid circuit?Repair or replace

the lock-up duty

solenoid circuit.Go to step 3.

3 CHECK THROTTLE POSITION SENSOR

CIRCUIT.

Check the throttle position sensor circuit.

TION SENSOR, Diagnostic Procedure with

Diagnostic Trouble Code (DTC).>Is there any trouble in throttle

position sensor circuit?Repair or replace

the throttle posi-

tion sensor circuit.Go to step 4.

4 CHECK TORQUE CONVERTER TURBINE

SPEED SENSOR CIRCUIT.

Check torque converter turbine speed sensor

circuit.

SENSOR, Diagnostic Procedure with Diagnos-

tic Trouble Code (DTC).>Is there any trouble in torque

converter turbine speed sensor

circuit?Repair or replace

the torque con-

ver ter turbine

speed sensor cir-

cuit.Go to step 5.

5 CHECK ENGINE SPEED INPUT CIRCUIT.

Check engine speed input circuit.

NAL, Diagnostic Procedure with Diagnostic

Trouble Code (DTC).>Is there any trouble in engine

speed input circuit?Repair or replace

the engine speed

input circuit.Go to step 6.

6 CHECK INHIBITOR SWITCH CIRCUIT.

Check inhibitor switch circuit.

Diagnostic Procedure without Diagnostic Trou-

ble Code (DTC).>Is there any trouble in inhibitor

switch circuit?Repair or replace

the inhibitor switch

circuit.Go to step 7.

7 CHECK BRAKE LIGHT SWITCH CIRCUIT.

Check brake light switch circuit.

Diagnostic Procedure without Diagnostic Trou-

ble Code (DTC).>Is there any trouble in brake

light switch circuit?Repair or replace

the brake light

switch circuit.Go to step 8.