torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 977 of 2870

EX(H4SO)-9

EXHAUST

Front Exhaust Pipe

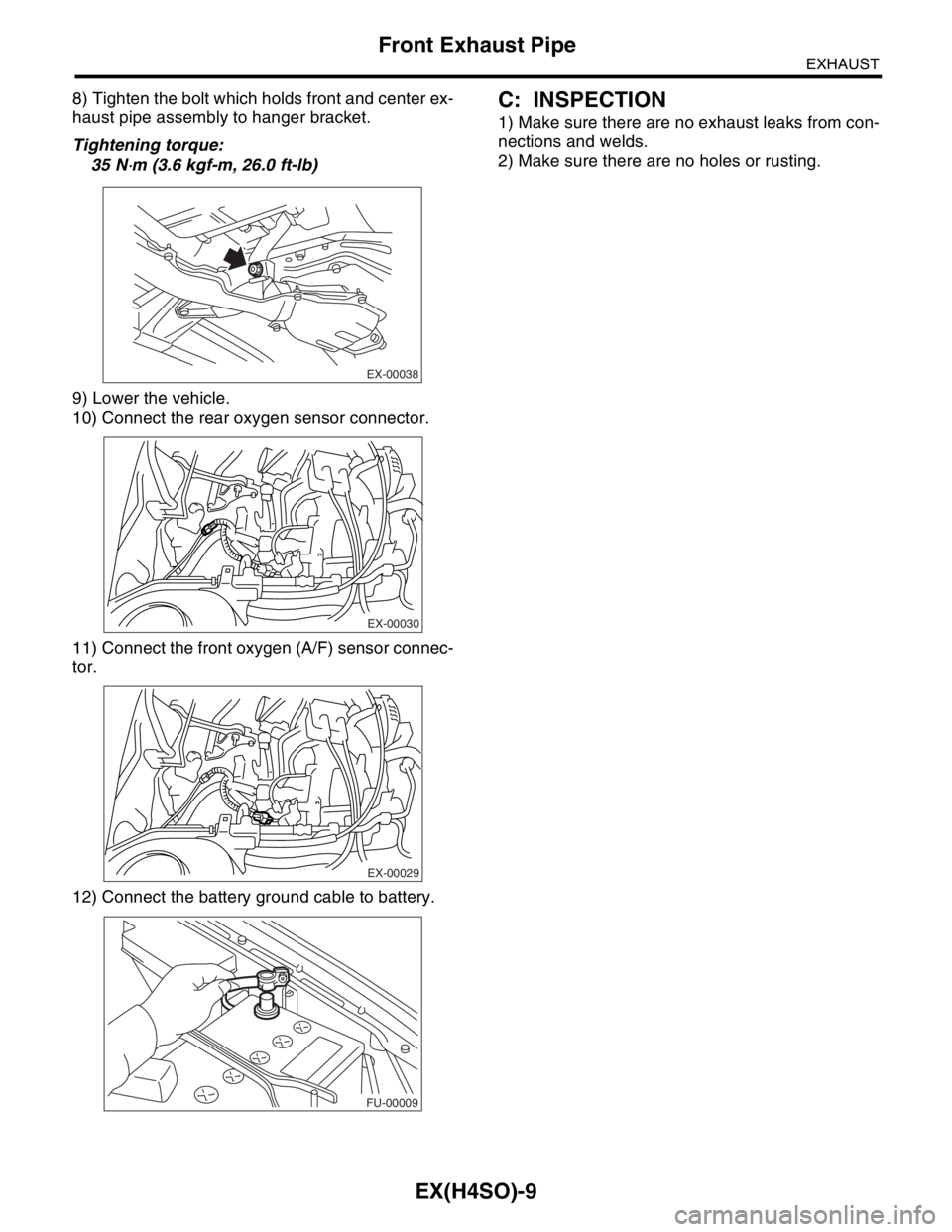

8) Tighten the bolt which holds front and center ex-

haust pipe assembly to hanger bracket.

Tightening torque:

35 N

⋅m (3.6 kgf-m, 26.0 ft-lb)

9) Lower the vehicle.

10) Connect the rear oxygen sensor connector.

11) Connect the front oxygen (A/F) sensor connec-

tor.

12) Connect the battery ground cable to battery.

C: INSPECTION

1) Make sure there are no exhaust leaks from con-

nections and welds.

2) Make sure there are no holes or rusting.

EX-00038

EX-00030

EX-00029

FU-00009

Page 979 of 2870

EX(H4SO)-11

EXHAUST

Rear Exhaust Pipe

4. Rear Exhaust Pipe

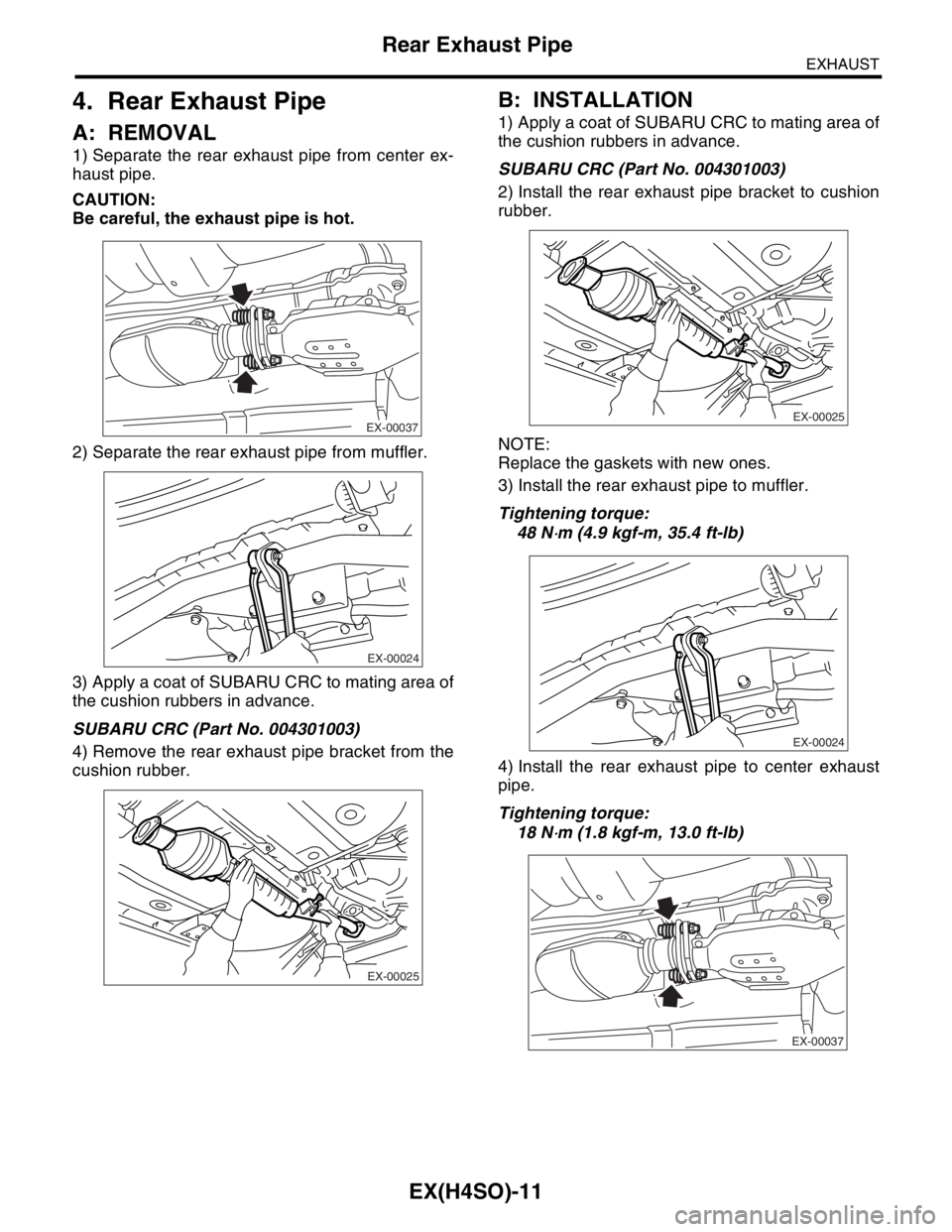

A: REMOVAL

1) Separate the rear exhaust pipe from center ex-

haust pipe.

CAUTION:

Be careful, the exhaust pipe is hot.

2) Separate the rear exhaust pipe from muffler.

3) Apply a coat of SUBARU CRC to mating area of

the cushion rubbers in advance.

SUBARU CRC (Part No. 004301003)

4) Remove the rear exhaust pipe bracket from the

cushion rubber.

B: INSTALLATION

1) Apply a coat of SUBARU CRC to mating area of

the cushion rubbers in advance.

SUBARU CRC (Part No. 004301003)

2) Install the rear exhaust pipe bracket to cushion

rubber.

NOTE:

Replace the gaskets with new ones.

3) Install the rear exhaust pipe to muffler.

Tightening torque:

48 N

⋅m (4.9 kgf-m, 35.4 ft-lb)

4) Install the rear exhaust pipe to center exhaust

pipe.

Tightening torque:

18 N

⋅m (1.8 kgf-m, 13.0 ft-lb)

EX-00037

EX-00024

EX-00025

EX-00025

EX-00024

EX-00037

Page 981 of 2870

EX(H4SO)-13

EXHAUST

Muffler

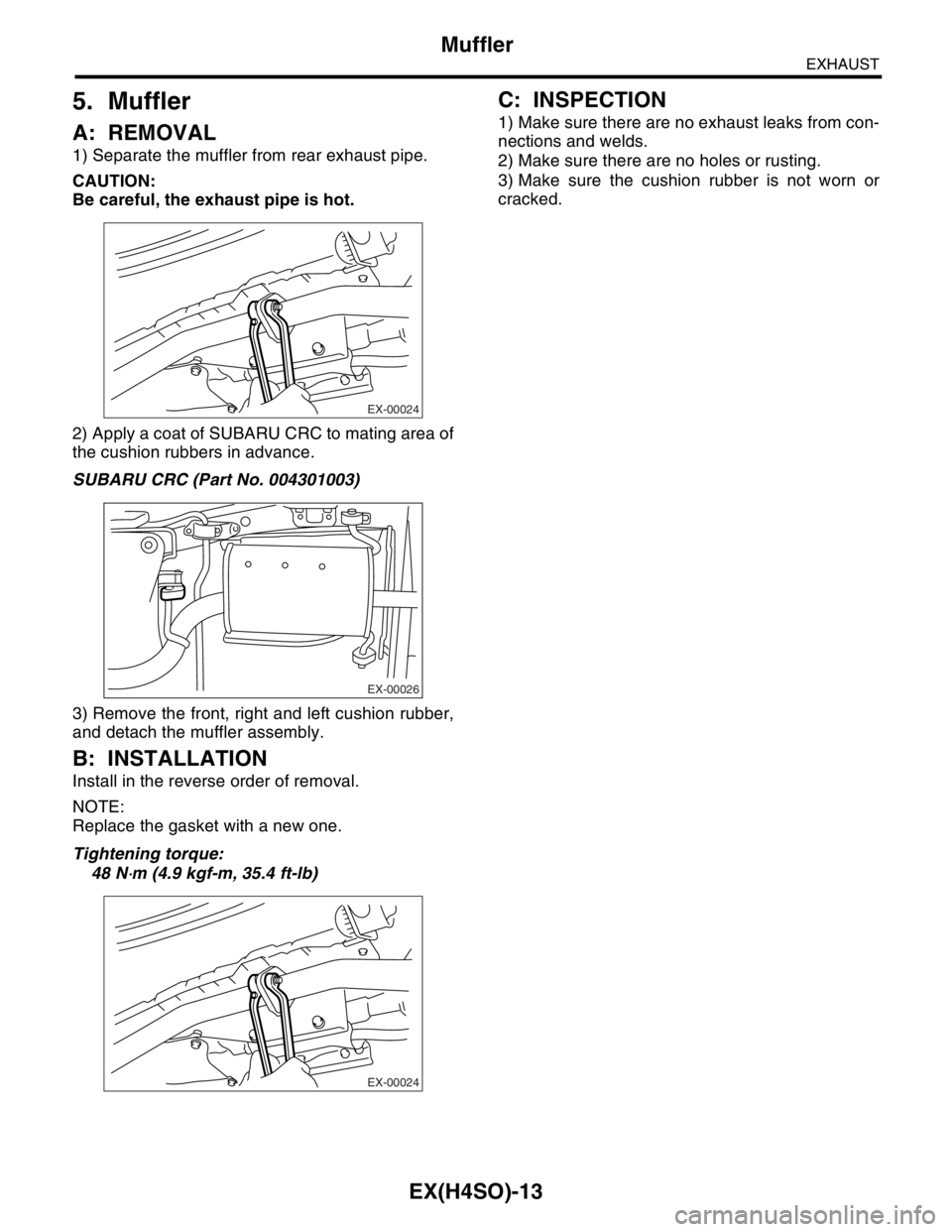

5. Muffler

A: REMOVAL

1) Separate the muffler from rear exhaust pipe.

CAUTION:

Be careful, the exhaust pipe is hot.

2) Apply a coat of SUBARU CRC to mating area of

the cushion rubbers in advance.

SUBARU CRC (Part No. 004301003)

3) Remove the front, right and left cushion rubber,

and detach the muffler assembly.

B: INSTALLATION

Install in the reverse order of removal.

NOTE:

Replace the gasket with a new one.

Tightening torque:

48 N

⋅m (4.9 kgf-m, 35.4 ft-lb)

C: INSPECTION

1) Make sure there are no exhaust leaks from con-

nections and welds.

2) Make sure there are no holes or rusting.

3) Make sure the cushion rubber is not worn or

cracked.

EX-00024

EX-00026

EX-00024

Page 987 of 2870

CO(H4SO)-4

COOLING

General Description

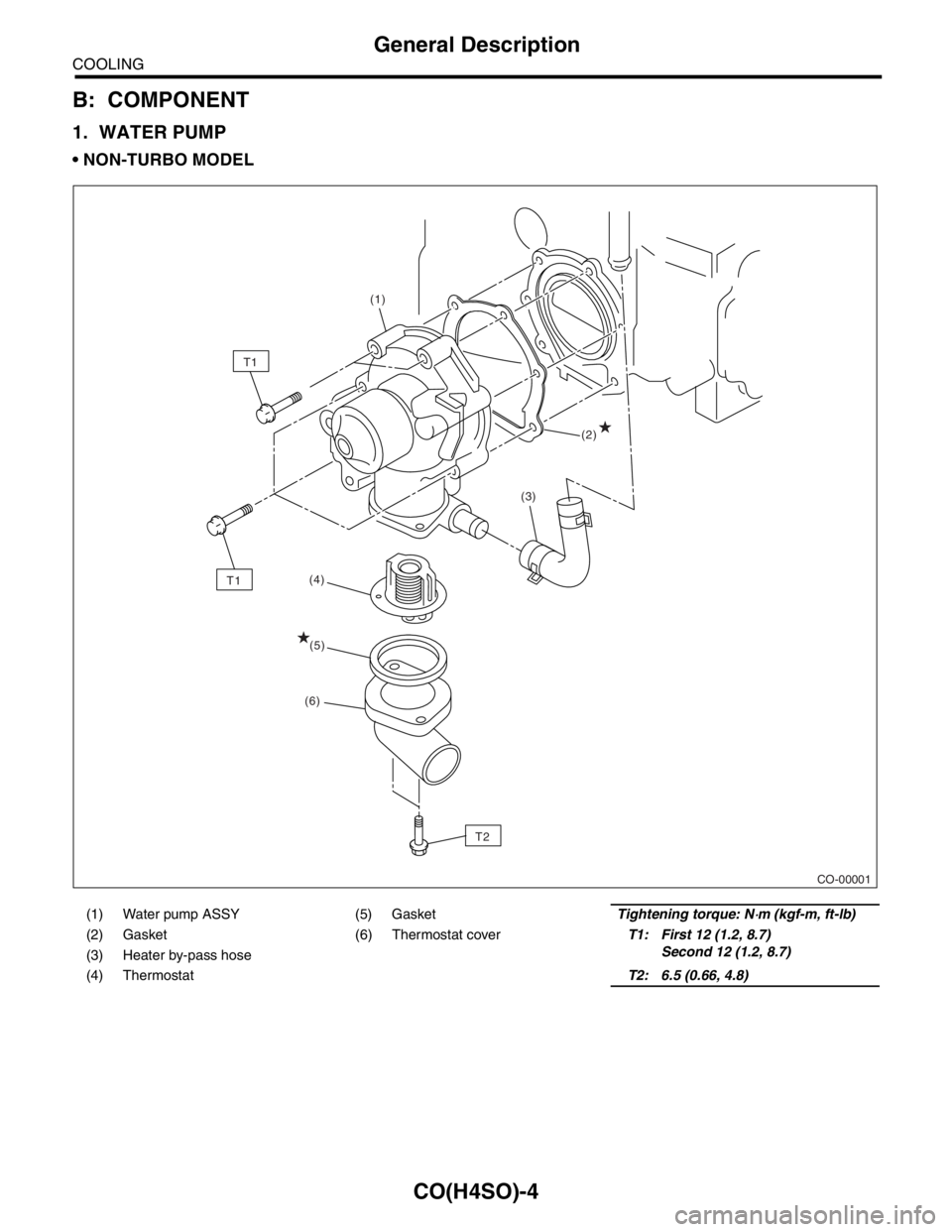

B: COMPONENT

1. WATER PUMP

NON-TURBO MODEL

(1) Water pump ASSY (5) GasketTightening torque: N⋅m (kgf-m, ft-lb)

(2) Gasket (6) Thermostat coverT1: First 12 (1.2, 8.7)

Second 12 (1.2, 8.7)

(3) Heater by-pass hose

(4) ThermostatT2: 6.5 (0.66, 4.8)

CO-00001

T2(2) (1)

(4)

T1

(3)

(5)

(6)

T1

Page 988 of 2870

CO(H4SO)-5

COOLING

General Description

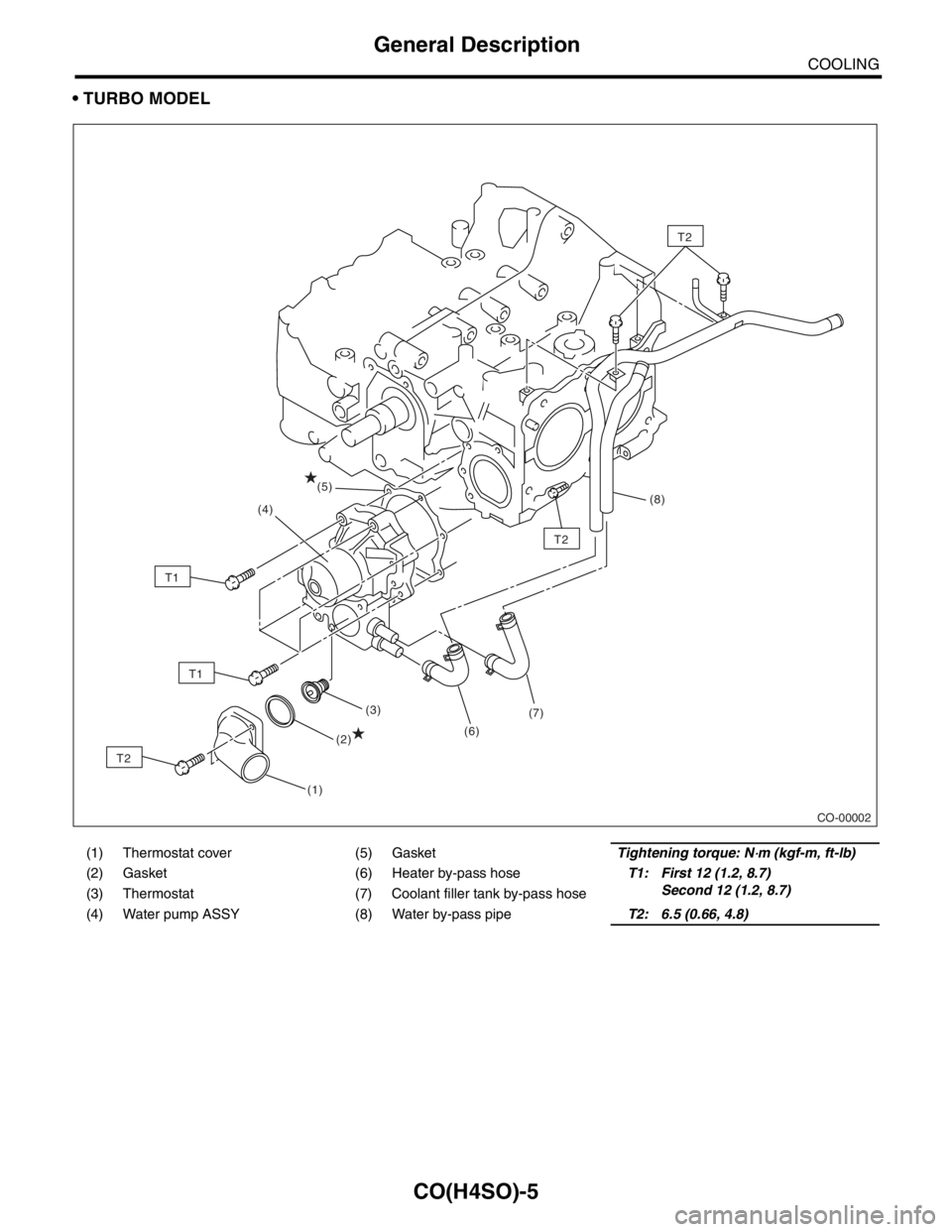

TURBO MODEL

(1) Thermostat cover (5) GasketTightening torque: N⋅m (kgf-m, ft-lb)

(2) Gasket (6) Heater by-pass hoseT1: First 12 (1.2, 8.7)

Second 12 (1.2, 8.7)

(3) Thermostat (7) Coolant filler tank by-pass hose

(4) Water pump ASSY (8) Water by-pass pipeT2: 6.5 (0.66, 4.8)

CO-00002

T2

(1)(3)

(6)(7)(8)

(4)

(2)

(5)

T2

T2

T1

T1

Page 989 of 2870

CO(H4SO)-6

COOLING

General Description

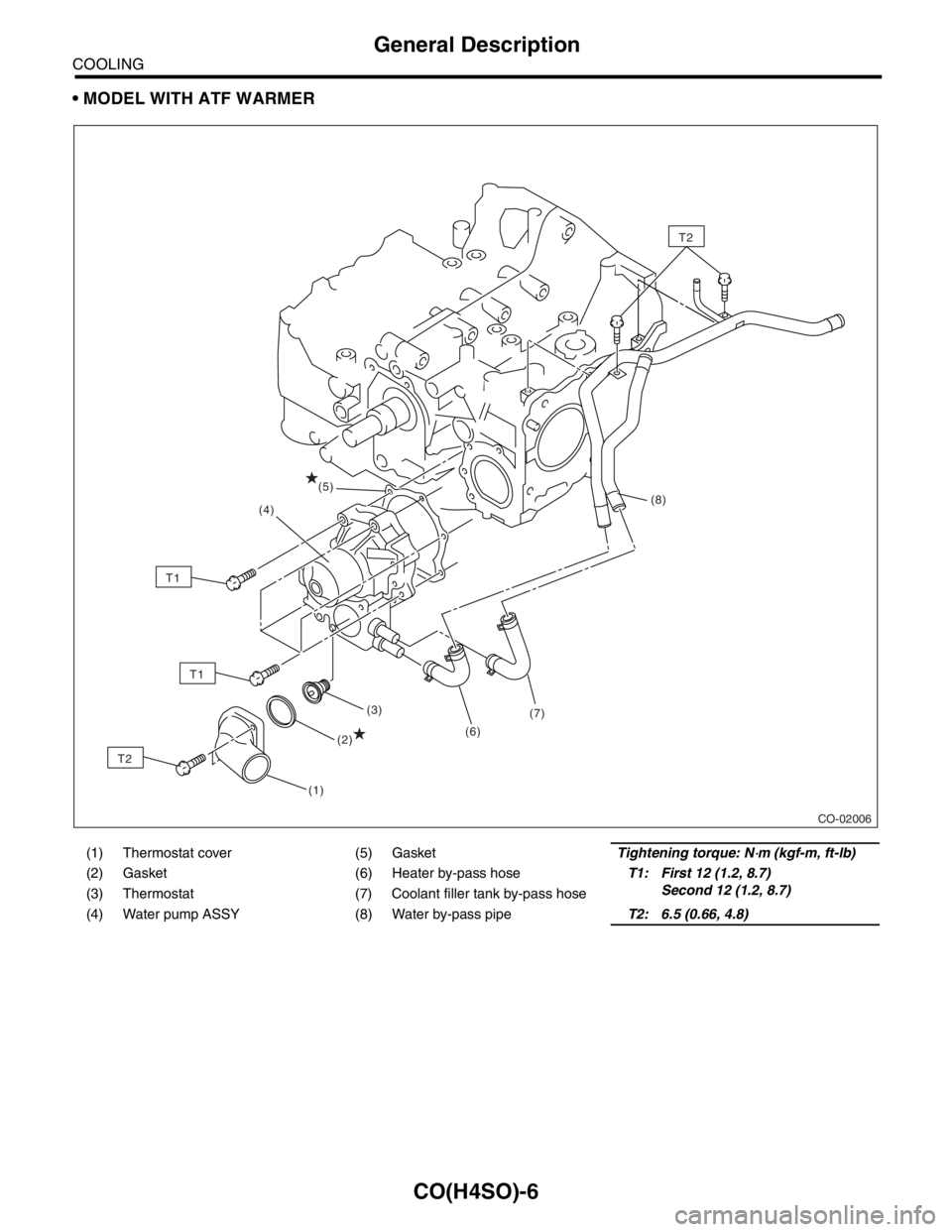

MODEL WITH ATF WARMER

(1) Thermostat cover (5) GasketTightening torque: N⋅m (kgf-m, ft-lb)

(2) Gasket (6) Heater by-pass hoseT1: First 12 (1.2, 8.7)

Second 12 (1.2, 8.7)

(3) Thermostat (7) Coolant filler tank by-pass hose

(4) Water pump ASSY (8) Water by-pass pipeT2: 6.5 (0.66, 4.8)

CO-02006

(1)(3)

(6)(7)(8)

(4)

(2)

(5)

T2

T2

T1

T1

Page 990 of 2870

CO(H4SO)-7

COOLING

General Description

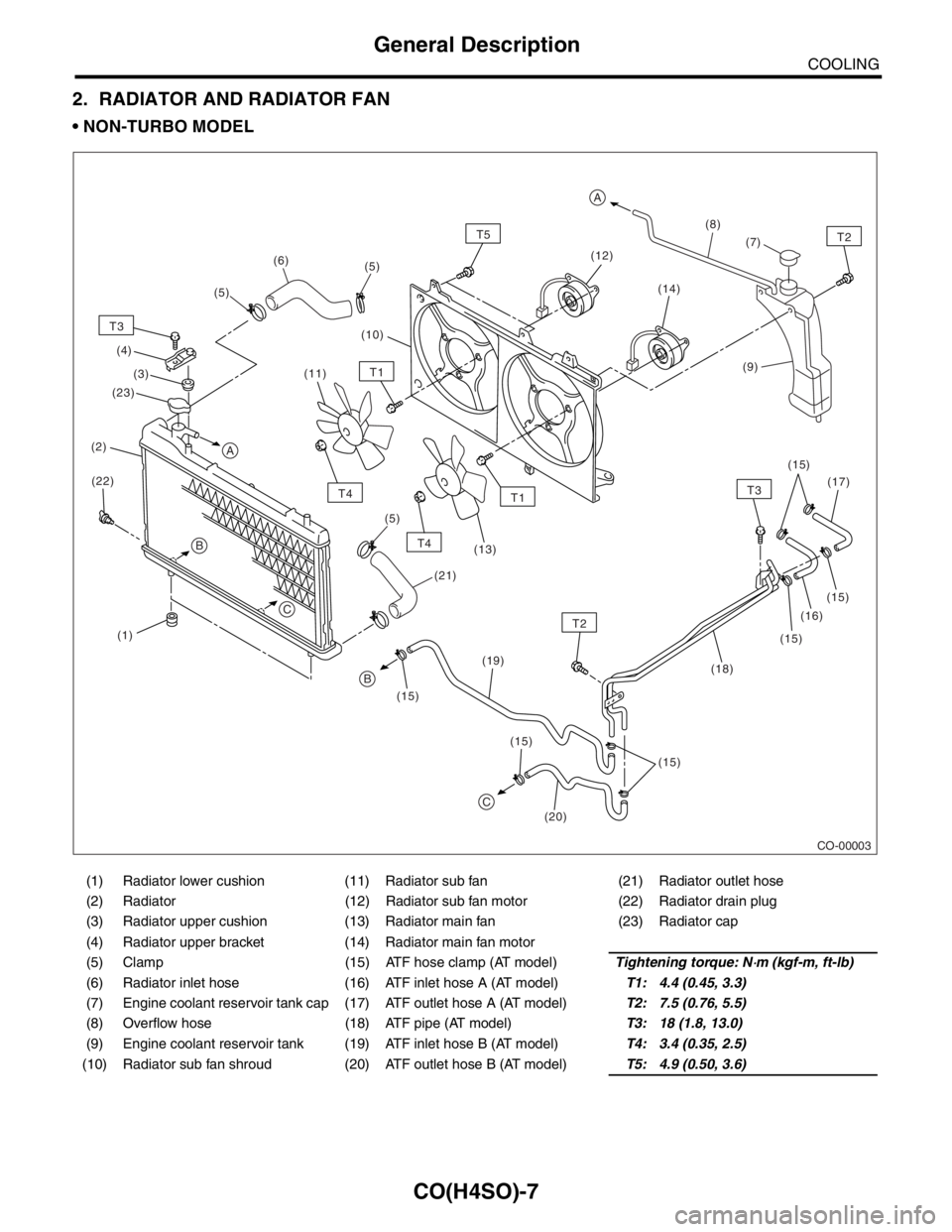

2. RADIATOR AND RADIATOR FAN

NON-TURBO MODEL

(1) Radiator lower cushion (11) Radiator sub fan (21) Radiator outlet hose

(2) Radiator (12) Radiator sub fan motor (22) Radiator drain plug

(3) Radiator upper cushion (13) Radiator main fan (23) Radiator cap

(4) Radiator upper bracket (14) Radiator main fan motor

(5) Clamp (15) ATF hose clamp (AT model)Tightening torque: N

⋅m (kgf-m, ft-lb)

(6) Radiator inlet hose (16) ATF inlet hose A (AT model)T1: 4.4 (0.45, 3.3)

(7) Engine coolant reservoir tank cap (17) ATF outlet hose A (AT model)T2: 7.5 (0.76, 5.5)

(8) Overflow hose (18) ATF pipe (AT model)T3: 18 (1.8, 13.0)

(9) Engine coolant reservoir tank (19) ATF inlet hose B (AT model)T4: 3.4 (0.35, 2.5)

(10) Radiator sub fan shroud (20) ATF outlet hose B (AT model)T5: 4.9 (0.50, 3.6)

CO-00003

(9)

(1)(10)(8)

(2)

T3

T2

T2

T4

T4(14)

(20) (22)(3) (4)

(19)(16)

(18)(7)

(17)

(15) (15)

(15)

(15) (15) (15)(12)

(11)

(13)

T5

T1

T1

(5) (5)

(5)(6)

(21)

A

A

C

T3

B

B

C

(23)

Page 992 of 2870

CO(H4SO)-9

COOLING

General Description

(1) Radiator lower cushion (18) ATF pipe (AT model) (31) Oil cooler inlet hose B (MT model

with oil cooler)

(2) Radiator (19) ATF inlet hose B (AT model)

(3) Radiator upper cushion (20) ATF outlet hose B (AT model) (32) Oil cooler outlet hose B (MT

model with oil cooler)

(4) Radiator upper bracket (21) Radiator outlet hose

(5) Clamp (22) Radiator drain plug (33) Spacer (MT model with oil cooler)

(6) Radiator inlet hose (23) Engine coolant filler tank (34) Cushion (MT model with oil

cooler)

(7) Engine coolant reservoir tank cap (24) Engine coolant filler tank cap

(8) Over flow hose (25) Engine overflow hose (35) Setting washer (MT model with oil

cooler)

(9) Engine coolant reservoir tank (26) Radiator under cover (AT model)

(10) Radiator fan shroud (27) Engine air breather hose

(11) Radiator sub fan (28) Oil cooler inlet hose A (MT model

with oil cooler)Tightening torque: N

⋅m (kgf-m, ft-lb)

(12) Radiator sub fan motorT1: 4.4 (0.45, 3.3)

(13) Radiator main fan (29) Oil cooler outlet hose A (MT

model with oil cooler)T2: 7.5 (0.76, 5.5)

(14) Radiator main fan motorT3: 18 (1.8, 13.0)

(15) ATF hose clamp (AT model) (30) Oil cooler pipe (MT model with oil

cooler)T4: 3.4 (0.35, 2.5)

(16) ATF inlet hose A (AT model)T5: 4.9 (0.50, 3.6)

(17) ATF outlet hose A (AT model)

Page 993 of 2870

CO(H4SO)-10

COOLING

General Description

C: CAUTION

Wear working clothing, including a cap, protec-

tive goggles, and protective shoes during opera-

tion.

Remove contamination including dirt and corro-

sion before removal, installation or disassembly.

Keep the disassembled parts in order and pro-

tect them from dust or dirt.

Before removal, installation or disassembly, be

sure to clarify the failure. Avoid unnecessary re-

moval, installation, disassembly, and replacement.

Be careful not to burn your hands, because each

part in the vehicle is hot after running.

Be sure to tighten fasteners including bolts and

nuts to the specified torque.

Place shop jacks or rigid racks at the specified

points.

Before disconnecting electrical connectors of

sensors or units, be sure to disconnect the ground

cable from battery.

Page 1006 of 2870

CO(H4SO)-23

COOLING

Water Pump

B: INSTALLATION

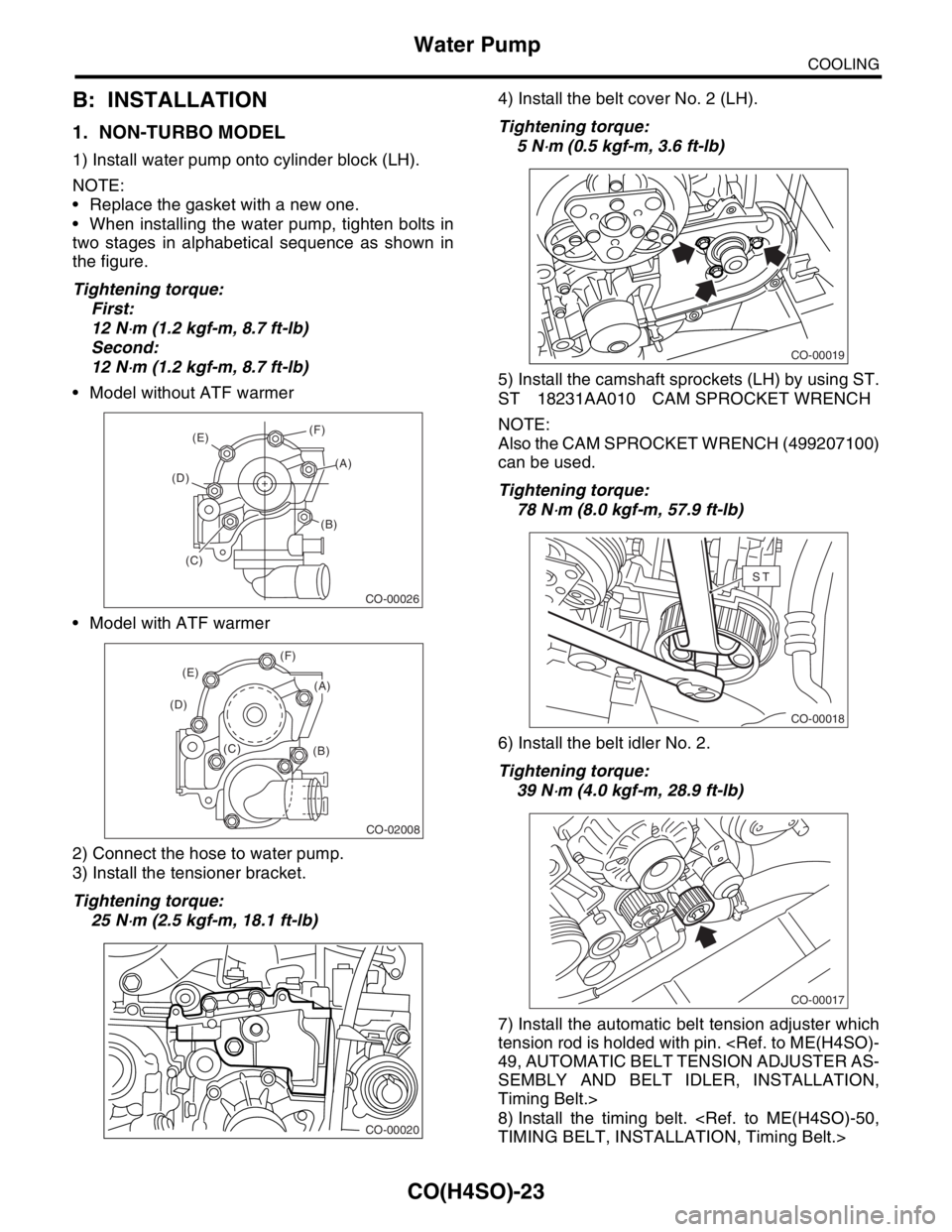

1. NON-TURBO MODEL

1) Install water pump onto cylinder block (LH).

NOTE:

Replace the gasket with a new one.

When installing the water pump, tighten bolts in

two stages in alphabetical sequence as shown in

the figure.

Tightening torque:

First:

12 N

⋅m (1.2 kgf-m, 8.7 ft-lb)

Second:

12 N

⋅m (1.2 kgf-m, 8.7 ft-lb)

Model without ATF warmer

Model with ATF warmer

2) Connect the hose to water pump.

3) Install the tensioner bracket.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)4) Install the belt cover No. 2 (LH).

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

5) Install the camshaft sprockets (LH) by using ST.

ST 18231AA010 CAM SPROCKET WRENCH

NOTE:

Also the CAM SPROCKET WRENCH (499207100)

can be used.

Tightening torque:

78 N

⋅m (8.0 kgf-m, 57.9 ft-lb)

6) Install the belt idler No. 2.

Tightening torque:

39 N

⋅m (4.0 kgf-m, 28.9 ft-lb)

7) Install the automatic belt tension adjuster which

tension rod is holded with pin.

SEMBLY AND BELT IDLER, INSTALLATION,

Timing Belt.>

8) Install the timing belt.

CO-00026

(E)

(D)

(B)

(C)(A) (F)

CO-02008

(B) (C) (D)(E)(F)

(A)

CO-00020

CO-00019

CO-00018

ST

CO-00017